Indexed In

- Genamics JournalSeek

- Academic Keys

- JournalTOCs

- China National Knowledge Infrastructure (CNKI)

- Access to Global Online Research in Agriculture (AGORA)

- Centre for Agriculture and Biosciences International (CABI)

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- SWB online catalog

- Publons

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Review Article - (2023) Volume 14, Issue 6

Review on the Current Scenario in Active and Intelligent Packaging Technologies

Abhishek Ranvare* and Hritvik JadhavReceived: 13-Jan-2023, Manuscript No. JFPT-23-19576; Editor assigned: 16-Jan-2023, Pre QC No. JFPT-23-19576 (PQ); Reviewed: 30-Jan-2023, QC No. JFPT-23-19576; Revised: 14-Apr-2023, Manuscript No. JFPT-23-19576 (R); Published: 21-Apr-2023, DOI: 10.35248/2157-7110.23.14.1024

Abstract

The traditional role of packaging is to provide protection from the external environment and to provide convenience in distribution. The changing global trends need innovation in the sector of food packaging. Active and intelligent packaging systems will be the innovative packaging systems of this era. In this review, we have covered the active packaging systems and intelligent packaging systems with their types. Active packaging and intelligent packaging these two terms differ from each other. The active packaging system's main objective is to extend the shelf life with the help of absorbing and releasing systems. The absorbing systems in active packaging include the O2 absorbers, CO2 absorbers, and ethylene absorbers. The releasing systems include antioxidant and CO2 emitters. The intelligent packaging systems monitor the shelf life of the product and give a visual indication of the quality of the product. The intelligent packaging includes data carriers, indicators, and sensors. The holograms and thermo chromic inks also come under the intelligent packaging’s use of active and intelligent techniques are limited at the commercial level.

Keywords

Food packaging; Active packaging; Absorbing and releasing systems; Intelligent packaging

Introduction

Food packaging is defined as enclosing food to protect it from tampering/contamination from physical, chemical and biological sources. The aim of food packaging is to protect the food from external conditions. The traditional role of packaging is in distribution of products. Food packaging plays a critical role in food supply chain. The packaging helps to protect the food from the external condition and helps to retain the organoleptic qualities of food. Food packaging plays a major role in prevention of physical, chemical and microbial hazards. Singh, et al. food packaging is a critical part of supply chain, which plays major role in the transport of the food products. Packaging help to protect the food from moisture, oxygen, light, dust, and pets, chemical and biological components. For the supply of safe, nutritious and wholesome food, a proper packaging material and system is required. Packaging plays an important role in maintaining the quality of product. It helps to reduce the use of preservatives. Physical, chemical and biological are the three main protections given by the packaging to the food. By these protections food packaging helps to increase the shelf life of product. The type of packaging will depend on the type of individual food product. Food packaging contains unique code on label, which helps to trace the product. The food packaging also helps to maintain the safety and wholesomeness of product. In future the traditional packaging system will be replaced by the modern packaging system. The deterioration of food due to environmental influences can be prevented by food packaging. Packaging plays a secondary role as it helps in marketing, provides traceability and helps to indicate the tampering. The quality of products is deteriorated by the mass transform for the packaged food products. The moisture absorption, O2 invasion, flavor loss and migration of components in food packaging responsible for the deterioration of the food. During the development of packaging systems, designer should understand the mass transfer phenomenon [1].

Literature Review

Active packaging

The popularity of active packaging among the consumers is increased for the high quality, safe wholesome and nutritious products. This packaging technology acts on the surface of food or at the headspace of packaging. This system act by emitting or absorbing certain compounds in the package. As per the Eu regulation, active packaging is defined as deliberately incorporate that the components that would release or absorb substance from the packaging of food or surrounding of food. Active packaging is intended to increase the shelf life and to improve the packaging conditions of food. It involves the interaction of internal gases at atmosphere and food products. Active packaging is one of the innovative approaches for the longer shelf life of product. Active packaging can be used to manufacture the high-quality products. Active packaging can also be defined as a packaging in which subsidiary constitutes has been deliberately include in eighter packaging or the package headspace to enhance the performance of food packaging system. It helps to maintain the nutritional value and ensures the safety of food product. The active packaging includes major two types of systems which are absorbing and scavenging [2].

