Indexed In

- Open J Gate

- Genamics JournalSeek

- Smithers Rapra

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- Publons

- Geneva Foundation for Medical Education and Research

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Research Article - (2024) Volume 14, Issue 3

Scanning Electron Microscopic Evaluation of Spray Coated Micro-Fibrillated Cellulose on the Packaging Paper

Kirubanandan Shanmugam*Received: 11-Dec-2020, Manuscript No. ACE-24-7478; Editor assigned: 16-Dec-2020, Pre QC No. ACE-24-7478 (PQ); Reviewed: 30-Dec-2020, QC No. ACE-24-7478; Revised: 16-Aug-2024, Manuscript No. ACE-24-7478 (R); Published: 13-Sep-2024, DOI: 10.35248/2090-4568.24.14.343

Abstract

This technical report investigates the scanning electron microscopic studies of the spray coated micro-fibrillated cellulose on the base sheet to increase its barrier properties and mechanical properties. The surface morphology and topography of the cellulose fibrils on the spray coated base sheet is investigated through the micrographs of the spray coated paper. The performance of spray coating of micro-fibrillated cellulose on the base sheet is assessed.

Keywords

Scanning electron microscope; Morphology; Topography; Cellulose fibrils

Introduction

The scanning electron microscopy is the most important tool for morphological and topographical analysis of the material surface at a suitable magnification. In my research work, it is used to evaluate the surface morphology and topography of the spray coated micro-fibrillated cellulose on the base sheet through the investigation of different size of fibres and particles of cellulose on the base sheet. The digital images acquired in SEM, by the secondary electron mode-I and mode-II have suitable quality and resolution for further image processing and analysis to investigate the surface pores of the coated paper and size of the cellulose fibrils in the coated surface on the base sheet. The present investigation exemplifies how scanning electron microscopy does useful in assessing the performance of spray coating of microfibrillated cellulose and coating coverage on the base sheet and a coating layer/film on the base sheet [1].

Past decade, coating is an alternative and novel process to increase the barrier properties and mechanical properties of the paper. Recent studies confirmed that the coating of microfibrillated cellulose on the base sheet enhance its barrier and mechanical properties of the base sheet. Micro fibrillated cellulose is a bio-renewable and biodegradable material and the dimension of the diameter of 5-60 nm and several micrometres in length. The development of spray coating of micro-fibrillated cellulose on the base sheet is a part of my Ph.D. work. The spray deposition of nano-cellulose on the base sheet is assessed by coating coverage on the surface of the base sheet. The coating material coverage on the base sheet is evaluated by scanning electron microscopy investigation of the surface of the coated and uncoated base sheet.

The micrographs of the surface of the spray coated paper are collected in the secondary electron mode (low mode-I and high resolution mode-II) in FEI nova SEM. The micrographs are used to study the micro/nanofibers orientation, cellulose particles and surface porosity of the coated paper. This report investigates the scanning electron microscopic of the micro-fibrillated spray coated paper. Moreover, the image analysis of the micrographs using Image J software is performed. Using the image analysis of the micrographs, the fibre diameter is evaluated [2].

Materials and Methods

MFC (Micro-Fibrillated Cellulose) suspension as a coating formulation used for spray deposition on the base sheet. Among many coating techniques, the spray coating is a novel technique and has many advantages such as the production of even coating surface in the base sheet and contactless coating with the substrate. This work investigates a lab scale spray coating of Micro Fibrillated Cellulose (MFC) which is a bio-based nanomaterial and diameter of fibre from 5 nm-60 nm and length of several micrometres on paper substrates and evaluated its barrier properties and mechanical properties. A laboratory scale spray coating of MFC suspension used from 0.25 to 1.5 wt.% on the paper substrates is developed and assessed the coating performance on the base sheet by scanning electron microscopy [3].

Scanning electron microscopy of the coated papers

Sample preparation: The spray coated paper (4 mm × 4 mm) is fixed on the stab using carbon tape and blowed with nitrogen to remove the any dust or any loose material on the sample and then coated with iridium with a maximum thickness of 10 μm. Moreover, the iridium coated samples are blowed off with nitrogen to remove any dust and loose materials on the sample before loading into the FEI-NOVA Nano SEM 450.

Parameters for scanning electron microscopy: Nanocellulose is a biodegradable and delicate material in nature and highly susceptible to high accelerating voltage. Therefore, the parameters for collecting micrograph is optimized. The surface morphology and topography of the spray coated paper was characterized using FEI-NOVA Nano SEM 450.

