Indexed In

- Genamics JournalSeek

- Academic Keys

- JournalTOCs

- China National Knowledge Infrastructure (CNKI)

- Access to Global Online Research in Agriculture (AGORA)

- Centre for Agriculture and Biosciences International (CABI)

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- SWB online catalog

- Publons

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Research Article - (2025) Volume 16, Issue 1

Development and Shelf-Life Evaluation of Pasteurized BBQ Chicken Wings

Gullula Varma*Received: 28-Feb-2024, Manuscript No. JFPT-24-25040; Editor assigned: 01-Mar-2024, Pre QC No. JFPT-24-25040; Reviewed: 15-Mar-2024, QC No. JFPT-24-25040; Revised: 07-Apr-2025, Manuscript No. JFPT-24-25040; Published: 14-Apr-2025, DOI: 35248/2157-7110.25.16.1138

Abstract

This study aims to develop a value-added ready to eat chicken drumette and flab using barbecue sauce. Four experimental groups were made: 780 g, 790 g, 800 g of barbecue sauce and formulation without barbecue sauce taken as control. The drumette, flab and marinade were mixed in a 3:1 ratio for better results and kept aside for resting. The marinated chicken drumette, flab was prepared using conventional oven cooking methods at a temperature of 180? For 15 min. The sensory parameters were evaluated for the cooked product, while the proximate analysis was done for the raw product. The formulation with 790 g of barbecue sauce (T2) had scored as best with the overall acceptability of 8.82. The shelf-life studies for the best accepted marinated chicken drumette were performed through sensory, proximate and microbial analysis for one week during the storage period at a temperature of 4? There was a significant (p<0.05) decrease in the appearance, flavor, taste, overall acceptability and moisture of the T2 sample during the storage period of one week at 4? While protein, fat and ash were the increasing pattern. The results of the microbial analysis showed the presence of microbial growth during the storage period of one week at a temperature of 4, which was below the standard limits. Hence through the present study, a new variant of chicken drumette and flab was developed with a shelf life of 6 days at refrigeration conditions.

Keywords

Chicken drumette; Flab; Barbecue sauce; Marination; Sensory; Proximate; Microbial

Introduction

Poultry is one of the fastest-growing segments of the agricultural sector in India today. The production of eggs and broilers has increased at a pace of 8 to 10 percent annually, compared to the 1.5 to 2 percent annual growth of crop. As a result, India is now the world's third egg producer in the world. The Potential in the sector is due to a combination of factors-growth in per capita income, a growing urban population and falling real poultry prices. Poultry meat is the fastest-growing component of global meat demand and India, the world's second-largest developing country, is experiencing rapid growth in its poultry sector. In India, poultry sector growth is being driven by rising incomes and a rapidly expanding middle class, together with the emergence of vertically integrated poultry producers that have reduced consumer prices by lowering production and marketing costs. Integrated production, the market transition from live birds to chilled and frozen products and policies that ensure supplies of competitively priced corn and soybeans are keys to future poultry industry growth in India. There are several small poultry dressing plants in the country. These plants are producing dressed chickens. In addition to these plants, five modern integrated poultry processing plants are producing dressed chicken, chicken cut parts and other chicken products. These plants will manufacture egg powder and frozen egg yolk for export [1].

Areas of production

Overall, Tamil Nadu counts for maximum egg production. In Andhra Pradesh, Hyderabad is the city with maximum poultry and hatcheries. Besides the state of Andhra Pradesh, Vishakhapatnam, Chittoor, Karnataka, Tamil Nadu, Maharashtra, Gujarat, Madhya Pradesh, Orissa and the Northeastern States are the major egg contributors.

Meat: This term refers to the muscles of animals that are consumed as food. This broad definition also includes the internal organs of animals utilized for food. Cattle, sheep, pigs and poultry, the latter of which is dominated by chicken, are the most prevalent animals bred for meat globally.

Meat is a high-quality protein source that contains all essential amino acids and highly bioavailable minerals and vitamins. Meat is high in vitamin B12 and iron, which are scarce in vegetarian diets. Meat is thought to be a good source of vitamins, protein and energy.

Poultry: All domesticated birds kept for meat are referred to as poultry. Although chickens are the most popular poultry, turkeys, ducks, geese, guinea fowls and pigeons are also popular (Table 1).

| Vitamin | Boiler | Turkeys |

|---|---|---|

| Vitamin A | 41.00 mg | 2.00 mg |

| Vitamin B1 | 0.06 mg | 0.06 mg |

| Vitamin B2 | 0.12 mg | 0.16 mg |

| Vitamin C | 1.60 mg | Nil |

| Vitamin B6 | 0.35 mg | 0.41 mg |

| Vitamin B12 | 0.31 mg | 0.40 mg |

Table 1: Vitamins (Per 100 g edible portion).

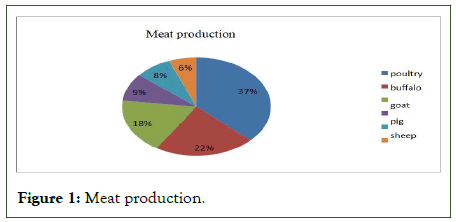

Chicken: Chicken is a good source of protein since it contains most of the essential amino acids, a lot of unsaturated fatty acids, low cholesterol and vitamins like A, B12, as well as minerals like iron, selenium and folic acid, all of which are important for the human body (Figure 1 and Table 2).

Figure 1: Meat production.

| Parameters | Breast boneless skinless | Boneless with skin | Thigh skin less | Thigh skin | Wings | Whole chicken (with skin) |

|---|---|---|---|---|---|---|

| Calories | 165 | 197 | 209 | 229 | 203 | 239 |

| Protein (g) | 31 | 30 | 26 | 25 | 30 | 24 |

| Total fat (g) | 3.6 | 7.8 | 10.9 | 15.5 | 8.1 | 13.4 |

| Saturated fat (g) | 1 | 2.2 | 3 | 4.3 | 2.3 | 3.7 |

| Monounsaturated fat (g) | 1.2 | 3 | 4.1 | 6.1 | 2.6 | 5.4 |

| Polyunsaturated fat (g) | 0.7 | 1.7 | 2.5 | 3.4 | 1.8 | 2.9 |

| Cholesterol (mg) | 85 | 84 | 95 | 93 | 85 | 76 |

| Sodium (mg) | 74 | 71 | 88 | 84 | 92 | 73 |

| Iron (mg) | 1 | 1 | 1.3 | 1.3 | 1.2 | 1.3 |

Table 2: Nutritional values for cooked chicken.

BBQ wings: BBQ wings, short for barbecue wings, are a popular and mouthwatering dish enjoyed by people all over the world. These delectable morsels of poultry, typically made from chicken wings, are known for their irresistible combination of smoky, sweet and savory flavors. Whether served as an appetizer, snack or main course, BBQ wings are a crowd-pleaser that can elevate any meal or gathering.

The origins of BBQ chicken wings can be traced back to the United States, particularly the southern region. Barbecuing and grilling meat has been a long-standing tradition in American cuisine and chicken wings, which were once considered an inexpensive and often overlooked part of the chicken, found their way into the world of barbecue. The transformation of chicken wings from humble beginnings to a beloved culinary delight can be attributed to the creative genius of American chefs and grill masters [2].

The magic of BBQ wings lies in the rich and flavorful barbecue sauce that coats them. This sauce is a harmonious blend of ingredients like tomato paste, molasses, vinegar, spices and sometimes a hint of sweetness from ingredients like brown sugar or honey. The sauce is generously applied to the wings, which are then grilled, smoked or baked to perfection. This cooking process not only infuses the wings with the smoky essence of the grill but also caramelizes the sauce, creating a tantalizing, sticky glaze.

BBQ wings come in various styles and regional variations, each with its unique twist on the classic recipe. Whether you prefer the tangy, vinegar-based sauces of the Carolinas, the sweet and smoky flavors of Kansas City, or the spicy kick of Texas-style barbecue, there's a BBQ wing flavor profile to suit every palate.

