Indexed In

- Genamics JournalSeek

- Academic Keys

- JournalTOCs

- China National Knowledge Infrastructure (CNKI)

- Access to Global Online Research in Agriculture (AGORA)

- Centre for Agriculture and Biosciences International (CABI)

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- SWB online catalog

- Publons

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Case Report - (2021) Volume 12, Issue 5

Determination of Engineering Properties of Coffee Beans and Coffee Powder

Naraganti Snehitha1* and Murlidhar Meghwal22National Institute of Food Technology Entrepreneurship and and Management Kundli, Sonepat, Haryana, India

Received: 18-Jan-2021 Published: 04-Feb-2021, DOI: 10.35248/2157-7110.21.12.547

Abstract

The knowledge about engineering properties of coffee beans is important in case of design of machine/equipment, developing processes and handling procedures, packaging practices and transporting the processed powders. This work primarily focused on evaluating engineering properties of Roasted, Unroasted coffee beans and Coffee powder. These engineering properties were listed by researchers as size, dynamic angle of repose, coefficient of static friction, bulk and true densities, and porosity. The geometrical statistical data collected for these coffee seeds and beans in terms of their average length, width and thickness are 8.57 mm, 6.91 mm and 4.39 mm for unroasted and 11.43 mm, 8.61 mm, 5.66 mm for roasted coffee beans. Bulk density, True density, Angle of repose, Specific gravity, Porosity, Moisture content are calculated for Unroasted, Roasted coffee seeds and Coffee powder. Porous density, Compact density, Compressibility index, Hauser ratio, Sieve analysis, Static coefficient of friction is calculated for coffee powder on Glass, Paper board, Thermocol. There is no doubt that the work done here definitely will aid optimal design of machines required for harvesting, processing and handling of coffee seeds and beans for good quality products at high efficiency.

Keywords

Unroasted coffee seeds; Roasted coffee seed; Coffee powder; Engineering properties

Introduction

Advanced technologies of procession, transportation and storage of agricultural production as well as planning of new production operations and designing of new machines and tools are impossible without studies of physical and mechanical properties of agricultural materials serving the functions of structural and technological parameters of machines and equipment. Before a cup of coffee is made, freshly harvested coffee berries have to undergo various processes in the post-harvest operation. Then, the coffee beans will undergo roasting, grinding, packing and transporting processes which require knowledge of basic physical properties data of the coffee beans.

Many researches have been carried out on the physical and engineering properties of the agricultural products. The information on size, density, and crushing strength are required for the development of the grading system for barriers and for the pulpers. The physical properties such as size, friction angle, angle of repose, crushing strength and bulk density are important in the design of the handling system, grading and hulling [1,2].

Many researchers agreed that knowledge of the physical and engineering properties of agricultural products are important in the design and analysis of machines for agricultural processing operations. The important properties they recommended include: size, shape, bulk and true densities, coefficients of friction, angle of repose, geometric mean diameter, sphericity, projected area, terminal velocity and cracking force. Some of these researchers also reported parameters width, thickness, volume, surface area, geometric mean diameter and sphericity. They reported the regression equation for the length of pine nut with respect to their dimensions mentioned above. Some of them also investigated some of these properties at different moisture level but reported that some of these properties of coffee such as length, width, thickness, were not affected by moisture content. This work intends to investigate the following properties of coffee seeds and beans: size (length, width and thickness), geometric mean diameter, and sphericity, angle of repose, bulk and true densities, porosity, coefficient of friction [3-8].

The present study was thus planned and carried out in order to fill the knowledge gap on engineering properties of unroasted, roasted and coffee powder. The study on the flow characteristics of engineering properties will be useful to have control over processing parameter that lead to improved quality and output of the coffee beans. The objectives are to: investigate the engineering properties of coffee beans and coffee powder. Pictorial views of Micrometer, oven for determination of moisture content, roasted beans and unroasted beans.

Materials and Methods

Coffee seeds used for all the experiments were obtained from fresh and ripe berries. The normal wet processing method of sorting, cleaning, and drying was followed to remove impurities.

Sample preparation

Coffee beans will be roasted separately using an oven with direct heating. Roasting coffee transforms the chemical and physical properties of green coffee beans. When roasted; the green coffee bean expands to nearly double its original size, changing in color and density. As the bean absorbs heat it shifts to yellow in color then to light cinnamon brown and then to rich dark brown color coffee can be roasted by grinding coffee bean.

