Indexed In

- Genamics JournalSeek

- Academic Keys

- JournalTOCs

- China National Knowledge Infrastructure (CNKI)

- Access to Global Online Research in Agriculture (AGORA)

- Centre for Agriculture and Biosciences International (CABI)

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- SWB online catalog

- Publons

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Research Article - (2024) Volume 15, Issue 1

Experimental Investigation of Biogas Injera Baking Stove Using Circular Ring Pipe Burner

Taha Abdella Geda*, Demis Alemu Ambie and Kamil Dino AdemReceived: 01-Feb-2024, Manuscript No. JFPT-23-23893; Editor assigned: 05-Feb-2024, Pre QC No. JFPT-23-23893 (PQ); Reviewed: 19-Feb-2024, QC No. JFPT-23-23893; Revised: 26-Feb-2024, Manuscript No. JFPT-23-23893 (R); Published: 04-Mar-2024, DOI: 10.35248/2157-7110.23.15.1083

Abstract

Baking and cooking are day-to-day human activities that demand energy from different sources. Injera is stapled food in Ethiopia mainly baked by traditional biomass injera baking stove. In order to minimize the environmental and social impact of traditional non-clean energy sources of energy, different research has studied replacing traditional stoves with clean and renewable energy sources. However, still the existing injera baking stove has low performance and heat distribution problems. The purpose of this study is to solve this problem by developing injera baking biogas stove with better performance. The experimental investigation was conducted using a biogas plant in Addis Ababa University 4 Kilo Campus. A detailed energy analysis of energy demand, energy output, and baking performance has been performed. Injera baking time is 3 minutes, idle time is 2 minutes between successive injera baking. Thus, the designed injera baking biogas stove achieved uniform heat distribution and improved performance.

Keywords

Biogas injera baking stove; Burner; Performance

Introduction

Biogas can contribute to reduce the reliance on solid biomass energy sources, improving environmental sustainability, as well as the welfare of rural households. Biogas has the dual advantages of providing energy for rural households such as energy for lighting and for cooking, while at the same time providing high-quality organic fertilizer from the slurry produced after the gas is extracted. Biogas improves the quality of life of rural households as it reduces indoor air pollution and is non-polluting hence no harmful gases such as CO2, CO, NO2, and SO2 are evolved. Enhance the share of renewable energy, minimizing dependency on fossil fuels. The method of disposal is safe and efficient and hence no space is wasted in the form of landfills. Biogas cooking stove is widely used in developing countries; however, it is not yet popular for injera baking. There are a number of efforts by the Ministry of Water, irrigation and electricity-Alternative Energy Development Directorate and SNV to develop a bio-gas stove for baking injera. In 1996, a biogas injera baking stove was tested. It was a three-ring stove consisting of three concentric rings made from a ½’’ steel pipe. The performance of the concentric three-ring injera stove was determined by baking injera. The power output of the stove was 11 kW, corresponding to the gas consumption 41 l/min. The gas consumption per injera was 193 l (3108 kJ/injera). The average efficiency of the three-ring biogas stove was 16% in the range of improved biomass stove. This result indicates that performance of stove is quite low for a biogas gas stove [1].

Dejene Kebede et al., at the Institute of Technology of Bahirdar University attempt to design biogas stove used for Injera baking. The stove was designed by covering the flame under an insulated material. Burner for the biogas was designed based on the demand for energy needed during baking and the amount of gas supplied from the biogas plant. Heat transfer analysis between burner and mitad by radiation, convection heat transfer between flame and wall and heat flow through insulation also was assessed on the paper to come up with a suitable injera baking biogas burner. Getu Alemayehu partnering with SNV has successfully demonstrated application of the biogas stove for injera baking application. The newly tested stove demonstrates the lacks uniformity of heat in the Mitad to bake Quality injera. Although efforts have been done to develop injera baking stove, still there is problems with low stove efficiency and low heat distribution throughout baking pan. Hence biogas injera baking stove is to be developed which meet the requirement of heat distribution and efficient performance. The new stove has a conical shape burner with a lower diameter of 150 mm and an upper diameter of 500 mm. Clay Injera baking pan of 450 mm and 15 mm with thermal conductivity of 5 W/m .K and specific heat capacity 0.83 KJ/kg.K is used in this experiment. The motivation and objective of this project is to develop an innovative biogas injera baking stove which and achieves uniform heat distribution of baking pan/mitad and bake quality injera [2].