The active packaging system known as the functional packaging system in which material contains physical or chemical components which are released in the controlled manner. Oxygen scavengers, carbon dioxide scavengers, moisture absorbers ethylene absorbers, time temp controllers are some of the important food packaging systems. The shelf life of refrigerated foods is short. The use of active packaging helps to increase the shelf life by three to four weeks.

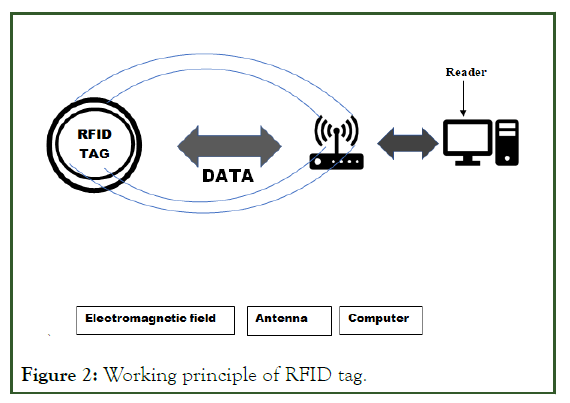

Naturally food releases gases that may affect the quality of food products. The active packaging system deals with the gases produced during that presents in the headspace of packets. Due to the active packaging, the selective gases will remain in the packets. Active packaging system prevents the moisture migration, microbial growth and helps to retain the flavor and aroma. The combination of active packaging technologies with other technologies helps to increase the shelf life of products (Figure 1).

Figure 1: Types of packaging system.

Application of Active packaging system

O2 absorber/scavengers: The main aim of oxygen scavenging system is to remove the residual oxygen from the packets. The packaging system helps to absorb the O2 from the packaging. They are also known as O2 scavenger. The agents used as oxygen scavenger helps to reduce the concentration of oxygen in the sachets. The specialized mechanism triggers the active compound in the sachet. The oxygen scavenging system helps in retention of nutrients like vitamin C. There are some food products which are sensitive to oxygen; it becomes necessary to remove the O2 from the packets. The modified atmospheric system is used to exclude the oxygen from the packaging, but some amount of residual oxygen remains in the packet. The <0.01 vol. % of oxygen can achieved with the help of oxygen scavenging system. The iron and ascorbic acid are used as an O2 scavenger [3].

The iron powder helps to achieve less than 0.1% of oxygen level in the package. The iron powder is used in the form of sachets. The iron present in the sachet is highly permeable to the oxygen. The amount of scavenger is added in the sachet is totally depends upon the residual oxygen present in the packet and the residual oxygen present in the packet. The oxygen absorbing films are developed by the cryovac cooperation. There are some negative impacts of this oxygen absorbing filum. The contact of iron powder with the food product result in the loss of flavor.

In many cases O2 is responsible for deterioration of food. The MAP and vacuum packaging system helps to remove O2 from the packaging system. The use of O2 scavengers helps to preserve the oxygen sensitive products. The films and sachets of oxygen scavenger are used. The capacity of O2 scavenger films is lower compared to the O2 scavenger sachets. O2 can also be used in the alone or the combination with the MAP. The effective packaging material with oxygen barrier should be used in combination with O2 scavenger. The use of oxygen scavengers in food packaging helps to create oxygen free environment. The presence of oxygen is responsible for the growth of aerobic bacteria which are responsible for loss in color, texture and nutritive values. The oxygen free environment helps to prevent the oxidation and rancidity of product. The decreased partial pressure of oxygen fish helps to reduce the metabolism of fresh foods and increase the shelf life of final products. The pink color of meat is retained under low concentration of oxygen higher concentration of oxygen leads to red color of meat. The combined use of the oxygen scavenger system with vacuum packaging and Modified Atmospheric Packaging (MAP) result in complete removal of oxygen. The enzyme based oxygen scavengers are based on glucose oxidase/catalase. The oxygen scavenging systems are suitable for the high temperature application such as the hot fill and retort. This system is also suitable for the hot fill or retort of fish and meat products [4].

