Indexed In

- Genamics JournalSeek

- Academic Keys

- JournalTOCs

- China National Knowledge Infrastructure (CNKI)

- Access to Global Online Research in Agriculture (AGORA)

- Centre for Agriculture and Biosciences International (CABI)

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- SWB online catalog

- Publons

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Review Article - (2024) Volume 15, Issue 6

Scope and Opportunities of Papain as Food Tenderizing Agent for Food Processing in Ethiopia

Birhanu Zeleke*Received: 22-Jul-2023, Manuscript No. JFPT-23-22306; Editor assigned: 25-Jul-2023, Pre QC No. JFPT-23-22306 (PQ); Reviewed: 08-Aug-2023, QC No. JFPT-23-22306; Revised: 20-Dec-2024, Manuscript No. JFPT-23-22306 (R); Published: 28-Dec-2024, DOI: 10.35248/2157-2518.24.15.1134

Abstract

The main aim of food preservation is to minimize the growth of microorganisms during the storage period, thus promoting longer shelf life and reduced hazard from eating the food. Fruit and vegetables are an important supplement to the human diet as they provide the essential minerals and vitamins and fiber required for maintaining health. Papain is a proteolytic enzyme present in papaya that breaks down proteins and has a number of food processing applications. The objective of this review is to carefully study the extraction methods for papain enzyme and to employ grinding and ultra-sonication extraction techniques and determining application of papain as preservatives in future studies. Papaya fruit contains cysteine proteinases, presenting Papaya fruit as an important tool medicinal/pharmacological utilization. Papaya fruit, seed, leaves and fruit contain carpaine, an alkaloid with bitter taste which has a strong depressant action on the heart. Food preservation is basically done for preserving the natural characteristics of food, to preserve the way food look and to increase the shelf value of food for storage. Since papaya is a popular fruit well-known for its food and nutritional values worldwide fortification through a best preservative enzyme is nedeed. enzymes have become important tools for various markets such as food and animal feed, biofuels, detergents, textiles, pulp and paper, mainly for preservation.

Keywords

Bio-catalysis; Cysteine proteases; Enzyme biotechnology; Immobilization; Industrial processes Papain

Abbreviations

CP: Crude Protein; CF: Crude Fibre; DM: Moisture Content; DM: Dry Matter; DNA: Deoxyribonucleic Acid; PPF: Papaya Peel and Fruit; EDTA: Ethylene dimethylene tetraamine; NEM: Net Energy Metering; pH: Power of Hydrogen

Introduction

Enzymes are biological catalysts and are natural in origin unlike chemical catalysts. They are polymers catalyzing chemical reactions that are fundamental to life, comprising rapid synthesis of complex compounds, degradation of high-molecular-weight structures and processing of biomolecules into their active state. Enzymes are superior to any other chemical catalysts, with much greater catalytic power and stereo specific with the ability to convert non chiral substrates to chiral products, and these properties are exploited in the food industry. All the enzymes used in the food industry are protein in nature, and food technologists normally use them in the manufacture, processing, preparation, and treatment of food which means for food preservation. The papaya is an attractive and delicious tropical fruits with many nutritional and medicinal properties. Papaya has been cultivated in several countries for local consumption and export market (Figure 1). About sixty countries are producing papaya from which most of them are from developing countries. Fruits and vegetables play a number of important roles in human health. They provide antioxidants that are important in neutralizing free radicals known to cause cancer, cataracts, heart disease, hypertension, stroke and diabetes. They are also most important sources of vitamin A, a nutrient important for several metabolic activities in the body, in addition to its role as antioxidant [1-3].

Figure 1: Papaya fruit tree.

The papaya fruit contains 85% water, 10-13% sugar, 0.6% protein, much of vitamin A and fair amount of B1, B2 and C. Unripe papaya is a rich source of papain (digestive enzyme), which is a vegetable pepsin aids in digestion in acidic, alkaline or neutral medium, pharmaceutical industry in medicine as well as in the food acquiring industry, in the tanning of leather, in the paper and adhesive industries as well as in sewage disposal and it is also used in dairy, bakery, fish, perfumery plastics.

