Indexed In

- Genamics JournalSeek

- Academic Keys

- JournalTOCs

- China National Knowledge Infrastructure (CNKI)

- Access to Global Online Research in Agriculture (AGORA)

- Centre for Agriculture and Biosciences International (CABI)

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- SWB online catalog

- Publons

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Research Article - (2020) Volume 11, Issue 3

Effect of Drying on Physicochemical Characteristics of Bhut Jolokia (Chilli Pepper)

Elivino Kennao1, Anu Kumari1, Mayank Singh2*, SA Hossain1, Anamika Das1, Prachi K Wasnik1 and BK Bharti12Dairy Technology Division, ICAR-National Dairy Research Institute, Karnal, Haryana, 132001, India

Received: 03-Apr-2020 Published: 20-Apr-2020, DOI: 10.35248/2157-7110.20.11.823

Abstract

Bhut Jolokia, chilli pepper has health-benefiting effects for which it is used in foods and pharmaceutical products. It is highly perishable at higher moisture content, and sun-drying of it requires more time in comparison to other modern methods. This article presents the oven drying of Bhut Jolokia at (40 and 70)°C, for the determination of its drying characteristics. The drying conditions, physicochemical properties and the models were studied to describe the drying behaviour. The moisture content reduced significantly (p<0.05) after drying. The sun-drying (ambient, 30°C), and oven drying at (40 and 70)°C, took nearly (27, 20.5 and 13.5) h, respectively, to reduce the final moisture content in each of the samples to 9% (approximately). The half-time (t1/2) for drying of chilli under the sun, and in oven at (40 and 70)°C, was (2.60, 2.43 and 1.84) h, respectively. The pH, ascorbic acid and colour (L*, a*, b*) values were found to decrease significantly (p<0.05) in each of the chillies samples. PAGE was found as the most suitable model to describe the drying characteristics of Bhut Jolokia. It was concluded that oven drying method gave the product with acceptable physicochemical (pH, titrable acidity, ash, capsaicin content, ascorbic acid), colour (L*, a*, b* values) and sensory characteristics.

Keywords

Bhut Jolokia; Drying model; Physicochemical; Sensory attributes

Introduction

Today, India is the biggest producer of chilli in the world, meeting nearly half of the world’s consumption demand [1]. It exports every year, around 35000 tonnes of chillies worth Rs. 80 crores [1-3]. The total chilli production in India for the year 2018-2019 was 1845664 tonnes out of which around 468500 tonnes was exported worth Rs. 541117.50 lakh (Spices Board of India, Ministry of Commerce and Industry, Government of India, 2019). Based on pungency, chilli is classified as mildly pungent (Mundu), medium pungent (Sannam) and highly pungent (Naga king) chillies. The chilli is a semi-perennial herb which belongs to the family Solanaceae, genus Capsicum which includes more than 30 species [4,5]. The origin of chilli is considered in Mexico (American tropics) with secondary centres in Guatemala and Bulgaria. It is believed that the chilli have been introduced to India by Portuguese and to the north-eastern part of India by Christian missionaries [6]. In India, it is mainly grown in the Brahmaputra flood plains viz., Assam, Nagaland, Manipur. The chilli is called by different names which change region to region. In Assam, it is called Bhut Jolokia, Ghost chilli and Bih Jolokia. In Nagaland, it is called Naga Jolokia, Naga Morish, Raja Mirchi and King Chilli. In Manipur, it is called as Umorok and Go-morok. In western India, it is called ghost pepper. However, in scientific literature, it is famous by name Bih, Bhut and Capsicum chinense Jacq [7-9]. In the year 2006, the Bhut Jolokia was recognized as the hottest chilli in the whole world which has 1,041,427 Scoville Heat Units (SHU) or 401.5 times hotter than Tabasco and was also certified by Guinness World Records [4,8,10,11]. The high capsicum content makes it unique to use in fresh, dried and powdered forms to add flavour, colour and taste in curries, chutneys, pickles and other food preparations [12]. In the pharmaceutical industry, it is used as ointments, high-dose dermal patches, creams, bandages and in drugs preparation to cure a headache [1], night blindness [1], rheumatism [4], gastritis [8], spondylitis, chronic congestion [1]. Besides, it is used in pain relief of peripheral neuropathy, symptomatic treatment of arthritis [8], muscle and joint pains and neurogenic pains [13], such as Herpes zoster [2,12]. Chillies detoxify the blood as they remove waste products from our body and increases supply nutrients to the tissues. It also acts as gastrointestinal detoxicants, thereby helping indigestion. The capsaicinoids content are mainly responsible for the functionality of chillies. Capsaicin (N-Vanillyl-8-methyl-6-(E)- noneamide) is represented with 69% in the group of capsaicinoids; dihydro capsaicinoids with 22%; nor-dihydro capsaicinoids with 7%; homocapsaicin and homo-hydro capsaicin takes only 1% in the group of capsaicinoids. The capsaicin and dihydrocapsaicin content have the anti-cancer, stimulative and carminative property [14]. The capsaicin is a vanilloid, the heaviest of this class of compound in nature and the amount of these two ranges in ratio 1:1 to 2:1. The capsaicin content in chilli pepper (Bhut Jolokia) is higher than any other Indian chilli [7]. The chilli pepper is a good source of vitamin A, B, C along with potassium, magnesium and iron content [15]. The ripening stage signified by the red colour of chilli is due to the presence of carotenoids, tocopherols, capsaicinoids and ascorbic acid. Thus the change in colour suggests the declination in these alkaloid contents in chilli [16].

