Indexed In

- Genamics JournalSeek

- Academic Keys

- JournalTOCs

- China National Knowledge Infrastructure (CNKI)

- Access to Global Online Research in Agriculture (AGORA)

- Centre for Agriculture and Biosciences International (CABI)

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- SWB online catalog

- Publons

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Research Article - (2019) Volume 10, Issue 12

Optimization of Feed Moisture and Sugar Content in the Development of Instant Rice Porridge Mix Using Extrusion Technology

Khan MA*, Mahesh C, Srihari SP, Sharma GK and Semwal ADReceived: 11-Nov-2019 Published: 13-Dec-2019

Abstract

Instant rice porridge mix was developed using twin-screw extruder based on rice extrudates, sugar, milk powder, flavoring agents and dry nuts. Response surface methodology was used to optimize the ingredients levels. Stability of instant rice porridge mix packed in polypropylene (PP) and Metallised polyester (MP) pouches was evaluated by monitoring changes in physico-chemical and sensory attributes periodically. Effect of feed moisture and sugar content on the Increase in feed moisture and sugar content on the functional and sensory attributes of the rice porridge mix was studied. An increase in the moisture content and sugar content resulted in the decrease in expansion ratio with the increase in bulk density thereby affecting the sensory quality of rice porridge mix. Instant rice porridge mix remained stable and acceptable for 9 and 12 months in PP and MP packaging materials under ambient temperature conditions. Irrespective of packaging materials and the storage period, porridge mixes get reconstituted in hot water within 1 minute.

Keywords

Rice; RSM; Packaging material; Shelf-life; Overall acceptability

Introduction

Today due to urbanization and lack of time in preparing fresh foods, instant foods play an important role in everyone’s day to day life. Instant food mixes mean not only a simple, fast and convenience food but also it is easy to prepare, hygienic, free from microbial contamination and convenient to eat. As modern food habits are completely different from olden days, the existence of these instant foods fulfills the needs of modern human beings. The use of instant mixes in the development of foods has become a way of life and certainly, they will be an integral part of food habits in the future. Instant mixes acceptability is mainly due to the convenience, value addition, attractive appearance and textural properties associated with them [1,2].

There is a demand for nutritious convenience foods with longer shelf-life due to improving economic status. This has pushed the food scientists/ technologists to evolve new technologies to meet new challenges based on available raw materials and requirements of the society. The concept of instant food in the developed world has been prevalent for long, but recently its inception in the Indian market has taken place. Due to changing food habits and lifestyles of people, the ready-to-eat foods, instant foods and convenience foods gaining popularity in all segments of the population. Extrusion technology is well-known in the plastics industry, has now become a widely used technology in the agri-food processing industry, where it is referred to as extrusion-cooking. With the help of sheer energy, exerted by the rotating screw and additional heating of the barrel, the food material is heated to its melting point or plasticizing point [3]. Rice porridge is one of the most popular desserts relished by all segments of the population irrespective of age in India. It is prepared by the partial dehydration of whole milk usually with sugar and rice [4]. The preparation of porridge is a time-consuming process as it requires long time cooking of rice and milk which are the basic ingredients in the preparation of rice porridge. Earlier [5] developed instant rice porridge from jasmine rice mixed with other ingredients and reported that processing of rice porridge has influenced the properties of rice starch and formation of complexes which can affect starch resistance to enzyme digestion. High protein porridge was developed using twin-screw extruder with cowpea and sorghum as the main ingredients [6]. They reported that with the increase in cowpea concentration there was a significant change in attributes like water absorption index, water solubility index, protein content, colour etc. A study was carried out by Nicole et al. [7] in the development of composite porridge using maizesorghum and wheat blends by extrusion technology and reported that extrusion technology resulted in a redistribution of insoluble to soluble fibre ratio which in turn affect the resistant starch formation with an increase in in vitro protein digestibility. Murugkar et al. [8] optimized the process for the development of nutritionally rich instant porridge with sprouted legumes, malted millets and papaya and reported that flour concentration, cooking time and sugar concentration significantly affected the organoleptic quality, texture and rheological attributes of porridge mix. Gandhi et al. [9] developed mango flavoured instant porridge mix using extrusion technology and found that mango pulp (30%), feed moisture (15%) and sugar content (15%) were optimum to get sensorily highly acceptable instant porridge mix. During combat operations or when deployed inaccessible terrains Armed Forces have to carry their own ration for which the rations have to be light in weight with long shelf life providing high calories with nutrition. Keeping in this mind, earlier many dehydrated convenience foods using cereals and pulses along with vegetables were developed [10-12]. Vijaya Rao et al. [13] developed wheat porridge using freeze-dried technology and found that the product gets reconstituted in 5 minutes. But due to the high processing cost involved in the production, the product could not get attention from Armed Forces. Later Khan et al. [14] developed instant wheat porridge (Dalia) mix using freeze-thaw dehydration technology and reported that irrespective of packaging materials and the storage period, instant porridge mix gets reconstituted within 5 minutes in boiling water. Jha et al. [15] studied physico-chemical properties of instant kheer prepared using the traditional method and concluded that products prepared using traditional methods lack stability and hence cannot be marketed commercially. The current studies were undertaken to develop instant rice porridge mix having a shelf-life of more than 12 months, which gets reconstituted within 2-3 minutes in hot water using extrusion technology and the levels of ingredients used were optimised by response surface methodology.

