Indexed In

- Genamics JournalSeek

- Academic Keys

- JournalTOCs

- China National Knowledge Infrastructure (CNKI)

- Access to Global Online Research in Agriculture (AGORA)

- Centre for Agriculture and Biosciences International (CABI)

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- SWB online catalog

- Publons

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Research - (2020) Volume 11, Issue 4

Maintenance of Fruit Bioactive Compounds in Jelly Candy Manufacturing by Alginate/Pectin Cold-Set Gelation

Matheus Henrique Mariz de Avelar, Letícia Nagura de Lima and Priscilla Efraim*Received: 14-Apr-2020 Published: 30-Apr-2020, DOI: 10.35248/2157-7110.20.11.826

Abstract

Enhancing the conservation of nutrients and bioactive compounds during fruit processing is desirable. Therefore, this study evaluated the potential of the alginate/pectin cold-set gelation technique in the manufacturing of jelly candies formulated with fruit pulps (blackberry, guava, mango, strawberry, and orange). A compared study between strawberry cold-set jellies (SAP) and a standard strawberry pectin jelly candy (SP) was carried out. The candies were evaluated by scanning electron microscopy and sensory acceptance and were characterized by the physicochemical characteristics (instrumental texture and color, moisture content, pH, and water activity) and bioactive compounds content (ascorbic acid, total phenolic, and total anthocyanin compounds). The physicochemical characteristics of the different fruits did not influence the cold-set gelation process, which indicates the applicability of the process in a wide variety of fruits jelly candy formulations. SAP showed lower moisture content and water activity value than SP. Microscopic images showed a dense and homogeneous network with a large number of pores in cold-set jellies, differing from the sparse and micellar network of pectin candies. The bioactive compounds contents of SPA (734.08 mg ascorbic acid/100 g and 254.4 mg gallic acid/ 100 g) were significantly higher (p<0.05) than the compounds of jellies obtained by the conventional process (597.4 mg ascorbic acid/100 g and 76.7 mg gallic acid/100 g). There was no significant difference (p<0.05) between the candies with any of the evaluated sensory attributes, indicating cold-set gelation as a potential technology for fruit jelly candy manufacturing with a high content of natural bioactive compounds of the fruit.

Keywords

Candy; Cold-setting gels; Confectionery; Functional foods; Hydrocolloids; Phytonutrients

Introduction

The industrial manufacturing of candies elaborated with fruit and vegetable ingredients has been set as a great alternative for obtaining products with claims of healthiness and naturalness in the confectionery market. Candies produced from the fruit can differ from conventional products by their sensory quality, absence of synthetic dyes and aromas, and partial reduction of the sugar content [1-4].

In recent years the candy market has been stimulated by the growing consumer demand for healthier products and sustainability claims on their labels. In this context, cleaner food production, with reduced energy consumption and waste emissions for the environment has gained prominence [5,6].

Jellies and gummies are a significant segment of the candy market. The main ingredients of these products are sucrose and other sugar syrups added by hydrocolloids. Their technological characteristics vary according to the gelling agent used in the processing and the final moisture content [7-9].

Among the jelly candy manufacturing steps, the syrup cooking represents the highest energy demand of the industrial line [10]. In this context, the use of cold-set gelation techniques in the candy gel structuring showed the potential to reduce the energy consumption during the candy manufacturing process by the dispense of the syrup cooking step [11].

Sodium alginate and high methoxylation pectin are hydrocolloids with a specific capacity of cold-set gelation. When combined and acidified to pH 3.4-3.8, provide the formation of cohesive networks of gel at room temperature by biomolecular mechanisms not elucidated [12,13].

The alginate and pectin cold-set gelation has also a high technological potential to maintain natural compounds and sensory characteristics of fruit pulps in candy formulations. The low processing temperatures can enable the conservation of the thermosensitive nutrients and functional components of the fruits. In this context, this study aimed to evaluate the performance of sodium alginate and high methoxylation pectin cold-set gelation in the production of jelly candies with fruit pulp and compare the obtained products with jellies produced by the conventional process.

Materials and Methods

Material

The ingredients used in the jelly candy manufacturing were: sucrose (União, São Paulo, Brazil), glucose syrup (Excell 1040, Ingredion, Mogi Guaçu, Brazil), frozen fruit pasteurized (blackberry, guava, orange, mango, and strawberry) (Brasfrut, Feira de Santana, Brazil), strawberry juice concentrate (30°Brix, Loop, Piracicaba, Brazil), high methoxylation pectin (HM 121 Slow, Degree of esterification 58%, CPKelco, Limeira, Brazil), sodium alginate (Algin I-3G-150, viscosity (300-400) mPa•s, Kimica, Providencia, Chile), Glucono- Delta-Lactone (GDL) (Art Alimentos, São Paulo, Brazil) and citric acid (ACS, Synth, Diadema, Brazil).

Development of jelly candies

Cold-set jelly candy manufacturing: The cold-set jelly candy manufacturing process was defined from modifications in the process of obtaining pure alginate/pectin gels [11,13], following the steps: (1) dissolution of sucrose, glucose syrup and fruit pulp in water, (2) dispersion of hydrocolloids (alginate and pectin) in the solution of sugars and fruit pulp, (3) dissolution of Glucono-Delta- Lactone (GDL) to acidify the system, (4) deposition of the final candy syrup in starch molds and (5) drying in an oven at 35°C/72 h. The ingredients were mixed with a digital mechanical bench agitator (Tecnal, model TE-039/1, Piracicaba, Brazil) at 380 rpm. The syrup was manually dosed with a funnel and the candies were dried in a forced-air circulation drying oven (Tecnal, model TE- 394/2, Piracicaba, Brazil).