These savory treats are often served with complementary side dishes like coleslaw, they are equally at home at a backyard barbecue, sports bar or a cozy family dinner. The act of enjoying BBQ wings can be a messy yet delightful experience, as diners savor every bite while licking their fingers clean.

In this introduction, we've barely scratched the surface of the world of BBQ wings, a dish that has earned its place as a beloved and iconic part of the global culinary landscape. Whether you're a fan of the classics or an adventurous foodie looking to explore new flavors, BBQ wings offer a tantalizing journey for your taste buds that's hard to resist. So, roll up your sleeves and prepare for a delicious adventure with BBQ wings [3].

Chicken wings have become a successful example of economically processed poultry products, due to their cheap price. From a chicken, wings contribute 5% of the total meat. The whole chicken wing is an all-white meat portion composed of three sections (Figure 2).

- Drumette

- Flat/Wingate

- Tip

Figure 2: Chicken drummet and flat

Two joints connecting three sections are identified visually. Wing is bend in two places which corresponds to each joint and bent back manually and later cut in to drumette, flat and tip. For making of BBQ chicken, wings will we have to collect without skin birds?

Objectives

- Development of pasteurized BBQ chicken wings.

- To determine physio chemical properties characteristics of BBQ chicken wings.

- To determine shelf-life study of products by microbial analysis.

This chapter deals with the research findings of earlier researchers critically examined with references to the objective of the present investigation.

Febrianta et al., investigated parameters like physical, chemical, oxidative stability, antioxidant potential, pathogenic bacteria and sensory evaluation of chicken breast marinated with microencapsulation of turmeric extract on the first, third, sixth, ninth and twelfth days of storage at 4°C.

Ab Aziz et al., studied the effects of different storage temperatures and times on a broiler chicken pectoralis major muscle's physical, chemical and microbial properties. He reported that as the storage temperature drops, there is a significant increase in drip loss and cooking loss. Similarly, storage duration significantly affected cooking loss, on samples stored for 72 hr exhibiting greater cooking loss than those stored for 24 hr.

Obajuluwa et al., conducted a study on the effects of four unconventional marinades on beef quality (Pawpaw leaves extract, lime juice, carbonated drinks and distilled water). In a complete randomized design, 1500 g of beef excised from the thigh muscle was cut into twelve whole pieces of similar size and randomly distributed into four experimental groups (CRD).

Ortega-Heras et al., had formulated low-salt marinated chicken breasts with seasonings made from red grape skins.

Gomez et al., studied the effects of processing and preservation technologies on the sensory and nutritional properties of meat products He proposed that the combination of various processing and preservation methods yields good sensory quality results; thus, more research into combinations of different techniques is required to ensure that the nutritional value of meat is not compromised.

Prabakaran et al., surveyed meat. They found that poultry is raised in a variety of agro-ecological zones and production systems around the world and under various economic regimes.

Incilia et al., investigated the effects of homemade marinades made with natural ingredients found in most restaurants and households on Salmonella typhimurium, Listeria monocytogenes, and the most natural microbiota of chicken products like wings, drumsticks and breast meat.

Gomez et al., studied the RTE products made from beef and meat analog had been marinated (teriyaki and beer) were sousvide cooked at varying temperatures (70°C and 80°C) and times (60, 90, and 120 minutes for beef; 90, 120 and 150 minutes for meat analog). Cooking sous vide at 80°C resulted in fewer cooking losses.

Jeong et al., studied the effects of marinade on pork ham-cooked sous-vide under various conditions. The non-marinade pork ham was served as the control group [4]. Raw meat had total viable and coliform counts of 84.6 and 3.67 Log CFU/g, respectively. The total viable counts decreased after the addition of marinade to 3.00–14.67 Log CFU/g. Coliforms were not found.

Lytou et al., studied that pomegranate juice is a product with enhanced functional properties that could be used as an alternative to traditional marinating ingredients to effectively reduce microbial growth with a better sensory result.

Lytou et al., conducted an experiment in which lemon juice, apple cider vinegar, pomegranate juice and combinations of these ingredients were used to make five different marinades. Three different temperatures (4°C, 10°C and 20°C) were investigated, as well as five different marinating time intervals (1, 3, 6 and 9 hours).

Kanchi et al., studied the shelf life of chicken samosas made with broiler chicken (aged 8 weeks). The chicken samosa recipe was standardized and the product was vacuum-packed and aerobically packaged in LDPE and stored at 4°C. In chicken samosa packed under various packaging technologies, the storage term caused substantial variations in pH, TBA value and total plate count.

Mathew et al., studied the effect of vacuum-packaged chicken shelf life at various storage temperatures and with various LDPE packing materials. The experiment lasted 60 days and the results were analyzed for chemical and microbiological characteristics. At freezing temperatures, vacuum packaging significantly slowed the growth of microbial deterioration and protein and fat levels gradually decreased.

Dogu-Baykut and Gunes, studied the effects of different packaging circumstances on the quality of marinated chicken drumsticks held at 4°C. MAP reduced yeast and mold counts, as well as lactic acid bacteria and total viable counts. Reduced O2 and higher CO2 in the packaging hindered oxidation.

Istrati et al., studied the effects of marinating fresh beef slices in marinades made of dry red wine, lime-tree honey, salt, spices and seasoning plants such as thyme, marjoram, garlic and horseradish. Meat pieces were vacuum-packed and stored at 4°C for 12 days after marination. The experiments showed that marinating weakens the structure of beef meat, resulting in an improvement in the functional properties of adult beef.

Komoltri and Pakdeechanuan, studied that marinating of the meat directly affects the texture and flavour and is important for the product yield. The study investigated the effects of various marinating solutions on the physical, chemical, microbiological and sensory properties of golek chicken, a popular dish in Malaysia, Indonesia and southern Thailand.

Silina et al., experimented with how venison in a mayonnaise or vinegar marinade changed its colour (using CIE L*, a*, b* values) and softness over time. The marinated meat was placed in polypropylene trays, hermetically sealed with a high-barrier polymer film under a modified environment (CO2 40%+N2 60%) and iron-based oxygen scavenger sachets were placed in the packages. Venison sealed in air ambiance was utilized as a control. The color of the marinated venison (L*, a* and b* values) varies amongst venison samples treated with various marinades. In all packages, shear force readings tended to decrease as storage time increased regardless of marinade type [5].

Tomaszewska-Gras and Konieczny, investigated the influence of several marinades on the thermal stability of collagen. Imitation marinades, marinades created according to original recipes and ready-to-use marinades were employed in industrial practice to marinate chicken wings.

Yusop et al., evaluated the instrumental and sensory qualities of cooked Chinese-style marinated chicken about marinating time (30, 60, 120 and 180 minutes) and acidic marinade pH (3.0, 3.2, 3.4, 3.6, 3.8, 4.0 and 4.2). A significant increase in flavor is obtained by increasing the marinating period to 180 minutes.

Bjorkroth, studied those marinated meats are becoming more popular. In addition to flavour, marinating has become necessary to improve product sensory attributes and shelf life. Marinades that are complex and made from spiced sauces from Finland. They are acidic water-oil emulsions with salt, sugar, sorbate and benzoate.

Scott ML, reported that chicken is a great source of protein, which contains essential amino acids, fats, vitamins that are essential for hiren body chicken wings contain about 7.3% fat.

Lawrie RA, reported that chicken is usually cut into chicken breast, thigh, drumstick, whole leg, curry cuts. Chicken meat is rich in protein and has low content of carbohydrate. Chicken product utilization brings commercial value and should be able to decrease the wastage.

Gault, reported that marination of meat improves the tenderness. This process improves the water holding capacity of meat and juiciness. Immersion, injection and tumbling are the methods involved in marination.