Chillies are highly perishable on account of higher moisture (70%-80% wet basis) at the time of harvesting and often lead to microbial spoilage and are highly vulnerable to the virus in comparison to fungus and bacteria. The viruses responsible for the quality deterioration in the chilli are Cucumber mosaic virus (CMV), Potato virus Y (PVY), Chilli leaf curl virus (ChLCV) [17]. Farmers have been continuously trying to meet the increasing demand of the market in terms of quality and quantity but which they fail to achieve it due to lack of efficient post-harvest practices and high spoilage since the moisture is the root cause of deterioration. Sun-drying is the oldest (traditional) method of preservation and takes 7-10 days to reduce the moisture content to (10-15)% depending on weather conditions [18]. This open sun drying of chillies contaminates them with dirt, dust, rainfall, mud, and a loss of (40-60)% of total quantity due to, birds, rodents, insects and microorganisms. Therefore, the alternative process that could reduce the processing time along with the production of uniform product quality is the demand of time. Thus, the hot air oven-drying method, which reduces the moisture content and takes a short processing period, could be the solution. Hence in this paper, the effect of hot air oven drying on physicochemical attributes of chilli has been discussed.

Materials and Methods

The fresh good quality chillies (Bhut Jolokia) of family Solanaceae, genus Capsicum was purchased from the local market of Kohima, Nagaland. The morphology of the chilli shape, colour and size were examined [19]. The electronic balance (model no. CT 10001) was used for weight measurement manufactured by Contech Instruments Ltd., Mumbai, India. The moisture ratio was determined using the page model, and the pH of samples was determined using pH meter (model no. 5002/4) supplied by DBK Instruments, Mumbai, according to the method suggested by AOAC (2002) [20]. The total acidity (%) was determined by the volumetric method suggested by AOAC (2002) [20]. Ascorbic acid and ash content was determined according to the method suggested by AOAC (2002) [20]. The capsaicin content (%) was determined by Spectrophotometric method. The chillies were packed in sterile polythene bags and stored under refrigeration for further use. The sensory attributes of the sample were analysed using the 9-point hedonic scale. The standard Capsaicin (8-methyl-Nvanillyl- trans-6-nonenamide) was purchased from M/s Hi-Media Laboratories Pvt. Ltd supplied by Nu-Scientific Biotechnologies, Karnal, Haryana, India. Chemicals used for the analysis were purchased from the authorized suppliers of Merck.

Drying of chillies

Open sun drying: The chillies were washed adequately with RO water and spread uniformly over a black colour polythene film for drying under the sun. The samples were tested for moisture content after every 15 min interval for 2 h, after that 30 min for the same period until the difference between two consecutive readings of moisture content is less than 0.05 g.

Oven drying: The chillies were spread over a perforated aluminium tray placed in a hot air oven maintained at 40°C and 70°C. The samples were tested for moisture content after every 15 min interval for 2 h, then, every 30 min interval for the same period and finally after every 1 h till the difference between two consecutive readings of moisture content is less than 0.05 g.

Determination of moisture content

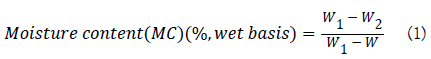

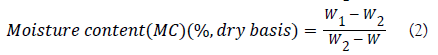

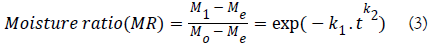

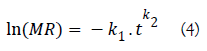

The moisture content of the sample was determined by Gravimetric method (AOAC 2002) [20]. The clean and dry aluminium dish was kept in an oven maintained at 100 ± 1°C for 1 h. Allow it to cool to the room temperature in a desiccator and weigh the dish. 3 g of the sample was accurately taken into the clean and dry dish which has been already heated. After that, the sample was kept in a hot air oven at 105 ± 1°C for 4 h. It was then cooled in a desiccator and weighed such that the difference between consecutive readings was less than 0.05 g. The product marked T0 was control sample, T1 and T2 were samples oven-dried at (40 and 70)°C, respectively, and T3 was sample dried in the open sun drying. The moisture content in the food on a different basis can be represented as:

Taking log to the base (e) on both sides in equation (3)

Again, taking the log to the base (e) on both the sides in equation (4)

Where,

MC: Moisture content (%)

W: Weight of the empty dish (g)

W1: Weight of the dish with the material before drying (g)

W2: Weight of the dish with the material after drying (g)

t: Time interval

MR: Moisture ratio

M1: Moisture content (g) at an interval of time (min)

Me: Equilibrium moisture content

Mo: Initial moisture content (g)

Kl and K2, are the drying constants evaluated by linear regression after logarithmic transformation

Determination of drying rate

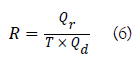

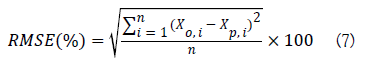

The drying rate was determined by using the equation (6), and the performance of the drying rate was evaluated by determining root mean square error for the drying rate as mentioned in equation (7).