Materials and Methods

Rice, skim milk powder, sugar, cashew nuts, almonds, hydrogenated vegetable fat, and cardamom were purchased from the local market.

Chemicals and reagents required for analysis were procured from local vendors and were of AR grade from M/s SD Fine Chemicals and M/s Merck.

Processing of raw materials

Preparation of sugar and cardamom powder: Sugar was grounded in a laboratory model using a laboratory model ultracentrifugal mill (Retsch R1, Haan, Germany) whereas cardamom was de-podded and finally powdered in ultracentrifuge mill.

Preparation of fried cashew-nuts and almonds: Cashew-nuts and almonds were cut into small pieces using dry fruits cutter and fried in hydrogenated fat at (170-180)°C in an aluminum frying pan till they turn into light brown in colour and are used in the development of instant rice porridge mix.

Conditioning of rice flour

Rice flour was mixed with sugar powder (0%-8%) and conditioned with different moisture contents (12%, 15% and 18%). After correcting deviations in moisture from mass balance, samples were packed in polypropylene bags and stored at (5-6)°C for 24 hr, to ensure a uniform level of hydration. After 24 hrs, the conditioned rice flour was allowed to reach normal room temperature and mixed thoroughly before sieving using 500-micron sieve and used for the further extrusion process.

Extrusion processing

A Brabender laboratory twin-screw co-rotating extruder (M/s. Brabender Inc, Germany) with 9 heating zones was used for the experiment purpose. The screws for the extruder were 25 mm in diameter and 800 mm in length. The extrusion temperature was a measure of the temperature of the barrel surface in contact with food. Various temperature zones studied were set at (50, 60, 75, 90, 110, 130, 150,170 and 190)°C for 9 with a fixed screw speed of 180 rpm and feed rate of 80 rpm. A face cutter attached at the product end was used to cut the extruded products once it left the extrusion die (3 mm). The extrudates were allowed to cool and evaluated for expansion ratio, bulk density, water absorption index and overall acceptability scores.

Experimental design for the preparation of instant rice porridge mix

A statistical software Design expert® version 8.0 from Statease Inc; USA, was used to construct as well as to analyze the design. The 5-level central composite rotatable design using 3 independent variables was obtained with 20 experimental combinations. Since parameters like consistency, taste, and overall acceptability influence the final product quality, they were chosen as responses while the quantity of milk powder, sugar and water for reconstitution were taken as variables. The variables were standardized to simplify computation and deduce the relative effect of variables on the responses. The independent variables with their coded and actual values with a range of levels are given in Table 1 [3]. A second-order polynomial equation was fitted to the data to obtain regression equations for consistency, taste and overall acceptability of product preparation/reconstitution.

| Parameters | Moisture Content (%) | Level of sugar content (%) | ||||

|---|---|---|---|---|---|---|

| 0 | 2 | 4 | 6 | 8 | ||

| Expansion ratio (ER) | 12 | 4.12 ± 0.12 | 3.96 ± 0.12 | 3.84 ± 0.12 | 3.72 ± 0.12 | 3.52 ± 0.12 |

| 15 | 4.01 ± 0.11 | 3.86 ± 0.11 | 3.72 ± 0.11 | 3.61 ± 0.11 | 3.38 ± 0.11 | |

| 18 | 3.84 ± 0.10 | 3.68 ± 0.10 | 3.54 ± 0.10 | 3.41 ± 0.10 | 3.26 ± 0.10 | |

| Bulk density (g/cc) (BD) | 12 | 0.14 ± 0.01 | 0.16 ± 0.01 | 0.19 ± 0.01 | 0.24 ± 0.01 | 0.31 ± 0.01 |