Definition of the jelly candy formulation: To define the candy formulation, 9 treatments were tested, with the variation of:

(a) The percentage of polymer blend (alginate/pectin) required to promote gelation (20, 40 or 60) g/kg

(b) The GDL content required for acidification of the system (5, 10, 20, or 30) g/kg

The contents were determined after preliminary tests. The polymer blend was fixed at 1:1 (kg: kg) ratio of alginate: pectin, due to harder gels are obtained with these contents [12]. The sucrose: glucose syrup ratio was fixed at 2: 1 (kg: kg, d.b) according to the better results of Avelar and Efraim [11]. The pulp content of the formulations was fixed at 120 g/Kg (w.b) and the final soluble solids content of the candy syrups was fixed at 71°Brix.

The alginate and pectin cold-set gelation depends on the pH of the system, so the nine treatments were formulated with five different fruit pulps with different pH ranges: blackberry, guava, orange, strawberry, and mango. These fruits were selected due to their different sensory and nutritional characteristics (color, flavor, and bioactive compounds). The soluble solids content of each fruit pulp was considered on a dry basis as non-crystallizable sugar solids (glucose syrup) in the balance of sugar ratio (Table 1).

| Ingredients | Formulation | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| F1 | F2 | F3 | F4 | F5 | F6 | F7 | F8 | F9 | |

| Polymer blend (g/kg)* | 20 | 40 | 60 | ||||||

| GDL** (g/kg) | 5 | 10 | 5 | 10 | 20 | 5 | 10 | 20 | 30 |

F: formulation; *Polymer blend composed of alginate: pectin ratio of 1:1; kg: kg; **GDL: Glucono-Delta-Lactone

Table 1: Experimental proposal for the definition of fruit alginate/pectin jelly candy formulation.

Drying conditions: After the tests with the different fruits, a strawberry candy formulation (F5) was selected to conduct a drying study to determine the time and temperature parameters for the cold-set candy manufacturing process. Strawberry was selected due to its great acceptability and the widespread use of strawberry flavor in confectionery products.

A drying curve was performed during 72 h in a forced air circulation drying oven (Tecnal, model TE-394/2, Piracicaba, Brazil) at temperatures of (35, 45, and 55)°C, temperatures commonly used in the jelly candies production) [9,14,15]. Samples were collected each 12 h for physical and physicochemical characterization.

Definition of the fruit solids content in the formulation: A reformulation study was carried out to increase the final fruit solids content of the developed candy. Strawberry pulp and juice concentrate was used to test formulations with (0.1, 0.2, 0.3, and 0.4) kg/kg of strawberry on a wet basis. The formulation used as reference was the selected in the tests for jelly candy development. The final soluble solids content of the candy syrups was fixed at 71°Brix and the strawberry solids content was considered as noncrystallizing solids, replacing glucose syrup solids in the sugar ratio of each candy syrup.

Jelly candy processing

The strawberry alginate and pectin cold-set jelly candies (SAP) were compared with strawberry pectin jelly candies (SP). The SAP formulation was defined in the tests for increasing the fruit solid content. The SAP processing followed the steps previously described while the drying conditions used were those determined in drying study. The SP samples were prepared by the dissolution of sucrose, glucose syrup, citric acid and pectin in strawberry juice concentrate, heating at atmospheric pressure until 71°Brix, dosing in starch molds, drying in a forced air circulation drying oven at 35°C/72 h and demoulding [14].

Physical and physicochemical characterization

The fruit pulps and the strawberry juice concentrate were characterized in relation to pH according to AOAC Official Method 981.12 [16] using potentiometer (Digimed, model DM- 20, São Paulo, Brazil), titratable acidity according to AOAC Official Method 981.15 [16], the moisture content in a vacuum oven according to AOAC Official Method 920.151 [16], water activity using water activity analyzer (Aqualab, model 4TEV, Decagon Devices Inc., Pullman, USA) after equilibrium at 25°C, and instrumental color using a digital colorimeter (Hunter Lab UltraScan PRO, Washington DC, USA) in the CIELAB system (L*, a*, and b*), in triplicate.

The jelly candies produced in the tests for the definition of formulation were evaluated in relation to pH [16] and hardness parameter, using a Texture Analyzer (TA-XT2i model, Surrey, England), with a cylindrical aluminum probe P/35, pre-test, test and post-test speeds of (2.0, 2.0 and 10.0) mm/s, respectively, penetration distance 1 mm, in ten replicates [17].

The strawberry candies submitted to the drying study were characterized in relation to pH, moisture content, hardness, and water activity [16,17].

The SAP and SP samples were characterized in relation to pH and moisture content [16], water activity, instrumental color, and texture profile analysis “TPA” using a Texture Analyzer (TA-XT2i model, Surrey, England) [18]. The samples were compressed twice using a D/40 acrylic disk, which allowed the sample to be deformed without penetration, 2 consecutive cycles of 40% compression, crosshead moved at a constant speed of 1.0 mm/s with trigger point 0, 01 N., in ten replicates. The microstructure of the SAP and SP gels was evaluated by Scanning Electron Microscopy, using a tabletype microscope (model TM-3000, Hitachi High Technologies America, Inc., Japan) [19].

Bioactive compounds content

SAP and SP candies and the strawberry juice concentrate were evaluated in relation to the total phenolic compounds content using FolinCiocalteu reagent and absorbance measured at 765 nm using a spectrophotometer (model Cirrus 80, Femto, São Paulo, Brazil) [20].

The ascorbic acid content was determined by the titratable method [21], and the total anthocyanin content was evaluated by the pH differential spectroscopic method, using two buffer solutions: 0.025 M potassium chloride (pH 1.0) and a 0.4 M sodium acetate (pH 4.5). The extraction was performed with ethanol as a solvent: 0.1 M HCl (85: 15%, v:v) and the absorbance measured in a spectrophotometer (model Cirrus 80, Femto, São Paulo, Brazil), at 510 and 700 nm. The absorbance of the diluted sample (A) was calculated by Equation 1.