Where,

R: Drying rate (g/min)

T: Time is taken for drying (min)

Qr: Amount of moisture removed (g)

Qd: The total dry bone weight of the sample (g)

Where,

Xo: Observed value

XP: Predicted value

Determination of pH

5 g chilli was dissolved in 45 ml of distilled water and mixed well. The sample preparation was used for pH determination at temperature (30 ± 1°C) using a pH meter. The pH of both fresh and dried chilli was determined.

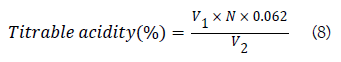

Determination of acidity

The whole chilli stalk was crushed using 20 ml distilled water in pestle and mortar. The extract obtained was filtered using filter paper. The filtered extract was titrated against 0.1N of NaOH using a few drops of 1% phenolphthalein solution as an indicator until the pink colour endpoint was obtained. The percentage of acidity was calculated by using the following formula.

Where,

V1: Volume of NaOH (ml)

V2: Volume of sample (ml)

N: Normality (N)

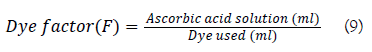

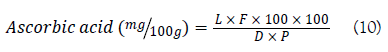

Determination of ascorbic acid

Dye solution (A): 50 mg of 2, 6-Dichlorophenol indophenols dye and 42 mg of sodium bicarbonate (NaHCO3) was taken in a beaker and then dissolved in distilled water. The volume was made up to 250 ml. This solution was filtered and kept in a clean bottle and placed in a cool place.

Standard ascorbic acid solution: 50 mg ascorbic acid was taken in 50 ml volumetric flask, and the volume was made up to 50 ml with an oxalic acid solution (0.4%). This solution was kept in a cool place for 24 h before use.

Titration: 4 g Oxalic acid was taken in a volumetric flask, and the volume was made up to 1 L with distilled water. Standard ascorbic solution (5 ml) was taken in a conical flask and was titrated against dye solution till light pink colour persisted.

Preparation of sample (B): 10 ml of sample (prepared for total acidity determination) was taken in a volumetric flask, and the volume was made up to 100 ml with 0.4% oxalic solution.

Titration: 10 ml of sample (A) was taken in a conical flask and titrated against the solution B till light pink colour persisted. Three consecutive readings were taken for each sample.

Where,

L: Volume of dye used (ml)

F: Dye factor

D: Amount of sample taken for dilution (g)

P: Volume of a sample taken for titration (ml)

Determination of ash

AOAC (2000) method was followed for determining the ash content in chillies [20]. 2 g of the sample was accurately weighed in the completely dried crucible. After placing it into the crucible, it was ignited until wholly burnt off. Then the crucible was placed in the muffle furnace which was set to a temperature of 550 ± 5°C for 5 h. After heating the sample was transferred to desiccator for cooling and measurement.

Determination of capsaicin

Sample preparation: Capsaicin content was determined by the spectrophotometric method [21]. 1 mg of the crude extract of both the dry and fresh chilli was dissolved in 5 ml of 0.4% sodium hydroxide solution and 3 ml of 3% phosphomolybdic acid, and allowed to stand for one hour in the dark. The solution was filtered and centrifuged at 5000 rpm for 10 to 15 min. The absorbance of the blue colour solution was read at 650 nm against blank reference solution in microprocessor UV/VIS spectrophotometer (Microtech gasper, Microtech engineers, Lucknow, India). The capsaicin content in both the dry and fresh chilli was calculated by putting the value in the linear regression equation (12) mentioned below obtained from the standard capsaicin calibration curve and expressed in mg/g.

Preparation of standard curve: One mg of standard capsaicin was dissolved in 1 ml of methanol. Standard capsaicin solution was then diluted to the range of (100, 80, 60, 40 and 20) μg/ml. The absorbance values at 650 nm of capsaicin in five standard solutions were measured and plotted against capsaicin concentration to get a standard curve.