| 15 | 0.17 ± 0.02 | 0.19 ± 0.02 | 0.22 ± 0.01 | 0.26 ± 0.02 | 0.35 ± 0.02 | |

| 18 | 0.23 ± 0.03 | 0.25 ± 0.03 | 0.28 ± 0.03 | 0.31 ± 0.03 | 0.39 ± 0.03 | |

| Water absorption index (WAI) | 12 | 4.95 ± 0.13 | 4.91 ± 0.10 | 4.75 ± 0.11 | 4.12 ± 0.11 | 3.75 ± 0.12 |

| 15 | 5.59 ± 0.11 | 5.13 ± 0.11 | 5.01 ± 0.10 | 4.81 ± 0.12 | 4.11 ± 0.10 | |

| 18 | 6.45 ± 0.10 | 6.0 ± 0.12 | 5.7 ± 0.11 | 5.01 ± 0.11 | 4.76 ± 0.12 | |

| Overall acceptability (OAA) score of porridge | 12 | 7.0 ± 0.15 | 7.2 ± 0.14 | 7.5 ± 0.13 | 8.0 ± 0.16 | 7.4 ± 0.15 |

| 15 | 7.5 ± 0.12 | 7.7 ± 0.13 | 7.9 ± 0.14 | 8.5 ± 0.14 | 7.9 ± 0.12 | |

| 18 | 7.3 ± 0.14 | 7.4 ± 0.12 | 7.6 ± 0.13 | 8.0 ± 0.13 | 7.5 ± 0.11 | |

Table 1: Effect of feed moisture and level of sugar content on functional and sensory quality of rice extrudates and rice porridge mix.

Sugar powder and milk powder were weighed separately according to the formulations obtained in Table 1. Keeping the weight of fried cashew nuts, fried almonds, hydrogenated fat and cardamom powder constant for all formulations based on 100 g coarse extrudates. Coarse extrudates were roasted in an aluminum frying pan with hydrogenated fat till the temperature reaches to 90. To this roasted cashew nuts and almonds were added with continuous mixing. The mixture was allowed to cool until the temperature reaches 70. To this known quantity of milk powder was added followed by sugar powder and cardamom powder. The mixture was again heated with continuous mixing till the temperature reaches 90. The final product was allowed to cool until the temperature attains room temperature and finally packed in airtight containers for further storage studies.

Reconstitution of instant rice porridge mix

All the combinations obtained were reconstituted in hot water (product: water) (1:1.2) within 1-2 minutes with continuous stirring. The reconstituted rice porridge was subjected for sensory evaluation by a panel of 15 semi trained judges on a 9 point hedonic scale [16].

Physico-chemical analysis

Expansion ratio was determined by the method of Fan et al. [17] by taking the diameter of 10 extrudates with the help of Vernier calipers, averaged and divided by the diameter of the die nozzle of the extruder. The bulk density of the extrudates was calculated as mass per unit volume. The water absorption index of the product was determined by the method prescribed by Anderson et al. [18]. Extrudates were subjected for sensory evaluation by a panel of semi-trained judges to evaluate overall acceptability measured w.r.t. colour, crispness, taste, and hardness on a 9 point hedonic scale (Wadikar 16). The proximate analysis of the extrudate was carried out by standard procedures [19,20]. Carbohydrate content was estimated by difference and the calorific value of the extrudates was determined by computation. Changes in free fatty acid (FFA) content and peroxide value (PV) of the processed samples were analysed during storage according to the standard procedures of AOCS [21]. Changes in the thiobarbituric acid (TBA) value during storage were estimated by the steam distillation method as described by Tarladgis et al. [22]. The Hydroxyl Methyl Furfural (HMF) content was measured according to Bunker et al. [23], while the fatty acid profile of fat extracted from instant rice porridge was determined using using standard AOCS [21] methods with the help of Gas-Liquid Chromatograph (Chemito, HR 1000, Chennai, India) on a 10% diethylene glycol-succinate column (DEGS, 8 × 1/8″) with nitrogen as carrier gas and flame ionization detector. During analysis, the column temperature was maintained at 190°C while the injector and detector temperatures were kept at 230°C.

Results and Discussion

Effect of feed moisture and sugar content on the expansion ratio, bulk density, water absorption index and sensory quality of extrudates were evaluated as these attributes play a very important role in determining the final quality of extrudates that are used in the preparation of instant porridge mixes. The experiments were aimed to achieve extrudates with maximum expansion ratio, water absorption index and minimum bulk density scoring higher sensory scores and the results are shown in Table 1 and was observed clearly that with the increase in feed moisture and sugar content, there was a decrease in expansion ratio which is also referred as gelatinization index from 4.12 to 3.84 and 3.52 respectively.

