Indexed In

- Genamics JournalSeek

- Academic Keys

- JournalTOCs

- China National Knowledge Infrastructure (CNKI)

- Access to Global Online Research in Agriculture (AGORA)

- Centre for Agriculture and Biosciences International (CABI)

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- SWB online catalog

- Publons

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Research Article - (2023) Volume 14, Issue 11

Design and Development of Infrared Batch Heating Chamber for Reduction of Moisture Content to Enhance the Storability of Ragi (Eleusine coracana) Flour

Roshan Kumar Sharma* and Dharmendra KhokharReceived: 26-Apr-2023, Manuscript No. JFPT-23-21126; Editor assigned: 28-Apr-2023, Pre QC No. JFPT-23-21126 (PQ); Reviewed: 12-May-2023, QC No. JFPT-23-21126; Revised: 26-Jun-2023, Manuscript No. JFPT-23-21126 (R); Published: 03-Jul-2023, DOI: 10.35248/2157-7110.23.14.1070

Abstract

Finger millet has a three-month shelf life, and also need proper preservation and packaging processes are essential. Infrared radiation treatments with wavelengths ranging from 0.5 to 100 meters are used to eliminate moisture and improve the shelf life of food products. A infrared batch dryer has been designed to decreases the moisture content of sample as it is exposed to high temperatures, but increases as storage time increases. A sample treated at 110℃ for 2, 3, 4 minutes shows minimum moisture content after 90 days storage, which is good for flour. The IR treatment at 110℃ for 2 minutes is best for use, followed by S15 and S13, treated at 110℃ for 3 and 1. The sample treated at 110℃ for 2,3,4 minutes showed minimum moisture content after 90 days storage, which is good for flour. The IR treatment at 110℃ for 4 minutes i.e. S16 is best for use followed by S15 and S13, treated at 110℃ for 3 and 4. The sample treated with 50℃ for 1 minute and fresh (control) flour sample showed nearly similar effect on physicochemical and nutritional properties of ragi flour as compared to sample treated at 70℃, 90℃ and 110℃. The IR treatment at 90℃ for 2 minutes i.e. S10 is best for use followed by S16 and S14, treated at 110℃ for 4 and 2. Finally, the IR treatment at 110℃ for 2 minutes i.e. S14 is best for use.

Keywords

Finger millet; Infrared radiation; Infrared batch dryer; Pulses; Ragi

Introduction

The right to food is essential for holistic well-being, and India is committed to becoming a malnutrition-free country. However, the nutrient consumption situation in India is still severe, with cereals, vegetable pulses, and non-vegetarian goods decreased in every second family. The term 'millet’ includes a number of coarse or inferior grains that have high nutritive value like bajra, jowar and ragi. Millets are also known as ‘dry crops’ because they are grown in the drier parts of the country. Ragi crop in India has covered 10.14 lakh ha (25.06 lakh acres) during kharif 2021 to 2022. Small millets are nutritionally superior to rice and wheat, providing low-cost proteins, minerals and vitamins to the poor [1]. They have indefinite storage life and untapped grain yield potential, making them potential future food crops in rain fed areas.

Tropical finger millet scientifically known as Eleusine coracana is cultivated from sea level to 3,000 masl. Due to its great nutritional value and advantageous health effects, it is a staple diet in Africa and India. Finger millet is one of the rich sources of nutrients. It is composed of dietary fiber (18%), calcium (344 mg/100 g), tannins (0.04% to 3.47%), phytate (0.48%), oxalate (0.27%), cyanide (0.17%), saponins (0.36%), phenolics (0.3% to 3%) and polyphenols. They are also rich in amino acids (isoleucine, phenylalanine, leucine and methionine), minerals (calcium, phosphorus and iron) and vitamins, including B (1.71 mg) and E (22 mg). Finger millet is a popular food in southern India due to its high nutritional content [2]. It is consumed in the form of a porridge called Ragimudde, which is the staple diet of many residents of South Karnataka. Though the finger millet and its product like flour is highly enriched with nutrition the preservation and packaging techniques are more important for us. From various study it has been seen that the storage/shelf life of finger millet is generally observed 3 months for maximum. So there is a need to extend shelf life by making dry product by efficient and low cost dryer which can be used by farmer on field for low cost postharvest management and packaging as well.