Methodology

Description of the developed injera baking biogas stove

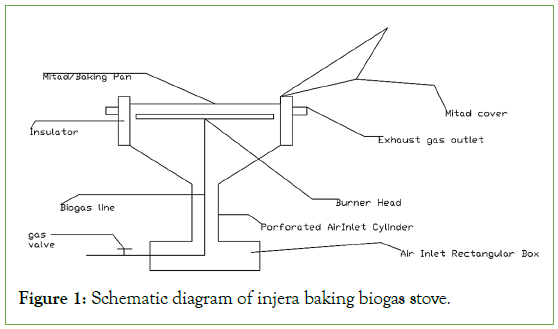

A schematic layout of the Injera baking biogas which has been considered in the present study is demonstrated in Figure 1. The stove consists of a combustion chamber where the biogas fuel is burned by mixing with air coming through air inlet system. The major components the stoves are burner, stand, gas and air supply line. Its burner is a multi-holed burning ports type with 2.5 mm diameter. This biogas stove burner has three concentric circle burner head placed at a distance of 70 mm from each other and is used for combustion of biogas. The distance between the baking pan and the stove burner is 30 mm, and the gap between each of the port is 5 mm. Biogas supply tube is 200 mm long with inner diameter of ½ inch were used in this design (Figure 1).

Figure 1: Schematic diagram of injera baking biogas stove.

A sufficient quantity of air is mixed with biogas for proper combustion in the burner head. This is where combustion takes place. The combustion chamber has a cylindrical and cone shape part and the pan (mitad) is installed on this part. The circular concentric with crossed hollow round pipe biogas supply lines are placed in the combustion chamber that helps to supply and distribute biogas to the combustion chamber and in turn distribute heat to the baking pan. The upper part of the stove below the pan is a cylindrical and conical shape part to hold the pan in its upper part and joined to the lower part of the stove and these areas are where combustion takes place. The cylindrical bottom part of the stove is used for entering the air to the burner (Combustion Chamber) and is made of 2 mm thick sheet metal. The upper cylindrical combustion unit and air inlet sections are insulated using 50 mm thick gypsum and covered with metal sheets. The injera baking cover is a standard item made of aluminium with a wooden holder at the edge. The pan seat is on the top of burner to mount the baking pan. The baking seat is insulated by a 5 cm gypsum Insulator. The pan is made of clay with a thickness of 15 mm and 450 mm diameter [3].

Biogas mix reaches the stove with the help of gas pipe line at the gas inlet of the stove; the air is supplied from bottom of stove. The biogas goes into the burner head through pipe line. The burner head is part of a burner that incorporates the burner ports. The cone and the shape of the burner head are formed in such a way as to allow the gas pressure to distribute everywhere before the mixture of gas and air leaves the burner through the ports with a speed only slightly above the specific flame speed of biogas. For the complete combustion of biogas, more oxygen is drawn from the surrounding air [4].

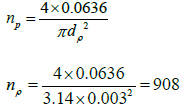

Mathematical model

Based on the Energy analysis, a thermodynamic model of the Injera Baking Biogas Stove is presented in this section.

Biogas consumption: For sizing the major dimensions of biogas injera baking stove biogas consumption rate, burner diameter, Energy required for baking injera, and airflow required for biogas combustion were required and these values are based on experimental and literature values (Table 1).

| Property | Value |

|---|---|

| Methane and carbon dioxide content | 60% and 40% (v/v) |

| Caloric value | 22 MJ/m3 |

| Specific gravity | 0.94 |

| Flame speed factor | 11.1 |

| Air requirement for combustion | 5.7 m3/m3 |

| Combustion speed | 40 cm/sec |

| Inflammability in air | 6%-25% |

| LHV, KJ/m3 | 33884.24 |

| HHV, KJ/m3 | 37632.6 |

| Density | 0.67886 |

| Calorific value KJ/kg of fuel | 55.64 |

| Air fuel ratio | 17.3 |

| Ratio of specific heat | 1.31 |

| Molecular weight | 16.043 g/kmol |

Table 1: Input data for the design of the injera baking biogas stove.

