Indexed In

- Genamics JournalSeek

- Academic Keys

- JournalTOCs

- China National Knowledge Infrastructure (CNKI)

- Access to Global Online Research in Agriculture (AGORA)

- Centre for Agriculture and Biosciences International (CABI)

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- SWB online catalog

- Publons

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Research Article - (2020) Volume 11, Issue 1

Osmotic Dehydration of Garden Egg (Solanum aethiopicum): The Shrinkage and Mass Transfer Phenomena

DK Adekeye1*, OI Aremu1, OK Popoola1, EO Fadunmade1, IS Adedotun2 and AA Araromi32Department of Pure and Applied Chemistry, Osun State University Osogbo, Osun State, Nigeria

3Department of Industrial Chemistry, Ekiti State University Ado-Ekiti, Ekiti State, Nigeria

Received: 03-Dec-2019 Published: 28-Dec-2019, DOI: 10.35248/2157-7110.20.11.817

Abstract

Osmotic dehydration is usually employed to lower the water activity of fruits and vegetables and thus has a wide range of applications in food preservation. This study investigates the osmotic dehydration of garden egg (Solanum aethiopicum) using sodium chloride solution (NaCl) of varying concentrations (20, 40 and 60)% w/w as osmotic solutions. Different parameters such as percentage water loss (%WL), weight reduction (%WR) and solid gain (%SG) were investigated at different solution temperature (25, 35, 45, 55, and 65)°C, agitation time (20, 40, 60, 80, 100, 120, 140, 160 and 180) min and osmotic solution concentration (20, 40 and 60)% w/w to ascertain the optimum dehydration performance of the process. The performance efficiency of the process was evaluated at different osmotic solution concentrations (20, 40 and 60)% w/w with respect to time (20-180) min at a constant temperature of 40°C. The performance efficiency of the process was also evaluated at different osmotic solution concentrations (20, 40 and 60)% w/w with respect to temperature (25, 35, 45, 55, and 65)°C at the constant time (180 min). The results of this study showed that %SG and %WL increased with increase in concentration with respect to time whereby the optimum values for these parameters being 157% and 45.80% respectively were achieved at 60% w/w osmotic solution concentration, while optimum %WR (34.70%) with respect to time was achieved at 40% w/w osmotic solution concentration. Therefore, the order of %SG and %WL by the garden egg with respect to time was (60>40>20)% w/w. The optimum %SG, %WL, and %WR were achieved at 65°C in 60% w/w osmotic solution with the values of (133, 53.11 and 40.10)% respectively. The results from this study, therefore, showed that osmotic dehydration could potentially reduce the water activity of the garden egg.

Keywords

Osmotic dehydration; Food preservation; Water activity; Garden egg; Rural area

Introduction

It has been stated that about 20%-40% percent of the fruit and vegetable production in many countries of the world goes waste due to a lack of proper and adequate storage systems [1]. Therefore, good storage systems and preservation technologies are necessary to ensure the safety, extension of shelf life and the quality of foods. Several techniques have been developed to satisfy the current demands of economic preservation of food and consumer satisfaction in safety, nutritional and health aspects. Some of these techniques include heat treatment (pasteurization and sterilization) [2], Preservation by low water activity (aw) [3], Preservation by organic acids [4] Preservation by carbon dioxide [5] and Osmotic Dehydration [6,7].

Osmotic dehydration aims at extending the life of food by removing water without phase transition according to Matuska et al. [8]. The process is carried out by immersing the raw material in a hypertonic solution. Optimization of the osmotic process is done in order to achieve and ascertain optimum dehydration. This optimization includes optimization of temperature, concentration, immersion time and mass of the substance. When all these parameters are optimized, different variables such as mass loss, mass transfer gain, color change, etc. can be determined [9-11]. Osmotic dehydration has been known to be one of the best and suitable methods to increase the shelf life of fruits and vegetables. This process is preferred over others due to their vitamins and minerals, color, flavor and taste retention property [1]. Several researchers have reported the potential of this process to reduce the perishability of fruits and vegetables by reducing their high water content [1,12,13]. For instance, Bchir et al. [14] reported the Osmotic dehydration of pomegranate seed carried out at different temperatures (30, 40 and 50)°C in 50 °Brix sucrose, glucose and mixture of two in 50:50. The results of their study showed 46% water loss in sucrose, 37% in glucose and 41% in mixture solution after 20 min; also, the increase in temperature increases the water loss. Mercali et al. [15] also worked on optimization of osmotic dehydration of banana with respect to temperature (25°C-55°C) salt (0-10 g/100 g) and sucrose (30-60 g/100 g) concentrations. The result of their study showed water loss and solid gain by the banana during the dehydration process. Several osmotic dehydration studies have been reported for various kinds of fruits and vegetables but none have been reported for garden egg (Solanum aethiopicum) to our best of knowledge.