CO2 emitters and scavengers: CO2 helps to retard the microbial growth and reduce the rate of respiration. For the meat and meat products, high levels of CO2 are beneficial to avoid the microbial growth. CO2 helps to control the respiration rate of fruit and vegetables. The high level of carbon dioxide retards the growth of microorganisms in the meat and poultry products. The shelf life of perishable products can be increased by the combination of O2 scavengers and CO2 emitters. CO2 emitters are used in the form of sachets and films. The concentration of CO2 is controlled by generation, penetration and absorption. The growth of mould and aerobic bacteria is inhibited by the higher concentration of CO2. The concentration of CO2 (>20%) helps to prevent the growth of spoilage causing microorganisms.

CO2 scavengers are used in products such as coffee, fish, meat, nuts and snacks. Iron oxide, calcium oxide, calcium hydroxide, ferrous carbonate is used as the CO2 scavengers. The packed coffee beans produce CO2 produce due to the non-enzymatic browning. The CO2 scavenger’s is used to absorb the naturally produced CO2 in coffee beans packets. The CO2 scavenging system also used in fermented products like kimchi (lactic acid fermented), sauce, pickles and the natural cheese. In the high perishable food products, oxygen scavengers and carbon dioxide scavenger are used in to increase the shelf life of the food products [5].

Ethylene absorber: Climatic fruits release ethylene during the ripening process. Ethylene acts as hormone which cis responsible for ripening process. After full ripening the fruits can easily spoiled. The control of ethylene with ethylene scavengers will help to increase the shelf life of final products. The effective storage of kiwi, banana, and avocado is done by using the ethylene scavenger. Potassium permanent, activated carbons are used as an ethylene scavenger. The single use of potassium paramagnet can develop the toxicity in product, it is used in the combination of silica gel and placed inside the sachet. In the ripening process plants releases ethylene, which have positive and negative impacts on the fresh produce. Ethylene helps in ripening process but also increases respiration rate. Increased reparation rate will be leads to the degradation of product. In the leafy products, ethylene is responsible for the degradation of chlorophyll. The degradation of chlorophyll is not desirable for the leafy products. The solid or dispersed plastic sachets are used to ad incorporate ethylene scavengers in the packaging system. Ethylene scavengers are used to increase shelf life in climatic fruits such as apple, mango, banana and tomato [6].

Moisture absorbers: Moisture is a critical component for the growth of microbes. The excess moisture in the products is a favorable condition for the microbial growth. Moisture absorbers are important to prevent the microbial growth and helps to prevent the fogy filum formation in packaging system. In the fresh produce, the excesses moisture is a result of respiration. The excess water leads to the growth of bacterial and mould which is responsible for the spoilage of food products. Silica gel, molecular sieves, natural clays are used in moisture absorbing substances. The moisture absorbers are mostly used in moisture sensitive products like dried foods. The moisture absorbers help to maintain the RH of packaged products by absorbing or releasing the moisture in products. Super sorbents such as carboxy methyl cellulose, graft polymer of starch is used as the moisture absorbers. They can absorb 500 times more water than its original weight. The moisture absorbers are used in products like meat, poultry and fish products [7].

Ethanol emitters: The ethanol spray is used on bakery products such as the bread and cookies. The stalting of bakery products prevents by the use of the ethanol sprays help to reduce the microbial growth. Ethanol emitters are also used in the form of sachets and films. Sachets are made up of food grade material. Ethanol condenses on surface of food products and helps to inhibit the growth of microorganisms. Ethanol scavenger helps to eliminate the avoid the use of preservatives such as the sorbates and benzoates. Ethanol emitters are available in encapsulated form the main disadvantage of the method is it gives off flavor and odour.