Where,

C: Total capsaicinoids content in terms of capsaicin equivalent (μg/mg)

c: Concentration of capsaicin in an extract of the chilli (μg/ml)

V: Volume of solvent (ml)

m: Quantity of extract taken (mg)

Y: Absorbance (OD)

X: Concentration of capsaicin (μg/ml)

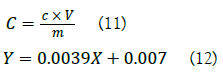

Determination of colour

The image analysis technique can be used for measuring and analysing the colour of food surfaces [22]. The colour of the chillies was determined by image analysis technique. The chilli sample was transferred to a glass container of 1 mm thickness, circular in shape, having height and diameter of (3 and 2) cm, respectively, such that no void (space) left. The samples were scanned at 300 dpi resolution using a flatbed scanner (model no. HP Scanjet 3970, Hewlett-Packard India, Mumbai, India) connected to a PC. The image scanned was then processed using Adobe Photoshop 7.0 software to determine the means value of colour parameters viz., ‘L’, ‘a’ and ‘b’. The colour values were further put in equations to observe CIE colour parameters viz., ‘L*’, ‘a*’ and ‘b*’ values [23]. The various equations required for the calculation of CIE parameters are shown below.

Sensory analysis

The samples were subjected to sensory evaluation by a panel of seven trained judges using a 9-point score-card [24].

Statistical analysis

The experimental data performed in triplicates (n=3) were subjected to two-way ANOVA using SPSS (version 21.0) software (IBM Corporation, Armonk, New York, USA). Post hoc analysis was carried out using Tukey ’ s test of Honestly Significant Difference (HSD) at 0.05 level of significance. The precision of fit of the model was evaluated using the coefficient of determination (R2), and Root Mean Square Error (RMSE).

Results and Discussion

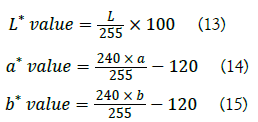

Effect on moisture

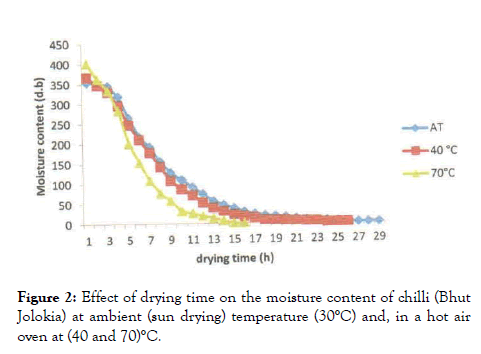

The initial moisture content of fresh chilli was 374% on a dry matter basis (db) and of the dried chilli was 9.2% (db). The drying of chilli in the oven and under the sun was continued until the moisture difference between two successive readings was less than 0.05 g. It was observed that the rate of drying was highest at 70°C, followed by 40°C and the minimum was for open sun drying. The drying rate decreased with the decrease in moisture content which caused an increase in drying time (t). It happened due to a decrease in moisture with time available for the drying and eventually reduced the rate of drying. Thus, in a hot air oven, the drying rate was highest at 70°C at the beginning of the process in comparison to open sun drying. Thus, the hot air oven drying at 40°C took 20.5 h to reduce the moisture content from (367.29 to 9.30)% (db) while at 70°C it took nearly 13.5 h to reduce the moisture content from (401.00 to 8.71)% (db). The open sun drying of chillies took 27 h, to reduce the moisture content from (353.72 to 9.70)% (db). During drying, the migration of moisture took place from inside to the outer surface of the chilli, and the evaporation rate of moisture from chilli surface to air decreased with the decrease in product moisture content. The drying time was found to reduce with an increase in temperature, which had revealed an inverse relation between drying time and temperature for the chilli. The drying rate curve at three different temperature viz., sun/ ambient temperature (30°C), 40°C and 70°C, is shown in Figure 1 and the images of fresh and dried chilli samples are shown in Figure 2.

Figure 1: Images of Bhut Jolokia (chilli) samples dried under the sun and in a hot air oven.

Figure 2: Effect of drying time on the moisture content of chilli (Bhut Jolokia) at ambient (sun drying) temperature (30°C) and, in a hot air oven at (40 and 70)°C.

Effect on drying rate

The drying rate signifies the amount of moisture evaporated in a particular period. An exponential decrease in Moisture Ratio (MR) with the increase in drying time was observed. The drying rate was calculated after determining the time of half response (t1/2), which is the time required for removing the first half of the free moisture present in the chilli. The half-time corresponds to the time required to reach the moisture ratio of 0.5 [25]. The half-time for drying of chilli at ambient temperature (30°C), 40°C and 70°C were (2.60, 2.43 and 1.84) h, respectively, which indicated as temperature increased the half-time decreased. Under sun drying (30°C) and in a hot air oven at 40°C and 70°C, the total drying period was (27, 20.5 and 13.5) h, respectively. It was observed that the rate of drying was highest in hot air oven drying at 70°C. The low RMSE (%) value of 2.63 at the drying temperature of 40°C indicated the best-fitted Page model, but the high value of the coefficient of correlation (R2) for the model at the temperature of 70°C has signified the model was highly significant (p<0.05) to predict the total drying period. The drying equations, time of half response (t1/2) and predicted total drying period as determined by the Page model with RMSE (%) are presented in Tables 1 and 2.