Bulk density is considered as a link with the expansion ratio [24] as both describe the puffing effect of extrudates, found to decrease with the increase in feed moisture and sugar contents and found to be in the range of 0.14 to 0.28 and 0.14 to 0.31 respectively. Overall acceptability which was evaluated as a sum of attributes viz. colour, crispiness, taste and hardness of extrudates by subjecting extrudates for sensory evaluation Table 1. Beyond 15% feed moisture and 6% sugar content there was a significant decrease in sensory scores. Based on these criteria, feed moisture (15%) and sugar content (6%) were found to be optimum to get desired extrudates for the preparation of instant rice porridge mix. A central composite rotatable design with 20 experimental combinations with 3 independent variables and 3 responses was used for the optimisation of instant rice porridge mix based on rice extrudates.

Numerical optimisation procedure of the design expert software version was used for the optimisation. In order to minimize the effect of unexpected variability in the observed responses, experimental runs were randomised. Each model was evaluated for the main, linear, quadratic and interactive effects. F-ratio and co-efficient of determination (R2) were used to determine the adequacy of the models. As the co-efficient of determination (R2) was more than 80% and lack of fit is insignificant the models were considered as best suited describing the effect of independent variables on the responses [25]. The effect of variables on the responses could be predicted using the following multiple regression equations.

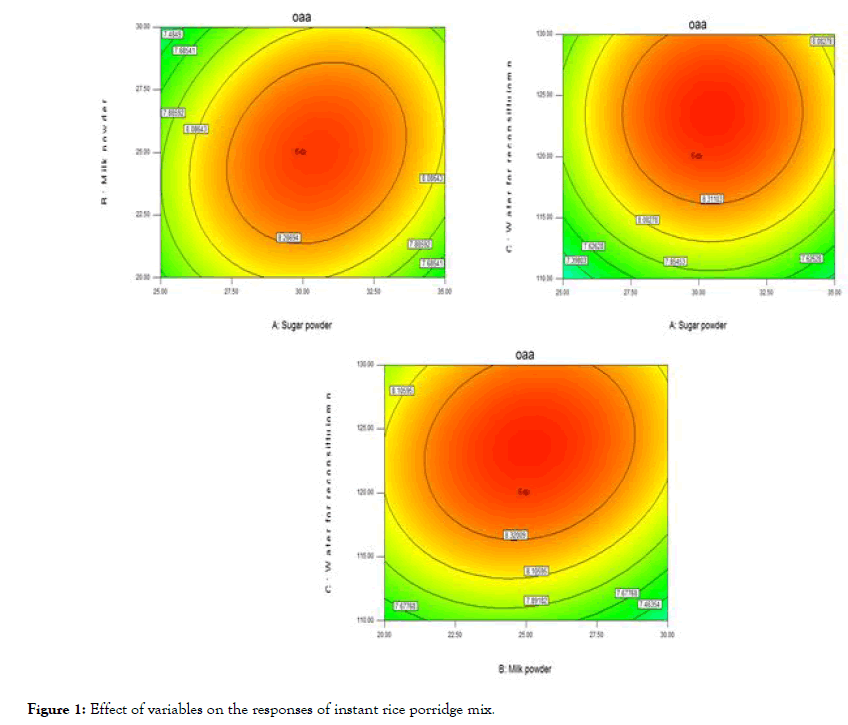

The above equations revealed that at linear and interactive levels, sugar and water for reconstitution had a significant positive effect on the consistency, taste and overall acceptability while milk powder had a negative effect on all responses. At the interactive level all the variables had a significant positive effect on all the responses studied. Similarly, at quadratic levels, variables showed a significant negative effect on the responses. The effect of sugar, milk powder and water for reconstitution on the overall acceptability of instant rice porridge is shown in Figure 1.

Figure 1: Effect of variables on the responses of instant rice porridge mix.

It is clear from the fig that with the increase in the levels of sugar, milk powder and water for reconstitution, overall acceptability goes on increasing upto a certain level and then declined. The same trend was observed in the case of the consistency and taste of the instant rice porridge mix.