Antimicrobial packaging system: Antimicrobial agents help to reduce the growth of microbe to increase the shelf life of food products. The growth of pathogenic microorganisms is prevented with the help of antimicrobial agents. The active antimicrobial agents such as sorbates, benzoates, propionates, nitrates, chlorides and alcohols. Antimicrobial films are not much effective than the direct use of antimicrobial agents in food products. When the antimicrobial agents are incorporated in films, they lose their activity. The antimicrobial agents are used in fruit juices, fruit snacks, fish, and meat and poultry products. The controlled release of antimicrobial agents by diffusion and evaporation from the filum helps to inhibit the growth of microorganisms. The reaction between glucose oxidase and oxidase release acids and peroxides. These acids, peroxides, sorbates prevent the growth of bacteria, mould and pathogenic microorganisms [8].

Flavor/odour absorber: Flavor scalping is the technique used to remove undesirable flavor from the food packets. The use of polymeric packaging material result in the loss of flavor. Depending on the type of food products, the requirement of odours is different. Cellulose acetate, citric acid, ferrous, zeolites are used to remove undesirable flavor from the package. This packaging system used for fruit juices, fried snacks, cereal and pulses products [9].

Flavor/aroma releasers: The pleasant aromas are incorporated in the polymer material to improve the aroma which attracts the customer. There are some common polymers such as PE, PP, Ethylene Vinyl Acetate (EVA), ionomer, nylon, polyester, and polyvinyl chloride which release the aromas in the food packets. In recent days LDPE films containing the encapsulated flavor’s which improves the quality of the product. It also helps to improve the shelf life of products.

Temperature controlling system: Temperature affects the nutritional and organoleptic qualities of food products. Depending on the food type serving temperature is different either hot or cold. Insulating material is used to control the temperature of food products. This packaging system used for the ready to eat meal, meat, fish, and poultry and beverages. This packaging system includes the plastic containers, double walled containers, hydrocarbons and ammonium nitrate.

The shelf life of products is identified with the help of temperature integrator tags. The spoiled products are identified with the help of integrator tags (Table 1) [10].

| Sr. no. | Type of active packaging system | Substance used in mode of action | Application in food | Benefits in foods |

|---|---|---|---|---|

| 1 | Oxygen scavenger | Enzymatic system (glucose oxidase, alcohol oxidase ethanol vapor) chemical systems powdered iron oxide, catechol, ferrous carbonate, ascorbic acid. | 1. Cooked meat. 2. Dried meat product. 3. Fruits and vegetables juices. |

1. Prevent discolouration, browning and rancidity. 2. Prevent the growth of mould. 3. It helps to retain vitamin C. |

| 2 | Moisture scavenger | Silica gel, propylene glycol, polyvinyl alcohol diatomaceous earth. | 1. Mushroom, fish and meat product, strawberries, maize. | 1. Extend the shelf life. 2. Decrease the moisture condensation in the packaging. 3. It reduces browning and discolouration. |

| 3 | Ethylene scavenger | Activated charcoal, silica gel-potassium permanganate, powdered oya stone, zeotile. | Climacteric fruits and vegetables. | 1. It helps to slow down the ripening process. 2. Extend the shelf life and improve the quality. |

| 4 | Antioxidant releasing system | BHA, BHT, TBHQ, ascorbic acid, tocopherol. | Free fatty fish, fat containing instant powders, nuts and oils, fresh fish, fried products. | 1. It improves the oxidative stability. |

| 5 | CO2 emitters | Iron powder, calcium hydroxide, ferrous carbonate-metal halide. | Fresh fish and meat products. | 1. Extend the shelf life. 2. Reduction in headspace volume of MAP. |

| 6 | Anti-microbial releasing system | Sorbate, benzoate, propionate, sulphur dioxide, ethanol, ozone. | Fresh and processed meat products. fresh sea food, processed fruit and vegetables products. | 1. Inhibit the microbial growth. 2. Extend the shelf life. |

Table 1: Types of active packaging and its application.