Garden egg plants are fruit vegetables of some varieties which are white with egg-like shape, hence the name ‘eggplants’ [16]. Garden egg is cultivated all year round in different parts of Nigeria and West Africa and serves as one of the main sources of income for many rural farmers and households. Eggplant nutritious value is comparable to the values of other common vegetables. Its fresh weight is composed of 1.4% protein, 93% moisture, 0.3% minerals, 1.3% fibre, 0.3% fat, and the remaining 4% consists of various carbohydrates and vitamins (A and C). It also contains water (about 92.5%), protein (1%), fat (0.3%), and carbohydrates (6%). Similarly, eggplant contains nutrients such as dietary fibre, vitamin K, niacin, vitamin B6, folate, ascorbic acid, magnesium, manganese, pantothenic acid, phosphorus, potassium, iron, and copper [17]. According to Okito et al. [18], eggplant is most popular in southern Nigeria particularly in Igbo land, because of both cultural and traditional importance. In Nigeria, though there are no official figures recorded for Solanum gilo and Solanum aethiopicum production, the crop has a wide distribution as a garden crop [19]. Production of eggplant is however constrained by preservation technique, a wide range of pests and diseases reducing total production as well as production quality. This research is therefore aimed at investigating osmotic dehydration using the salt solution as a possible preservation technique for the garden egg.

Materials and Methods

Materials

Garden eggs (Solanum aethiopicum), salt (NaCl) solution of varying concentrations (20, 40 and 60)% w/w, analytical weighing balance, oven, stopwatch, distilled water, volumetric cylinder, beakers, conical flasks, Aluminium foil, and cotton wool.

Methods

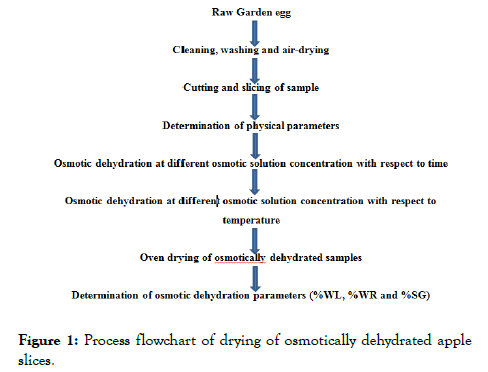

Sample collection and preparation: The garden eggs which have no defects were sourced from a local market (Mojere) at Ado- Ekiti, Ekiti State, Nigeria. The plant was identified by the Herbarium curator at the Department of Plant Science and Biotechnology, Ekiti State University, Ado-Ekiti, Southwestern Nigeria. The samples were prepared by cleaning, washing with distilled water and air-drying at room temperature for 24 hours prior to the Osmo-dehydration experiments. Thereafter, the samples were cut into slices (each slice weighing 10 g) enough to carry out the experiments (Figure 1).

Figure 1: Process flowchart of drying of osmotically dehydrated apple slices.

Osmotic solution preparation: Osmotic solutions (50 mL) of varying concentrations (20, 40 and 60)% w/w were prepared using analytical grade salt and distilled water by dissolving the appropriate amount of salt in 50 mL distilled.

Determination of physical parameters of the raw garden egg sample

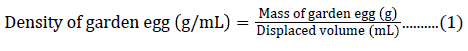

Determination of density of the raw garden egg: The density of the garden egg sample was determined by estimating the weight of 10 g of the sample in 100 ml distilled water in a volumetric cylinder. The displaced volume was measured and density was calculated by Equation 1. The experiment was conducted in triplicate.

Moisture and solid content determination (MC and SC): 10 g of the raw garden egg sample was dried in an air-drying oven at the temperature of 105°C for 24 hours . The final weight of the dried sample was recorded. The percentage of moisture and the solid content was calculated by Equations 2 and 3.

Where Wi and Wf are the weight of the garden egg before and after drying respectively while MC is moisture content of the garden egg.

Experimental

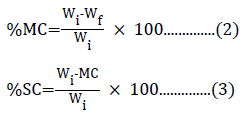

The Osmo-dehydration experiments were performed in batches at different agitation times, salt solution concentration and solution temperature in order to understudy the effect of temperature, time and concentration on %water loss (%WL), %solid gain (%SG) and %weight reduction (%WR) of the garden egg. The %WL, %SG, and %WR were calculated by Equations 4-6.

Where Wa is the initial mass of fresh sample (g), Wb is the mass of sample after time (t) of osmotic dehydration (g), Wc is the solid gain, Wd is the oven-dry mass of sample (g) after time (t) of osmotic dehydration and We is the initial dry mass of sample (g).

Effect of osmotic solution concentrations and osmodehydration time on osmotic dehydration of the garden egg slices: The osmotic dehydration experiments were performed at a temperature of 40°C using a water bath equipped with an incubation system. The experiments were performed in batch at time intervals of (20, 40, 60, 80, 100, 120, 140, 160 and 180) min using 50 mL osmotic solution of different concentrations (20, 40 and 60)% w/w. At the end of the batch experiment, the samples were blotted with cotton wool to remove excess water from the surface. Thereafter, the samples were weighed in order to determine the %WR of the garden egg slices. Following this, the samples were dried in an air-drying oven at the temperature of 105°C for 24 hrs in order to determine the actual %WL and %SG by the garden egg slices [21].

Effect of osmotic solution temperature on osmotic dehydration of the garden egg slices: The effect of osmotic solution temperature was studied using 10 g of the garden egg slices in different solution concentrations of (20, 40 and 60)% w/w. Each sample in each osmotic solution was agitated for a period of 180 min at the temperatures of (25, 35, 45, 55 and 65)°C. Weighing and drying were carried out as described in the process above.