Hedrick et al., reported that for brining meat, the most common ingredient used is salt as it dissolves in water and thus increases the ionic strength of water. As the mechanism of tenderization of meat involves uptake of liquid, this results in the juiciness of meat.

Shelly McKee and Christine Alvarado reported that salt is included in brining meat because it increases the flavour and increases the moisture retention capacity. The effects of brining on the sensory properties of the meat were good. Brining increased the perception of saltiness, sweetness, juiciness and overall flavour.

Mark Krasnow, reported that brining also increased sensory attributes of the meat. Differences between the low-sodium brine and the high-sodium brine were not the same. Saltiness perception was drastically increased in the high sodium brined meat compared to low sodium brined meat [6].

Gillett et al., reported that meat products that were messaged are having improved. Weight, colour and moisture retention compared to that are not massaged. And so as tumbling is used for the brine injected meats to improve the meat quality. Brined meat had great tenderization effect when compared to unbrined meat as the thear force of unbrined meat is increased.

M. Zell et al., reported that uniform ohmic cooking of whole meats is achieved to the brined meat which is designed to ensure an even se distribution in the meat. Using a procedure multipoint designed followed by optimized tumbling, it is possible to cook whole muscle by ohmic heating to produce good quality meat products.

Mani-Lopez et al., reported that smoking as a food processing method during ancient days has made significant contributions for ensuring food safety as a cheap and effective way for preserving food commodities liquid smoke flavour is used as a replacement for traditional smoking method as it reduces environmental pollution.

Hai Li, et al., flavour compounds such as chili marinade, vinegar, black pepper, mexican seasoning gives sensory scores that are high. Studies shows that, volatile flavor compounds that are used for marinating meat have more advantages in quality and sensory.

Nithin CT, et al., reported that antimicrobial efficacy of vinegar for growth inhibition of mesophilic and lactic acid bacterial counts and enhancement of shelf life. It is used in meat products to slow down the growth rate or microorganisms. It also retains the shelf life of cut meats.

Beuchat L, et al., reported that standard plate count method is very effective compared to Sim plate method as it would not have any effect on TPC test. The number of colonies formed in each dilution of sample is represented as the colonies formed per unit of sample.

Materials and Methods

This chapter deals with the details of material produced and the method used for processing and analysis.

Procurement of raw materials

Chicken raw meat is procured from industry, delightful Gourmet Pvt. Ltd and other raw materials from Bangalore. List of raw materials used pasteurized BBQ chicken wings. Raw materials selected for these products were:

- Raw chicken without skin drummet and flat

- Tomato ketchup

- Pineapple juice

- Apple cider vinegar

- Water

- Brown sugar

- Tabasco sauce

- Worcestershire sauce

- Black pepper crushed

- Vinegar

- Iodized salt

- Smoke flavor

- Onion powder

- Garlic

- Lemon juice

Raw materials used for processing of pasteurized BBQ chicken wings

Meat: Fresh, cleaned chicken wings were a primary ingredient for a BBQ chicken wings. It gives structure and palatability to the product. It increases nutritional value by increasing the protein content. That wing part is cut into two parts, one is a flat wing and another one is a drumette. Drumette and flat was packed in Low-Density Polyethene (LDPE) pouch. Later, they are stored at 0°C to 4°C.

Salt: Salt, specifically Sodium Chloride (NaCl), is vital in foods for various reasons, including sensory appeal, processing technology and preservation. Salt is widely used as a flavoring agent and a food preservative in commercial and home cooking. Salt is involved in the prevent microbial growth in food.

Apple cider vinegar: It generally consists of 4%-7% acetic acid and 93%-96% water. It acts as a natural preservative and it may aid weight loss, lowers blood sugar and cholesterol.

Tabasco sauce: Tabasco is an American brand of hot sauce made from tabasco peppers, vinegar and salt. It is produced by McIlhenny Company of Avery Island in south Louisiana.

Worcestershire sauce: It is used as flavoring in stews and is one of the key ingredients in a Bloody Mary cocktail. It is also used in some Caesar salad recipes and improves cheese on toast immeasurably.

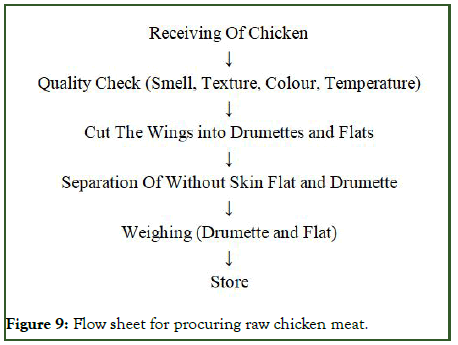

Smoke flavor: As an alternative to traditional smoking, smoke flavorings may be added to foods to give them a smoky flavor (Figures 3-9 and Table 3) [7].

Figure 3: Weighing machine.

Figure 4: Brining machine.

Figure 5: Tumbler.

Figure 6: Oven.

Figure 7: Filling conical.

Figure 8: Refractometer.

| S. no | Name of the equipment | Capacity |

|---|---|---|

| 1 | Weighing machine | 15 kg |

| 2 | Brine injector | 20 kg |

| 3 | Tumbling machine | 15 kg |

| 4 | Oven | 20 kg |

| 5 | Mixer | 0.500 kg |

Table 3: Name of the equipment with capacity.

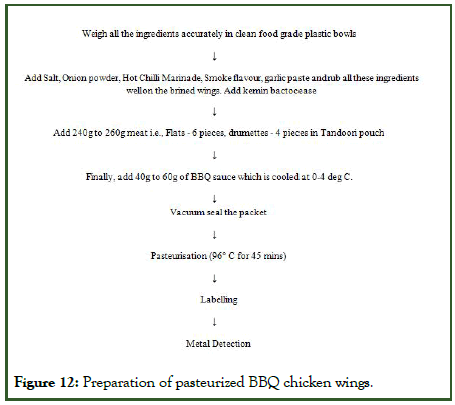

Figure 9: Flow sheet for procuring raw chicken meat.

Raw materials that are slaughtered, fresh and maintained 4°C temperature is procured from vendor. These are received by checking the quality of meat such as color which should be in white to pale pink, tender texture, smell should be light bloody and temperature shall be maintained 4°C. These raw materials are mechanically cut the wings into drumette and flat [8].

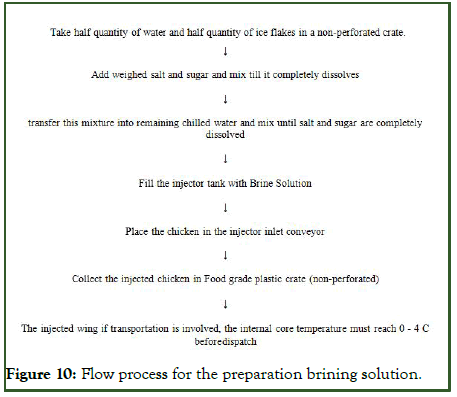

Preparation of brining solution

Requirements:

- Sugar: 200 g

- Salt: 50 g

- Chilled water: 1 lit

- Ice flakes: 1 kg

Preparation: Sugar and salt 1:4 ratio is mixed with 1 lit of chilled water, when mixing is completed the ice flakes are added to maintain the temperature instead of normal water. This brining solution is fed into the brining injector where chicken is passed on a conveyor and been injected with injecting needles (Figure 10).

Figure 10: Flow process for the preparation brining solution.

Preparation of pineapple juice

Pineapple juice is made from the queen variant. This is used in the preparation of BBQ sauce for BBQ chicken wings. Intended use for flavoring in BBQ chicken wings.

- Whole pineapple is taken and then washed, peeled (with clean knives), cutting into pieces, grinding with the use of a mixer.

- Straining/filtration of pulp with use of muslin cloth.

- Final strained juice (10â??-13â?? Brix).