| Treatments | pH | Acidity (%) | Ash (%) | Capsaicin (%) | Ascorbic acid (mg/100g) | Lightness (L*) | Redness (a*) | Yellowness (b*) | Colour and appearance | Texture | Overall acceptability |

|---|---|---|---|---|---|---|---|---|---|---|---|

| T0 | 5.23 ± 0.03a | 0.56 ± 0.03a | 0.61 ± 0.01a | 2.32 ± 0.15a | 315.3 ± 0.6a | 37.63 ± 1.43a | 34.64 ± 1.60a | 19.02 ± 00a | 7.67 ± 0.33a | 7.50 ± 0.28a | 7.67 ± 0.33a |

| T1 | 4.57 ± 0.06b | 1.33 ± 0.01b | 0.48 ± 0.02b | 2.30 ± 0.03a | 233.17 ± 3.37b | 31.37 ± 1.47b | 29.79 ± 0.92b | 14.96 ± 0.47b | 7.17 ± 0.16b | 8.17 ± 0.16b | 7.83 ± 0.44a |

| T2 | 4.60 ± 0.00b | 1.37 ± 0.02b | 0.46 ± 0.02c | 2.29 ± 0.05a | 226.67 ± 5.08c | 30.04 ± 1.83c | 26.62 ± 1.95c | 14.52 ± 0.47c | 8.17 ± 0.16c | 8.00 ± 0.00b | 8.03 ± 0.16b |

| T3 | 3.36 ± 0.08c | 1.54 ± 0.07c | 0.47 ± 0.02c | 2.31 ± 0.17a | 120.00 ± 2.78d | 28.43 ± 2.10d | 18.93 ± 1.59d | 11.17 ± 0.78d | 6.17 ± 0.16d | 6.33 ± 0.33c | 6.50 ± 0.28c |

T0: Fresh chilli; T1 and T2: Chilli dried in Hot air oven at (40 and 70)°C, respectively; T3: Chilli dried in the open sun. The values (mean ± SE) represent different superscript (a, b, c, d) within the column which differs significantly at 0.05% level of significance.

Table 1: Physicochemical properties and the sensory attributes of Bhut Jolokia (chilli).

| Drying Temperature (°C) | Equation | Coefficient of correlation | Half time (t1/2) (h) | Drying time (h) | RMSE (%) |

|---|---|---|---|---|---|

| *30°C | MR=exp(-0.213t1.123) | 0.989 | 2.596 | 26.5 | 3.12 |

| 40°C | MR=exp(-0.247t1.145) | 0.992 | 2.435 | 20.5 | 2.63 |

| 70°C | MR=exp(-0.361t1.047) | 0.993 | 1.84 | 13.5 | 4.52 |

*: Sun/Ambient Temperature; RMSE: Root Mean Square Error

Table 2: Drying characteristics of Bhut Jolokia (chilli) determined using the Page model.

Effect on pH and acidity

The pH of control and the dried chilli processed at different temperatures under oven and sun-drying differed significantly (p<0.05). The pH of control, oven-dried at (40 and 70)°C, and sun-dried chilli was 5.23, 4.57, 4.60 and 3.36, respectively. The significant difference (p<0.05) was observed between control, oven and sun-dried chilli samples while a non-significant (p>0.05) difference was observed between the oven-dried chillies processed at (40 and 70)°C. The change in pH of chillies was due to a difference in processing temperature and period of treatment which had caused the breakdown of capsaicin and ascorbic acid content. As the control sample which was not given heat treatment had the capsaicin and ascorbic acid content 2.32% and 315 mg/100g but after heat treatment (drying) both values were found to decrease. The capsaicin is an active component of the red pepper, and its amount varies depending on the light intensity and temperature [26,27]. The change in pH due to heat treatment, thereby affected the acidity content in chilli pepper. And, the extent of increase in acidity was in proportion to change in pH and the opposite direction. The acidity of the oven and the sun-dried chilli pepper increased from its original content. However, no significant difference (p>0.05) was found between both the oven-dried samples. The acidity and pH content of fresh and dried chillies using different drying methods is presented in Table 1. The increase in acidity was due to the difference in the amount of capsaicin break down due to thermal treatment which further affected the growth of micro-organism. The highest acidity in sun-dried chilli was because of the low rate of evaporation of moisture from the surface, which gave enough time for the growth of microorganism. The researcher reported that sun-dried chilli has more tendencies to become contaminated with microorganisms than other drying processes [28].

Effect on ash

The ash content of control chilli was higher than sun-dried and the oven-dried chillies at (40 and 70)°C, which was (0.48 and 0.46)%, respectively. The lowest ash content was found in sundried chilli (0.47%) while the maximum was found in the control chilli (0.61%) sample. A significant (p<0.05) difference was observed among the ash content of control and, oven-dried chillies at (40 and 70)°C. However, no significant difference was observed between the chillies dried under oven at 70°C and sun. The study reported 0.67% ash in Bhut Jolokia [29].