The design analysis of the biogas injera baking stove, therefore, involves the determination of the following important parameters: Biogas consumption, size of burner and burner port, and the dimension of the burner head. Input energy can be calculated by multiplying the volume of gas consumed with the calorific value of the gas by measuring the volume of gas consumed. The average power consumption of existing Clay mitad is in the range of 3.5 kw to 3.9 kw [5-7].

Biogas stove component and system design: Combustion of biogas generates heat energy directly used for cooking when their air-to-fuel ratios are properly adjusted.

Theoretically, biogas is a mixture of 60%-75% CH and 25%-40% CO2 with a calorific value as shown in table 1. The mature technology to convert biogas directly into heat at household scale is a biogas burner (stove).

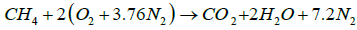

Biogas burns in oxygen to give carbon dioxide and water:

The stoichiometric theoretical combustion equation for biogas can be obtained from balancing the following equation:

After balancing the equation, the final theoretical combustion equations will be the following:

The theoretical air required for complete combustion of biogas can be calculated by using the following formula:

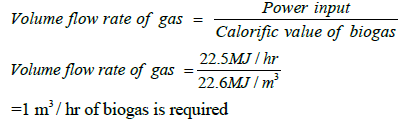

The Power needed, for 2 hours of baking time is: 7200 × 3500=22.5 MJ/ hr

Chemical Power=Volume flow rate of gas × Calorific Value of gas …………. (2)

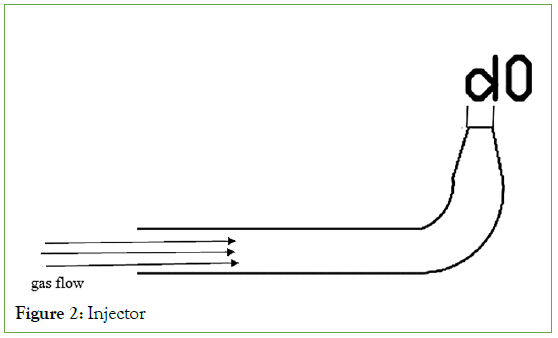

Biogas supply pipe the size and shape of the gas supply pipe determine the gas flow rate and hence heat input for a givengas composition and supply pressure as shown in Figure 2.

Figure 2: Injector

Air requirements: For 1 hour injera baking requires 1 m3 of biogas. Therefore, from stoichiometric calculation

Air requirement=5.7 × 1=5.7 m3 of air is required to bake one session of injera baking.

The air inlet part is cylindrical of diameter 5 cm and height of 15 cm with 24 holes of 1 cm dia round the circle and rectangular box of 20 cm × 15 cm × 20 cm is used to ensure complete combustion.

Mixing tube: The mixing tube diameter is the major element in the design of the biogas stove. Throat Tube (mixing tube) from the complete combustion process the Stoichiometric primary aeration required is 5.7.

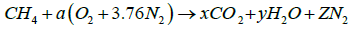

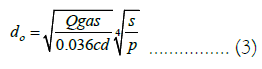

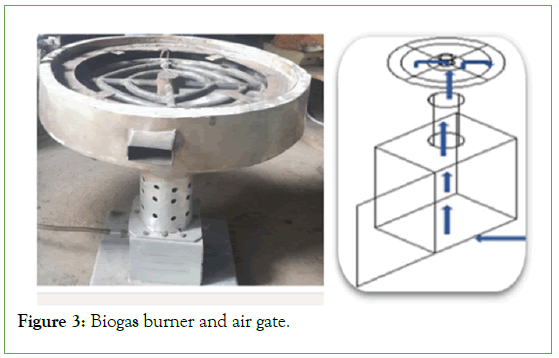

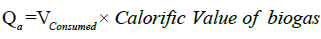

Burner: In order to ensure best efficiency and performance the following factors were considered. The volume of burner manifold is made large enough to allow the complete mixing of fuel with air, the size, shape and number of burner port holes is designed to allow easy passage of the biogas fuel-air mixture, formation of stabilized flame and complete combustion of fuel, without causing lifting up of flame [8]. The burner is directed to the baking pan /mitad by designing the burner properly. However, the design must allow for particular problems that can occur when burning gas. In this study, burner assembly of three rings, a central cylinder and hallow pipes is used as indicated below in Figure 3.