Papain is an endolytic plant cysteine protease enzyme which may be extracted from the plant's latex, fruit, leaves and roots. It is a monomeric protein of 23.4 kDa, with a temperature of maximum activity of 37°C it is stable and active under a wide range of conditions and Identification of papain involves determination of papain content the protein content in the samples during purification by Bradford method [4-6].

Composition of papain

Unripe papaya is a good source of carbohydrates, proteins, vitamins; in fact, the level of these decreases as the fruit ripens. It has been observed that protein, fat, and carbohydrate contents of PPF are reduced significantly upon ripening. An ultimate analysis of PPF confirms the presence of carbon (38.10%) and nitrogen (1.49%). Microbes can be properly grown and developed when the C-to-N ratio of raw materials is in the range of 25-30:1 (Table 1). The result shows that PPF has a good C-to-N ratio (26:1), that is, microbial reactions can occur easily on the surface of PPF [7].

| Sample of papaya fruit | Moisture content (%) | DM (%) | CF (%) | Ash (%) | CP (%) | Fat (%) | Carbohydrate (%) |

|---|---|---|---|---|---|---|---|

| Unripe | 54.48 | 45.52 | 14.52 | 5.25 | 10.56 | 0.23 | 30.35 |

| Hard ripe | 58.22 | 41.78 | 13.67 | 4.84 | 9.04 | 0.31 | 27.87 |

| Very ripe | 68.39 | 31.61 | 9.67 | 3.15 | 6.89 | 0.33 | 20.04 |

Table 1: Proximate compositions of PPF at different stages of ripening.

Vitamin composition and non-nutritive component of PPF peel at different stage of ripening also decrease from unripe PPF sample to very ripe. Papain is a single-chained polypeptide with three disulfide bridges and a sulfhydryl group that are highly essential for the activity of the enzyme. Papain is expressed as an inactive precursor, prepropapain.

For the formulation of an active papain requires several cleavage steps that include an initial cleavage of the 18 amino acid preregion followed by further cleavage of the glycosylated 114 amino acid proregion (Table 2). This proregion serves as an intrinsic inhibitor and folding template [8].

| Maturity stage | Score range |

|---|---|

| 0 | Fruit completely developed. 100% green skin color. |

| 1 | Represent papaya with yellow color cover area of between 1% until 25% of the skin fruit surface. |

| 2 | Represent papaya with 1/4 mature. Fruit skin with up to 50% until 75% yellow covered area. |

| 3 | Represent papaya with 3/4 mature. The fruit surface covered with up to 50% until 100%. |

| 5 | Mature. Fruit covered with 76% yellow color or totally yellow color and area near the stem is green. |

Table 2: Stages of papaya maturity according to skin color when stored at room temperature.

Application on food and its methods

All food products except the ones growing in our kitchen garden have food preservatives. Every manufacturer adds food preservatives to the food during processing. The purpose is generally to avoid spoilage during the transportation time. Food preservation is basically done for preserving the natural characteristics of food, to preserve the way food look and to increase the shelf value of food for storage [9].

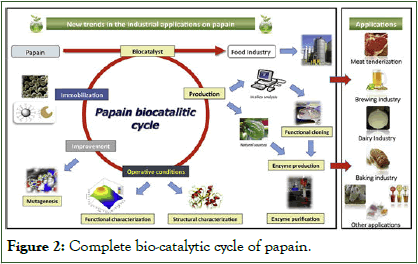

Food is so important for survival, so food preservation is one of the oldest technologies used by human beings to avoid its spoilage (Figure 2). Different ways and means have been found and improved for this purpose, preservation method (boiling, freezing and refrigeration, pasteurizing, dehydrating, smoking, pickling are the traditional) sugar, salt, alcohol, vinegar are also often used as food preservatives., artificial food preservation method (Nuclear radiation is also being used now as food preservatives, modified packaging techniques like vacuum packing and hypobaric packing also work as food preservatives), chemical food preservation method, antimicrobial agents (they inhibit the activity or kill the bacteria, molds, insects and other microorganisms.), chelating agent and antioxidants application are basic methods applied commonly [10].

Figure 2: Complete bio-catalytic cycle of papain.