Mode 1: This mode is used for collecting the low resolution micrograph at 100 μm and this micrograph is ideal for investigating the survey of the surface of the nanocellulose coated sheet and the roughness of the coated surface. The optimized parameters for high voltage and spot size are 3 KV and 2.00 respectively. The working distance and aperture size are 5 mm and 6 (30 mm) [4].

Mode 2: This mode is used for collecting the micrograph at 1 μm and 10 μm (high resolution (UHR) imaging) and this micrograph is ideal for investigating the fibre orientation and size of the fibres and pores in the surface of the spray coated surface. The optimized parameters for high voltage and spot size are 3 KV and 2.00 respectively. The working distance and aperture size are 5 mm and 6 (30 mm).

Results and Discussion

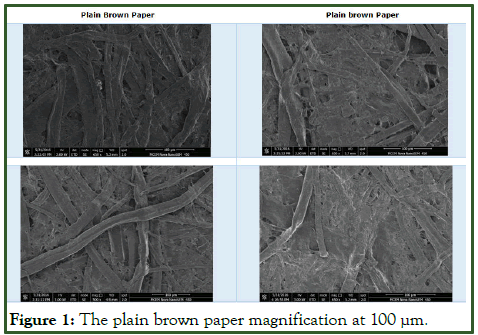

Figure 1 shows the secondary electron image at low magnification of the uncoated paper and shows the network structure of cellulose fibres on the surface of the paper at low magnification. The micrograph of uncoated paper shows the presence of various size of surface pores. Figure 1 A shows clearly visible of network structure of the cellulose fibrils and surface pores in the uncoated paper. Figure 1 B shows the fillers occupied the space between two fibres in the surface of the paper. Figure 1 C shows the complete network structure of the cellulose fibres in the surface of the paper. Figure 1 D confirms the fillers occupies the space between fibres in the paper. The cellulose fibres in the uncoated paper is 13.68 μm ± 3.27 μm. The mean size of the pores in the surface of the uncoated sheet is 8.36 μm ± 1.44 μm [5].

Figure 1: The plain brown paper magnification at 100 μm.