Results and Discussion

Physical parameters

The garden egg has a relative density (1.05 g/mL) corresponding to that of pure water (approximately 1.00 g/mL). The percentages of moisture content and solid content of the garden egg are 95.00% and 5.00% respectively (Table 1), which implies that the majority of the matter is composed of water (moisture).

| Physical parameter | Values |

|---|---|

| Density | 1.05 g/mL |

| %Moisture content | 95 |

| %Solid content | 5 |

Table 1: Physical parameters of the garden egg.

The high moisture content and low solid content could possibly account for reason the garden egg has a density corresponding to that of pure water. It has also been shown that the larger percentage of eggplant is made up of moisture [17].

Effect of salt concentration and osmo-dehydration time on osmotic dehydration of the garden egg slices

The solution concentration and dehydration time are important factors that affect SG, WL, and WR. %Water loss, %weight reduction and %solid gained by the garden egg slices were estimated at different concentrations of salt solution (20, 40 and 60)% w/w and time (20, 40, 60, 80, 100, 120, 140, 160 and 180) min at the temperature of 40°C. The results are discussed below.

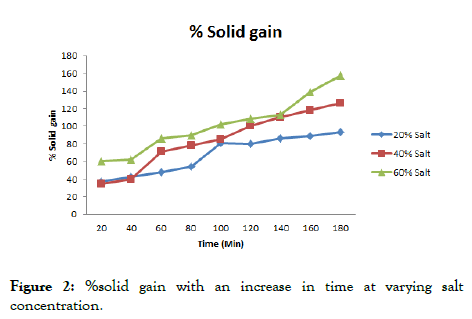

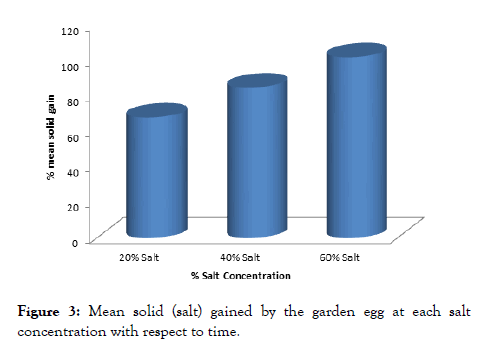

%Solid (salt) gain: The %SG for 20% w/w solution concentration are (37, 43, 48, 54, 81, 80, 86, 89 and 93)%; 40% w/w solution concentration are (35, 40, 71, 78, 85, 100, 110, 118 and 126)%; 60% w/w solution concentrations are (60, 62, 86, 90, 102, 108, 113, 139 and 157)%. The results are shown in Figure 2 and Table 2, while the mean %SG is shown in Figure 3. This implies that %SG by the garden egg slices for all the concentrations (20, 40 and 60)% w/w increases with an increase in dehydration time from (20 to 180) min. Thus, the solid gained by the garden egg with concentration change was time dependent.

| Concentration (% w/w) | Time (min) | Weight after osmo-dehydration (g) | Weight after oven drying (g) | % water loss | Solid gain (g) | % solid gain | % weight reduction |