The levels of ingredients required for the development of the instant rice porridge mix were based on the numerical optimisation of the variables and criterion used along with predicted and actual values of the responses Table 2. The optimised recipe for the preparation of instant rice porridge was sugar powder (30.63 g), milk powder (24.92 g), cardamom powder (0.5 g), cashew nuts (5.0 g), almond (5.0 g) and hydrogenated fat (5.5 g) based on 100 g rice extrudates. The predictions for water for reconstitution, taste and overall acceptability were 123.60, 8.52 and 8.53 respectively with the desirability of 0.0.96 Figure 1. Instant rice porridge was prepared based on the solution obtained and responses were measured and found that measured responses were very much close to the predicted ones reconfirming the adequacy of the models. Therefore, the optimised set of conditions was recommended for the preparation of the instant rice porridge mix.

| Exp. No. | Variable levels (coded) | Responses | ||||

|---|---|---|---|---|---|---|

| X1 | X2 | X3 | Consistency | Taste | OAA | |

| 1 | -1 | -1 | -1 | 7 | 7.1 | 7.1 |

| 2 | 1 | -1 | -1 | 7.1 | 7 | 6.9 |

| 3 | -1 | 1 | -1 | 6.5 | 6.5 | 6.5 |

| 4 | 1 | 1 | -1 | 6.9 | 7 | 7 |

| 5 | -1 | -1 | 1 | 7.4 | 7.4 | 7.4 |

| 6 | 1 | -1 | 1 | 7.5 | 7.3 | 7.3 |

| 7 | -1 | 1 | 1 | 7.3 | 7.4 | 7.3 |

| 8 | 1 | 1 | 1 | 7.7 | 7.7 | 7.8 |

| 9 | -1.7 | 0 | 0 | 6.9 | 6.9 | 6.8 |

| 10 | 1.68 | 0 | 0 | 7.2 | 7.1 | 7.2 |

| 11 | 0 | -1.7 | 0 | 7.5 | 7.4 | 7.4 |

| 12 | 0 | 1.68 | 0 | 7.2 | 7.3 | 7.3 |

| 13 | 0 | 0 | -1.7 | 6.8 | 6.9 | 6.8 |

| 14 | 0 | 0 | 1.68 | 7.8 | 7.8 | 7.8 |

| 15 | 0 | 0 | 0 | 8.4 | 8.5 | 8.4 |

| 16 | 0 | 0 | 0 | 8.6 | 8.5 | 8.6 |

| 17 | 0 | 0 | 0 | 8.5 | 8.6 | 8.5 |

| 18 | 0 | 0 | 0 | 8.4 | 8.4 | 8.4 |

| 19 | 0 | 0 | 0 | 8.5 | 8.5 | 8.5 |

| 20 | 0 | 0 | 0 | 8.4 | 8.6 | 8.5 |

Table 2: Experimental design matrix for instant rice porridge mix at various levels.