The total anthocyanin content was calculated by Equation 2.

Where “A” was the previously calculated absorbance (Equation 1), M is the molecular weight of cyanidin-3-glucoside (449.2 g/mol), DF is the dilution factor, ε is the molar absorptivity coefficient (29600 M-1cm-1 ), λ is the cuvette optical pathlength (1 cm) and m is the weight of the sample (g) [22].

Sensory analysis

The strawberry jellies (SPA and SP) were evaluated sensorially in relation to the appearance, color, aroma, flavor and texture attributes by 120 evaluators in an acceptance test performed at the Food Sensory Analysis Laboratory of the Department of Food Technology-FEA/UNICAMP (approved by the Committee of Research Ethics at the State University of Campinas, with Certificate of Presentation for Ethical Assessment-CPEA 86627118.5.0000.5404), using a structured 9-point hedonic scale ranked 9: I liked it extremely and 1: I disliked it extremely [23].

Statistical Analysis

Analysis of Variance (ANOVA), Tukey’s test, Friedman's test, and Nemenyi's test were applied to the results at a 95% confidence interval using XLSTAT statistical software (Addinsoft, New York, NY, 2016).

Results and Discussion

Physical and physicochemical characterization of the fruits

The results of the physicochemical characterization of the fruit ingredients are presented in Table 2.

| Fruit pulp | Physical and physicochemical parameters | |||||||

|---|---|---|---|---|---|---|---|---|

| Aw | Instrumental Color | Moisture Content (kg/kg) | pH | Soluble solids content (°Brix) | Titratable acidity (g citric acid/100g) | |||

| L* | a* | b* | ||||||

| Blackberry | 0.9922 ± 0.0003b | 9.45 ± 0.70d | 33.41 ± 0.81a | 16.20 ± 1.09a | 9.26 ± 0.01b | 3.29 ± 0.01d | 8.20 ± 0.16c | 1.014 ± 0.015b |

| Guava | 0.9940 ± 0.0004ab | 43.94 ± 1.82c | 35.76 ± 2.07a | 33.25 ± 2.91b | 9.06 ± 0.92c | 4.08 ± 0.01b | 8.33 ± 0.05c | 0.504 ± 0.015d |

| Mango | 0.9949 ± 0.0003a | 55.34 ± 0.92b | 19.40 ± 0.26c | 72.69 ± 1.24a | 8.63 ± 0.03d | 4.27 ± 0.01a | 13.10 ± 0.08b | 0.402 ± 0.003e |

| Orange | 0.9771 ± 0.0018c | 67.28 ± 2.96a | 10.32 ± 2.07d | 69.40 ± 3.23a | 8.35 ± 0.03e | 4.07 ± 0.01b | 18.80 ± 0.09a | 1.151 ± 0.040a |

| Strawberry | 0.9943 ± 0.0000ab | 52.21 ± 4.58b | 25.34 ± 2.25b | 27.68 ± 3.30b | 9.42 ± 0.02a | 3.51 ± 0.01c | 7.40 ± 0.01d | 0.878 ± 0.016c |

| Strawberry juice concentrate | 0.9621 ± 0.0001 | -18.82 ± 0.00 | 20.66 ± 0.14 | 12.24 ± 0.46 | 6.85 ± 0.02 | 3.26 ± 0.01 | 30.00 ± 0.05 | 2.650 ± 0.034 |

Aw: water activity. Mean values of 10 replicates of instrumental texture measurements and triplicates of instrumental color, pH. Aw, titratable acidity, and moisture content measurements. Mean values followed by (*) in the same line are significantly different (p<0.05)

Table 2: Physical and physicochemical parameters of the fruit pulps and strawberry juice concentrate.

The average values for water activity were located slightly out of the 0.98 range indicated for fruit pulps [24]. In general, the physicochemical parameters of the fruit pulps presented mean values closed to the ranges reported by the literature [25-29]. Considering the indicated values for the physical and physicochemical parameters of strawberry pulp, the strawberry juice concentrate presented averages within the expected range.

Development of the candy formulations

The nine formulations proposed in Table 1 were defined in preliminary tests. According to these initial experiments, it was not possible to obtain adequate gelled structures in formulations with less than 20 g/kg of polymeric mixture. Smaller contents provided weak structures that break during the drying step. The solution of sugars and fruit pulp should have total soluble solids content until 65 °Brix, due to the occurrence of saturation and crystallization of sucrose in syrups with higher soluble solids content.

The values of the hardness of the nine evaluated formulations are presented in Table 3. The gelation occurred successfully at all the formulations with the five evaluated fruit pulps. The highest hardness averages were obtained in treatments produced with 60 g/Kg of polymeric mixture.

| Hardness (N)* | pH** | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fruit candies | F1 | F2 | F3 | F4 | F5 | F6 | F7 | F8 | F9 | F1 | F2 | F3 | F4 | F5 | F6 | F7 | F8 | F9 |

| Blackberry | 47 ± 19c | 58 ± 27c | 91 ± 22bc | 99 ± 22bc | 88 ± 22bc | 185 ± 40a | 179 ± 25a | 161 ± 33a | 139 ± 27ab | 4.12 ± 0.05abc | 3.93 ± 0.06bc | 4.08 ± 0.05abc | 4.09 ± 0.01abc | 3.90 ± 0.02bc | 4.29 ± 0.05ab | 4.13 ± 0.02ab | 3.96 ± 0.03ab | 3.83 ± 0.05c |

| Guava | 59 ± 22c | 63 ± 17c | 168 ± 32ab | 165 ± 41ab | 136 ± 21bc | 216 ± 39a | 203 ± 30a | 208 ± 36a | 194 ± 28a | 4.20 ± 0.04ab | 3.96 ± 0.01b | 4.35 ± 0.08a | 4.14 ± 0.06ab | 3.93 ± 0.07b | 4.32 ± 0.03a | 4.13 ± 0.05ab | 4.02 ± 0.03ab | 3.90 ± 0.11b |