Discussion

Intelligent packaging system

The status of food and its surrounding environment can provide with the help of intelligent packaging system. The quality of product is detected by the sensing, tracing, recording, or communicating information about the product. The active packaging and intelligent packaging differ from each other. The intelligent packaging will be the part of packaging. The major functions of food packaging are to provide e the containment, protection, convenience and communication. The function of communication is done with the help of indicators and sensors. The life cycle of packaged product is monitored with the help of intelligent packaging. These packaging system helps to improve the food insecurity and safety verification of the packaged commodities. The indicators monitor the freshness’ of packaged commodity. The intelligent packaging system rely on the use of external users and devices. The intelligent packaging system will be helpful to eliminate the use of chemical preservatives in future. The data carriers, indicators, sensors are the three measure groups of intelligent packaging system. The aim advantage intelligent packaging system that communicates with consumer with the Witten, graphic and text form [11].

The intelligent packaging system helps to improve the quality standards like Hazard Analysis Critical Control Points (HACCP) and the Quality Analysis and Critical Control Points (QACCP). The Smart packaging system is not different from the intelligent packaging and active packaging system. Smart packaging is in one hand use in the intelligent packaging to monitor the changes in the product and on other hand active packaging acts upon the changes. Intelligent packaging can define as the external or internal indicators that provides the information about the aspect of the history of package and quality of packaged products [12].

Mechanism of intelligent packaging system

The concept of intelligent packaging comprises the interaction of product, the package and environment. The quality of product is monitored with the help of sensors and indicators. These sensors and indicators placed inside or outside the package. The message from the sensors about the quality of product should be translated clearly. Intelligent packaging system has ability to detect, record and measure the changes in the product [13].

Data carriers

The flow of information within the supply chain is made more efficient with the help of data carriers. Data carriers are used to monitor the quality of product, traceability, theft protection and Counterfeit protection.

Types of data carriers

Barcode: The barcode which is printed on the label of food packages helps in inventory control, stock recording and checkout. There are two types of barcodes used in the intelligent packaging system. The one-dimensional barcode and twodimensional barcodes printed on the label as per the requirement of product. The barcode scanner used to decode the information. In two-dimensional barcodes, combination of dots and spaces in the array of matrix is used. The barcodes are mostly used by the retailers.

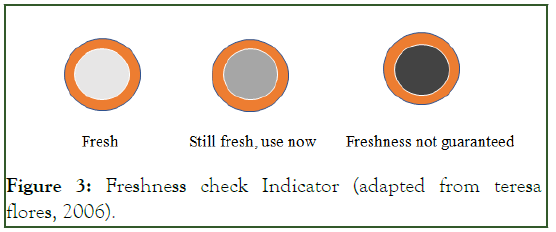

Radio frequency indication: RFID is a separate segment from the indicators and sensors. These tags are attached for the identification and the tracking purpose. The various information such as the location, product name, manufacturing date and expiry date will be given with theses tags. The chip and antenna are the main two parts of RFID tags (Figure 2). RFID tags are falls under Auto ID group which also includes the barcodes, magnetic ink, voice reorganization and biometrics [14].

Figure 2: Working principle of RFID tag.

Indicators: The presence or absence of any substance and the reaction between particular substances are determined by the indicators. Indicators are being placed inside or outside the package. There is main two type of indicators are used. The external indicators are attached to the outside of package, whereas the internal indicators are attache inside the package. The barcode used on label helps in traceability of the product. Now a day’s barcodes are used on the fruits, which give the information about the originality of product, nutritional information and also help in the marketing of product [15].

Types of indicators

Time-temperature indicators: The temperature of food product is an important environmental factor which affects the shelf life of product. The serving temperature o product is different according to the type of product. The increased the temperature of product is responsible for the deterioration, self-destruction, loses in the national an organoleptic characteristic. For the chilled and frozen products. Time-temperature indicators helps to monitor the quality of product. During the storage of such products, indicators continually monitor the quality of product. The types of time temperature indicators available in the market depend on the physical, chemical and microbial process. The time temperature indicators are cost effective, helps to monitor and record the temperature changes during the storage. The working of Time-temperature is simple. In pasteurization and sterilization process Time-temperature indicators are applied to monitor the efficiency of process. In the field of research and commercialization, TTI indicators are used to record the full history of product. The increase in temperature by 2% of perishable products like milk reduce the shelf life by 50%. The mechanism of time temperature indicator is based on the polymerization, diffusion based or enzymatic reaction. The timetemperature indicators are labels or small tags which are attached on the packaging. The response of time temperature indicator is used to analyse the freshness, microbial quality and deterioration of the food [16].