Moisture content is calculated by taking empty sample and then weighted. Now coffee powder is added and weight is measured then kept at temperature 1000 in oven and weights are measured at regular interval of time, three readings are noted. Likewise for roasted and unroasted coffee seeds readings are taken. Percentage of moisture content is calculated using Equation (1) [9].

% of moisture content in sample

A is weight of wet sample

B is weight of dry sample

Determination of engineering properties

Coffee beans are selected and for each roasted and unroasted beans the length (X), width (Y), thickness (Z), was measured using micrometer of 0.01 mm accuracy at each moisture level X, Y, Z are expressed in mm.

Equivalent seed diameter (Di)

The ratio of other dimensions to the length were Equivalent diameter is used as a general term for irregular shaped objects such as oblong, spherical and conical. Equivalent diameter gives us an idea about the geometry of the object. Fifty seeds and beans each were selected at random from a sample and their major diameter (length), intermediate diameter (width) and minor diameter (thickness) were measured. A Micrometer is used for measurement .The geometric mean diameter (Di) expressed in mm and calculated using equation (2) Mohsenin.

Sphericity (Ф)

Sphericity (Ф) is ratio of surface area of the sphere that has volume equal to the total volume of the solid to total surface area of the solid. In other words, it is measure of the degree by which an object is spherical in shape or it is measure of compactness of an object. It is expressed in fraction were calculated using the equation (3) [3-4]

Surface area (Sa)

The surface area of a solid object is measure of total area that surface of the object occupies, given formula for surface area as Equation (4).Surface area is expressed in sqmm. Di is Equivalent seed diameter.

Seed volume (v)

Seed volume is the total space occupied by given unit mass of coffee seeds. Volume can be calculated using Equation (5) and (6) Seed volume is expressed in cubic mm [10].

Surface area and volume equations are given by other researchers [11,12]

Seed mass

Coffee seeds are measured by taking 1000 seeds were selected randomly and their mass was measured using an electronic balance having accuracy up to 0.001 g and seed mass is expressed in gram [13]

Bulk density (ρb)

Bulk density is defined as mass of particulate matter to the total space or volume it occupies. It is denoted by ρb and expressed in kilogram per cubic meter. Bulk density of coffee beans both roasted and unroasted seeds was measured by filling a cylinder container. Cylinder diameter and height is measured, from which the volume of the cylinder is calculated, mass of the seeds filled in cylinder is measured by electric balance. Now bulk density is calculated using equation (7) [3]

True density (ρt)

True density is the ratio of mass of particulate matter to the total space or volume occupied by that matter excluding void spaces particulate matter. True density is denoted by the symbol ‘ρt’ and expressed in kilogram per cubic. True density at various mc levels was determined by adopting liquid displacement method where toluene was used as liquid. Mass of coffee seeds was taken and immersed in toluene and the volume displaced was noted. True density is calculated using equation (8) Pome-ramz and Meloan

Porosity (ϴ)

Porosity is the degree or measure of the void or empty space of the volume within the substance over the total volume occupied by the substance. Porosity is shown by the symbol ϴ. Porosity expressed in percentage. Generally it varies from 0 to 1 (in fraction) and 0 to 100 (in percent). Porosity was calculated by the standard relationship of true and bulk density using equation (9).

Angle of repose

Sliding or slippery particulate materials are kept on a flat surface, they form a heap and in this condition they form an angle with the horizontal and slanting plane of the material shown by symbol ‘α’ and is expressed in ‘degrees’. Angle of repose varies from 0 to 90 degrees. Angle of repose was determined using a ply box provided with a removal front panel. The box was filled with seed sample, front panel was quickly removed so that seeds could flow and assume a natural slope. The angle of repose was calculated from the measurement of depth of free surface of the sample at the center and base diameter of the heap formed outside the container and with the help of following equation (10).

Where h is the height of the heap and r is the radius formed by the heap.