|---|---|---|---|---|---|---|---|

| 20% Salt | 20 | 8.41 | 0.87 | 19.6 | 0.37 | 37 | 15.9 |

| 40 | 8.95 | 0.93 | 19.8 | 0.43 | 43 | 10.5 | |

| 60 | 8.75 | 0.98 | 22.3 | 0.48 | 48 | 12.5 | |

| 80 | 8.63 | 1.04 | 24.1 | 0.54 | 54 | 13.7 | |

| 100 | 8.24 | 1.3 | 30.7 | 0.81 | 81 | 17.6 | |

| 120 | 8.02 | 1.31 | 22.8 | 0.8 | 80 | 19.8 | |

| 140 | 7.88 | 1.36 | 29.8 | 0.86 | 86 | 21.2 | |

| 160 | 7.76 | 1.39 | 31.3 | 0.89 | 89 | 22.4 | |

| 180 | 7.5 | 1.43 | 34.3 | 0.93 | 93 | 25 | |

| Mean | 26.08 | 0.67 | 67.89 | 17.62 | |||

| SD | 5.48 | 0.21 | 20.78 | 4.87 | |||

| 40% Salt | 20 | 8.62 | 0.85 | 17.3 | 0.35 | 35 | 13.8 |

| 40 | 8.5 | 0.9 | 19 | 0.4 | 40 | 15 | |

| 60 | 8.24 | 1.21 | 24.7 | 0.71 | 71 | 17.6 | |

| 80 | 7.9 | 1.28 | 28.8 | 0.78 | 78 | 21 | |

| 100 | 7.6 | 1.35 | 32.5 | 0.85 | 85 | 24 | |

| 120 | 7.48 | 1.5 | 35.2 | 1 | 100 | 25.2 | |

| 140 | 7.2 | 1.61 | 39 | 1.1 | 110 | 28 | |

| 160 | 6.91 | 1.68 | 42.7 | 1.18 | 118 | 30.9 | |

| 180 | 6.83 | 1.76 | 44.3 | 1.26 | 126 | 34.7 | |

| Mean | 31.5 | 0.85 | 84.78 | 23.35 | |||

| SD | 9.82 | 0.32 | 32.34 | 7.17 | |||

| 60% Salt | 20 | 8.54 | 1.1 | 20.6 | 0.6 | 60 | 14.6 |

| 40 | 8.22 | 1.12 | 24 | 0.62 | 62 | 17.8 | |

| 60 | 8 | 1.36 | 28.6 | 0.86 | 86 | 20 | |

| 80 | 7.86 | 1.4 | 30.4 | 0.9 | 90 | 21.4 | |

| 100 | 7.61 | 1.52 | 34.1 | 1.02 | 102 | 23.9 | |

| 120 | 7.45 | 1.58 | 36.3 | 1.08 | 108 | 25.5 | |

| 140 | 7.4 | 1.63 | 37.3 | 1.13 | 113 | 26 | |

| 160 | 7.22 | 1.69 | 41.7 | 1.39 | 139 | 27.8 | |

| 180 | 6.99 | 1.71 | 45.8 | 1.57 | 157 | 30.1 | |

| Mean | 33.2 | 1.01 | 101.89 | 23.01 | |||

| SD | 8.14 | 0.32 | 32.24 | 4.98 | |||

Table 2: Osmo-dehydration parameters with respect to time and concentration.

Figure 2: %solid gain with an increase in time at varying salt concentration.

Figure 3: Mean solid (salt) gained by the garden egg at each salt concentration with respect to time.

The results from this study showed that the %SG during this process was highest (157%) for the solution with the highest salt concentration (60% w/w) and higher (126%) for 40% w/w sucrose solution than that of 20% w/w salt solution (93%). Therefore, the order of %SG by the garden egg with respect to time is (60>40>20)%. This trend could be attributed to the fact that when the transport of solid (salt) between the fruit ’ s external surface film and internal pores are equal, the transboundary movement of the solid will not be significantly permissible; however, increasing concentration could re-initiate the transboundary movement (depending on the nature of the solid and fruit) and hence, the osmotic dehydration process would be concentration-dependent. The mean values of the %SG in Figure 3 also showed that there was a linear relationship between %SG and concentration change during the osmotic dehydration process.

The results of this study further showed that a higher concentration of salt solution would imply a higher concentration of salt particles to be fixed on the surface and in the pores of the garden egg (i.e. voids created by the osmotically removed water). Filling of air spaces with the hypertonic solution of the salt may have resulted in subsequent binding of the solute to the surface of the osmotically dehydrated garden egg thereby resulting in solid gain and increased weight of the actual matter. These findings confirmed that a high concentration of a salt solution (>50% w/w) is a mass transfer rate-limiting parameter during the osmotic dehydration process [22]. Thus, increased salt concentration has a significant effect on solid gain. These results corroborate to those obtained by the study on osmotic dehydration of mango slices [23].

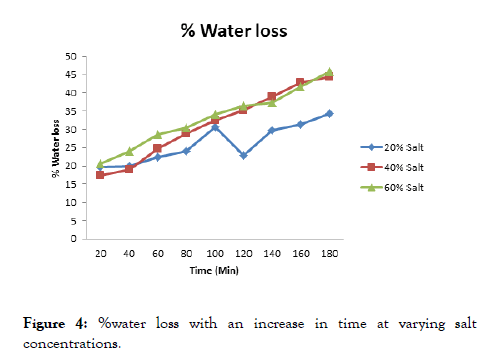

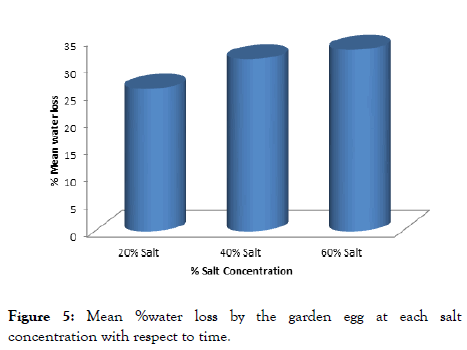

%Water loss: The most important parameter to examine in osmo-dehydration process is the water loss. It is expected that during a dehydration process, water is lost. The amounts of water loss by the garden egg expressed in percentages are shown in Figure 4 and Table 2. The %WL for 20% w/w solution concentrations are: (19.60, 19.80, 22.30, 24.10, 30.70, 22.80, 29.80, 31.30 and 34.30)%; 40% w/w solution concentrations are: (17.30, 19.00, 24.70, 28.80, 32.50, 35.20, 39.00, 42.70 and 44.30)% while that of 60% w/w solution concentrations are: (20.60, 24.00, 28.60, 30.40, 34.10, 36.30, 37.30, 41.70 and 45.80)%. The results from this study showed that the amount of water removed during this process was highest (45.80%) for solution with the highest salt concentration (60% w/w) and higher (44.30%) for 40% w/w salt solution than that of 20% w/w salt solution (34.30%).

Figure 4: %water loss with an increase in time at varying salt concentrations.

These results showed that as the osmo-dehydration time increases, the amount of %WL also increased. This stretched that there was a linear relationship between %WL and osmo-dehydration time of the garden egg. A study by Lewicki and Pawlak [24] also showed that water loss during the osmotic dehydration process increased with an increase in dehydration time. Also, as the concentration of salt increases, the %WL increases. This also showed the linearity of the %WL with an increased concentration of the salt solution. These results were further supported by the mean values for water loss as represented in Figure 5.