| Mango | 92 ± 24d | 88 ± 23cd | 157 ± 26bc | 152 ± 16cd | 137 ± 16cd | 219 ± 23ab | 246 ± 37a | 224 ± 29ab | 245 ± 38a | 4.19 ± 0.00ab | 4.01 ± 0.06abc | 4.09 ± 0.27abc | 4.11 ± 0.05abc | 3.94 ± 0.03bc | 4.35 ± 0.06a | 4.18 ± 0.01ab | 3.95 ± 0.01bc | 3.87 ± 0.02c |

| Orange | 55 ± 19c | 64 ± 15c | 88 ± 19c | 91 ± 16bc | 79 ± 7c | 167 ± 24a | 160 ± 22a | 154 ± 30a | 143 ± 26ab | 4.15 ± 0.02ab | 3.95 ± 0.05abc | 4.25 ± 0.05a | 4.06 ± 0.01abc | 3.83 ± 0.02bc | 4.26 ± 0.01a | 4.13 ± 0.03abc | 3.93 ± 0.04abc | 3.81 ± 0.01c |

| Strawberry | 121 ± 25cd | 108 ± 23d | 147 ± 21bcd | 122 ± 38cd | 107 ± 25d | 241 ± 32a | 229 ± 28a | 188 ± 19ab | 160 ± 23abc | 4.17 ± 0.01abc | 3.90 ± 0.01abcd | 4.27 ± 0.02a | 4.04 ± 0.00abcd | 3.82 ± 0.05bcd | 4.25 ± 0.03ab | 3.57 ± 0.04d | 3.90 ± 0.00abcd | 3.78 ± 0.02cd |

F: formulation. Mean values of 10 replicates (*) and triplicates (**). Mean values followed by different letters in the same column are significantly different (p<0.05)

Table 3: Mean values of hardness (N) and pH of the 9 cold-set experimental proposed fruit candy formulations.

The physical-chemical characteristic of the fruits (pH and acidity) showed a low influence in the gel formation process, despite the alginate/pectin cold-set gelation mechanism occurs on specific pH conditions. Almost all candy formulation presented pH values outside the 3.4-3.8 range considered ideal for gelation of alginatepectin complexes [12,13].

As expected, formulations with higher GDL content showed the lowest pH values. The same results were observed in the study of model jelly candy processing by alginate/pectin cold-set gelation with no added fruit ingredients [11].

According to the results, the strawberry formulation 5 was selected to conduct the next study, due to the great gel hardness and to the pH mean closed to the recommended range for alginate/pectin gelation.

Determination of the drying parameters

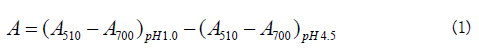

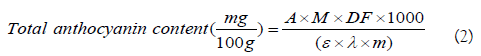

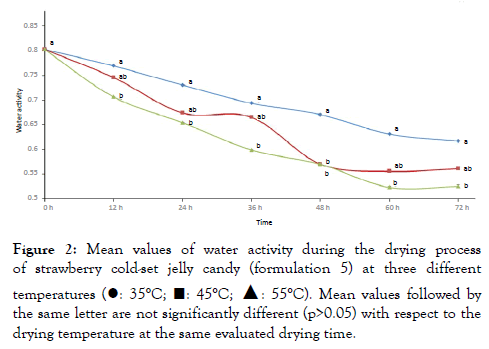

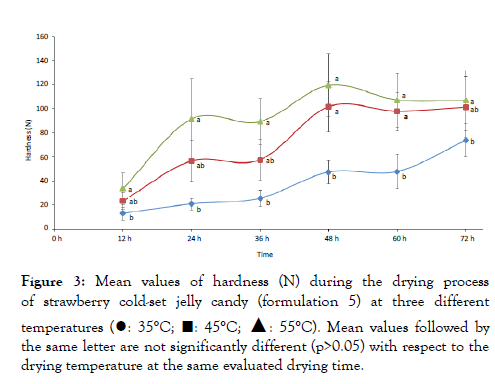

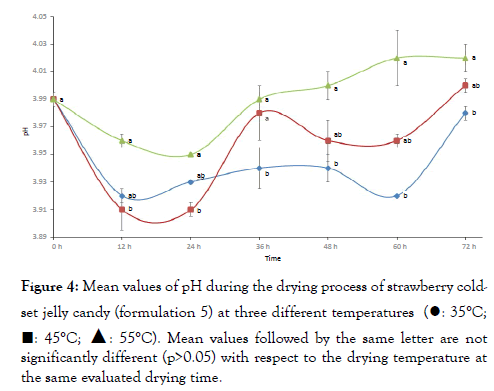

The curves generated for the physical and physicochemical parameters in the drying study are shown in Figures 1-4.

Figure 1: Mean values of moisture content (kg/kg) during the drying process of strawberry cold-set jelly candy (formulation 5) at three different temperatures (●: 35°C; ■: 45°C; ▲: 55°C). Mean values followed by the same letter are not significantly different (p>0.05) in respect to the drying temperature at the same evaluated drying time.

Figure 2: Mean values of water activity during the drying process of strawberry cold-set jelly candy (formulation 5) at three different temperatures (●: 35°C; ■: 45°C; ▲: 55°C). Mean values followed by the same letter are not significantly different (p>0.05) with respect to the drying temperature at the same evaluated drying time.

Figure 3: Mean values of hardness (N) during the drying process of strawberry cold-set jelly candy (formulation 5) at three different temperatures (●: 35°C; ■: 45°C; ▲: 55°C). Mean values followed by the same letter are not significantly different (p>0.05) with respect to the drying temperature at the same evaluated drying time.