Figure 3: Biogas burner and air gate.

There are two parts of burner: Base and Head. The base part of the burner consists of injector nozzle, mixing tube. The top part of burner is circular shape with multiple drilled flame port and known as burner head. The dimension of burner is equal to the baking pan diameter to make heat reach heat to all parts of baking pan. There is a gas inlet at the base. Biogas gas and air mix in the tube, and this mixture is ignited at the top of the tube. Heat is liberated in the ensuing combustion reaction chamber [9].

This burner has both cylindrical and ring pipe burner’s distribution heat over the pan bottom surface. Burner port is at which the gas flow from it and burnt. The total area of burner port area is limited to prevent flame lift. In this design, the size and position of the burner port is defined by various factors such as the heat pattern required, the need for burner ports to be close enough together for cross-lighting and the need for adequate secondary air supply [10].

The flame lifts off from the port and can blow off and go out. Flame lift occurs when the speed of the gas/air mixture through the burner port is higher than the speed of the flame burning in the gas. Biogas has a stoichiometric flame speed of only 0.25 m/s, so the total flame port area must be chosen so that the mixture velocity through the port is much lower than this Figure [11]. The flame velocity at flame front is likely to be 50% of the stoichiometric value, as the flame is not fully aerated at this point. Even if the burner port size is designed correctly for a particular situation, a variation in condition can result in flame lift. Increased supply pressure will increase the mixture flow rate and velocity, also causing flame lift.

The total burner port area can be chosen be defined on first usage.

Using 3 mm of port diameter holes, the total number required will be:

Using flame stabilization, it should be possible the number of burner ports up to 1/3 so 302 holes can be used. The biogas burner port uses 302 holes at 3 mm diameter.

The amount of power output from a burner, referred to as burner heat release, depends on how much fuel the burner consumes and how much chemical energy the fuel has (heating value), which is referred to as the heating value of the biogas and can be written as follows:

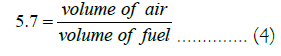

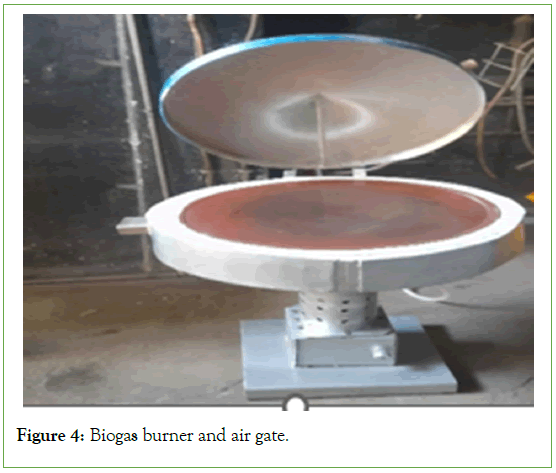

Assembly injera baking biogas stove: Clay Injera baking pan of 450 mm diameter and thickness of 15 mm with thermal conductivity of 5W/m.K and specific heat capacity 0.83 KJ/kg.k is used. Clay has properties of retaining heat for long time. The baking pan used for the proposed system is 15 mm thick and 450 mm in diameter. Hence, reducing baking pan thickness will result in saving a significant amount of energy. Therefore, the thickness the baking pan utilized in this system is reduced to 15mm. The thermo physical properties of clay k=0.5 W/m2.k, Cp=830 j/ kg.k and ρ=1900 kg/m3 is used as the insulating material.The three concentric circularburner head facilities combustion and allow distribute heat through the baking plate. The upper seat of the pan, combustion chamber inlet air, and stand are assembled by bolt and welding as shown in Figure 4.

Figure 4: Biogas burner and air gate.

Experimental work

In order to determine the performance of the designed stove measuring instrument such as an infrared thermometer, thermal camera, weight balance, pressure gauge, and gas flow meter is used during testing. The biogas stove is tested in Addis Ababa 4 kilo University at a room temperature of 22 °C. Schematic diagram of a testing set up used is given in Figure 4. In this study the moisture in the batter is released when water brought to boil and is kept boiling. This test is designed to yield several numerical indicators including time to bake, heating time and heat distribution [12].