Figure 5: Mean %water loss by the garden egg at each salt concentration with respect to time.

The loss of water could be attributed to the increase in the concentration of the surrounding medium of the garden egg. This increase in concentration thereby results in cell shrinkage of the garden egg by plasmolysis with loss of shape of cellular walls together with loss of turgor pressure. Prinzivalli et al. [25] studied the osmotic dehydration of strawberry and their results showed that as the water was being lost, there was a gradual disconnection and breakdown of the tissue, with a loss of shape of cellular walls together with loss of turgor pressure during the process. The results of this study are also in line with previously reported work on osmo-dehydration of fruits by Ganjloo et al. [26].

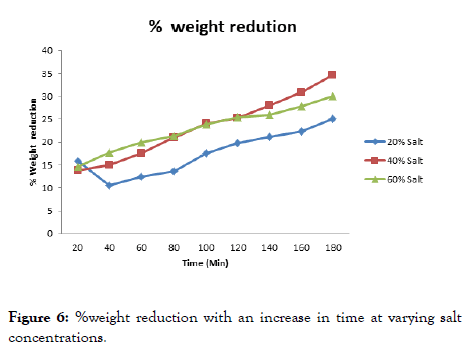

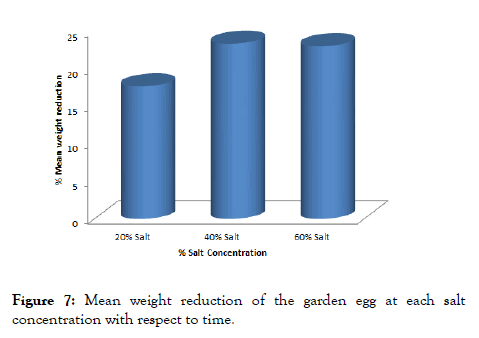

%Weight reduction: The results of this study (Figure 6 and Table 2) present the weight reduction of the garden egg samples in percentages. The %WR for (20, 40 and 60)% w/w solution concentrations are: (15.90, 10.50, 12.50, 13.70, 17.60, 19.80, 21.20, 22.40, 25.00)%; (13.80, 15.00, 17.60, 21.00, 24.00, 25.20, 28.00, 30.90, 34.70)% and (14.60, 17.80, 20.00, 21.40, 23.90, 25.50, 26.00, 27.80, 30.10)% respectively. These results showed that %WR of the garden egg slices for all the concentrations (20, 40 and 60)% w/w increases with an increase in dehydration time from (20 to 120) min. This implies a linear relationship between %WR of the garden egg and osmo-dehydration time. Also, the results showed that %WR was highest (34.70%) for 40% w/w salt solution, followed by 60% w/w (30.10%) then 20% w/w (25%) salt solution which means that weight reduction is not linearly dependent on the increase in salt concentration (Figure 6).

Figure 6: %weight reduction with an increase in time at varying salt concentrations.

The mean weight reduction as represented in Figure 7 also showed the non-linear relationship between weight reduction and increased solution concentration. The non-linearity between these osmotic-dehydration variables may have been as a result of the amount of water lost and solid gained during the process. The %WR with respect to concentration changes of the solution are all in the order of (40>60>20)% w/w.

Figure 7: Mean weight reduction of the garden egg at each salt concentration with respect to time.

Thus, our study showed that a higher concentration of the salt solution may not imply a higher amount of weight loss or reduced during the osmotic dehydration process of the garden egg as the difference in magnitude of water loss to solid gain could affect the total weight lost. Lewicki and Lukaszuk [27] stated that weight loss in fruits during the osmotic dehydration process could be attributed to substantial changes in cellular tissue and cell plasmolysis. Therefore, the weight loss of the garden egg may have been influenced by the degradation of the middle lamellae during osmosis and cell plasmolysis during the osmotic dehydration processes. Similar observations were reported byLe Maguer et al. [28] on osmotic dehydration oftrawberries.

Effects of solution temperature on osmotic dehydration of garden egg slices

The solution temperature is also an important factor that affects SG, WL, and WR.

Effects Water loss, weight reduction and solid gain by the garden egg slices using the osmotic solution of varying concentrations were studied at different temperatures (25, 35, 45, 55 and 65)°C for the duration of 180 min. The results are shown in Table 3.

| Concentration (% w/w) | Temperature (ºC) | Weight after osmo-dehydration (g) | Weight after oven drying (g) | % water loss | Solid gain (g) | % solid gain | % weight reduction |