Figure 4: Mean values of pH during the drying process of strawberry coldset jelly candy (formulation 5) at three different temperatures (●: 35°C; ■: 45°C; ▲: 55°C). Mean values followed by the same letter are not significantly different (p>0.05) with respect to the drying temperature at the same evaluated drying time.

There was a significant difference (p<0.05) between the averages of all physical-chemical parameters at the three evaluated temperatures. As expected, the speed of the dehydration process was higher as higher the drying temperature. Visually it was observed that candies dried at (45 and 55)°C presented a crystallized layer on the surface whose thickness increased over the drying time. It indicates that the drying at these temperatures promotes higher and faster dehydration causing the sucrose crystallization on the product surface.

Jelly candies must have an average moisture content of (0.08-0.22) kg/kg and water activity between 0.5-0.75 for better stability [30], which was reached for all drying temperature after 12 hours of drying.

The pH means oscillated during the drying process at the three evaluated temperatures, with falls at 12 h and 36 h and pecks after 24 h and 60 h. The changes in the pH are related to the slow acidification comportment of GDL, in which cyclic ester structure is gradually converted into gluconic acid in an aqueous medium [31-33]. For the manufacturing of fruit cold-set jelly candies, GDL is an optimal acidulant due to the slow formation of the gel, which makes possible dosing the syrup in the drying molds on time [11].

The drying condition of 35°C/72 h was selected due to the better texture characteristics, absence of a layer of crystallized sucrose on the surface, and the adequate values of Aw and moisture content presented by the candies.

Reformulation tests to increase the fruit content

After selecting the polymeric mixture and GDL contents and the drying conditions of the process, reformulation tests were carried out to evaluate the possibility of increasing the fruit solids content in the candy and, in this way, obtain a product with high appeals of naturalness and healthiness.

The soluble solids of the strawberry pulp and juice concentrate were considered as non-crystallisable solids (glucose syrup) in the balance of the sugar ratio. The polymeric mixture and GDL contents were fixed at the concentrations selected in the tests for jelly candy development.

In the reformulation tests, the moisture content of the pulp was a limiting factor for increasing the fruit content in the formulation due to the standardization of the final soluble solids content of the candy syrup (71 °Brix). For this reason, 200 g/kg of strawberry pulp (w.b) was the highest content reached in the candy syrup formulation, which corresponds to 8.1g/Kg (db) of strawberry solids in the candy after the drying step. Using strawberry concentrate juice, it was possible to perform tests ranging from (100, 200, 300, and up to 400) g/kg in the syrup formulation.

The gelation occurred successfully at all the tested formulations. The candy syrup produced with 400 g/kg of strawberry juice concentrate was selected due to the highest strawberry solids content reached in the tests.

The final strawberry alginate/pectin jelly candy syrup (SPA) consisted of strawberry juice concentrate (400 g/Kg), sucrose (440 g/Kg), glucose syrup (110 g/Kg), sodium alginate (20 g/Kg), high methoxyylation pectin (20 g/Kg), glucono-delta-lactone (10 g/Kg). The formulation of strawberry pectin jelly (SP) consisted of strawberry juice concentrate (395 g/Kg), sucrose (465 g/Kg), glucose syrup (120 g/Kg), high methoxyylation pectin (14 g/Kg) and citric acid (6 g/Kg).

Physical, chemical and physical-chemical characterization of the developed candies

Physical and physical-chemical characterization: The results of the physical and physical-chemical characterization of the strawberry jelly candies are presented in Table 4.

| Physical and physicochemical parameters | Chemical parameters | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Instrumental Texture | Instrumental Color | pH | Aw | Moisture Content (kg/kg) | AA (mg ascorbic acid g-1) | TPC (mg gallic acid g-1) | TAC (mg cyanidin-3- glycoside g-1) | ||||||||

| Hardness (N) | Springness | Cohesiveness | Gumminess | Chewiness | Resilience | L* | a* | b* | |||||||

| SA | 7.672 ± 1.154 | 0.206 ± 0.077* | 0.031 ± 0.000 | 0.234 ± 0.037 | 0.049 ± 0.025* | 0.007 ± 0.002* | 7.506 ± 0.231* | 0.730 ± 0.409 | 0.660 ± 0.190* | 3.646 ± 0.317 | 0.5686 ± 0.001* | 1.14 ± 0.13* | 734.083 ± 13.10* | 254.44 ± 35.64* | 0.0515 ± 0.0201 |

| SP | 4.576 ± 3.080 | 0.064 ± 0.029* | 0.026 ± 0.012 | 0.188 ± 0.202 | 0.012 ± 0.011* | 0.015 ± 0.013* | -12.273 ± 0.789* | 2.533 ± 1.121 | -0.383 ± 0.112* | 3.263 ± 0.011 | 0.6016 ± 0.0035* | 1.51 ± 0.01* | 597.376 ± 84.08* | 76.66 ± 10.00** | 0.0560 ± 0.0000 |

| SJC | - | - | - | - | - | - | - | - | - | - | - | - | 1575.34 ± 00.00 | 660.00 ± 31.50 | 0.5121 ± 0.0804 |

| General average | 6.124 | 0.135 | 0.028 | 0.211 | 0.03 | 0.011 | -2.383 | 1.631 | 0.138 | 3.454 | 0.5851 | 13.28 | - | - | - |

Aw: water activity; AA: Ascorbic Acid content; TPC: Total Phenolic Compounds content; TAC: Total Anthocyanin Content; SAP: strawberry alginate/pectin jelly candy; SP: strawberry pectin jelly candy; SJC: Strawberry Juice Concentrate. Mean values of 10 replicates of instrumental texture measurements and triplicates of instrumental color, pH. Aw and moisture content measurements. Mean values followed by (*) in the same line are significantly different (p<0.05)

Table 4: Physical and physicochemical parameters and bioactive compounds contents of strawberry jelly candies and strawberry juice concentrate.