The quality of meat products is a major problem that currently concern both meat industry and consumers [11]. Meat and other food acceptability factors include: Tenderness, juiciness, flavor, aroma, color, texture, in which tenderness is generally considered the most important palatability factor by the consumer. Food meat tenderizer, beer chill-proofing, cheese production, extraction of flavor and color compounds from plants are also application of papain on food area [12,13].

Basic objectives

The main objectives of the study include applying cheap and locally available food preservative papain enzyme, to preserve the natural characteristics of food, to preserve the way food looks and to increase the shelf value of food for storage.

Significance of this review and future work

The basic significance is to apply papain enzyme as an active preservative which allow food basically meat has long shelf life and prevent spoilage, to differentiate preservatives applied on common and special food.

The review also deals with other minor importance of papain enzyme during application beside preservation such aids digestion in acidic, alkaline or neutral medium. It also exhibits pain relieving properties. This work will open researcher eyes of advanced researchers for further similar investigations in which food science related studies and investigation spread more.

Literature Review

Origin and application area of papain enzymes

Enzymes are biological catalyst that increase the rate of otherwise slow reactions by decreasing the reactions activation energy, without undergoing any neat change in there structures at the end of a reaction. Enzymes are more selective than conventional chemical catalyst. High selectivity is one of the main advantages including reduced side reactions and thus easier separations. Papain is first named in the late nineteenth century by Wurtz and Bouchut who partially purified the product from the sap of papaya. When named, it was simply recognized as a proteolytically active constituent in the latex of tropical papaya fruit. In the 1980’s, the geometry of the active site was reviewed and the three-dimensional structure was determined to a 1.65 Angstrom resolution.

Enzymes have been used from old days which resulted in more understanding in enzymes, increasing demand and applications. However, many researchers in academia and industry are still looking for more applications and better technologies. The relationship between structure and function has been extensively investigated, but still remains as one of the hottest current issues in enzyme engineering [14].

Enzymes in detergent industry: Enzymes have been used in detergent formulations to overcome the eutrophication of water caused by phosphorus detergents. Proteases, amylases, lipases, and celluloses have been used to degrade protein, carbohydrate, and lipid stains on clothes. Enzymes in detergent Industry have many advantages as follows:

• Lower cost since used at low detergent concentrations.

• Acceptable to environment: Biodegradability and no harmful

impact on sewage treatment processes.

• Higher efficiency in stain removal.

• Less use of pollutants such as phosphate, bleach, and caustic.

Enzymes for bioenergy: Even though bioethanol and biodiesel as popular bioenergy are currently produced and utilized, researches on other bioenergy are required. Hydrogen can be produced by cyanobacteria, where nitrogenase and hydrogenase are involved. For efficient production of bioenergy from cyanobacteria, the enzymes involved are to be investigated in detail and engineered if required [15].

Enzymes for biomedical analysis: Enzymatic biosensors broadly used in the biomedical sector are used to detect clinical biomarkers such as cholesterol, glucose, glutamate, lactate, and urea. Disposable blood glucose sensor is by far the most extensively studied and commercialized due to the large population of patients with diabetes and other metabolic disorders.

Enzymatic biosensors for the real-time detection of brain dopamine have also been reported as a replacement to the conventional fast scan cyclic voltammetry.

Papaya fruit contains cysteine proteinases, presenting Papaya fruit as an important tool for medicinal/pharmacological utilization. Papaya fruit, seed and leaves and fruit contain carpaine, an alkaloid with bitter taste which has a strong depressant action on the heart. PPF has high nutritive value and is rich in minerals and vitamins. The combination of minerals, vitamins, phenolic antioxidants, and dietary fiber present in PPF may be responsible for its health beneficial effects against physiological and pathological deformities, such as cardiovascular diseases, inflammation, and aging. Promote lung health. If you are smoker, or if you are frequently exposed to second hand smoke. Eating vitamin A rich foods, such as papaya, help your lung healthy and save your life [16].

For agricultural and food industry: Biosensors are used to check the fresh-ness of raw foods and to control quality and safety during the production. In these cases, sensing appliances are used to measure various compositions and evaluate rancidity, maturity, decline, and shelf life of the food.

For pesticide detection: Herbicides, insecticides, fungicides, and rodenticides are heavily utilized in agriculture and need to be monitored by the industry, health care professionals, and regulatory agencies. Two methods dictate enzymatic bio-sensors for pesticides: direct technique where the enzymatic reaction leads to a change in the amount of measurable chemical and indirect technique which monitors inhibition on the enzyme.