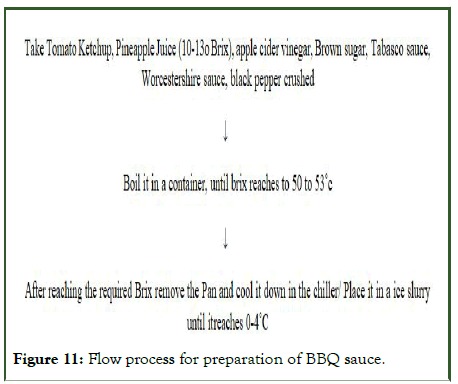

Preparation of BBQ sauce

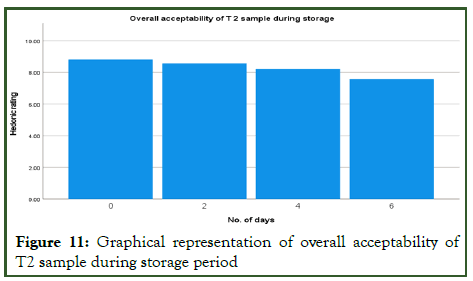

Used as either a dipping sauce, glaze on products before grilling, stir fry, marinade or adding to a meal. Intended use for flavoring in BBQ chicken wings. Not suitable for vulnerable groups (Table 4 and Figures 11 and 12) [9].

Component list

- Tomato ketchup

- Fresh pineapple juice (strained)

- Apple cider vinegar

- Brown sugar

- Tabasco sauce

- Worcestershire sauce

- Black pepper crushed

Figure 11: Flow process for preparation of BBQ sauce.

Figure 12: Preparation of pasteurized BBQ chicken wings.

<

| Ingredients | Control (g) | T1 (g) | T2 (g) | T3 (g) |

|---|---|---|---|---|

| Brined flat wings without skin | 1050 | 1050 | 1050 | 1050 |

| Brined drummets wings without skin | 1220 | 1220 | 1220 | 1220 |

| Salt | 7 | 7 | 7 | 7 |

| Lemon juice | 5 | 5 | 5 | 5 |

| Hot chilli marinade | 3 | 3 | 3 | 3 |

| Garlic paste | 8 | 8 | 8 | 8 |

| Onion powder | 5 | 5 | 5 | 5 |

| Smoked flavour (pb24) | 7 | 7 | 7 | 7 |

| Barbeque sauce | - | 680 | 690 | 700 |

| Kemin bactocease | 13 | 13 | 13 | 13 |

Table 4: Analysis of developed formulations.

Process of packing method

- Weighing all ingredients and marinated with wings.

- Take LDPE packing cover and band seal the pack.

- Pasteurization (96°C for 45 mins).

- Labeling

- Pass the sample through the metal detector.

- Place it in the FG chiller (0°C-4°C) (Tables 5 and 6).

| Packing material | Details |

|---|---|

| Inner packing | LDPE package |

| Label | As per approved nutritional standards |

| Coding | Date of manufacture: Batch no.: |

Table 5: Packing information.

|

Attribute |

Target |

Min |

Max |

|

No of pcs per packet |

10 |

10 |

10 |

|

Flats |

6 |

6 |

6 |

|

Drumettes |

4 |

4 |

4 |

Table 6: Weight dimensions flat and drummet.

Sensory examination

Organoleptic quality of foods in general terms is the combination of all our senses of a perception coming together when choosing and consuming a food product. The pasteurized BBQ wings analysis was conducted at the sensory evaluation chamber at Licious, by semi-trained panels. After the preparation marinade BBQ sauce is added and vacuum sealed the product and kept in Oven for 45 minutes at 96°C and the attributes like appearance, flavor, texture, juiciness, taste and overall acceptability were evaluated to decide the acceptance of the food. The formulations were given sensory scores based on the 9-point hedonic scale (Table 7) [10].

| Attributes | Description |

|---|---|

| Appearance | |

| Brown | Light brown=0, Golden brown=9 |

| Flavor | |

| Spicy | Poor=0, Extremely good=9 |

| Texture | |

| Soft-Firm | Poor=0, Extremely good=9 |

| Juiciness | |

| Dry-Juicy | Poor=0, Extremely good=9 |

| Taste | |

| Spicy | Poor=0, Extremely good=9 |

| Overall acceptability | Extremely unacceptable=0, |

| Extremely acceptable=9 | |

Table 7: Methodology of sensory evaluation and limits.

Physico-chemical analysis

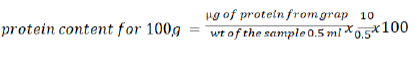

Determination of total protein: Take a sample with a known weight/volume (10 mg) and dissolve it in a known volume of water (10 ml). Fill 5 test tubes with 0.1 ml to 0.5 ml of the standard protein solution. Pipette 0.5 ml of the unknown sample into each of the two test tubes (duplicates). To each tube, add 0.5ml of alkaline copper reagent. Mix everything and set aside for 10 min. 2 ml phenol reagent, quickly added to each tube and mixed. Heat for 5 min in a water bath at 55°C. Cool under running water and compare the absorbance to a blank at 650 nm. Draw a standard curve by charting the standard concentration on the x-axis and the absorbance on the y-axis. Calculate the amount of protein in the sample using the graph [11].

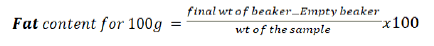

Determination of crude fat: The Soxhlet technique can be used to estimate fat. Weigh 2 to 5 g of sample, depending on fat content, then roll in a sheet of filter paper to produce a sample packet of varied samples into the Soxhlet equipment' extractor flask. After putting some absorbent cotton at the bottom of the container. Add organic solvent one and a half times the capacity of the extractor and the extracted lipid for 6 hours at a condensation rate of 5-6 droplets per sec or until the solvent in the extractor flask becomes colorless after adding some absorbent cotton at the bottom. After that, turn off the heaters and let the room drop down to normal temperature. Remove the sample packets from the freezer and place them at room temperature for a few min to remove the solvent. Store the defatted sample in desiccators.

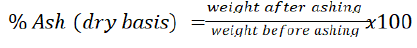

Determination of ash: Ash is the inorganic residue left after water and organic materials have been removed from the food by heating in the presence of oxidizing agents and it serves as a measure of the overall amount of minerals in the food. Chicken products should be dehydrated. Put the sample in a Muffle furnace with water (550°C-600°C) to vaporize volatile compounds and burn organic molecules. Oxides, phosphates, chlorides and silicates are generated from we minerals.

Determination of pH: A direct probe method was used to determine the pH of the surface of fish cubes, using a pH meter with a flat probe electrode. Every batch had its pH meter probe calibrated and standardized (using pH 4.00 and pH 7.00 buffer solutions). Fresh cubes, marinated popcorn and marinated popcorn after 24 hours of storage following marinating were all tested for pH. Measurements were taken three times.

Determination of total moisture: The total moisture content was determined using a hot air oven. On the petri dish, about 5 g-10 g of sample was weighed. For the typical drying cycle, the temperature was set at 105°C for 3 to 4 hours [12]. Fresh cubes, marinated popcorn and marinated popcorn after 24 hours of storage after marinating were all given total moisture values.

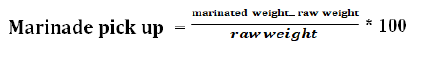

Marinade pick up: In this method, samples were weighed before and after marinating. The excess marinade was carefully drained off by applying a paper towel to the sample surfaces.

Microbial analysis

Microbial analysis of the sample was done on 0th day, 2nd day, 4th day and 6th day microbial evaluation of product follows different parameters:

- Total plate count

- Yeast and mold test

- Escherichia coli test

- Salmonella test

- Staphylococcus aureus

Total plate count media and reagents:

- 0.1% peptone water/phosphate buffer/peptone salt solutiondiluent and dilution tubes.

- Plate Count Agar (PCA)-media.

Procedure: In sterile stomacher bags, 10 g of meat samples were homogenized for 2 minutes in 90 ml of sterile buffered peptone water (10-1). Serial dilutions from the stomached samples were made using 9 ml peptone water blanks, based on our assumptions about the amount of the microbial population (10-2).