|---|---|---|---|---|---|---|---|

| 20% Salt | 25 | 8.72 | 1.31 | 20.9 | 0.81 | 81 | 12.8 |

| 35 | 8.01 | 1.4 | 28.9 | 0.9 | 90 | 19.9 | |

| 45 | 7.77 | 1.53 | 32.6 | 1.03 | 103 | 22.3 | |

| 55 | 7.33 | 1.6 | 37.7 | 1.1 | 110 | 26.7 | |

| 65 | 7.75 | 1.61 | 33.6 | 1.11 | 111 | 22.5 | |

| Mean | 30.74 | 0.99 | 99 | 20.84 | |||

| SD | 6.33 | 0.13 | 13.09 | 5.12 | |||

| 40% Salt | 25 | 8.68 | 1.11 | 19.3 | 0.61 | 61 | 13.2 |

| 35 | 7.56 | 1.38 | 33.2 | 0.88 | 88 | 24.4 | |

| 45 | 6.7 | 1.66 | 44.6 | 1.16 | 116 | 33 | |

| 55 | 5.3 | 1.7 | 49 | 1.2 | 120 | 37 | |

| 65 | 6.33 | 1.68 | 48.5 | 1.18 | 118 | 36.7 | |

| Mean | 30.93 | 1.01 | 100.6 | 28.86 | |||

| SD | 17.89 | 0.25 | 25.71 | 10.13 | |||

| 60% Salt | 25 | 7.75 | 1.39 | 31.4 | 0.89 | 89 | 22.5 |

| 35 | 7.02 | 1.55 | 40.3 | 1.05 | 105 | 29.8 | |

| 45 | 6.5 | 1.78 | 47.8 | 1.28 | 128 | 35 | |

| 55 | 6.11 | 1.82 | 52.11 | 1.32 | 132 | 38.9 | |

| 65 | 5.99 | 1.83 | 53.11 | 1.33 | 133 | 40.1 | |

| Mean | 30.04 | 1.17 | 117.4 | 33.26 | |||

| SD | 19.67 | 0.2 | 19.55 | 7.23 | |||

Table 3: Osmo-dehydration parameters with respect to temperature and concentration.

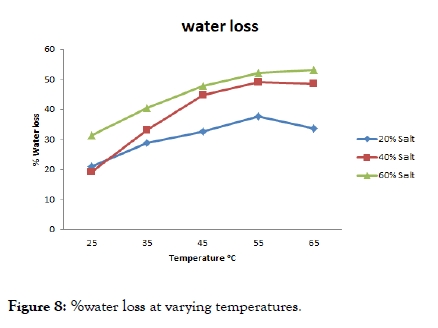

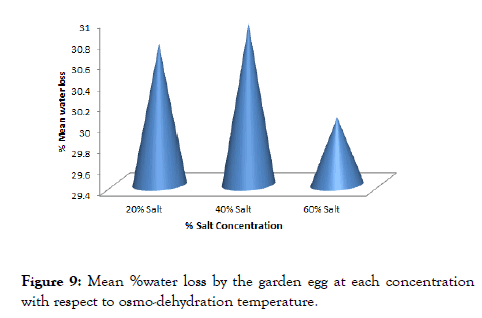

%Water loss: The results obtained for water loss by the garden egg with respect to temperature change expressed in percentages are shown in Figure 8 and Table 3, while the mean %WL is shown in Figure 9. The %WL for 20% w/w solution concentrations are (20.90, 28.90, 32.69, 37.70 and 33.60)%; 40% w/w solution concentrations are: (19.30, 33.20, 44.60, 49.00 and 48.50)%; 60% w/w solution concentrations are: (31.40, 40.30, 47.80, 52.11 and 53.11)% after osmo-dehydration. These results showed that %WL by the garden egg slices for solution concentrations of (20 and 40)% w/w increased with an increase in dehydration temperature from (25-55)°C and reduced at 60°C while that of 60% w/w increased from 25 to 65°C. Also, the results showed highest %WL (53.11%) by the garden egg for salt solution with concentration of 60% w/w at the temperature of 65°C, higher %WL (49.00%) for 40% w/w salt solution at the temperature of 55°C, while 20% w/w salt solution has the least value for %WL (37.70%) at 55°C (Figure 8).

Figure 8: %water loss at varying temperatures.

Figure 9: Mean %water loss by the garden egg at each concentration with respect to osmo-dehydration temperature.

This implies that the temperature solution has a significant effect on water loss during the osmotic dehydration process of the garden egg. The %WL with respect to concentration changes and temperature of the solution is all in the order of (60>40>20)% w/w. However, the least mean %WL value was recorded for the salt solution with a concentration of 60% w/w (Figure 9) which could be attributed to the efficiency of the osmotic solution to remove water at the selected temperatures.

It has been shown that an increase in temperature up to a certain limit is known to increase the rate of osmosis while further increase in temperature affects the semi-permeability of the cell walls and reduces the rate of osmosis [29]. This fact could account for the reason for the reduction in water loss at a temperature above 55°C in this study. The results of this study corroborate with previously reported works by Li and Ramaswamy [29].

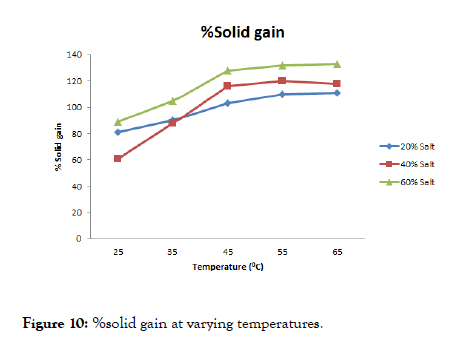

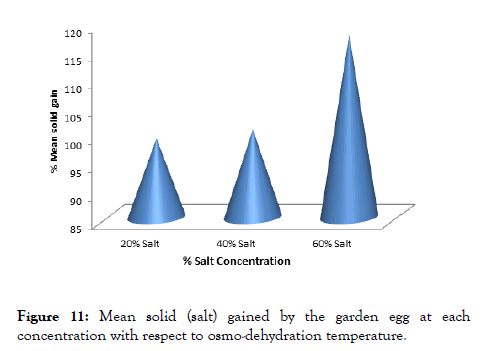

%Solid (Salt) gain: The %SG by the garden at varying concentrations of the osmotic solution was evaluated at different temperatures (25, 35, 45, 55 and 65)°C for 180 min. The results from the experiments are shown in Figure 10 and Table 3. The results of solid gain for: 20% w/w solution concentrations are: (81, 90, 103, 110, and 111)%; 40% w/w solution concentrations are: (61, 88, 116, 120 and 118)%; 60% w/w solution concentrations are: (89, 105, 128, 132 and 133)%. These results showed that %SG by the garden egg slices for concentrations of (20 and 60)% w/w increased with an increase in dehydration temperature from (25-60)°C (Figure 10).