Storage study of optimised sample

Optimised instant rice porridge mix had moisture 1.92%; protein 7.3%; fat 10.12%; Table Sugar 47.8%; ash 1.59% providing energy of 437 K Cal/100 g. Instant rice porridge mix prepared was packed in polypropylene (PP) and metallised polyester packaging materials and stored at ambient temperature conditions. Instant rice porridge mix was found to get reconstituted within 2 minutes in hot water irrespective of packaging materials and storage period. The role of packaging materials on the storage stability of instant rice porridge mix under ambient temperature conditions was investigated on the changes in lipid peroxidation as measured by Peroxide Value (PV), Thiobarbituric Acid Value (TBA) and Free Fatty Acid Value (FFA). It is clear from the Table 3 that there was a significant increase in PV, TBA and FFA contents in PP packed samples as compared to MP packed samples. The peroxide value of instant rice porridge mix packed in PP increased from 5.28 to 24.52 compared to 5.28 to 20.18 for those packed in MP packed samples after the end of 12 months of storage. The thiobarbituric acid value is a measure of the formation of secondary oxidation products and changes in thiobarbituric acid value was found to have a direct impact on the sensory quality of instant rice porridge. During storage, there was a significant increase in TBA values irrespective of packaging materials. Initially, an instant rice porridge mix had TBA value of 0.065 mg of MA/Kg sample. After 12 months of storage, TBA values were found to be 0.096 and 0.089 mg of MA/Kg sample in PP and MP packed samples respectively. Earlier studies have shown the TBA value to increase with the storage period [26,27]. Free fatty acid values were found to increase from 0.81 to 2.82 and 2.29 in PP and MP packed samples respectively after 12 months of storage. Earlier also, Clayton and Morrison [28] and Khan et al. [14] reported an increase in FFA content in the samples studied and attributed the increase in FFA content due to the decomposition of hydroperoxides and not due to the hydrolysis of lipids during storage as lipase activity was destroyed during extrusion and also during preparation of instant rice porridge. During storage, instant rice porridge mix packed in PP and MP packaging materials were evaluated for changes in Hydroxymethyl furfural content which is formed upon heat treatment of milk and milk products by the Maillard reaction as well as by isomerisation and subsequent degradation of sugars [29,30]. It was found that after 12 months of storage, there was an increase in HMF content from 4.12 to 14.12 and 12.16 mg/Kg of the sample in PP and MP packed samples respectively. Earlier also, Mrithyunjaya and Bhanumurthi [31] observed an increase in HMF content in dried whole milk during storage. Jha and Patel [15] reported an increase in HMF content of instant kheer mix powder during storage and reported that the increase in HMF content is temperature-dependent. Changes in overall acceptability scores of the reconstituted instant rice porridge samples stored at ambient temperature conditions packed in PP and MP packaging materials have been shown in Table 4. During storage, a score of 7.0 was taken as the limit for acceptability on a 9 point hedonic scale. Based on these criteria, instant rice kheer mix packed in PP remained acceptable for 10 months at ambient temperature conditions while MP packed samples remained stable and acceptable for 12 months. Fatty acid profile of instant rice porridge mix has been shown in Table 5 and it revealed that except for a slight decrease in the unsaturated fatty acid with the corresponding increase in saturated fatty acids, the changes in fatty acids were not appreciable significant. Since skim milk powder was used in the preparation of instant rice porridge, calcium was found to be present in larger concentrations. Minerals like iron, zinc and copper were found to be in lower concentrations. Practically no significant changes in any of the minerals were observed during the storage of instant rice porridge mix.

During storage, there were no changes in the microbiological status was observed. Initially, the total plate count was ranged between 100 and 200 colonies/g and after 12 months of storage, TPC was found to increases in the range between (300-500) colonies/g. Yeast and mold counts were found to be in the acceptable limits in both the fresh and stored samples. All the samples were free from Salmonella, S. auerus and E. coli.

Interrelationship between physico-chemical and sensory changes in instant rice porridge mix

| Response variables | Optimum product | |

|---|---|---|

| Predicted values | Experimental values* | |

| Consistency | 8.49 | 8.50 ± 0.1 |

| Taste | 8.57 | 8.56 ± 0.2 |

| Overall acceptability (OAA) | 8.59 | 8.54 ± 0.2 |

*n=15

Table 3: Predicted and experimental values of the response variable at optimum formulation of instant rice porridge mix.

| Storage Period (months) | PV | FFA | TBA | HMF | OAA | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| PP | MP | PP | MP | PP | MP | PP | MP | PP | MP | |

| 0 | 5.28a | 5.28a | 0.81a | 0.81a | 0.065a | 0.065a | 4.12a | 4.12a | 8.5a | 8.5a |

| 3 | 8.98b | 8.02bx | 1.26b | 1.02bx | 0.073b | 0.068bx | 7.62b | 6.01x | 7.4b | 8.0bx |

| 6 | 13.36c | 11.46cx | 1.82c | 1.21cx | 0.081c | 0.076cx | 8.85c | 7.12cx | 7.2c | 7.7cx |

| 9 | 20.65d | 13.61dx | 2.32d | 1.84dx | 0.099d | 0.081dx | 10.32d | 8.42dx | 7.0d | 7.5dx |

| 12 | 26.52e | 18.18ex | 2.82e | 2.29ex | 0.096e | 0.089ex | 15.12e | 11.01ex | 6.8e | 7.3ex |

*mean ±SD (n=3); **mean ±SD (n=15); a-e values within the same column followed by different superscripts differ significantly (p ≤ 0.05); x: significantly different from their corresponding PP packed samples (p ≤ 0.05)

Table 4: Changes* in moisture content (%), peroxide value (meq O2/kg fat), free fatty acid value (% oleic acid), thiobarbituric acid value (mg MA/kg sample), Hydroxyl Methyl Furfural (mg/Kg) and overall acceptability score (OAA) of instant rice porridge mix packed in PP and MP pouches and stored under ambient temperature (15-34) conditions.

| Fatty acids | Initial | Relative % (6 M) | Relative % (12 M) | ||

|---|---|---|---|---|---|

| PP | MP | PP | MP | ||

| Capric | 0.23 | 0.25 | 0.25 | 0.28 | 0.27 |

| Lauric | 0.46 | 0.48 | 0.46 | 0.51 | 0.48 |

| Myristic | 1.99 | 2.05 | 2.02 | 2.2 | 2.04 |

| Palmitic | 27.13 | 30.32 | 28.89 | 32.81 | 30.95 |

| Stearic | 6.25 | 7.02 | 6.91 | 7.84 | 7.21 |

| Oleic | 50.76 | 48.12 | 48.92 | 45.79 | 47.86 |

| Linoleic | 13.12 | 11.56 | 12.24 | 10.23 | 10.82 |

Table 5: Changes in Fatty acid profile in rice porridge mix during storage.