The dilutions ranged from 10-3 to 10-5. One cc of each dilution was aseptically dispensed onto separate, duplicate petri dishes using a pipette and sterile tips. With a circular and side-to-side motion of plates on a flat level surface, 12 to 15 ml of plate count agar (tempered-heated and held at 45â?? in the liquid state) was aseptically poured over (pour-plate method) and completely and uniformly mixed.

Once the agar plates had solidified, they were inverted and incubated for 482 hours at 35°C. The colonies were counted using standard counting protocols, with the findings expressed in colony forming units per milliliter (cfu/ml). A negative control plate was produced for each set of food items investigated by pouring 1 ml of peptone water blank onto duplicate petri plates and then adding plate count agar as directed above [13].

Counting colonies: Select plated containing 15-300 colonies. Calculate the cfu/g or by multiplying the average count with the dilution factor.

Calculation

Cfu/g=Sum of colonies/((n1+0.1n2) × d)

N1=the number of dishes retained in the 1st dilution

N2=the number of dishes retained in the 2nd dilution

D=the dilution factor corresponding to the first dilution

Yeast and mold test materials and equipment

- Basic equipment (and appropriate techniques) for preparation of a food

- Equipment for plating

- Incubator set at 22°C-25°C

- Arnold steam chest

- pH meter

Media and reagents

- Potato dextrose agar (M114), commercially available in dehydrated form

- Potato dextrose-salt agar (M114). The same medium as above was amended with 75 9 NaCI. This medium requires 20 9 agars rather than 15 g agar per lifer.

- Malt extract agar (M78), commercially available in dehydrated form

- Plate count agar (standard methods) (M112)

- Tartaric acid solution, 10%, sterile

- Antibiotic solution (s)

Procedure: Dilute 19.5 gm of PDA in 500 ml of distilled water sterilize in an autoclave at 101â?? 15 lbs pressure for 15 min.

Spread plate method: Fill 15 ml-20 ml of PDA into sterile petri plates and set them to solidify. After the meat sample has solidified, place 1 ml of the diluted meat sample on the agar plates, allow it to harden and then close the lids. Incubate the plates for five days at room temperature in an incubator. After a few days, count the colonies and keep track of the total.

Calculation

Cfu/g=sum of colonies/((n1+0.1n2) × d)

N1=the number of dishes retained in the 1st dilution

N2=the number of dishes retained in the 2nd dilution

D=the dilution factor corresponding to the first dilution

Salmonella: 25 g of samples were placed in sterile stomacher bags, harmonized for 2 min in 225 ml of sterile buffered peptone water and pre-enriched at 35°C-37°C for 24 hrs. After that, 1 ml of the pre–enriched culture was transferred to Fluid Selenite Cysteine Medium (FSCM) and incubated at 35°C-37°C for 18-24 hrs. In a separate experiment, 0.1 ml of the pre-enriched culture was added to 10 ml of Rappaport Vasiliadis Soy (RVS) broth and incubated for 18 to 24 hours at 41°C.

Following incubation, the enriched sample is properly mixed with the contents of the tube using vortexing or other similar methods. Apply a 10 ul loopful of inoculums to BGA (Bright Green Agar with phosphates) and either XLD (Xylose-Lysine Deoxycholate) agar plates. Use a single sample enrichment to cover the entire agar plate. Incubate for 18-24 hours at 35°C. Choose colonies that are usual [14].

Reagents and media: Rappaport Vassiliadis medium (Hi Media M880: In 1000 mL purified/distilled water, dissolve 49.17 g. If required, heat the medium to entirely dissolve it. Fill tubes as required and sterilise by autoclaving for 15 minutes at 10 lbs pressure (115°C).

Xylose-Lysine Deoxycholate agar (XLD agar (Hi-Media M031F: In 1000 mL distilled water, dissolve 56.93 g. Heat, stirring often, until the medium boils. Do not overheat or autoclave. Transfer to a 50°C water bath right away. Pour into sterilized petri plates after chilling.

Brilliant green agar medium Hi-Media MU016: In 1000 mL purified/distilled water, dissolve 58.09 g. To dissolve completely the medium, bring to a boil. Autoclave for 15 min at 15 pounds pressure (121°C). Prevent overheating.

Picking colonies: After the required incubation period has passed, examine the differential agar plates and standards for the presence of spore colonies that fit the salmonella colony description.

Pick well-isolated colonies brilliant green agar: Select colonies that are pink and opaque with a smooth appearance and borders that are covered with red color in the media on brilliant green agar. Look for colonies with a tan appearance and a green background on every busy plate. Choose black colonies that have (H2S-positive) or (H2S-negative) black cores or red colonies that have (H2S-positive) or (H2S-negative) black centers. The colony's rim may still be yellow in 24 hours, but it should turn red. Three colonies from each plate, if available. Pick just from the surface and middle of the colony.

Staphylococcus aureus: Pour 12 ml-15 ml of Baird Parker agar in a petri dish. Allow it to set. Pipette out 0.1 ml of sample (suspension-10-1) on a preset plate of agar. Ensure uniform spreading with the help of an L-shaped glass spreader. Incubate the plates at 37°C for 24 to 30 h. Observe the colonies at the end of the incubation period. A clear zone and grey-black colonies are observed.

Reagents and media: Baird Parker agar base (Hi-Media M043): In 950 mL purified/distilled water, dissolve 63.0 g. Bring to a boil to completely dissolve the medium. Autoclave at 15 lbs pressure (121°C) for 15 minutes to sterilize. Cool to 50°C before.

In 1887, Escherichia discovered the bacteria now known as Escherichia coli in human feces. A few other researchers proposed using E. coli-related organisms as indicators of the presence of enteric pathogens in water and food. E. coli is non-sporulation, gram-negative and facultative anaerobic. Rod-shaped cells are the most common type.

E. coli strains can create toxins that are potentially fatal. E. coli food poisoning is most commonly caused by eating unclean vegetables or raw meat. Gastroenteritis, urinary tract infections and newborn meningitis can all be caused by virulent E. coli strains.

Media and reagents

- 0.1% peptone water/phosphate buffer/peptone salt solutiondiluent

- Nutrient broth/agar

- MacConkey Broth (MCB)/Agar (MCA)

- EMB agar

- Tryptone water

- MR-VP medium

- Phenol red broth base

- Carbohydrates-lactose, sucrose

Procedure: Using a sterilized loop, all presumptive-positive LST broth tubes from coliform testing were transferred aseptically into E. coli broth (EC) tubes connected with Durham tubes.

EC tubes were inspected for gas production in the Durham tubes after incubation at 45.5°C (0.2°C) for 48 hours (2 hours) [15]. Using the MPN table supplied in the standardized protocol, an MPN for fecal coliforms was calculated.

Positive EC tubes were streaked with a sterile loop on Eosin Methylene Blue (EMB) agar and incubated at 35â?? (2â??) for 24-48 hours. Due to the fermentation of lactose, Escherichia coli colonies were distinguished by their typical green metallic shine.

Potentially positive plates were subculture on plate count agar plates before being tested for E. coli biochemically using IMViC assays (Indole, methyl red, voges proscaure and citrate).

Positive results are demonstrated by the profiles - + - - and + + - -. At this stage, E. coli count was obtained using the same MPN. Table 8 described for total coliforms count.

| No. | Parameter | Standard limit (cfu/g) |

|---|---|---|

| 1 | Total plate count | 10000 (cfu/g) |

| 2 | Yeast and mold count | 100 (cfu/g) |

| 3 | Escherichia coli | 100 (cfu/g) |

| 4 | Salmonella | Absent in 25 g |

| 5 | Staphylococcus | 100 (cfu/g) |

Table 8: Standard limits for all the microbial tests (FSSAI).