Gas indicators: The gas indicators usually provide the quantitative information of gases like CO2, O2, Water vapor and ethanol through the colorimetric changes. The gas indicators are also known as integrity indicators. It as internal indicator, which is placed inside the packet it helps to monitor the atmosphere of the packet. If the gas is generated inside the packet due to the chemical and enzymatic changes in the food, the indicators result in the color change. The functionality of oxygen scavengers is checked by the O2 indicators. If the O2 is present in the packet, the O2 indicator will give pink color. The absence of oxygen result in a blue color. The form of gas indicators attached on label is in printed form or in the label form. The most of the gas indicators are based on the color change. The CO2 shows color change when the CO2 is below threshold. In the MAP packaging system high concentration of CO2 is used to preserve the products. Hence, the CO2 indicators are used in the MAP. In the gas indicator, if the color change is reversible then the reading will be the shows false by the indicator [17].

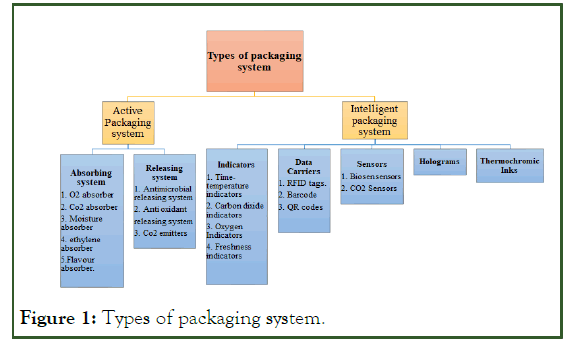

Freshness indicators: The chemical changes in the product are monitored during shelf life of the product. The concept of most of the indicators is based on the color changing ability of its own (Figure 3). The freshness indicator used in fish products is total volatile basic nitrogen. The chitosan based film is used to monitor the pH. of product. The reaction between the metabolites and indicators gives the microbial quality of the product. The chemical changes are also recorded with the help of these indicators [18].

Figure 3: Freshness check Indicator (adapted from teresa flores, 2006).

Sensors: A sensor is a device which is used to locate, detect and quantify the matter that is giving signal for the detection of physical, chemical and microbiological property to which responds it. There is main two parts of sensor. The receptor part of the sensor which helps to detect the presence or activity of substance, concentration of certain chemicals. The transducer part which is used to convert the measured signal to the analytical signal [19].

Types of sensors

Biosensors: The receptors of biosensors are mase up from the biological materials such as the nucleic acids, hormones, antigens and enzymes. The type of transducer depends upon the electrochemical, optical active. There are some biosensors are able to detect the pathogenic bacteria such as salmonella, listeria and E. coli present in the food. The visual signals are given to indicate the positive results. The concentration of specific components is analysed with the help of biological sensing element. The main advantage of biosensors is its specificity and sensitivity. In the solid food sensitivity of sensors gets reduced. The disadvantage of biosensors is no not able to continuously monitor the quality of the product. The quality of product is monitored throughout the processing with the use of biosensors [20].

CO2 sensor: The progress of spoilage of foods is measured by the concentration of certain gases like CO2 or H2S. The monitoring of food is done with help of these sensors. Non-disruptive infrared sensors used as a chemical sensor. Polymer or solid electrolytes are used in chemical CO2 sensors.