A lighter and more opaque red color was observed in the SAP samples, which was confirmed by the instrumental color analysis. The mean value of SPA luminance (L*) was significantly lower (p<0.05) than those of SP while the SPA chromaticity index b* was significantly higher than those of SP.

There was no significant difference (p<0.05) between the hardness, gumminess, and cohesiveness. The SAP gel presented a texture with more elasticity, chewiness, and less resilience, as observed in the cold-set model jellies produced with alginate and pectin [11].

Both treatments showed moisture content and water activity values closed to the recommended ranges for gummies and jellies (0.08- 0.22 kg/kg of moisture content and water activity between 0.5- 0.75) [30]. However, the SP candies differ significantly (p<0.05) by the highest values for these parameters.

Chemical characterization: According to the average values for the contents of the bioactive compounds of processed strawberry pulp reported by the literature (Ascorbic acid content: (44-71) mg ascorbic acid/100 g frozen pulp; total anthocyanin content: (0.5-3.79) mg cyanidin-3-glycoside/100 g frozen strawberry; total phenolic compounds: 250 mg ellagic acid/100g frozen strawberry) [22,34,35] the strawberry juice concentrate presented mean values below the expected range for total anthocyanin and total phenolic compounds contents.

The juice concentrate processing occurs by heating treatment to remove the moisture content and increase soluble solids content. The process conditions (temperature and time) and storage probably caused changes in the fruit pulp´s final content of the thermosensitive nutrients and bioactive compounds.

The alginate/pectin candies showed higher mean values (p<0.05) for the ascorbic acid and total phenolic compounds contents. Ascorbic acid is a water-soluble vitamin essential for the health with antioxidant action, whose stability in food processing is subject to oxygenation and high temperature and water activity conditions [36]. Phenolic compounds have antioxidant and coloring properties and have a strong influence on the sensory quality and nutritional value of strawberries. They are susceptible to degradation in process conditions involving high temperatures, light, oxygen, enzymes, metal ions, and possible associations with other organic components [37,38]. The differences between the levels of ascorbic acid and phenolic compounds in the candy samples indicate that the cold-set process allows better conservation of these bioactive compounds in the final product.

The total anthocyanin contents showed no significant difference (p<0.05) between the candy samples. Anthocyanins are the most common fruit flavonoids. They have antioxidant activity and are related to red-blue pigmentation. In strawberry, anthocyanins are quantitatively the most important type of polyphenols. The pelargonidin- and cyanidin- glycosides or acylated forms are the major anthocyanin representative compounds in strawberry. The retention and stability of anthocyanins after food manufacturing is mainly determined by the processing temperature, but it is also influenced by other factors such as pH, the presence of oxygen, light, enzymes, and metal ions [39,40].

It was expected that the conventional heating process would imply higher degradation of the total anthocyanin content compared to the cold-set process. The similar anthocyanin contents of the samples can be justified by the high concentrations of sugar in the candy formulations, which may have a protective effect on the stability of anthocyanins during the syrup cooking, reducing the mobility of water and energy of activation of the degradation reaction [41]. Considering the anthocyanin content and the fruit solids of the strawberry juice concentrate, there was a loss of anthocyanin in both manufacturing processes, indicating that another common parameter of both processes (as oxygenation or pH) may have conducted to these levels.

The developed strawberry cold-set candy had higher fruit solids and total phenolic compounds contents than candies produced with fruit ingredients in other studies reported by the literature, such as fruit jellies elaborated with apple/blackberry puree and enriched with grape skin powders [42] and no-added sucrose chewy candies incorporated with differently processed açaí [43]. The high levels of fruit and phenolic compounds' contents of SPA enhance claims of naturalness and healthiness to the developed product.

The results of the chemical determinations indicate the viability of the alginate/pectin candy manufacturing process to the conservation and retention of bioactive compounds from fruit ingredients used in the formulation. SPA had retention of 93.53% of total phenolic compounds while SP allowed retention of 31.16%. The cold-set jelly candy process also has the potential of reducing energy consumption in the jelly candy industrial lines due to the elimination of the syrup cooking step. According to the results of a comparative bench study of energy requirement by Avelar and Efraim [11], the energy demand of the cold-set process (0.013 kWh) is statistically lower than the conventional heating process (0.035 kWh). In this way, the cold-set fruit jelly processing can also get claims of sustainability.

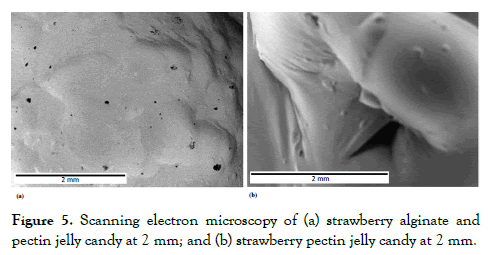

Microstructure: The scanning electron microscopy images of the candies are shown in Figure 5.

Figure 5: Scanning electron microscopy of (a) strawberry alginate and pectin jelly candy at 2 mm; and (b) strawberry pectin jelly candy at 2 mm.

The strawberry alginate/pectin candies presented a microstructure characterized by a dense and homogeneous surface with the presence of pores along with the network, similar to the microstructure observed in pure alginate and pectin gels [13] and model alginate/pectin candies produced by cold-set gelation [11]. These microstructural aspects can justify the instrumental color values and the visual opacity observed in the candy.

The strawberry pectin candies showed a non-homogeneous structure characterized by aggregates of micelles and the presence of large and sparse pores. Pure pectin gels are described in the literature as open networks with wires arranged in loose bundles or aggregates [11,44].

In general, the SPA microstructure observed in the scanning analysis differs from those reported in jellies and gummies produced with other conventional gelling agents [45,46].