Statistical analysis

Using SPSS 28.0.0(190), the generated data were analyzed using an ANOVA one-way test. Duncan's multiple range tests and Mann-Whitney U were employed for physicochemical and sensory quality, respectively. The data were analyzed with Microsoft Excel 2010 and expressed as mean and Standard Deviation (SD).

Results and Discussion

The results obtained from work “Development and shelf-life evaluation of pasteurized BBQ chicken wings” are presented in this chapter.

Sensory evaluation of pasteurized BBQ chicken wings

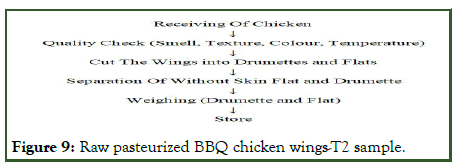

The developed formulations for the pasteurized BBQ chicken wings (Figure 9) were cooked by the conventional method at 180â?? for 10-15 minutes on the analysis day and attributes were observed. Freshly prepared formulations (Figure 10) were used for the analysis. The sensory attributes of all the products, both control and trail samples, were well accepted by the panelists. The highest score of the sensory evaluation was for pasteurized BBQ chicken wings of trial 2. The lowest score was for control without the addition of barbecue sauce. The sensory profile was close to the findings of Lytou, who reported that usage of pomegranate juice as marinade solution increased the sensory properties of chicken meat [16]. Sensory evaluation was done to compare the quality of different trails of pasteurized BBQ chicken wings developed with barbecue sauce and control sample without barbecue sauce. The results obtained from the sensory evaluation with and without the addition of barbecue sauce in pasteurized BBQ chicken wings are shown in Table 9.

Figure 9: Raw pasteurized BBQ chicken wings-T2 sample.

Figure 10: Cooked pasteurized BBQ chicken wings-T2 sample.

| Attributes | Control | T1 | T2 | T3 |

|---|---|---|---|---|

| Appearance | 8.61 ± 0.08a | 8.72 ± 0.10a | 8.94 ± 0.14b | 8.91 ± 0.04b |

| Flavor | 8.51 ± 0.10a | 8.63 ± 0.13a | 8.81 ± 0.01a | 8.81 ± 0.05a |

| Texture | 8.53 ± 0.10a | 8.66 ± 0.08a | 8.8 ± 0.05a | 8.76 ± 0.06a |

| Juiciness | 8.57 ± 0.07a | 8.69 ± 0.05b | 8.86 ± 0.02c | 8.75 ± 0.05c |

| Taste | 8.52 ± 0.09a | 8.61 ± 0.19a | 8.88 ± 0.03b | 8.79 ± 0.03b |

| Overall acceptability | 8.49 ± 0.14a | 8.73 ± 0.11a | 8.82 ± 0.08a | 8.77 ± 0.15a |

Table 9: Sensory evaluation of pasteurized BBQ chicken wings.

All the values in the above table are represented as mean ± standard deviation (n=3). Same superscripts in a row represent no significant difference between the reported values.

Physico-chemical analysis of the pasteurized BBQ chicken wings

The physico-chemical analysis of the raw pasteurized BBQ chicken wings with and without barbecue seasoning was conducted on the day of processing. The parameters like moisture, protein, fat, ash, pH and marinade pick up percentage of the control and trials are evaluated (Table 10).

| Parameters (%) | Control | T1 | T2 | T3 |

|---|---|---|---|---|

| Moisture | 54.16 ± 0.16a | 62.31 ± 0.03b | 65.03 ± 0.19c | 68.14 ± 0.20d |

| Protein | 15.35 ± 0.13a | 14.31 ± 0.07b | 14.78 ± 0.07c | 14.67 ± 0.04c |

| Fat | 7.38 ± 0.03a | 5.44 ± 0.03b | 5.26 ± 0.01c | 5.06 ± 0.04d |

| Ash | 2.51 ± 0.04a | 3.38 ± 0.02b | 3.81 ± 0.03c | 4.36 ± 0.05d |

Table 10: Chemical analysis (%) of control and treated formulations.

All the values in the above table are represented as mean ± standard deviation (n=3). Same superscripts in a row represent no significant difference between the reported values.

Moisture content: The mean values for moisture of control and developed pasteurized BBQ chicken wings samples were depicted in Table 10. An increase in moisture content was observed for the developed product within the range of 62.31%-68.14% compared to the control with 54.16%. The increased moisture content of the developed product might be due to marinade absorption caused by tissue breakdown due to increased acidity and enzymatic reaction. Kumar et al., reported a similar finding in the moisture content of chicken tikka treated with lemon and ginger extract marinade solution. He reported that an increase in moisture content was due to an improvement in hydrophilic properties of marinating.

Protein content: A decrease in protein content of the marinated sample was observed with a range of 14.67%-14.31% compared to the control of 15.35%. Kumar et al., reported similar findings in the protein content of chicken tikka treated with lemon and ginger extract marinade solution. He reported that a decrease in protein content occurs due to the leaching of sarcoplasmic protein into the marinade [17].

Fat content: A decrease in fat content of the marinated sample was observed with a range of 5.44%-5.06% compared to control of 7.38%. Kumar et al., reported a similar finding in the fat content of chicken tikka treated with lemon and ginger extract marinade solution. He reported that change might be due to the inverse relationship between moisture and fat in various foods.

Ash content: An increase in ash content of the marinated sample was observed with a range of 3.38%-4.36% compared to control of 2.51%. Kumar et al., reported a similar finding in the ash content of chicken tikka treated with lemon and ginger extract marinade solution. He concluded that an increase in ash content might be due to the high amount of minerals present in the marinade seasonings.

pH: The decrease in the pH of the marinated sample was observed with a range of 5.81%-5.32% when compared to the control sample of 6.30%. This might be due to the presence of lemon extract in the developed marinated product. Kumar et al., reported a similar finding in the pH of chicken tikka treated with lemon and ginger extract marinade solution. He reported that due to the presence of acidic ingredients in the marinade, the pH of the product decreases with marination. The results of pH for the control and pasteurized BBQ chicken wings were shown in Table 11.

|

Parameter |

Control |

T1 |

T2 |

T3 |

|

pH |

6.30 ± 0.02a |

5.81 ± 0.05b |

5.45 ± 0.03c |

5.32 ± 0.05c |

Table 11: pH analysis of control and treated formulations.

All the values in the above table are represented as mean ± standard deviation (n=3). Same superscripts in a row represent no significant difference between the reported values.

Marinade pick up: A decrease in the marinade pick-up % was observed in trials with a range of 2.46%-2.52% to the control sample of 2.72%. This might be due to the presence of lemon extract in the formulation of seasoning. The results agreed with that reported by Yusop, in chicken breast. The studies concluded that the marinade uptake was greater at higher pH marinade values in the product. The results for the marinade pick up in control and trails are shown in Table 12.

| Parameter | Control | T1 | T2 | T3 |

|---|---|---|---|---|

| Marinade pick up (%) | 2.72 ± 0.03a | 2.46 ± 0.04b | 2.50 ± 0.02c | 2.52 ± 0.05c |

Table 12: Marinade pick up (%) analysis of control and treated formulations.

All the values in the above table are represented as mean ± standard deviation (n=3). Same superscripts in a row represent no significant difference between the reported values.

Shelf-life study of pasteurized BBQ chicken wings

The formulated pasteurized BBQ chicken wings T2 was more acceptable with the over the acceptability of 8.82. The shelf-life studies were conducted on the T2 sample during the storage period of one week at a temperature of 4°C. The sensory, proximate, and microbial analysis of the T2 sample was evaluated. For sensory, cooked T2 sample was used and the raw T2 sample was used for proximate and microbial analysis.