Application on food as preservatives: Functional properties of papain have developed an increasing interest in a wide range of industrial uses, mainly in meat tenderization, foods, feeds, brewing and the textile industry. Papain has also been described as an active additive in tooth-bleaching dentifrices and skin products. This part of the review summarizes the main applications of this enzyme. Enzymes can be used to enhance the production of nutrient-dense foods; that is, foods that are high in nutrients but low in calories. Enzymes could achieve this by breaking down rigid plant-based foods to release the nutrients such as vitamins and minerals; hydrolyzing anti-nutritive substances such as phytates and enzyme inhibitors; through transformation of substrates as in the formation of allicin; or by simply concentrating or stabilizing beneficial components in foods.

Meat tenderization

The use of exogenous proteases to improve meat tenderness has become an increasing focus of interest recently. It is a priority for the meat industry to be able to cover the increasing demand for guaranteed tender meat and give added value to lower-grade meat cuts. Many approaches have been based on improving postmortem tenderness, such as mechanical tenderization, water content enhancement, and different enzymatic treatments. Traditionally, meat is softened by auto proteolysis (mainly mediated by cathepsins and capains), keeping it at 4°C for 7-10 days. Under optimal operating conditions (pH around 7-8 and temperature between 60 and 65°C) papain is able to hydrolyze almost any protein present in muscle tissue, as well as tendons and ligaments, which makes it a potent meat softener.

Natural tenderizers are defined as those natural products such as different fruit and vegetables that contain proteolytic enzymes. To achieve efficient utilization of tough meat, these proteolytic enzymes obtained from natural products may be used. Among these plant proteolytic enzymes most commonly discussed papain is basic enzyme. There are numerous studies in which the meat softening effect of papain has been evaluated when enzyme is injected into the animal before being slaughtered, allowing a homogenous distribution of papain in the meat of the animal. Today, this technique presents ethical concerns and is not used, since the injection of active papain can cause suffering and stress in animals [17].

An alternative is the injection of inactive papain. For this purpose, papain is usually treated with hydrogen peroxide to oxidize the catalytic cysteine and then injected into the animal. Once the animal is sacrificed, the anoxic conditions induce the reduction of catalytic cysteine and thus the reactivation of papain. However, this ante-mortem method presents some drawbacks, mainly due to the difficulty in predicting the level of tenderization, since this depends on different physiological factors of the animal. Some problems that may appear are related to differences in texture as compared with high quality meat slices, over-tenderization, undesired tastes or smells, or degradation of organs hat may be of commercial interest. Postmortem application is generally acceptable for lower-grade meat cuts. Papain is supplied commercially in powder and liquid forms (e.g. Panol liquipanolt100), as well as combined with other proteases such as bromelain (e.g., Enzeco dual protease). Several commercial preparations may include other ingredients (salt, phosphates or flavor enhancers such as sodium glutamate).

Tenderizing effect of papaya

Papaya is a natural source of proteolytic enzymes. Kang and Warner reported that tenderization of meat by papaya was achieved by combined action of papain, chymopapain and papaya peptidase A. Among them chymopapain was the primary contributor for tenderization as it had more favorable action at neutral pH. Tenderization of meat can be improved by application of this papain which acts on the structural component of muscle. They reported that fully grown but totally green fruit of papaya were tapped to a maximum depth of two mm and the latex collected in a container was dried bellow 70°C to form powder. It was solubilized in water which showed greater enzymatic activity.

Factors affecting tenderness

Tenderness of meat is affected by both pre slaughter and post slaughter factors. Preslaughter factors include species, breed, age, sex, feeding and management, genetic influence and stress conditions. Among the commonly discussed preslaughter factors, species is the most important factor affecting tenderness.

Properties and basic constituents of papain enzyme

Principal properties of papain enzymes are mentioned as following:

Alternate names: Papaya peptidase I.

Specificity: Cleaves somewhat nonspecifically at exposed residues.

Source: Carica papaya latex.