Effect on capsaicin

The effect of heat treatment on the capsaicinoids content was observed as it is responsible for the characteristic burning (pungency) sensation. The capsaicin content of all the chillies samples dried under oven and sun varied non-significantly (p>0.05). The drying method did not significantly affect the capsaicin content of chilli. But, a decrease in capsaicin content of chilli dried under hot air oven at (40 and 70)°C was observed, which was 2.30 and 2.29, respectively. The heat treatment caused the degradation of capsaicin, an alkaloid and homovanillic acid derivative (8-methyl-N-vanillyl-6-nonenamide). The highest and lowest capsaicin content was found in control and sun-dried chillies which were 2.32 and 2.31, respectively. It caused the loss of capsaicin and other volatile compounds such as anthocyanins, carotenoids; and nutrients like ascorbic acid and minerals caused the change in colour (redness). The findings were in favour of results reported by researcher who quantified the concentration (5.36%) of capsaicin and dihydrocapsaicin in Bhut jolokia and claimed it as the source of natural colourants which degrades on thermal treatment [30]. The similar results reported says yellow-orange colour of peppers is due to α- and β-carotene, zeaxanthin, lutein, and β- cryptoxanthin and the red colour of peppers is due to the presence of carotenoid pigments of capsanthin, capsorubin, and capsanthin 5, 6-epoxide which degrades on heating [15]. The discolouration of chilli after thermal treatment was due to degradation of capsaicin and dihydrocapsaicin [24].

Effect on ascorbic acid

The ascorbic acid of chillies dried in hot air oven or under sun varied significantly (p<0.05). The control chilli had the highest ascorbic acid (315.3 mg/100 g), and the sun-dried was found to have the lowest ascorbic acid (120 mg/100 g). The oven-dried samples were found to have (233.17 and 226) mg/100 g ascorbic acids when dried in an oven at 40°C and 70°C, respectively. The drying of chilli significantly (p<0.05) reduced the ascorbic acid content in chilli. It was also observed as the drying temperature increased the ascorbic acid degradation increased. Thus, the temperature in the hot air oven-dried method had a detrimental effect on the retention of ascorbic acid of chilli. It was because heated air inherently exposed the products to oxidation, thus reducing their ascorbic acid content. The report says 75% loss of ascorbic acid during drying of chilli [31]. The breakdown of vitamin C content in fruits Juice also occurred due to storage at high temperature [32,33].

Effect on colour (L*, a*, b*) attributes

The harvesting of chilli is performed based on the colour as it denotes about their maturity status. The different colour is green, red, brown, orange, or yellow. The CIE colour attributes, L*(lightness), a*(redness) and b* (yellowness) values were studied to know the effect of heat treatment on chilli and its constituents. It was observed the drying of chilli in the oven at (40 and 70)°C, under the sun changed color attributes significantly (p<0.05) when compared with the control chilli sample as shown in Figure 1. L* value of all the chillies samples was found to decrease with increase in temperature, which caused the change in reddish colour of the chilli to dark brown colour. This change is due to degradation of capsaicinoids and flavonoids contents like glycosides and aglycones of myricetin, quercetin, luteolin, apigenin and kaempferol [34]. However, the change was maximum in the sun-dried sample, and the least was in oven-dried at 40°C. It was due to the growth of microorganism as in sun-drying temperature system does not increase at once, but slowly. It leads the progressive decrease in capsaicinoids content and thereby decreases in antimicrobial activity against Bacillus subtilis, Bacillus cereus, and Sarcina lutea. Similar changes were observed for a* value of chillies dried under oven and sun. The drying caused the decrease in a* value (redness) of chillies, and as temperature increased the discolouration of redness increased due to degradation of capsaicinoids mainly capsorubin, capsanthin which contributes redness to chillies. The redness of chillies is due to capsaicinoids [10]. The maximum redness was observed in fresh or control chilli, and the least redness was observed in sun-dried chilli. Thus, low-temperature oven drying is advisable to avoid the discolouration of red colour and provide more lightness to chillies. It is because of oxidation and decomposition of pigment during fast vaporization on the surface of chilli at elevated temperatures. The colour degradation in the sun-dried chilli was observed during drying [35]. The b* value decreased after heat treatment to chillies which caused a decrease in yellowness, due to degradation of pigment.