Injera baking process: Baking pan/mitad surface making is required to make the baking surface to smoothly remove injera from the baking pan; A layer of vegetable oil is put on the baking pan surface and the baking pan was heated until the vegetable oil is burned and creating a black organic tar which filled in the top surface of the baking pan as in Figure 5. Then after the surface is smoothed oil seed and flax seed is burnt on the heated surface and the burning seeds are rubbed into the surface to create the final smooth surface [13]. After such preparation, the bake pan was tested for injera baking applications. Injera is made by mixing teff flour with water making dough and fermenting it for three days. The injera baking pan is heated for 20 minutes to attain a working temperature of 255°C. After attaining working temperature, the thin dough is poured into a pan by 1-liter container and removed after three minutes of waiting with material named safed (Injera handling material to remove from pan). The weight of the dough and injera were measured (Figure 5).

Figure 5: Injera baking process.

Result and Discussion

Experiments were conducted to bake injera in Addis Ababa using biogas plant in Addis Ababa University 4 kilo Campus. The baking pan was heated with biogas energy and temperature was recorded at every 5 min interval by infrared thermometer. The laboratory test performed to evaluate the stove performance was based on a revised version of the Water Boiling Test Protocol (WBT 2013).

Water vaporized

This is a measure of the amount of water lost through evaporation during the test. It is calculated by simple subtraction of the initial mass of dough minus the final mass (Injera) as shown in Table 2.

| Mass of batter in gram | Mass of injera in gram | Moisture loss in gram |

|---|---|---|

| 420 | 280 | 140 |

Table 2: Product measurement of injera.

Mass of dough: This is a measure of the mass of dough heated to boiling.

Time to boil: This is simply the time taken to perform the test. It is a simple clock it is the time taken to heat the baking pan/ mitad to the temperature of baking was measured and found to be 20 minutes; the readings recorded with infrared thermometer are given in Table 3. The local boiling temperature of water in Addis Ababa is 92°C (Table 3).

| Heating time in min | 0 | 5 | 10 | 15 | 20 |

| Baking pan temperature in °C | 22 | 57 | 106 | 235 | 255 |

Table 3: Heating time of injera.

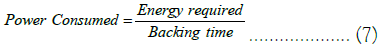

Input energy: Input energy can be calculated by multiplication the volume of gas consumed with the calorific value of the gas by measuring the volume of gas.

Chemical Energy (Input)=Volume of gas × Calorific Value of gas

Energy required for injera baking: The design of injera baking biogas stove starts with finding the energy demand using values illustrated in Table 4. Useful energy is a combination of sensible and latent heat used to evaporate water in the dough/batter at the boiling point of water. It is calculated in the following way. The mass of evaporated water can be obtained from the difference between the initial weight of batter and the final baked injera. The energy utilized to bake injera (Qinjera) is computed by using Equation 6 (Table 4).

| Pa | Mbatter | Minjera | Troom | Heat up time | Baking time | Idle time | Baked injera |

|---|---|---|---|---|---|---|---|

| Value | 420g | 280kg | 220C | 20min | 3min | 2min | 18 |

Table 4: Measurement values of baked injera.

Thermal energy required to bake a single injera (Einjera) is calculated based on Equation 6.

Einjera=mbatter × Cbatter (Tboil-Troom) + (mbatter-minjera) × hfg

Einjera= [0.42 × 4.187 (92-22) + (0.42-0.28) × 2260]=119.3808 +316.4

Einjera= 435.78 kJ

The time taken for cooking of one injera is about 3 minutes. The power required for injera baking can be calculated as:

Where, P-the power required for baking one injera. Baking time is 3 min, which is 180 seconds. Thus the power required to bake single injera is 2.4 kw.

Performance evaluation of the stove

Thermal Efficiency, Baking time, Energy Intensity, Biogas Consumption, and Heat distribution are used as performance indicators of the developed Biogas Injera Baking Stove and analysis are as follows.

Baking time: The time required to bake injera can be considered as one the of performance indicators of a stove. The time taken to bake one injera was measured and found to be 3 minutes. An idle time of 2 minutes was recorded between each injera. The idle time is to recover to the baking surface temperature which was reduced during the cooking of injera [14].

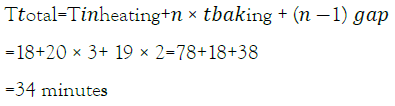

The total time required during the baking cycle is the sum of time taken for initial heating, baking, and the gap between successive Injera.