Storage conditions: Store at 4°C

Molecular weight: 23.000 Da

Inhibitors: Heavy metals, Carbonyls, NEM, p-Chloromercurobenzoate.

Extinction coefficient: 76,630 cm-1 M-1

Isoelectric point: pH 9.6

Catalytic residues of the enzymes are:

• Cysteine (C158)

• Histidine (H292)

• Asparagine (N308)

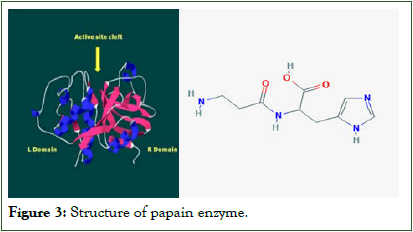

Papain is a single-chained polypeptide with three disulfide bridges and a sulfhydryl group that are highly essential for the activity of the enzyme. Papain is expressed as an inactive precursor, prepropapain. For the formulation of an active papain requires several cleavage 6 steps that include an initial cleavage of the 18 amino acid preregion followed by further cleavage of the glycosylated 114 amino acid proregion. This proregion serves as an intrinsic inhibitor and folding template. The active site, consisting of a cysteine and a histidine, lies at the surface of the cleft. Apart from four short α-helical segments and one short segment of β-structure, the conformation of the chain is irregular (Table 3).

| Amino acid | No | Amino acid | No |

|---|---|---|---|

| Lysine | 10 | Glycine | 28 |

| Histidine | 2 | Alanine | 14 |

| Arginine | 12 | Valine | 18 |

| Aspartic Acid | 7 | Isoleucine | 12 |

| Asparagine | 12 | Leusine | 11 |

| Glutaminic | 8 | Tyrosine | 19 |

| Threonine | 13 | Phenylalanine | 4 |

| Acid | 12 | Half cysteine | 6 |

| Serine Proline | 10 | Cysteine | 1 |

| Glutamine | 8 | Tryphtophan | 5 |

Table 3: Complete amino acid constituent of papain.

Discussion

Principal characteristics of purified papain

Purified papain will be white or grayish white, slightly hygroscopic powder. It is completely soluble in water and glycerol, and practically insoluble in most organic solvents. Its potency varies according to process of preparation. Papain can digest about 35 times its own weight of lean mean.

The best quality papain digests 300 times its own weight of egg albumin. It should be kept in well-closed containers. The best pH for its activity is 5.0 but it functions also in neutral and alkaline media. The following standard is recommended for high quality papain:

• Color should be creamy white.

• Moisture content should be above 10 percent.

• Total ash content should not be greater than 11.1% on

moisture free basis.

• Should not content any foreign substances.

• Should possess a proteolytic activity not less than that of

Ceylon reference [18].

Structure of papain

Papain consists of a single chain with 212 Amino acid residues. There are at least three amino acid residues present in the active site of the papain, including Cys25, His159, and Asp 158. The enzyme activity will be inhibited when Cys25 is oxidized or bound to a metal ion, the reducing agent cysteine (or sulfite) or EDTA can restore the enzyme activity. The other six cysteine residues form three pairs of disulphide bonds, both of which were not at the active site (Figure 3).

Figure 3: Structure of papain enzyme.

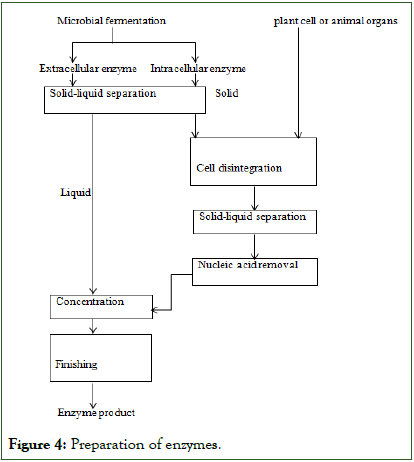

Extraction and analysis of papain

The first step in enzyme production is the selection of the enzyme source. Enzymes can be derived from microorganisms through fermentation processes, as well as plant and animal sources. Collecting the papain by scoring matured unripe fruits with longitudinal openings and then collecting the copious latex in containers set underneath the fruit still on the tree (Figure 4). The latex immediately taken to the laboratory and diluted with distilled water into the required concentrations to prevent it from coagulating [19]. The process consists of four main steps:

• Obtaining samples from environment.