Chemical sensors: In last year’s chemical sensors are becoming popular for the product quality and safety. The chemical change in the product such as the composition, concentration is detected with the help of receptor part of sensor. The receptors analyse the changes with surface adsorption. After the analysis of product by the receptors, the signal is transformed with help of transducers. The active transducers require external power for the measurement. If the external power is not required then it is called as passive indicators (Table 2) [21].

| Sr. no. | Technologies | Type of intelligent packaging | Information given | Application |

|---|---|---|---|---|

| 1 | Indicators | Time-temperature indicators (external) | Storage conditions | 1. Food products stored under chilled under frozen condition. 2. Musle based meat products. |

| 2 | Freshness indicators (internal) | 1. Chemical changes during storage. 2. Detect the presence of microbes and metabolites. |

1. Fish products. 2. Fermented products. 3. Fruits and vegetable products. 4. Meat products. |

|

| 3 | Oxygen indicators (internal) | 1. Storage condition. 2. Package leak. 3. Microbial growth. |

1. Used in the MAP packaging application. 2. Food products in reduced concentration of O2 |

|

| 4 | Carbon-dioxide indicators | 1. Storage condition. 2. Package leak. 3. Enzymatic and chemical change. |

1. Used in MAP or CAP of food packaging. 2. Used in fish products. |

|

| 5 | Data carriers | RFID tags | 1. Gives information about the temperature profile of the product. 2. It makes optimization in the supply chain and helps asses the quality of the product. |

1. Used to assess the quality of fish products. |

| 6 | Barcodes | 1. The use of barcodes facilates the inventory, stock recording and checkout. | It can used in all type of packaged commodity as per the requirement of customer. | |

| 7 | QR code | Gives the general information like packaging, labelling, nutritional information, manufacturing and expiry date. | It can use in all type of packaged commodity as per the requirement of customer. | |

| 8 | Sensors | Biosensors | Used to monitor the direct quality of products. | - |

| CO2 sensors | The concentration of CO2 is determined. | - |

Table 2: Types of intelligent packaging and its application.

Other Intelligent packaging technologies

Holograms: Holograms is one of the emerging tools in the intelligent packaging. The counterfeiting and brand name of the product is protected with the help of holograms. The use of holograms increases the attractiveness of the packaging that helps to manufacturers to stand out in the market. The tempering of the food products is prevented with help of the holograms. The counterfeiters are not able to remove the holograms, if the holograms are removed then the upper polymer filum on the packaging also get removed. The application of the hologram in the food sector is limited [22].

Thermochromic Ink: The colour of thermochromic ink changes with change in the temperature. In the irreversible thermochromic ink, it is invisible until exposed to the specific temperature. At specific temperature it will give intense colour. In the reversible ink, the heat changes the colour of ink and the original colour is returns as the temperature decreases. Leuno dyes have ability to change the molecular structure when exposed to specific temperature. The thermochromic inks works with leuno dyes. The thermochromic labels controls the counterfeiting and helps to increase the brand name of the product. The use of thermochromic inks in the food sector is limited [23].

Conclusion

In the recent years, the interest in the development of active and intelligent packaging is increased. The active packaging systems proved that it helps to extend the shelf life of the product with the retention of organoleptic and nutritional properties. Whereas the in intelligent the packaging helps to monitor the shelf life the product. It gives the information about quality of the product. The combine use of these technologies is necessary to give an extended shelf life with effective monitoring. The commercial application of these technologies is limited. The researchers need to focus on the development of cost-effective packaging systems. The high quality products will be manufactured with application of these systems to satisfy the consumer needs.

References

- Han JH. A review of food packaging technologies and innovations. Innovat Food Pack. 2004;12:3-12.

- Realini CE, Marcos B. Active and intelligent packaging systems for a modern society. Meat science. 2014;98(3):404-419.

- Dobrucka R, Cierpiszewski R. Active and intelligent packaging food-Research and development-A Review. Polish J Food Nut Sci. 2014;64(1):12-15.

- Yildirim S, Rocker B, Pettersen MK, Nilsen‐Nygaard J, Ayhan Z, Rutkaite R, et al. Active packaging applications for food. Compr Rev Food Sci Food Saf. 2018; 17:165-199.

- Agriopoulou S. Active packaging for food applications. EC Nutrition. 2018;6(2):86-87.

- Ozdemir M, Floros JD. Active food packaging technologies. Crit Rev Food Sci Nut. 2004;44(3):185-193.