Biogas consumption rate: This is a measure of the rate of biogas consumption while baking injera. It is calculated by dividing the equivalent biogas consumed by the time of the test. In this study, biogas consumption rate is 1 m3/ hr.

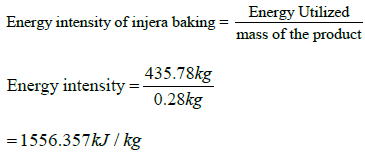

Energy intensity of injera baking: It is the ratio of energy used to produce an injera baking per mass of injera baked. In this Experimental work the total energy requirement is calculated based on 18 cycles of injera baking [15]. The mass of the dough before baking and the mass of the product injera were measured using Digital mass balance. The average moisture changes between the dough and the product injera was 0.14 kg, and the mass of injera is 0.280 kg. So, for 1 baking cycles conducted, the utilized energy was 435.78 kJ.

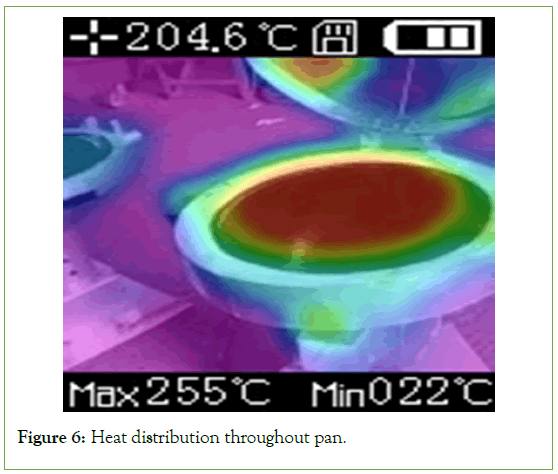

Heat distribution through the pan: In the biogas injera baking stove, injera were baked at different times. Heat distribution on plate is depicted in Figure 6. The infrared (IR) image was captured for 20 minutes in 5 minutes interval. The plate temperature was measured until reached well above optimum temperature for baking injera (204 °C-255 °C) (Figure 6).

Figure 6: Heat distribution throughout pan.

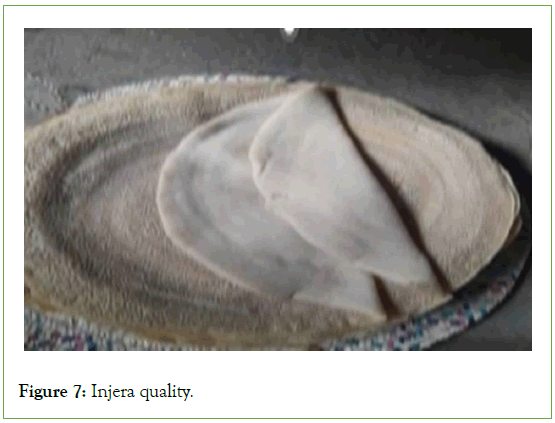

Injera quality: Heat was uniformly distributed in the pan, resulting in well-baked injera. Weight, size, and texture of injera were also acceptable. Injera quality is and indicator for uniform distribution of heat. Injera size and weight are 440 mm and 280 gram which is similar to market sold injera [16]. A photograph of the injera baked during the baking cycle is illustrated in Figure 7. The injera is similar in texture and taste to the one baked on conventional baking pans. It is also removed from the baking pan surface easily (without sticking) and the small bubbly structures (eyes) were similar to those obtained in conventional baking pans [17]. Eye size, texture, rollability, number of eyes, and color (surface and hole) of injera. Injera size and weight is 440 mm and 280 gram which is similar to market sold injera (Figure 7).

Figure 7: Injera quality.

Conclusion

In this study, a Design Manufacturing and Experimental Investigation of a Biogas Injera Baking Stove was carried out to improve the performance of a biogas injera baking stove by developing a biogas burner to solve heat distribute problem of baking pan. The designed biogas injera baking stove has been validated by using Experimental Investigation biogas plant located in Addis Ababa 4 kilo University. The size of burner and the total area of burner port is designed in such a way to allow distribution of heat and to prevent flame lift and backflash. In this design, the size and position of burner port is defined by the heat pattern required, the need for burner ports to be close enough together for cross-lighting and the need for adequate secondary air supply.