• Isolation of DNA and manipulation of the genetic material.

• Construction of metagenomic library.

• Screening of new function enzyme and sequencing of genetic

material from the Metagenomics.

Figure 4: Preparation of enzymes.

Conventionally, papain enzyme is produced from the milky latex obtained from the skin of the green fruit. Fruits that have nearly reached their full size but are still green give the highest latex yield and normally, latex yields are greatest in the first twelve months of tapping. In the second year, the yields are about 65% of the first year's diminishing more in each following year. This is because, the size and the number of fruits, as well as the latex yield decrease with age and height of trees [20].

Papain can be obtained from the latex of the papaya plant (Carica papaya), which is a natural source of other endopeptidases, such as chymopapain (EC 3.4.22.6), caricain (EC 3.4.22.30) and glycyl endopeptidase (EC 3.4.22.25). In fact, papain is a minor constituent (5-8%) among the papaya endopeptidases. Purification of papain from papaya latex has traditionally been carried out using precipitation methods, reaching high yields of up to 53 g of crude enzyme per kg of latex. Although these methods have routinely been used in industry, they can only achieve up to 39% purity of papain. After the purification process, crude papain usually has to be treated with reducing agents in order to protect the free cysteine thiol groups from oxidation, preserving its protease activity. When needed, free thiol groups of papain can be regenerated by the addition of low molecular mass thiols, such as cysteine or dithiothreitol.

Determination of enzymatic activity

If papain is to be exploited commercially for an export market or local food industry use, it is important to be able to determine the enzymatic activity. The method used to measure the papain activity must be validated in order to certify the results. Papain enzymatic activity can be determined by the measurement of the hydrolysis of natural proteins or synthetic substrates, like esters or low molecular weight amides. Such reactions may release dyes or chromogenic or fluorogenic products, which can be measured by spectrophotometers.

This involves using of casein as protease substrate in which dried samples of 0.05 g were dissolved in 5 mL sodium acetate buffer 10 mM (pH 7.5) and 5 mL calcium acetate buffer 10 mM (pH 7.5). For each sample 455 μL Casein 65% (w/v) were preheated in a thermal bath at 37 ± 1°C for 10 minutes and then 20 μL of these were added. After 10 min of reaction, the reactions were stopped by the addition of 455 μL trichloroacetic acid 110 mM and were kept in the thermal bath for another 30 min. The two form phases were separated by centrifugation at 9000 rpm and 4°C during 20 min (Fresco 17 Thermo) in order to discard the solid formed. The supernatant was taken for protease assays. Aliquots of 625 μL supernatant were added to 1570 μL sodium carbonate 500 mM and 250 μL of Folin Ciocalteus reagent. The protease activity was detected spectrophotometrically since the released tyrosine developed a blue coloration. Each sample was read in a spectrophotometer at 660 nm. The protein presented in each sample was determined by Biuret's method.

Whether papain is to be exploited commercially for an export market or for local food industry use, it is important to be able to determine the level of enzyme activity, a process known as assaying. This can be carried out by, say, the National Standards office. Papain is used to hydrolyse (or break down) proteins. Therefore, assays to measure papain activity are based on measuring a Product of the hydrolysis. There are two main methods of carrying out assays:

Method 1: This method relies on the ability of papain to clot milk. It is a low-cost method but is time consuming.

Furthermore, the absence of a standardized method of finding the clotting point, combined with variations in the milk powder used, can introduce errors.

Method 2: The second method is based on the science of light absorption, or absorptiometry. This technique measures the amount of radiation (or 'color' of light) absorbed by a chemical solution. It is known, for example, that a yellow-colored solution absorbs blue light. (Blue is the complementary color to yellow). The greater the concentration of yellow in the solution, the more blue light is absorbed [21].

Conclusion

Most traditional enzymes used in food processing are considered as ‘natural’ and biodegradable, and their use is attended by greener outcomes and lower environmental impacts. Enzymatic reactions are selective, reproducible, fast, efficient, and practically devoid of undesirable by-products. Thus, enzymes have become important tools for various markets such as food and animal feed, biofuels, detergents, textiles, pulp and paper, mainly for preservation. Since papaya is a popular fruit wellknown for its food and nutritional values worldwide fortification through a best preservative enzyme is nedeed.