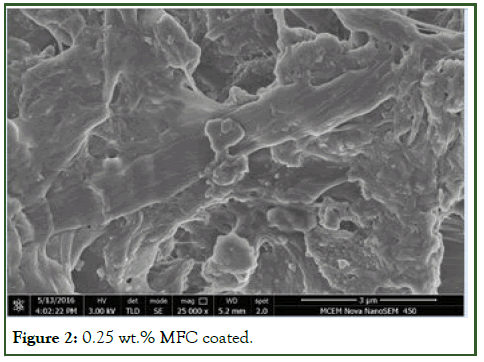

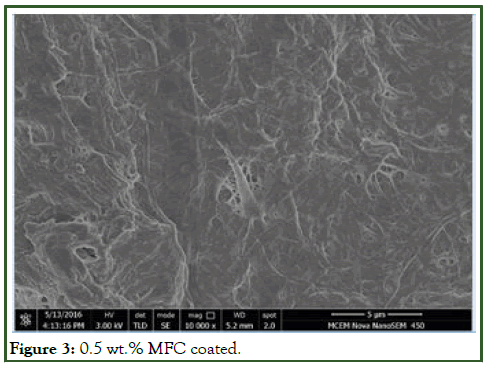

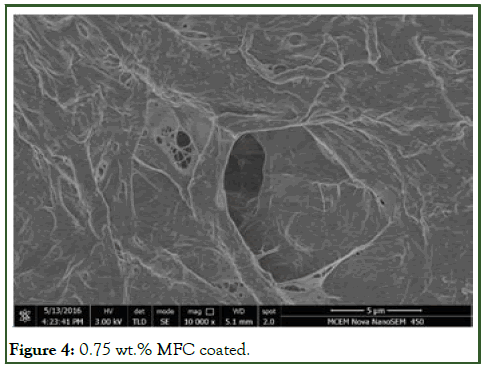

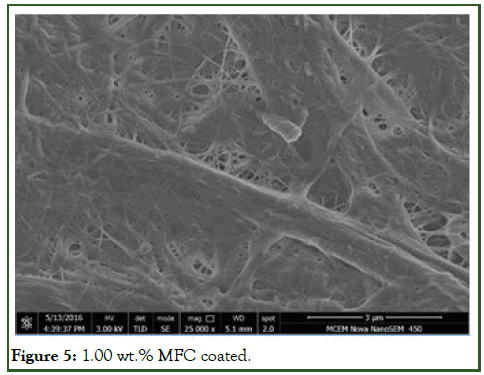

The Figure 2 shows the surface morphology of the paper spray coated with different concentration of micro-fibrillated cellulose on the base sheet. The surface of the spray coated paper with 0.25 wt.% of micro-fibrillated cellulose. It shows the large clumps of the cellulose fibres on the base sheet. Micro-fibrillated cellulose contains particle and different size of the fibres. Figure 3 shows the spray coated with 0.5 wt.% paper and the deposited micro fibrillated cellulose on the base sheet forms homogenous film with different size fibres and particles. The cellulose film on the spray coated paper has many surface pores. Figure 4 shows the spray coated with 0.75 wt.% paper and the homogeneous films are formed by the deposited MFC on the base sheet, the films contains different size of fibres and particles with surface pores. Figure 5 shows the spray coated with 1.00 wt.% paper and the homogeneous films with a cellulose fibrils network on the spray coated paper is formed.

In Figure 2, the size of the micro fibres in the 0.25 wt.% coated at high magnification varies from 1.23 μm to 0.094 μm in the diameter. The average size of the surface pores is 0.17 μm. In Figure 3, the average diameter of the micro fibre is 0.21 μm. The size of the surface pores ranged from 1.149 μm to 0.34 μm [6].

Figure 2: 0.25 wt.% MFC coated.

Figure 3: 0.5 wt.% MFC coated.

Figure 4: 0.75 wt.% MFC coated.

Figure 5: 1.00 wt.% MFC coated.

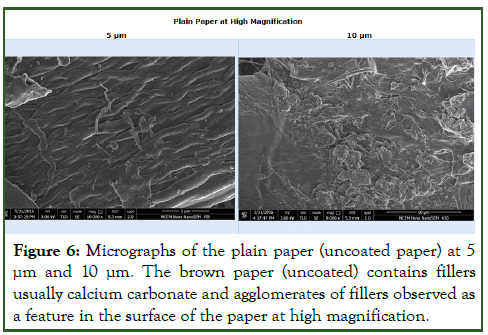

The Figure 6 shows the micrograph of uncoated paper collected at high magnification in SE Mode II. The micrograph confirms the complete network of cellulose fibrils in the surface of the paper. The paper surface contains fillers such as calcium carbonate to increase its opacity. In the second figure shows the particles of fillers on the paper surface. These fillers interacted with fibre void space [7].

Figure 6: Micrographs of the plain paper (uncoated paper) at 5 μm and 10 μm. The brown paper (uncoated) contains fillers usually calcium carbonate and agglomerates of fillers observed as a feature in the surface of the paper at high magnification.

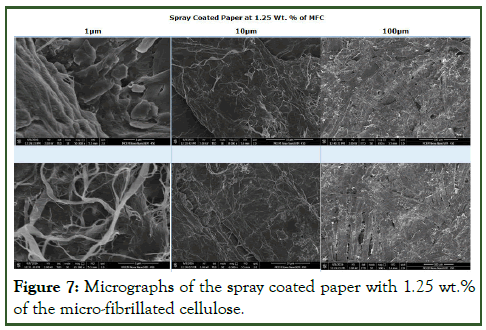

The Figure 7 shows the micrograph of the spray coated paper with 1.25 wt.% of the micro-fibrillated cellulose at high and low magnification. The micrograph (1 μm) shows the deposited clumps of cellulose fibres and cellulose fibres on the base sheet and confirmed the presence of different size of the fibre entangled with cellulose fibres clumps. The micrograph (10 μm) shows the different size of the cellulose fibres and formed layer on the base sheet. Moreover, the micrograph (100 μm) confirms the complete coverage of micro-fibrillated cellulose coating formulation on the base sheet. When compared to the micrograph (100 μm) of the uncoated paper, the coated paper showed that the coating formulation filed many surface pores and void space between the cellulose fibres [8].

Figure 7: Micrographs of the spray coated paper with 1.25 wt.% of the micro-fibrillated cellulose.

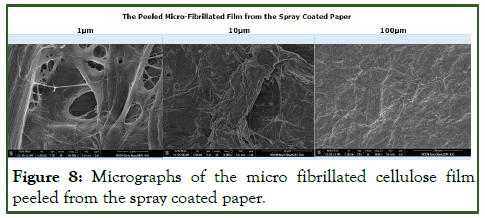

The Figure 8 shows the micrograph of the micro-fibrillated cellulose film peeled from the spray coated paper. The cellulose film has pores in the surface and consists of the different size of the cellulose fibres in the film. The cellulose film has surface roughness due to the presence of different size of cellulose fibres. This shows individual cellulose fibrils practically distinguishable, agglomerates of various size of cellulose fibres embedded in the surface of the peeled cellulose film and also shows the porous surface cellulose film with various surface voids [9].