Static coefficient of friction

Static coefficient of friction simply indicates the force of friction between two bodies under stationary condition. It is represented by μ and it does not have any dimensions as it is simply a ratio of two qualities and is shown in fractional values. It varies from 0 to 1. Static coefficient of friction of coffee seeds was determined over three different surfaces those are made up of glass (PBC), thermocol, paper board by using equation (11) [14]

μ is static coefficient of friction (dimension less quantity) and Ø is the angle formed between horizontal surface and the sliding plane in degrees.

Compressibility index

Compressibility Index (CPI) is the degree of the powder ability to be compacted. The Compressibility index of coffee seeds was calculated using the following equation (12) [15].

Where C is the compressibility index, T is compact density of coffee powder, B-Bulk density of coffee powder.

Hausner ratio (Hr)

Hausner ratio is used as an internal friction index for cohesive powders [16] and is the ratio of bulk density of compacted powder to that of porous powder of coffee seeds. This ratio correlates flowability of the powder and gives an idea about the flowability of the powder. Hausner ratio can be obtained from equation (13)

Where Hr represents the Hausner number and ρc and ρp are same as mentioned above. Hausner ratio depends on frictional forces of coffee powder. Hausner ratio gives indication about powder flowability in loosely packed state.

Car index (Ci)

Car index gives an idea indirectly about flow behavior of a powder. Car index is determined by H values as given in the equation (14)

Specific gravity

Specific gravity is the ratio of true density of coffee seed to the density of water, as density of water has been taken as the density of reference substance. If a substance has specific gravity less than one it means that the object will easily float on the surface of reference substance if the reference material is liquid and if the value is the more than one it means the substance will easily sink in the reference material if reference substance is liquid. Specific gravity is calculated by equation (15)

Specific surface area

The surface area per unit mass of the material is called specific surface area. It is represented by ‘Ssa’ and expressed in mm2 g-1. A powder has high specific area compared to whole solid block of material. In food processing such as in case of functional, nutraceutical and fortified food material greater specific surface area helps in easy absorption and greater bioavailability of material in human body. Specific surface area of coffee seeds is calculated using the equation (16)

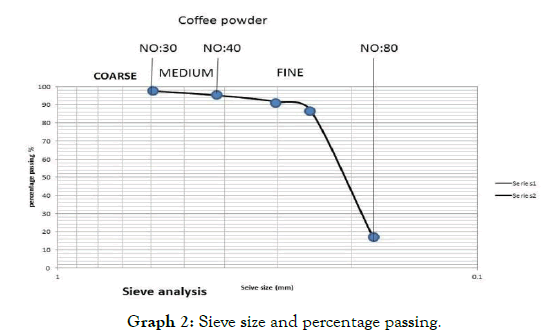

Sieve analysis

A sieve analysis is a practice or procedure used to assess the particle size distribution of a granular material. The particle size distribution is responsible for important physical properties such as solubility, flowability and surface reaction. In many industries sieve analysis is the standard for production and quality control of powders and granules. Advantage of the sieve analysis include easy handling, low investment costs, precise and reproducible results in a comparably short time and the possibility to separate the particle size. The different sieve sizes are taken they are arranged from top to bottom as larger to smaller size. 250 grams of coffee powder was poured in top most sieves. Shake the column; after the shaking is complete the material on each sieve is weighted.

Results and Discussion

Size and Shape

Length, Width and Thickness were measured by using micrometer for 50 coffee seeds both roasted and unroasted seeds. The average of all 50 seeds. By using this length, width, thickness we calculate diameter, sphericity, Surface area and seed volume for all the seeds are there in average values.

Engineering properties of coffee seeds

Bulk density, true density, angle of repose, specific gravity, porosity and moisture content are calculated for coffee seeds of roasted, unroasted and coffee powder.

Engineering properties of coffee powder

Porous density, compact density, compressibility and Hausner ratio are calculated for coffee powder.

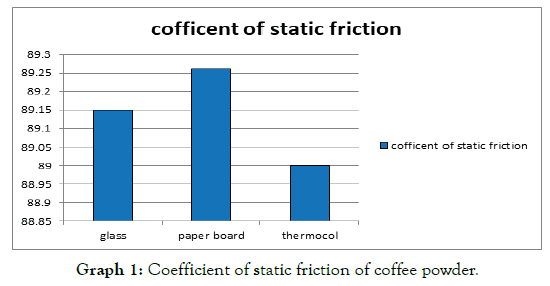

Static coefficient of friction

Coefficient of friction is calculated for coffee powder on the Glass (PBC), Paper board, Thermocol values.