The relationship between the physico-chemical and overall acceptability scores of instant rice porridge was done by regression analysis as it attempts to model the relationship between two variables by fitting a linear equation to observed data and the same has been shown in Table 6. Linear regression analysis was carried out between dependent and independent variables. The progression of physico-chemical changes in the product during storage influence the overall acceptability of the product. From the Table 6 it is clear that a negative correlation between overall acceptability score of instant rice porridge and PV found (-0.99) with a correlation determination of more than 90%. A similar trend was observed in the case of instant rice porridge packed in MP packaging material. The correlation between overall acceptability score and other chemical parameters like HMF, FFA and TBA were also found to be negatively correlated with a correlation of determination value of more than 90% indicating that a linear regression model is fitted for the study carried out.

| Dependent (Y) | Independent (X) | Packaging materials | Slope (m) | Intercept (In C) | Coefficient of correlation | Coefficient of determination (R2) |

|---|---|---|---|---|---|---|

| Overall acceptability score | PV | PP | -0.191 | 9.59 | -0.98 | 0.96 |

| MP | -0.22 | 9.58 | -0.97 | 0.944 | ||

| FFA | PP | -0.09 | 9.14 | -0.99 | 0.991 | |

| MP | -0.11 | 9.26 | -0.99 | 0.988 | ||

| TBA | PP | -0.88 | 9.43 | -0.99 | 0.99 | |

| MP | -1.13 | 9.46 | -0.97 | 0.95 | ||

| HMF | PP | -55.57 | 12.27 | -0.99 | 0.98 | |

| MP | -73.19 | 13.4 | -0.99 | 0.99 |

Table 6: Linear regression analysis (x → y) between dependent and independent variables.

Conclusion

It can be concluded that instant rice porridge has been developed wherein the reconstitution can be achieved in just two minutes. The extrusion process plays a key role in instantiating the product. Instant rice porridge mix remained stable and acceptable for 9 and 12 months in PP and MP packaging materials under ambient temperature conditions. Irrespective of packaging materials and the storage period, kheer mixes gets reconstituted in hot water within 2-3 minute.

REFERENCES

- Poonam S, Ahmed SB, Tundup T. Development of instant mix based on local foods of Ladakh. J Dairy Foods Home Sci. 2009;28:130-131.

- Anton AA, Luciano FB. Instrumental texture evaluation of extruded snack foods: a review evaluación instrumental de textura en alimentos extruidos: una revision, CYTA. J Food Sci. 2007;5:245-251.

- Moscicki L, van Zuilichem DJ. Extrusion-cooking and related technique. Extrusion-cooking techniques: applications, theory and sustainability. Wiley, Weinheim. 2011:1-24.

- Str Kumar DE, Thompkinson DK, Gahlot DP, Mathur ON. Studies on method of preparation and preservation of kheer. Indian J Dairy Sci. 1976;29:316-318.

- Srikaeo K, Sopade PA. Functional properties and starch digestibility of instant Jasmine rice porridges. Carbohydrate Polymers. 2010;82:952-957.

- Pelembe LA, Erasmus C, Taylor JR. Development of a protein-rich composite sorghum–cowpea instant porridge by extrusion cooking process. Lwt-Food Sci Technol. 2002;35:120-127.

- Nicole M, Fei HY, Claver IP. Characterization of ready-to-eat composite porridge flours made by soy-maize-sorghum-wheat extrusion cooking process. Pakistan J Nutr. 2010;9:171-178.

- Murugkar DA, Gulati P, Kotwaliwale N, Gupta C, Chakraborty SK, Aiman. Optimization of nutritionally rich instant porridge with sprouted legumes, malted millets and papaya and its comparison with conventional porridge in terms of textural, rheological and particle size properties. IJFANS. 2015;4:49-58.

- Gandhi N, Singh B, Priya K, Kaur A. Development of mango flavoured instant porridge using extrusion technology. J Food Technol. 2013;11:44-51.