It confirms the presence of the various size of pores in the surface of the film. It is observed that there are many discontinuity in the cellulose fibres. The different size of the fibres and pores are distributed randomly in the cellulose film. It confirms the random fibres network at microscale. The size of the pores in the films are irregular shape and the cellulose fibres are stretched on the surface of the film. The clear networks of the surface pores are observed.

It shows clumps of different size of the fibres in the film. While spray deposition of nano cellulose on the base sheet, the deposited cellulose fibrils form aggregates due to the interfibrillary hydrogen bonding.

The film has roughness in the surface due to the presence of the different size of the fibres. The surface roughness of the cellulose films seems to be caused by residual cellulose micro and nanofibers and it creates the uneven surface in the film [10].

Figure 8: Micrographs of the micro fibrillated cellulose film peeled from the spray coated paper.

Conclusion

The SEI micrographs of the spray coated paper confirms that the spray deposition of micro fibrillated cellulose on the base sheet provides good coating coverage of the base sheet surface and filled the surface pores on the surface of the base sheet. The spray coating of MFC does seem to form a more closed structure homogenous cellulose nanofiber film on the base sheet compared with the uncoated sheet.

Significance

The formation of nanocellulose film via spraying on the packaging paper promotes its barrier performance and mechanical properties. The spray coated nanocellulose on the base sheet fills the surface pores on the sheet and promotes its barrier performance. SEM micrographs can be used to test the quality of spray coated nanocellulose film on the sheet such as uniformity, morphology of spray coated nanofibers on the sheet and texture on the surface.

Acknowledgement

I would like to acknowledge the facilities used with the Monash centre for electron microscopy and atomic force microscopy. K. S. is grateful to Monash university, bioprocessing research institute of Australia and bioprocessing advanced manufacturing initiative and faculty of engineering international postgraduate research scholarship. I also acknowledge associate professor Warren Batchelor and professor Gil Garnier for the supervision of my doctoral research in spray coating.

References

- Shanmugam K. Spray coated cellulose nanofiber laminates on the paper to enhance its barrier and mechanical properties. J Sustain Environ Manag. 2022;1(1):10-17.

- Cheney B. Introduction to scanning electron microscopy. Mondo Odontostomatol. 1987;29(2):29-36.

[Google Scholar] [PubMed]

- Klemm D, Kramer F, Moritz S, Lindstrom T, Ankerfors M, Gray D, et al. Nanocelluloses: A new family of nature‐based materials. Angew Chem Int Ed Engl. 2011;50(24):5438-5466.

[Crossref] [Google Scholar] [PubMed]

- Scelza MF, Antoniazzi JH, Scelza P. Efficacy of final irrigation-a scanning electron microscopic evaluation. J Endod. 2000;26(6):355-358.

[Crossref] [Google Scholar] [PubMed]

- Baumgartner JC, Mader CL. A scanning electron microscopic evaluation of four root canal irrigation regimens. J Endod. 1987;13(4):147-157.

[Crossref] [Google Scholar] [PubMed]

- Gorman MC, Steiman HR, Gartner AH. Scanning electron microscopic evaluation of root-end preparations. J Endod. 1995;21(3):113-117.

[Crossref] [Google Scholar] [PubMed]

- Carrigan PJ, Morse DR, Furst ML, Sinai IH. A scanning electron microscopic evaluation of human dentinal tubules according to age and location. J Endod. 1984;10(8):359-563.

[Crossref] [Google Scholar] [PubMed]

- Ferrari M, Goracci C, Sadek F, Cardoso PE. Microtensile bond strength tests: Scanning electron microscopy evaluation of sample integrity before testing. Eur J Oral Sci. 2002;110(5):385-391.

[Crossref] [Google Scholar] [PubMed]

- Kühnisch J, Dietz W, Stosser L, Hickel R, Heinrich-Weltzien R. Effects of dental probing on occlusal surfaces-a scanning electron microscopy evaluation. Caries Res. 2006;41(1):43-48.

- Camilleri J. Scanning electron microscopic evaluation of the material interface of adjacent layers of dental materials. Dent Mater. 2011;27(9):870-878.

[Crossref] [Google Scholar] [PubMed]

Citation: Shanmugam K (2024) Scanning Electron Microscopic Evaluation of Spray Coated Micro-Fibrillated Cellulose on the Packaging Paper. Adv Chem Eng. 14:343.

Copyright: © 2024 Shanmugam K. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.