Figure 10: %solid gain at varying temperatures.

The increase in %SG from (25-65)°C showed the ability of the salt to overcome resistance to mass transfer with the increase in kinetic energy to undergo an interaction (surface bonding) with the active sites of the fruit. The %SG by the garden egg slices for concentrations of 40% w/w increased with an increase in dehydration temperature from (25-55)°C. The mean %SG as represented in Figure 11 also showed a linear relationship between %SG and increased solution concentration.

Figure 11: Mean solid (salt) gained by the garden egg at each concentration with respect to osmo-dehydration temperature.

The results corroborate to the results of Castello et al. [30] that worked on the osmotic dehydration of strawberries.

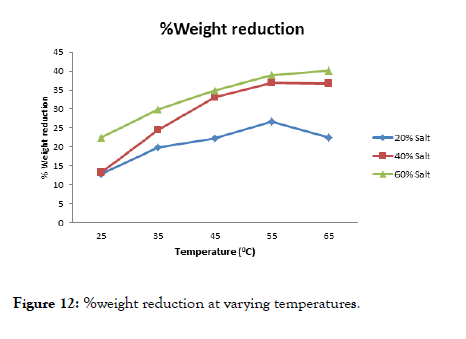

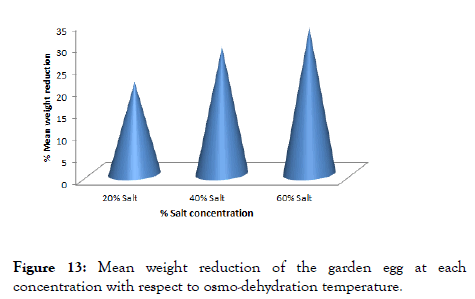

%Weight reduction: The amounts of water loss by the garden egg expressed in percentages are shown in Figure 12 and Table 3, while the mean %WR is shown in Figure 13. The osmodehydration process was carried out for a duration of 180 min at the temperature of (25, 35, 45 and 65)°C. The %WR for: 20% w/w solution concentration are: (12.80, 19.90, 22.30, 26.70 and 22.50)%; 40% w/w solution concentration are: (13.20, 24.40, 33.00, 37.00 and 36.70)%; 60% w/w solution concentration are: (22.50, 29.80, 35.00, 38.90 and 40.10)%. These results showed that %weight reduction by the garden egg slices for all the concentrations (20, 40 and 60)% w/w increased with an increase in osmo-dehydration temperature from (25-65)°C as shown in Figure 12 and Table 3.

Figure 12: %weight reduction at varying temperatures.

Figure 13: Mean weight reduction of the garden egg at each concentration with respect to osmo-dehydration temperature.

This showed a linear relationship between the osmo-dehydration temperature of the garden egg and the concentration of the salt solution. This relationship is further shown in Figure 13.

The results, therefore, showed that weight reduction is temperature-dependent. This result is consistent with the study reported by Katsiferis et al. [31] on osmotic dehydration of unripe oranges.

Conclusion

The results from this study, therefore, showed that osmotic dehydration by NaCl solution could potentially reduce water activity of garden egg to promote its shelf life or could be employed as a pre-treatment technique for further drying, wherefore, desalination (removal of excess salt) and rehydration of dried matter becomes a major advantage of this technique. The data from this study is an added value to the already existing information on conventional techniques for food preservation and osmotic dehydration processes. This study, therefore, showed an osmotic dehydration process to be a cheap, effective, alternative and beneficial technique for food preservation including garden egg.

Conflicts of Interest

The authors declare that there are no conflicts of interest.

REFERENCES

- Yadav AK, Singh SV. Osmotic dehydration of fruits and vegetables: a review. J Food Sci Technol. 2014;51:1654-1673.

- Heldman DR, Lund DB. Handbook of Food Engineering. CRC Press. 1992.

- Booth IR. Bacterial responses to osmotic stress: diverse mechanisms to achieve a common goal. The properties of water in foods ISOPOW 6. Springer, Boston, MA. 1998:456-485.

- Russel NJ, Gould GW. Food preservatives Blackie Academic and Professional, London. 1991:20.

- Gould GW. New methods in food preservation, Blackie Academic and Professional. 1995.

- Chenlo F, Chaguri L, Santos F, Moreira R. Osmotic dehydration/ impregnation kinetics of padrón pepper (Capsicum annuum) with sodium chloride solutions: process modelling and colour analysis. Food Sci Technol Int. 2006;12:221-227.