- Yadav DN, Sharma GK. Optimization of soy-fortified instant upma mix ingredients using response surface methodology. J Food Sci Technol. 2008;45:56-60.

- Uma D, Sharma GK, Semwal AD. Development of instant peas curry mix and its quality evaluation. J Food Sci Technol. 2008;45:152-156.

- Patki PE, Arya SS. Studies on storage stabiligy of instant khichdi mix. Indian Fd Packer. 1997;51:77-80.

- Vijay Rio D, Radhakrishna K, Jayathilakan K, Vasundhara TS, Bhagirathi B, Gopala Rao KR, et al. Manufacture of freeze-dried breakfast and dessert foods. J Fd Sci Technol. 1994;31:40-43.

- Khan MA, Semwal AD, Sharma GK, Bawa AS. Studies on the optimization and stability of instant wheat porridge (Dalia) mix. J Fd Sci Technol. 2014;51:1154-1160.

- Jha A, Patel AA. Kinetics of HMF formation during storage of instant kheer mix powder and development of a shelf life prediction model. J Food Process Pres. 2014;38:125-135.

- Wadikar DD, Kangane SS, Parate V, Patki PE. Optimization of multi-millet ready-to-eat extruded snack with digestibility and nutritional perspective. Ind J Nutr. 2014;1:104.

- Fan J, Mitchell JR, Blanshard JM. The effect of sugars on the extrusion of maize grits: I. The role of the glass transition in determining product density and shape. J Food Sci Technol. 1996;31:55-65.

- Anderson RA. Gelatinization of corn grits by roll-and extrusion-cooking. J Cereal Sci. 1969;14:4-12.

- Ogundana SK, Fagade OE. Nutritive value of some Nigerian edible mushrooms. Food Chem. 1982;8:263-268.

- Özyurt G, Polat A, Loker GB. Vitamin and mineral content of pike perch (Sander lucioperca), common carp (Cyprinus carpio), and European catfish (Silurus glanis). Turk J Vet Anim Sci. 2009;33:351-356.

- González JM, Quintero F, Márquez RL, Rosales SD, Quercia G. 11 Formulation effects on the lubricity of O/W emulsions used as oil well working fluids. Surfactants in Tribology. 2016;2:241.

- Tarladgis BG, Watts BM, Younathan MT, Dugan Jr L. A distillation method for the quantitative determination of malonaldehyde in rancid foods. J Am Oil Chem Soc. 1960;37:44-48.

- Bunkar DS, Jha A, Mahajan A, Unnikrishnan VS. Kinetics of changes in shelf life parameters during storage of pearl millet based kheer mix and development of a shelf life prediction model. J Fd Sci Technol. 2014;51:3740-3748.

- Asare EK, Sefa-Dedeh S, Sakyi-Dawson E, Afoakwa EO. Application of response surface methodology for studying the product characteristics of extruded rice-cowpea-groundnut blends. J Food Sci Technol. 2004;55:431-439.

- Henika RG. Use of response surface methodology in sensory evaluation. Food Technol. 1982;36:96-101.

- Toohy JJ, O’leary D, Kelly P M. Packaging and storage of whole milk powder. Irish J Fd Sci Technol. 1981;5:82-86.

- Ipsen R, Hansen PS. Factors affecting the storage stability of whole milk powder. Beretning. Statens Mejeriforsoeg (Denmark). 1988.

- Clayton TA, Morrison WR. Changes in flour lipids during the storage of wheat flour. J Sci Food Agr. 1972;23:721-736.

- Morales FJ, Jiménez-Pérez S. Study of hydroxymethylfurfural formation from acid degradation of the Amadori product in milk-resembling systems. J Agr Food Chem. 1998;46:3885-3890.

- Baldwin AJ, Auckland JD. Effect of preheat treatment and storage on the properties of whole milk powder: changes in physical and chemical properties. Neth Milk Dairy J. 1991;45:169-181.

- Mrithyunjaya N, Bhanumurthi JL. Shelf life of laminate and tin packed whole milk powder. Ind J Dairy Sci. 1987; 40:78-81.

Citation: Khan MA, Mahesh C, Srihari SP, Sharma GK, Semwal AD (2019) Optimization of Feed Moisture and Sugar Content in the Development of Instant Rice Porridge Mix Using Extrusion Technology. J Food Process Technol 10:816. doi: 10.35248/2157-7110.19.10.816

Copyright: © 2019 Khan MA, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.