In the present study (Graph 1) coefficient of static friction of coffee powder for glass, paper board, thermocol are drawn graph, the highest static friction is for paperboard. The increased coefficient of static friction on coffee powder is due to higher moisture content, lower moisture content and smooth surface of seeds resulted in the easy movement on test surface, while viscous nature of seeds leads to high resistance.

Graph 1:: Coefficient of static friction of coffee powder.

Sieve analysis

Coffee powder weight in each sieve is weighed and values in each sieve.

Above logarithmic Graph 2 is for sieve analysis, sieve size on x-axis and percentage of passing on y-axis. From the graph it is studied that as the percentage of passing of coffee powder is decreased when the sieve size also decreases. Sieve size no: 40-80 in between coffee powder is fine powder, sieve size no: 30-40 in between it is medium, below sieve size no: 30 it is coarse powder.

Graph 2: Sieve size and percentage passing.

Conclusions

Based on the results obtained and the conditions in which the experiment was conducted, the following conclusions are presented:

• The engineering properties of roasted coffee beans, unroasted coffee beans and coffee powder are calculated

• The increased coefficient of static friction on coffee powder is due to higher moisture content. Lower moisture content and smooth surface of seeds resulted in the easy movement on test surface, while viscous nature of seeds leads to high resistance

• In Sieve analysis when sieve size is decreased, percentage of passing of coffee powder also decreased

• The uniformity of coffee beans adds to its potential for successful mechanization of processing and handling operations

Conflict of Interest

The authors are declared no conflict of interest.

REFERENCES

- Silvia E, Sidebang B. Engineering properties of coffee beans from various colors of coffee cherries. Agri and Agri Sci Proc. 2015;3:274-277.

- Chandrasekar V, Viswanathan R. Physical and thermal properties of coffee. J Agric Engng Res. 1999;73:227-234.

- Özgüven F, Vursavuş K. Some physical, mechanical and aerodynamic properties of pine (Pinus pinea) nuts. J Food Eng.2005;68:191-196.

- Yalçın İ, Özarslan C, Akbaş T. Physical properties of pea (Pisum sativum) seed. J Food Eng. 2007;79:731-735.

- Akaaimo DI, Raji AO. Some physical and engineering properties of prosopis africana seed. Biosyst Eng. 2006;95:197-205.

- Ogunjimi LA, Aviara NA, Aregbesola OA. Some engineering properties of locust bean seed. J Food Eng. 2002;55:95-99.

- Baryeh EA. Physical properties of bambara groundnuts. J Food Eng. 2001;47:321-326.

- Cristo HP, Martins MA, Oliveira LS, Franca AS. Transverse flow of coffee beans in rotating roasters. J Food Eng.2006;75:142-148.

- Reh CT, Gerber A, Prodolliet J, Vuataz G. Water content determination in green coffee–Method comparison to study specificity and accuracy. Food Chem. 2006;96:423-430.

- Karababa E. Physical properties of popcorn kernels. J Food Eng. 2006;72:100-107.

- Jain RK, Bal S. Properties of pearl millet. J Agric Eng Res. 1997;66:85-91.

- Tunde-Akintunde TY, Akintunde BO. Some physical properties of sesame seed. Biosyst Eng. 2004;88(1):127-129.

- Altuntaş E, Özgöz E, Taşer ÖF. Some physical properties of fenugreek (Trigonella foenum-graceum L.) seeds. J Food Eng. 2005;71:37-43.

- Razavi SM, Amini AM, Rafe A, Emadzadeh B. The physical properties of pistachio nut and its kernel as a function of moisture content and variety. Part III: Frictional properties. J Food Eng. 2007;81:226-35.

- Baryeh EA. Physical properties of millet. J Food Eng. 2002;51:39-46.

- Guo A, Beddow JK, Vetter AF. A simple relationship between particle shape effects and density, flow rate and Hausner ratio. Powder Technol. 1985;43:279-284.

Citation: Murlidhar M, Snehitha N (2021) Determination of Engineering Properties of Coffee Beans and Coffee Powder 12:547

Copyright: © 2021 Snehitha N, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.