Based on the result, the newly designed burner enables uniform heat distribution to baking pan/mitad and hence bakes injera having eyes up to periphery, soft and flexible which is Injera size and weight are 440 mm and 280 gram which is similar to market sold injera. A photograph of the injera baked during the baking cycle is illustrated in fig.7. The injera is similar in texture and taste to the one baked on conventional baking pans. It is also removed from the baking pan surface easily (without sticking) and the small bubbly structures (eyes) were similar to those obtained in conventional baking pans. Eye size, texture, rollability, number of eyes, and color (surface and hole) of injera. The time taken to bake one injera was measured and found to be 3 minutes. An idle time of 2 minutes was recorded between each injera. Energy intensity of the stove is 1556.357 kJ/ kg. The performance of the desgned biogas injera baking stove is improved. This result is similar to other injera baking stove applicable to injera baking. A full-size injera 440 mm in diameter was baked successfully.

Acknowledgements

We would like to acknowledge Addis Ababa University School of Mechanical and Industrial staffs for their encouragement and for their insightful edition and comments of this work.

Conflict of Interests

The authors declare no competing interest in carrying out this study.

Author Contribution

Taha Abdella designed burner.

Demiss Alemu (PhD) mathematical modeling of heat transfer.

Kamil Dino (PhD) design and Selection of pan.

References

- Ethiopia Energy outlook. 2019.

- Anteneh G. A report on controlled cooking test results performed on ‘mirt with integrated chimney’ and ‘institutional mirt’ stoves. 2011.

- Assefa Y. Assessing environmental benefits of mirt stoves with particular reference to indoor air pollution (carbon monoxide and suspended particulate matter) and energy conservation. Unpublished Msc thesis, Addis Ababa University. 2007.

- Adem KD, Ambie DA. A review of injera baking technologies in Ethiopia: Challenges and gaps. Energy Sustain Dev. 2017; 41(1):69-80.

- HIVOS. A case for clean cooking: Injera baking stove makes its debut in Ethiopia. 2016.

- Jafar R, Awad A. State and development of anaerobic technology for biogas production in Syria. Clean Eng Technol. 2021; 5(1):100253.

- Kebede D, Kiflu A. Design of Biogas stove for injera baking application. Int J Novel Res Eng Sci. 2014; 1(1):6-21.

- Mshandete AM, Parawira W. Biogas technology research in selected sub-Saharan African countries–A review. Afr J Biotechnol. 2009; 8(2):32-33.

- David F. Msc in renewable energy and the environment. University of Reading, UK for an Advanced Biomass Module. 1996.

- Neela S, Fanta SW. Injera (An ethnic, traditional staple food of Ethiopia): A review on traditional practice to scientific developments. J Ethn Foods. 2020;7(1):32.

- Singh R, Malik RK, Tauro P. Anaerobic digestion of cattle waste at various retention times: A pilot plant study. Agricultural wastes. 1985;12(4):313-316.

- Teodorita AS, Dominik R, Heinz P, Michael K, Tobias F, Silke V, et al. Biogas handbook. University of Southern Denmark, Denmark. 2008:9-10.

- Usack JG, Wiratni W, Angenent LT. Improved design of anaerobic digesters for household biogas production in Indonesia: One cow, one digester, and one hour of cooking per day. The Sci World J. 2014.

- Khandelwal KC, Gupta VK. Popular summary of the test reports on biogas stoves and lamps prepared by testing institutes in China, India and the Netherlands. The Hague, SNV Netherlands Development Organisation. 2009.

- Mesele H,Mulu B, Asfafaw H. Energy consumption performance analysis of electrical mitad. ResearchGate. 2019.

[Crossref]

- Nyirenda K, Maurice T. Design of a co-digestion biogas plant to curb deforestation: Case study of Phalombe boarding secondary school in Malawi. ResearchGate. 2020.

- Onwukeme VI, Etienajirhevwe OF, MokobiSa EK. Production of biogas from cow dung, weeds and domestic wastes. Ethiop J environ stud manag. 2017;10(4):482-491.

Citation: Geda TA, Ambie DA, Adem KD (2024) Experimental Investigation of Biogas Injera Baking Stove Using Circular Ring Pipe Burner. J Food Process Technol. 15:1083.

Copyright: © 2024 G eda TA, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.