References

- Chandrasekaran M. Enzymes in food and beverage processing. Boca Raton, FL, USA: CRC Press; 2016.

- Ayele L, Etissa E, Dagnew A, Assefa W, Kebede G, Girma M, et al. Development of hermaphrodite papaya (Carica papaya L.) varieties for production in Ethiopia. Academic Res J Agric Sci Res. 2017;5(7):561-569.

- Tesfaye HAA, Bekele T, Madhusudhan A. Investigation of the levels of selected metals in edible and medicinal fruits grown in Dilla, Ethiopia. Bull Env Pharmacol Life Sci. 2015;3:44-53.

- Varmu DV. Papaya Waiting For a Planned Commercial Strategy. Fact for You. 2011.

- Tigist M, Getnet B, Beza K, Endalamaw M, Lulit M, Tamirat D, et al. Extraction and purification of papain enzyme from papaya leaf and the phytochemical components of the leaf. Biotechnology International. 2016;9(8):176-184.

- Lambri M, Roda A, Dordoni R, Fumi MD, de Faveri DM. Mild process for dehydrated food-grade crude papain powder from papaya fresh pulp: Lab-scale and pilot plant experiments. Chem Eng. 2014;38.

- Pathak PD, Mandavgane SA, Kulkarni BD. Waste to wealth: A case study of papaya peel. Waste and Biomass Valorization. 2019; 10:1755-1766.

- Paul BI, Nasreen MA, Sarker A, Islam MR. Isolation, purification and modification of papain enzyme to ascertain industrially valuable nature. Int J Biotechnol Res. 2013;3(5):11-22.

- Akpan IP, Omojola AB. Quality attributes of crude papain injected beef. J Meat Sci Technol. 2015; 3(4):42-46.

- SI di Madrid, Food preservatives Chemistry in our life. Dextra Editorial: Madrid, Spain, 2017.

- Yogiraj V, Goyal PK, Chauhan CS, Goyal A, Vyas B. Carica papaya Linn: An overview. Int J Herb Med. 2014; 2(5):1-8.

- Margean A, Mazarel A, Lupu MI, Canja CM. Tenderization, a method to optimize the meat sensory quality. Bulletin of the Transilvania University of Brasov. Series II: Forestry, Wood Industry. Agric Eng. 2017:125-130.

- Malik K, Norazan M, Ramaness P, Othman NZ, Malek R, Aziz R, et al. Cysteine Proteases from Carica papaya: An important enzyme group of many industrial applications. IOSR J Pharm Biolog Sci (IOSR-JPBS). 2016;11(2):11-16.

[Crossref]

- Yoo YJ, Feng Y, Kim YH, Yagonia CF. Fundamentals of enzyme engineering. 2017.

- Fernandez-Lucas J, Castaneda D, Hormigo D. New trends for a classical enzyme: Papain, a biotechnological success story in the food industry. Trends Food Sci Technol. 2017;68:91-101.

- Adiaha MS, Adiaha MS. Effect of nutritional, medicinal and pharmacological properties of papaya (Carica papaya Linn.) to human development: A review. World Scientific News. 2017;2(67):238-249.

- Zhang Y, He S, Simpson BK. Enzymes in food bioprocessing-novel food enzymes, applications, and related techniques. Curr Opin Food Sci. 2018;19:30-35.

- Patel AK, Singhania RR, Pandey A. Novel enzymatic processes applied to the food industry. Curr Opin Food Sci. 2016;7:64-72.

- Garcia E, Barrett DM. Preservative treatments for fresh-cut fruits and vegetables. Fresh-cut fruits and vegetables. 2002:267-304.

- Isa MM. The Extraction of Papain Enzymes from Papaya Leaves. 2010.

- Maiti AK, Ahlawat SS, Sharma DP, Khanna N. Application of natural tenderizers in meat – A review. Agric Rev. 2008;29(3):226-230.

Citation: Zeleke B (2024) Scope and Opportunities of papain as Food tenderizing agent for Food Processing in Ethiopia. J Food Process Technol. 15:1143.

Copyright: © 2024 Zeleke B. This is an open access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.