Sensory acceptance

The results of the sensory acceptance test are shown in Table 5.

| Sensorial attributes | ||||||

|---|---|---|---|---|---|---|

| Appearance | Color | Aroma | Flavor | Texture | Overall impression | |

| SAP | 6.0 ± 1.7 | 6.0 ± 1.6 | 6.0 ± 1.2 | 6.0 ± 1.9 | 4.0 ± 2.0 | 6.0 ± 1.7 |

| SP | 6.0 ± 1.9 | 7.0 ± 1.5 | 6.0 ± 1.4 | 6.0 ± 1.7 | 4.0 ± 2.3 | 5.5 ± 1.8 |

| General average | 6 | 6.5 | 6 | 6 | 4 | 5.7 |

SAP: Strawberry alginate/pectin jelly candy; SP: Strawberry pectin jelly candy. Mean values followed by (*) in the same line are significantly different (p<0.05)

Table 5: Sensorial attributes of the produced candies.

SPA and PJ showed low acceptance in relation to the texture parameter, with mean values located around the term “slightly disliked.” Compared to cold-set model candies without fruit pulp, the jellies produced from strawberry juice concentrate showed lower instrumental hardness values and lower sensory acceptance for texture [11]. These results indicate that high fruit contents in the candy formulation can modify the final candy gel texture and decrease its acceptability.

The evaluated strawberry jelly candies showed no significant difference (p<0.05) in relation to all the evaluated sensory parameters, which indicates viability in replacing the conventional candy production process with the cold-set gelation process without decreasing the sensory acceptance.

Conclusion

Fruit jelly candies were successfully produced by the alginate/pectin cold-set gelation technique with the maintenance of bioactive compounds from the fruit ingredients used in the formulation. The ascorbic acid and total phenolic compounds contents of the strawberry alginate/pectin candies were significantly higher (p<0.05) than those of strawberry pectin jellies. The mean values of the physical and physical-chemical parameters of the produced candies located in the range for this product category. Sensorially, there were no significant differences (p<0.05) between any of the evaluated attributes, indicating the potential for replacing the conventional jelly candy processing by the cold-set gelation process. It is worth noting that the cold-set manufacturing process also has the potential to reduce energy consumption in industrial jelly candy processing lines due to the elimination of the syrup cooking step. In this way, claims of healthiness and sustainability could be attributed to the cold-set products.

Acknowledgments

Conselho Nacional de Desenvolvimento Científico e Tecnológico - Brasil (CNPQ) for the fellowship to the first author, Coordenação de Aperfeiçoamento de Pessoal de Nível Superior - Brasil (CAPES)- Finance Code 001, Innovation Agency of University of Campinas (Inova-Unicamp) and the Brazilian National Institute of Industrial Property for the patent filling BR 10 2018 076817, that contemplates and protects the results of this study.

REFERENCES

- Avelar MH, Silva LB, Azevedo FB, Efraim P. A byproduct of uvaia (Eugenia pyriformis) processing as a natural source for coloring sugar hard‐panning confections. J Food Process Eng. 2019;42:e13250.

- Mongia G. Fruit ingredients in confectionery applications. The Manufacturing Confectioner. 2014;94:73-82.

- Mutlu C, Tontul SA, Erbaş M. Production of a minimally processed jelly candy for children using honey instead of sugar. LWT-Food Sci Technol. 2018;93:499-505.

- Silva LB, Queiroz MB, Fadini AL, Fonseca RC, Germer SP, Efraim P. Chewy candy as a model system to study the influence of polyols and fruit pulp (açai) on texture and sensorial properties. LWT-Food Sci Technol. 2016;65:268-274.

- Willmer K. Organic candy: The future of confectionery, says new report. Confectionery News. 2019

- Queiroz GC. Sustainability and Transparency, InBrasil Bakery and Confectionery Trends 2020. Institute of Food Technology-ITAL Campinas. 2014:233-257.

- Coyle S. Cooking Equipment for Jelly Candies. Manufacturing Confectioner. 2007;87:36.

- DeMars LL, Ziegler GR. Texture and structure of gelatin/pectin-based gummy confections. Food Hydrocoll. 2001;15:643-653.

- Eiri Board. Hand Book of Confectionery with Formulations. New Delhi: Engineers India Research Institute. 2012.

- Energy reduction factsheet: Saving energy in the confectionery manufacturing industry. 2019.

- Avelar MH, Efraim P. Alginate/pectin cold-set gelation as a potential sustainable method for jelly candy production. LWT-Food Sci Technol. 2020;123:109119.

- Toft K, Grasdalen H, Smidsrød O. Synergistic gelation of alginates and pectins. ACS Publications. 1986:117-132.

- Walkenström P, Kidman S, Hermansson AM, Rasmussen PB, Hoegh L. Microstructure and rheological behaviour of alginate/pectin mixed gels. Food Hydrocoll. 2003;17:593-603.

- Sufferling K. Gelatin gummies and pectin jellies. Manufacturing Confectioner. 2007;87:43.

- Moore CO. Starch Jelly Candy. The Manufacturing Confectioner. 2007;87:79-85.

- AOAC International, and Latimer GW. Official Methods of Analysis of AOAC International. Gaithersburg, Md: AOAC International, 2012. 19 Eds.

- Fadini AL, Jardim DC, Queiroz MB, Bertin AP, Efraim P, Mori EE. Sensory and texture characteristics of diet panned chewing gum produced with different types of polyols. Braz J Food Technol. 2005;8:113-119.

- Delgado P, Bañón S. Determining the minimum drying time of gummy confections based on their mechanical properties. CyTA-J Food. 2015;13:329-335.

- Marfil PH, Anhê AC, Telis VR. Texture and microstructure of gelatin/corn starch-based gummy confections. Food Biophys. 2012;7:236-243.