- Popa A, Hnatiuc M, Paun M, Geman O, Hemanth DJ, Dorcea D, et al. An intelligent IoT-based food quality monitoring approach using low-cost sensors. Symmetry. 2014;11(3):374.

- Almasi H, Jahanbakhsh Oskouie M, Saleh A. A review on techniques utilized for design of controlled release food active packaging. Crit Rev Food Sci Nutrit. 2021;61:2601-2621.

- Vasile C, Baican M. Progresses in food packaging, food quality, and safety-controlled-release antioxidant and antimicrobial packaging. Molecules. 2021;26(5): 1263.

- Vermeiren L, Devlieghere F, van Beest M, de Kruijf N, Debevere J. Developments in the active packaging of foods. Trend Food Sci Technol. 1999;10(3):77-86.

- Ghaani M, Cozzolino CA, Castelli G, Farris S. An overview of the intelligent packaging technologies in the food sector. Trend Food Sci Technol. 2016;51:1-11.

- Adam O, Sunday A, Mayowa O, Gloria A, Olabisi O. Effects of storage conditions and duration on seed germination of okra (Abelmoschus esculentus). Int Plant Soil Sci. 2017;20(6):1-6.

- Basra SMA, Ahmad N, Khan MM, Iqbal N, Cheema MA. Assessment of cotton seed deterioration during accelerated ageing. Seed Sci Tech. 2003;31:531-540.

- Begum M, Lokesh S, Ravishankar RV, Shailaja MD, Kumar TV, Shetty HS, et al. Evaluation of certain storage conditions for okra (Abelmoschus esculentus (L.) Moench) seeds against potential fungal pathogens. Int J Agr Biol. 2005;7(4):550-554.

- Bortey HM, Sadia AO, Asibou JY. Influence of seed storage techniques on germinability and storability of cowpea (Vigna ungiculata (L) Walp). J Agr Sci. 2016;8(10):241-248.

- Chormule SR, Changade NM, Patel JB. Effect of seed treatments on storability of vegetable seeds: A review. Plant Arch. 2018;18(1):28-32.

- Kamara EG, Massaquoi FB, James MS, George A. Effects of packaging material and seed treatment on weevil (Callosobruchus maculatus (F) Coleoptera: Bruchidae) infestation and quality of cowpea seeds. Afr J Agri Res. 9(45):3313-3318.

- Khadtar UM, Shinde AK, Patil PP, Bhave SG. Physiological studies on effect of different packaging material for storage of cowpea seed. Adv Agri Res Tech J. 2005;2(2):202-205.

- Khan AA, Sarker KU, Haque MM, Rubayet MT, Mian IH. Storage container, seed moisture level and storage condition effects on germination and prevalence of seed-borne fungi of onion seed. Glo J Sci Front Res. 2005;18(3):1-9.

- Lambat A, Lambat P, Gadewar R, Charjan S, Charde PN. Effect of storage containers on mycoflora and germinability of til. Int J Res Bio Agri Tech. 2018;2(3):10-12.

- Manoharapaladagu PV, Rai PK, Srivastava DK, Kumar R. Effects of polymer seed coating, fungicide seed treatment and packaging materials on seed quality of chilli (Capsicum annum L.) during storage. J Pharm Phytoch. 2018;6(4):324-327.

- Moharana RL, Basu AK, Bardouli SK, Hembram AK. Packaging materials for seed storage in Indian bean-Genotypic response. J Crop Weed. 2017;13(2):60-63.

- Patel JB, Babariya CA, Sondarva J, Ribadiya KH, Bhatiya VJ. Effect of storage conditions, packing materials and seed treatments on viability and seedling vigour of onion (Allium cepa L.) seeds. J App Nat Sci. 2006;9(2):1054-1067.

Citation: Ranvare A, Jadhav H (2023) Review on the Current Scenario in Active and Intelligent Packaging Technologies. J Food Process Technol. 14:1024.

Copyright: �© 2023 Ranvare A, et al. This is an open access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.