Sensory evaluation

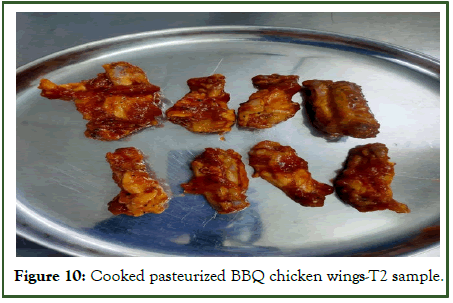

The sensory evaluation of pasteurized BBQ chicken wings was done for the T2 sample on the 0th day, 2nd day, 4th day and 6th day stored at 4°C. Sensory parameters were observed during the storage period. The sensory tests were conducted every two days of the storage period.

As regards sensory quality attributes, the mean sensory scores of 0th day products (freshly prepared) for all quality attributes were in the range of 8.72-8.90 which slightly decreased to 7.24-8.40 of product which was stored about 6 days [18]. The mean values for the sensory evaluation of pasteurized BBQ chicken wings during the storage period at a refrigeration temperature of 4°C were shown in Table 13.

The decrease in the sensory attributes score with an increase in storage period might be due to the presence of microbial growth. The lipid oxidation that occurs during the storage period of meat products results in the development of off-flavors that decrease the acceptability of the product. The graphical representation of the overall acceptability of T2 sample (Figure 11) depicts the decrease in the acceptability of the pasteurized BBQ chicken wings with an increase in the storage period at 4°C.

| Attributes | 0th day | 2nd day | 4th day | 6th day |

|---|---|---|---|---|

| Appearance | 8.90 ± 0.04a | 8.78 ± 0.07b | 8.61 ± 0.03c | 8.40 ± 0.08d |

| Flavor | 8.72 ± 0.10a | 8.58 ± 0.08b | 7.92 ± 0.15c | 7.24 ± 0.11d |

| Texture | 8.76 ± 0.06a | 8.68 ± 0.04a | 8.49 ± 0.24a | 8.24 ± 0.25a |

| Juiciness | 8.73 ± 0.11a | 8.68 ± 0.04b | 8.50 ± 0.16b | 8.26 ± 0.05c |

| Taste | 8.74 ± 0.20a | 8.69 ± 0.11b | 7.78 ± 0.09c | 7.31 ± 0.21d |

Table 13: Sensory evaluation of best accepted pasteurized BBQ chicken wings during storage period.

All the values in the above table are represented as mean ± standard deviation (n=3). Same superscripts in a row represent no significant difference between the reported values.

Figure 11: Graphical representation of overall acceptability of T2 sample during storage period

Appearance: Decrease in the appearance of the pasteurized BBQ chicken wings with a range of 8.90-8.4 was observed from the 0th day to the 6th day of storage at 4°C. The results were similar to the findings of Moawad et al., during his studies on the shelf life of raw chicken sausage incorporated with green tea and clove powder extracts at 4°C. He reported that the decrease might be due to the presence of microbial growth and tissue breakdown during storage period of meat products.

Flavor: A decrease in the flavor of pasteurized BBQ chicken wings with a range of 8.72-7.24 was observed from the 0th day to the 6th day of storage at 4°C. Dogu-Baykut and Gunes, reported similar results in the flavour of marinated chicken drumstick, which was aerobically packed and stored at 4°C. He reported that the decrease might be due to lipid oxidation during the storage period and release of off flavours.

Texture: A decrease in the texture of pasteurized BBQ chicken wings with a range of 8.76-8.24 was observed from the 0th day to the 6th day of storage at 4°C. Dogu-Baykut and Gunes reported similar results in marinated chicken drumsticks due to biochemical changes in tissues that occur during the storage period at 4°C [19].

Juiciness: A decrease in the juiciness of pasteurized BBQ chicken wings with a range of 8.73-8.26 was observed from the 0th day to the 6th day of storage at 4°C. The results were similar to the study of Dogu-Baykut and Gunes reported that due to the initiation of microbial growth in the meat products during the storage period, the juiciness of the product was decreased.

Taste: A decrease in the taste of pasteurized BBQ chicken wings with a range of 8.74-7.31 was observed from the 0th day to the 6th day of storage at 4°C. According to Galmarini et al., lipid oxidation leads to rancidity and is responsible for unacceptable taste and decreasing the product's shelf life, which is an important factor for the consumers.

Overall acceptability: A decrease in the overall acceptability of pasteurized BBQ chicken wings with a range of 8.8-7.59 was observed from the 0th day to the 6th day of storage at 4°C. Dogu-Baykut and Gunes, reported similar results in the overall acceptability of marinated chicken drumstick, which was aerobically packed and stored at 4°C. He concluded that at the presence of microbial growth and tissue breakdown by the proteolytic enzymes results decreased of over acceptability of product during the storage period.

Chemical analysis for the shelf-life study

The chemical analysis of pasteurized BBQ chicken wings was done for the T2 sample on the 0th day, 2nd day, 4th day and 6th day stored at 4°C. The analysis was conducted every two days of the storage period. The mean values for the chemical analysis of pasteurized BBQ chicken wings during the storage period at a refrigeration temperature of 4°C were shown in Table 14.

| Parameters (%) | 0th day | 2nd day | 4th day | 6th day |

| Moisture | 65.15 ± 0.11a | 64.70 ± 0.36b | 63.37 ± 0.30c | 61.27 ± 0.25d |

| Protein | 14.66 ± 0.11a | 14.77 ± 0.06b | 15.24 ± 0.08c | 15.31 ± 0.10d |

| Fat | 5.26 ± 0.06a | 5.36 ± 0.05b | 5.57 ± 0.05c | 5.71 ± 0.02d |

| Ash | 3.75 ± 0.05a | 3.85 ± 0.06b | 4.22 ± 0.08c | 4.29 ± 0.05d |

Table 14: Chemical analysis (%) of best accepted pasteurized BBQ chicken wings during the storage period.

All the values in the above table are represented as mean ± standard deviation (n=3). Same superscripts in a row represent no significant difference between the reported values.

Moisture: A decrease in the moisture content from 65.15%-61.27% was observed from the 0th day to 6th day of storage at 4°C. This might be due to evaporation and drip loss in meat during the storage period. According to Chaillou et al., bound water can easily evaporate and be utilized by microorganisms for growth during the storage of meat products. The results were also in agreement with that reported by Febrianta et al., during their studies on quality evaluation of chicken breast meat. Due to drip loss in treated chicken breasts, the moisture content of the product is not decreased with an increase in storage period.

Protein: An increase in the protein content with a range of 14.66%-15.31% was observed from the 0th day to the 6th day of storage at 4°C. This might be due to an increase in meat tenderness and degree of assimilation of nitrogenous compounds in marinated products during the storage period. Istrati et al., observed similar findings in the protein content of marinated beef during the storage period. He reported that during the storage period at a refrigeration temperature of 4°C, various biochemical and physicochemical modifications occur in meat. The tissue enzymes and bacterial enzymes were responsible for it.

Fat: An increase in the fat content with a range of 5.26%-5.71% was observed from the 0th day to 6th day of storage at 4°C. This might be due to the inverse relationship that exists between moisture and fat contents. The results were in agreement with that reported by Kaya and Basturk, in marinated meat products where the fat content of meat increased with a decrease in the moisture content of the product.

Ash: An increase in the ash content with a range of 3.75%-4.29% was observed from the 0th day to 6th day of storage at 4°C. The results agreed with that reported by Kaya and Basturk, in marinated meat products, who reported that due to a decrease in moisture content, there was an increase in the ash content of the product.