- Singleton VL, Orthofer R, Lamuela RMR. Analysis of total phenols and other oxidation substrates and antioxidants by means of folin-ciocalteu reagent. Methods Enzymol. 1999;299:152-178

- Cheftel H, Pigeaud ML. Estimation of ascorbic acid (vitamin C) by titration. Nature. 1936;138:799.

- Tonutare T, Moor U, Szajdak L. Strawberry anthocyanin determination by ph differential spectroscopic method–how to get true results. Acta Sci Pol Hortorum Cultus. 2014;13:35-47.

- Stone H, Sidel JL. Introduction to Sensory Evaluation. Sensory Evaluation Practices. Elsevier. 2004;1-19.

- Sandulachi E. Water activity concept and its role in food preservation. Institutional Repository of the Technical University of Moldova (IRTUM). 2012:40-48.

- Alamar PD, Caramês ET, Poppi RJ, Pallone JA. Quality evaluation of frozen guava and yellow passion fruit pulps by NIR spectroscopy and chemometrics. Food Res Int. 2016;85:209-214.

- Souza VR, Pereira PA, Silva TL, Lima LCO, Pio R, Queiroz F. Determination of the bioactive compounds, antioxidant activity and chemical composition of Brazilian blackberry, red raspberry, strawberry, blueberry and sweet cherry fruits. Food Chem. 2014;156:362-368.

- Gonçalves GA, Resende NS, Carvalho EE, Resende JV, Boas EVV. Physicochemical and volatile profile alterations in pasteurized and frozen strawberry pulp during storage. J Food Process Preserv. 2018;42:e13317.

- Leahu A, Damian C, Oroian M, Ropciuc S. Physico-chemical parameters of fruit juices-evolution during storage. Lucrari Stiintifice-Seria Zootehnie. 2013;59:213-217.

- Pelegrine DH, Silva FC, Gasparetto CA. Rheological behavior of pineapple and mango pulps. LWT-Food Sci Technol. 2002;35:645-648.

- Ergun R, Lietha R, Hartel RW. Moisture and shelf life in sugar confections. Crit Rev Food Sci Nutr. 2010;50:162-192.

- Imeson A. Food stabilisers, thickeners and gelling agents. John Wiley and Sons. 2011.

- Søltoft-Jensen J, Hansen F. New chemical and biochemical hurdles. In Emerging technologies for food processing. Academic Press. 2005:387-416.

- Xavier NM, Rauter AP, Queneau Y. Carbohydrate-based lactones: synthesis and applications. In Carbohydrates in Sustainable Development II. Springer, Berlin, Heidelberg. 2010:19-42.

- Asami DK, Hong YJ, Barrett DM, Mitchell AE. Comparison of the total phenolic and ascorbic acid content of freeze-dried and air-dried marionberry, strawberry, and corn grown using conventional, organic, and sustainable agricultural practices. J Agric Food Chem. 2003;51:1237-1241.

- Freire JM, Abreu CM, Rocha DA, Corrêa AD, Marques NR. Quantification of phenolic compounds and ascorbic acid in frozen fruits and pulps of acerola, cashew, guava and strawberry. Rural Sci. 2013;43:2291-2295.

- Uddin MS, Hawlader MN, Ding L, Mujumdar AS. Degradation of ascorbic acid in dried guava during storage. J Food Eng. 2002;51:21-26.

- Tulipani S, Mezzetti B, Capocasa F, Bompadre S, Beekwilder J, Vos CR, et al. Antioxidants, phenolic compounds, and nutritional quality of different strawberry genotypes. J Agric Food Chem. 2008;56:696-704.

- Volf I, Ignat I, Neamtu M, Popa VI. Thermal stability, antioxidant activity, and photo-oxidation of natural polyphenols. Chem Pap. 2014;68:121-129.

- Patras A, Brunton NP, O'Donnell C, Tiwari BK. Effect of thermal processing on anthocyanin stability in foods; mechanisms and kinetics of degradation. Trends Food Sci Technol. 2010;21:3-11.

- Rein M. Copigmentation reactions and color stability of berry anthocyanins. Helsinki: University of Helsinki. 2005.

- Tsai PJ, Hsieh YY, Huang TC. Effect of sugar on anthocyanin degradation and water mobility in a roselle anthocyanin model system using 17O NMR. J Agric Food Chem. 2004;52:3097-3099.

- Cappa C, Lavelli V, Mariotti M. Fruit candies enriched with grape skin powders: physicochemical properties. LWT-Food Sci Technol. 2015;62:569-755.

- Silva LB, Annetta FE, Alves AB, Queiroz MB, Fadini AL, Silva MG, et al. Effect of differently processed açai (Euterpe oleracea Mart.) on the retention of phenolics and anthocyanins in chewy candies. Int J Food Sci Technol. 2016;51:2603-2612.

- Löfgren C, Walkenström P, Hermansson AM. Microstructure and rheological behavior of pure and mixed pectin gels. Biomacromolecules. 2002;3:1144-1153.

- Moura SC, Berling CL, Garcia AO, Queiroz MB, Alvim ID, Hubinger MD. Release of anthocyanins from the hibiscus extract encapsulated by ionic gelation and application of microparticles in jelly candy. Food Res Int. 2019;121:542-552.

- Otálora MC, Barbosa HJ, Perilla JE, Osorio C, Nazareno MA. Encapsulated betalains (Opuntia ficus-indica) as natural colorants. Case study: Gummy candies. LWT-Food Sci Technol. 2019;103:222-227.

Citation: de Avelar MHM, de Lima LN, Efraim P (2020) Maintenance of Fruit Bioactive Compounds in Jelly Candy Manufacturing by Alginate/Pectin Cold-Set Gelation. J Food Process Technol 11:826. doi: 10.35248/2157-7110.20.11.826.

Copyright: © 2020 de Avelar MHM, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.