Effect on sensory attributes

The colour and appearance, texture, and overall acceptability were determined using the 9-point hedonic scale. The colour and appearance score for sun and the hot air oven-dried chillies maintained at (40, and 70)°C varied significantly (p<0.05). However, the chilli dried using hot air oven scored higher than the chilli dried under the sun, which scored the least. The decrease in score for chilli dried under the sun was due to its dark brown colour in comparison to hot air oven-dried chilli. The dark colour of sun-dried chilli was due to chemical and microbial reactions inside the chilli which co-occurred during evaporation of moisture. The texture scores for chilli dried using hot air oven were significantly higher (p<0.05) in comparison to control and the sun-dried chilli. The samples dried by hot air oven had more firmness as compared to sun-dried samples which had more uneven surface. The overall acceptability scores for the chilli dried by hot air oven method at 70°C scored significantly higher (p<0.05) than the sun and the oven-dried method at 40°C. However, the overall acceptability score for the sample dried using hot air oven maintained at 40°C was nonsignificant in comparison to control product. Since more similar characteristics were observed between these two. Hence, the present study recommends drying of chilli in a hot air oven at 40°C. The sensory scores for chillies dried in a hot air oven and under the sun are shown in Table 1, and the images in Figure 1.

Conclusion

The author has investigated the difference in physicochemical and sensorial properties of Bhut Jolokia when dried at open sun drying or under hot air oven. It was concluded that the drying rate decreased with the decrease in moisture content. The high value of R2 for the Page model at 70°C was chosen as the best model for prediction of the total drying period. The lowest ash content was found in sun-dried chilli while the maximum was found in the control chilli. Heating caused the loss of capsaicin and other volatile compounds such as anthocyanins, carotenoids; and nutrients like ascorbic acid and minerals caused the change in colour (redness). The control chilli had the highest ascorbic acid and the sun-dried was found to have the lowest ascorbic acid. L*, a* and b* value of all the chillies samples were found to decrease with increase in temperature. The colour and appearance score for sun and the hot air ovendried chillies maintained at 40°C and 70°C varied significantly (p<0.05). The chilli dried using hot air oven scored higher than the chilli dried under the sun.

Acknowledgements

The first author acknowledges Warner College of Dairy Technology, Sam Higginbottom University of Agriculture, Technology and Sciences, Naini, Prayagraj, Uttar Pradesh, for providing technical support and laboratory facilities during the investigation. The first author is highly thankful to third author.

Human and Animal Participants

This article does not contain any studies with human or animal subjects.

Conflict of Interest

The authors have declared no conflicts of interest for this article.

REFERENCES

- Malangmeih L, Rahaman SM. Economics of fresh naga king chilli in Manipur, India-A case study. Int J Environ Ecol. 2016;6:151-162.

- Seth T, Lyngdoh YA, Chattopadhyay A, Sharangi AB, Mishra GP. Export of onion, garlic and chilli: Three essential spices in daily kitchen. In Indian Spices. Springer, Cham. 2018:359-378.

- Tiwari A, Kaushik MP, Pandey KS, Dangi RS. Adaptability and production of hottest chilli variety under Gwalior agro-climatic conditions. Curr Sci. 2005;88:1545-1546.

- Gayathri N, Gopalakrishnan M, Sekar T. In vitro micropropagation of Capsicum chinense Jacq. (Naga King Chili). Asian J Plant Sci Res. 2015;5:13-18.

- Kehie M, Kumaria S, Devi KS, Tandon P. Genetic diversity and molecular evolution of Naga King Chili inferred from internal transcribed spacer sequence of nuclear ribosomal DNA. Meta gene. 2016;7:56-63.

- Bhutia KL, Bhutia ND, Khanna VK. Rich genetic diversity of capsicum species in northeast India, as a potential source for chilli crop improvement. J Agric Forest Meteorol Res. 2019;2:77-83.

- Baruah S, Zaman MK, Rajbongshi P, Das S. A review on recent researches on Bhut jolokia and pharmacological activity of capsaicin. Int J Pharm Sci Rev Res. 2014;24:89-94.

- Meghvansi MK, Siddiqui S, Khan MH, Gupta VK, Vairale MG, Gogoi HK, et al. Naga chilli: a potential source of capsaicinoids with broad-spectrum ethnopharmacological applications. J Ethnopharmacol. 2010;132:1-4.

- Verma PK, Rawat KK, Das N, Pradhan B. A botanical enigma of India’s hottest chilli Bhoot Jolokia (Capsicum chinense Jacq). New York Sci J. 2013;6:49-51.

- Ghosh BC, Jayaraj RK, Balasubramanyam BV, Kulkarni S. Process standardization and shelf life evaluation of chhana podo. Indian J Dairy Sci. 2007;60:322-326.

- Lee J, Park SJ, Hong SC, Han JH, Choi D, Yoon JB. QTL mapping for capsaicin and dihydrocapsaicin content in a population of Capsicum annuum ‘NB 1’× Capsicum chinense ‘Bhut Jolokia’. Plant Breed. 2016;135:376-383.

- Amruthraj NJ, Raj JP, Lebel LA. Effect of vegetable oil in the solubility of capsaicinoids extracted from Capsicum chinense Bhut Jolokia. Asian J Pharm Clin. Res. 2014;7:48-51.

- Caterina MJ, Leffler A, Malmberg AB, Martin WJ, Trafton J, Petersen-Zeitz KR, et al. Impaired nociception and pain sensation in mice lacking the capsaicin receptor. Sci. 2000;288:306-313.