- Moreira R, Chenlo F, Torres MD, Vázquez G. Effect of stirring in the osmotic dehydration of chestnut using glycerol solutions. LWT-Food Sci Technol. 2007;40:1507-1514.

- Matuska M, Lenart A, Lazarides HN. On the use of edible coatings to monitor osmotic dehydration kinetics for minimal solids uptake. J Food Eng. 2006;72:85-91.

- Jokić A, Gyura J, Lević L, Zavargó Z. Osmotic dehydration of sugar beet in combined aqueous solutions of sucrose and sodium chloride. J Food Eng. 2007;78:47-51.

- Ozdemir M, Ozen BF, Dock LL, Floros JD. Optimization of osmotic dehydration of diced green peppers by response surface methodology. LWT-Food Sci Technol. 2008;41:2044-2050.

- Singh B, Panesar PS, Nanda V, Kennedy JF. Optimisation of osmotic dehydration process of carrot cubes in mixtures of sucrose and sodium chloride solutions. Food Chem. 2010;123:590-600.

- Ferrari CC, Hubinger MD. Evaluation of the mechanical properties and diffusion coefficients of osmodehydrated melon cubes. Int J Food Sci Technol. 2008;43:2065-2074.

- Moraga MJ, Moraga G, Fito PJ, Martínez-Navarrete N. Effect of vacuum impregnation with calcium lactate on the osmotic dehydration kinetics and quality of osmodehydrated grapefruit. J Food Eng. 2009;90:372-379.

- Bchir B, Besbes S, Attia H, Blecker C. Osmotic dehydration of pomegranate seeds: mass transfer kinetics and differential scanning calorimetry characterization. Int J Food Sci Technol. 2009;44:2208-2217.

- Mercali GD, Ferreira Marczak LD, Tessaro IC, Zapata Noreña CP. Evaluation of water, sucrose and NaCl effective diffusivities during osmotic dehydration of banana (Musa sapientum, shum.). LWT- Food Sci Technol. 2011;44:82-91.

- Chen NC, Li HM, Kail T. Eggplant Production, AVRD. 2001.

- USDA-United States Department of Agriculture. Eggplant nutrient values and weights for edible portion. Variability and change on food production in Nigeria. 2nd Annual Conference and Gold. 2009:114-130.

- Okito A, Alves BR, Urquiaga S, Boddey R. Isotopic fractionation during N2 fixation by four tropical legumes. Soil Biol Biochem. 2004;36:1179-1190.

- Dauda SN, Aliyu L. Effect seedling age at transplant and poultry manure on fruit yield and nutrients of garden egg (S. gilo L.) varieties. J Trop Sci. 2005;5:38-41.

- AOAC. Official methods of analysis. Washington: Association of Official Analytical Chemists. 1990.

- Najafi AH, Yusof YA, Rahman RA, Ganjloo A, Ling CN. Effect of osmotic dehydration process using sucrose solution at mild temperature on mass transfer and quality attributes of red pitaya (Hylocereus polyrhizusis). Int Food Res J. 2014;21:625-630.

- Khoyi MR, Hesari J. Osmotic dehydration kinetics of apricot using sucrose solution. J Food Eng. 2007;78:1355-1360.

- Ito AP, Tonon RV, Park KJ, Hubinger MD. Influence of process conditions on the mass transfer kinetics of pulsed vacuum osmotically dehydrated mango slices. Drying Technol. 2007;25:1769-1777.

- Lewicki PP, Porzecka-Pawlak R. Effect of osmotic dewatering on apple tissue structure. J Food Eng. 2005;66:43-50.

- Prinzivalli C, Brambilla A, Maffi D, Scalzo RL, Torreggiani D. Effect of osmosis time on structure, texture and pectic composition of strawberry tissue. European Food Res Technol. 2006;224:119-127.

- Ganjloo A, Rahman RA, Bakar J, Osman A, Bimakr M. Kinetics modeling of mass transfer using Peleg’s equation during osmotic dehydration of seedless guava (Psidium guajava L.): effect of process parameters. Food Bioprocess Technol. 2012;5:2151-2159.

- Lewicki PP, Lukaszuk A. Effect of osmotic dewatering on rheological properties of apple subjected to convective drying. J Food Eng. 2000;45:119-126.

- Le Maguer M. Osmotic dehydration: review and future directions. InProceedings of the international symposium on progress in food preservation processes. CERIA Brussels. 1988;1:283-309.

- Li H, Ramaswamy HS. Osmotic dehydration: dynamics of equilibrium and pseudo-equilibrium kinetics. Int J Food Prop. 2010;13:234-250.

- Castelló ML, Fito PJ, Chiralt A. Changes in respiration rate and physical properties of strawberries due to osmotic dehydration and storage. J Food Eng. 2010;97:64-71.

- Katsiferis T, Zogzas N, Karathanos VT. Mechanical properties and structure of unripe oranges during processing of “spoon sweets”. J Food Eng. 2008;89:149-155.

Citation: Adekeye DK, Aremu OI, Popoola OK, Fadunmade EO, Adedotun IS, Araromi AA (2020) Osmotic Dehydration of Garden Egg (Solanum aethiopicum): The Shrinkage and Mass Transfer Phenomena. J Food Process Technol 11:817. doi: 10.35248/2157-7110.20.11.817

Copyright: © 2020 Adekeye DK, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.