Microbial analysis for the shelf-life study

The microbial count for the pasteurized BBQ chicken wings was shown in Table 12. Through the shelf-life study, the product was stored in a refrigeration condition at 4°C and the microbial count was determined for every two days [20]. Low initial could be due to low moisture content, good hygienic practices during processing, storage at 4°C and product handling. Modi et al., reported similar results during the storage of dehydrated chicken kebab mix and observed it to be microbiologically safe because of the low initial bacterial count.

| Parameters (CFU/g) | 0th day | 2nd day | 4th day | 6th day | 8th day |

|---|---|---|---|---|---|

| TPC | 35995 ± 0.0a | 67349 ± 0.14b | 128490 ± 0.16c | 375290 ± 0.20d | 518550 ± 0.23e |

| Yeasts and molds | 250 ± 0.23a | 354 ± 0.10b | 570 ± 0.07c | 780 ± 0.05d | 1083 ± 0.08e |

| Escherichia coli | 33.12 ± 0.12a | 58.10 ± 0.10b | 68.03 ± 0.15c | 82.08 ± 0.07d | 106.8 ± 0.26e |

| S.aureus | 25.03 ± 0.15a | 44.8 ± 0.26b | 61.8 ± 0.26c | 77.7 ± 0.25d | 109.8 ± 0.23e |

| Salmonella (Absent in 25 g) | Absent | Absent | Absent | Absent | Absent |

Table 15: Microbial changes (CFU/g) during the storage period.

According to FSSAI, standard limits for the microbial growth were 500000 CFU/g for aerobic plate count, 1000 CFU/g for yeasts and mold, 100 CFU/g for both E. coli and S. aureus.

Total plate count was in standard limit up to 6 days of storage period. An increase in yeasts and mold counts were found slightly higher in pasteurized BBQ chicken wings during the storage period of 6 days, but count in an acceptable limit. On the 8th day, count was found to be increased by 1083 CFU/g, which is above the acceptable limit. This might be due to the presence of higher moisture content.

As the growth of microbes on the 8th day exceeded the standard limit. The product was found to be unacceptable by the panelists. As regards microbiological quality, E. coli and S. aureus were within the narrow range of 82 CFU/g and 77 CFU/g during the storage period of 6 days. Salmonella was not detected in pasteurized BBQ chicken wings during the storage period up to 8 days. It could be due to the destruction of these bacteria during processing conditions.

N. Hussain et al., reported that the microbial load of a food is important to ensure its safety and the consumer’s health. Most bacteria and molds are known to havea higher tolerance to cold temperature rather than hot temperature. But due to high tolerance of acidic conditions by some bacteria and molds, microbial growth in the marinated chicken fillet was treated with lemon extract and chilli paste.

All the values in the above table are represented as mean ± standard deviation (n=3). Same superscripts in a row represent no significant difference between the reported values.

Conclusion

BBQ wings are a popular and mouthwatering dish enjoyed by people all over the world. And wings are a crowd-pleaser that can elevate any meal or gathering. To make this product, a different formulation has been carried out by increasing chicken percentage. From the above study, it can be concluded that the pasteurized BBQ chicken wings having 690 g barbecue sauce (T2) was acceptable in terms of sensory evaluation as compared to 0% (Control), 680 g (T1) and 700 g (T3). Freshly cooked pasteurized BBQ chicken wings on the day of processing got an over the acceptability of 8.82 for the T2 sample. The proximate analysis conducted on the day of processing resulted in the moisture, protein, fat and ash of the T2 sample as 65.03%, 14.78%, 5.26% and 3.81% respectively. The mean values of pH and marinade pick-up% of the T2 sample were found to be 5.45% and 2.5%. The pasteurized BBQ chicken wings T2 sample was observed for sensory, proximate and microbial parameters for one week stored at 4℃. Sensory parameters were acceptable and microbial growth was also within the standard limit up to 6 days of the storage period of pasteurized BBQ chicken wings. Hence through the present study, the least commercial used chicken drumette and flab were utilized to develop a new variant of marinated product with barbecue sauce.

References

- Ab Aziz MF, Hayat MN, Kaka U, Kamarulzaman NH, Sazili AQ. Physico-chemical characteristics and microbiological quality of broiler chicken pectoralis major muscle subjected to different storage temperature and duration. Foods. 2020;9(6):741.

[Crossref] [Google Scholar] [PubMed]

- Alvarado C, McKee S. Marination to improve functional properties and safety of poultry meat. J Appl Poult Res. 2007;16(1):113-120.

- Bjorkroth J. Microbiological ecology of marinated meat products. Meat Sci. 2005;70(3):477-480.

[Crossref] [Google Scholar] [PubMed]

- Chatterjee RN, Rajkumar U. An overview of poultry production in India. Indian J Anim Health. 2015;54(2):89-108.

- Hudspeth JP, Lyon CE, Lyon BG, Mercuri AJ. Weights and cooked yields of broiler parts related to eviscerated carcass weights. 1974.

- Doguâ?Baykut E, Gunes G. Quality of readyâ?toâ?cook marinated chicken drumsticks as affected by modified atmosphere packaging during refrigerated storage. J Food Process Preserv. 2014;38(1):615-621.

- Febrianta H, Yunianto VD, Nurwantoro N, Bintoro VP. Quality evaluation of chicken breast marinated with encapsulation of turmeric extract. Food Res. 2021;5:366-373.

- Gomez I, Ibanez FC, Beriain MJ. Physicochemical and sensory properties of sous vide meat and meat analog products marinated and cooked at different temperature-time combinations. Int J Food Prop. 2019;22(1):1693-1708.

- Gomez I, Janardhanan R, Ibanez FC, Beriain MJ. The effects of processing and preservation technologies on meat quality: Sensory and nutritional aspects. Foods. 2020;9(10):1416.

[Crossref] [Google Scholar] [PubMed]

- Henry SG, Abou-El-Hawa SH, Ramadan BR, Khalifa AH. Nutritional quality of ostrich meat, edible offal, and fat tissue. Assiut J Agri Sci. 2024;55(2):125-143.

- Incili GK, Akgol M, Aydemir ME, Alan S, Mutlu M, Ilhak OI, et al. Fate of Listeria monocytogenes and Salmonella typhimurium in homemade marinade and on marinated chicken drumsticks, wings and breast meat. LWT. 2020;134:110231.

- International Organization for Standardization. Microbiology of food and animal feeding stuffs: Horizontal method for the enumeration of yeasts and moulds-Part 2: Colony count technique in products with water activity less than or equal to 0, 95. International Organization for Standardization; 2022.

- Standard I. Microbiology–General guidance for the enumeration of coliforms. Part-I Colony count technique (First revision). IS. 2002;5401.

- IS 5402:2002 Standard I. Microbiology general guidance for the enumeration of microorganisms–colony count technique at 300C. Bureau of Indian Standards. New Delhi. IS. 2002;5402:1-5.

- IS 5887: Part 3: Sec 1: 2020 Methods for detection of bacteria responsible for food poisoning part 3 horizontal method for the detection, enumeration, and serotyping of salmonella section 1 detection of Salmonella spp. (Third Revision).

- IS 5887: Part I: Methods for detection of bacteria responsible for food poisoningâ?Part I: Isolation, identification, and enumeration of Escherichia coli. 1976.

- Istrati D, Ciuciu AM, Ionescu A, Vizireanu C, Dinica R. Influence of spice and wine based marinades on bovine Biceps femoris muscle tenderness. Afr J Biotechnol. 2012;11(79):14461-14467.

- Janky DM, Koburger JA, Oblinger JL. A comparison of brined and unbrined paired broiler carcass-halves for tenderness. Poultry Sci. 1982;61(4):716-718.

- Jeong K, Hyeonbin O, Shin SY, Kim YS. Effects of sous-vide method at different temperatures, times and vacuum degrees on the quality, structural, and microbiological properties of pork ham. Meat Sci. 2018;143:1-7.

[Crossref] [Google Scholar] [PubMed]

- Kanchi B, Nalla AR, Metla NK, Manyam SK, Vadapu KR. Effect of different packaging conditions on shelf life of chicken samosa stored at refrigeration temperature. Int J Curr Microbiol App Sci. 2017;6(5):2432-2437.

Citation: Varma G (2025) Development and Shelf-Life Evaluation of Pasteurized BBQ Chicken Wings. J Food Process Technol. 16:1138.

Copyright: © 2025 Varma G. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution and reproduction in any medium, provided the original author and source are credited.