- Purkayastha J, Alam SI, Gogoi HK, Singh L. Capsicum assamicum sp. nov.(Solanaceae), from Assam, northeastern India. Ozean J Appl Sci. 2012;5:55-66.

- Sarpras M, Gaur R, Sharma V, Chhapekar SS, Das J, Kumar A, et al. Comparative analysis of fruit metabolites and pungency candidate genes expression between Bhut Jolokia and other Capsicum species. PLoS One. 2016;11.

- Gnayfeed MH, Daood HG, Biacs PA, Alcaraz CF. Content of bioactive compounds in pungent spice red pepper (paprika) as affected by ripening and genotype. J Sci Food Agric. 2001;81:1580-1585.

- Meetei NT, Singh AK, Mandal N. Production of virus free naga king chilli (Capsicum chinense Jacq.) by in vitro meristem tip culture. International Conference on Agriculture. 44-47.

- Oberoi HS, Ku MA, Kaur J, Baboo B. Quality of red chilli variety as affected by different drying methods. J Food Sci Technol. 2005;42:384-387.

- Moscone EA, Scaldaferro MA, Grabiele M, Cecchini NM, Sánchez GY, Jarret R, et al. The evolution of chili peppers (capsicum-solanaceae): a cytogenetic perspective. Acta Hortic. 2007;745:137-170.

- AOAC. Official Methods of Analysis. Association of Official Analytical Chemists (16th Edn), Washington DC. 2002.

- Dubey RK, Singh V, Upadhyay G, Pandey AK, Prakash D. Assessment of phytochemical composition and antioxidant potential in some indigenous chilli genotypes from North East India. Food Chem. 2015;188:119-125.

- Yam KL, Papadakis SE. A simple digital imaging method for measuring and analyzing color of food surfaces. J Food Eng. 2004;61:137-142.

- Kumari A, Eljeeva Emerald FM, Simha V, Pushpadass HA. Effects of baking conditions on colour, texture and crumb grain characteristics of Chhana Podo. Int J Dairy Technol. 2015;68:270-280.

- Kuna A, Sahoo MR, Sowmya M, Mayengbam PD, Dasgupta M, Sreedhar M, et al. Nutrient and antioxidant properties of value added king chilli (Capsicum chinense) products. Int J Curr Microbiol App Sci. 2018;7:1-8.

- Hossain SA, Pal PK, Sarkar PK, Patil GR. Quality of Dudh churpi as influenced by moisture content and drying conditions of Prechurpi. J Food Sci Technol. 2001;38:462-466.

- Popelka P, Jevinová P, Šmejkal K, Roba P. Antibacterial activity of capsicum extract against selected strains of bacteria and micromycetes. Potravinárstvo: Slovak J Food Sci. 2017;11:223-229.

- Zewdie Y, Bosland PW. Evaluation of genotype, environment, and genotype-by-environment interaction for capsaicinoids in Capsicum annuum L. Euphytica. 2000;111:185-190.

- Mangaraj S, Singh A, Samuel DK, Singhal OP. Comparative performance evaluation of different drying methods for chillis. J Food Sci Technol. 2001;38:296-299.

- Ananthan R, Subash K, Longvah T. Assessment of nutrient composition and capsaicinoid content of some red chilies. Int Food Nutr Technol. 2014;72:1-4.

- Liu Y, Nair MG. Capsaicinoids in the hottest pepper Bhut Jolokia and its antioxidant and anti-inflammatory activities. Nat Prod Commun. 2010;5:91-94.

- Howard LR, Smith RT, Wagner AB, Villalon B, Burns EE. Provitamin A and ascorbic acid content of fresh pepper cultivars (Capsicum annuum) and processed jalapenos. J Food Sci. 1994;59:362-365.

- El-Ishaq A, Obirinakem S. Effect of temperature and storage on vitamin C content in fruits juice. Int Journal Chem Biomol Sci. 2015;1:17-21.

- Fattorusso E, Taglialatela-Scafati O. Modern alkaloids: structure, isolation, synthesis, and biology. John Wiley and Sons, 2008.

- Nascimento PL, Nascimento TC, Ramos NS, Silva GR, Gomes JE, Falcão RE, et al. Quantification, antioxidant and antimicrobial activity of phenolics isolated from different extracts of Capsicum frutescens (Pimenta malagueta). Molecules. 2014;19:5434-5447.

- Topuz A, Ozdemir F. Influences of gamma irradiation and storage on the capsaicinoids of sun-dried and dehydrated paprika. Food Chem. 2004;86:509-515.

Citation: Kennao E, Kumari A, Singh M, Hossain SA, Das A, Wasnik PK, et al. (2020) Effect of Drying on Physicochemical Characteristics of Bhut Jolokia (Chilli Pepper). J Food Process Technol 11:823. doi: 10.35248/2157-7110.2020.11.823

Copyright: © 2020 Kennao E, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.