Infrared radiation treatments are being used to reduce moisture and extend shelf life of food products, with wavelengths ranging from 0.5 to 100 meters. In both liquid and solid meals, IR heating can be used to kill bacteria, spores, yeast, and mould. As a result, the study is to design and develop an infrared batch dryer suitable for extension of shelf life of ragi flour and also to identify the optimum irradiation dose and disinfestations of grains to improve the shelf life and to study the physical, microbiological and sensory quality of radiation processed ragi before, during and after storage and cut down on waste and enhance storage conditions [3].

Materials and Methods

Design and development of IR batch heating chamber was done as per requirement and fabricated using food grade stainless material.

Ragi grains were shortened washed, and sun dried until they reached 13% moisture. They were ground separately using a laboratory scale grinding mill, sieved with mechanical mesh, and weighed with an analytical balance to make a 100 gram sample. The ragi flour was subjected to IR heat treatment. For the treatment the ragi flour was spread over the tray with 2 cm depth and kept inside the chamber for heat treatment which has been carried out at different temperature i.e. 50℃, 70℃, 90℃, and 110℃ and four time interval i.e. 1,2,3 and 4 minutes [4,5]. After treatment the 100 g sample was packed in polyethylene pouch and heat sealed. Samples were prepared by grinding and treating the samples by IR Heat treatment at different time and temperature. Samples were stored in polyethylene bag for a period of three months. Physicochemical and nutritional properties of ragi flour were determined periodically in laboratory (Table 1) [6].

| Sample | IR treatment | Sample | IR treatment | ||

|---|---|---|---|---|---|

| Nomenclature | Temperature in ℃ | Time in minutes | Nomenclature | Temperature in ℃ | Time in minutes |

| T50T1 | 50 | 1 | T90T1 | 90 | 1 |

| T50T2 | 50 | 2 | T90T2 | 90 | 2 |

| T50T3 | 50 | 3 | T90T3 | 90 | 3 |

| T50T4 | T70 | 4 | T90T4 | 90 | 4 |

| TT70T1 | T70 | 1 | T110T1 | 110 | 1 |

| TT70T2 | T70 | 2 | T110T2 | 110 | 2 |

| TT70T3 | T70 | 3 | T110T3 | 110 | 3 |

| TT70T4 | T70 | 4 | T110T4 | 110 | 4 |

| FF | Sample without IR treatment | ||||

Table 1: Samples were prepared by grinding and treating the samples by IR heat treatment at different time and temperature.

Results and Discussion

A rectangular chamber of stainless steel (SS 304) of 18 gauge (1.27 mm), a food grade metal containing racks. The drying chamber has a length of 38.5 cm, width of 15 cm and height of 75 cm as outer dimension and having length, width and height, 30, 10 and 60 cm respectively as inner dimensions. This chamber hoses the trays which are used to hold the sample for heat treatment in the chamber. In the chamber, the slots are spaced 5 cm apart according to the food material size, shape, and density for required treatment. The slots are used for heat treatment and drying of the product [7,8]. The tray's dimensions (length, width and height) are 28.5 cm, 9.00 cm, and 2.5 cm respectively. Each side of the double walled drying chamber is insulated with glass wool to reduce heat loss considering the drying temperature, availability and cost of insulating material.

The double walled door is attached with hinges and heat resistance rubberized sealing system. The drying chamber is the part of the dryer where the food materials to be dried are fed and drying takes place. The developed infrared heat dryer can be operated with single phase at 220 v and maintain a maximum temperature of 350℃ within 10 minutes. The temperature can be maintained to a desired temperature by setting the temperature in the controller, but the actual product temperature remains below 10℃ due to short time of treatment. Moisture removed from the product is escaped from the chamber through the exhaust fan [9-12].

All the samples (100 g each) were treated and packed in polyethylene bag. The observed data of moisture content clearly indicate that the moisture content is inversely affected by the temperature. It means when the sample exposed to high temperature and for more time the moisture content decreases [13].

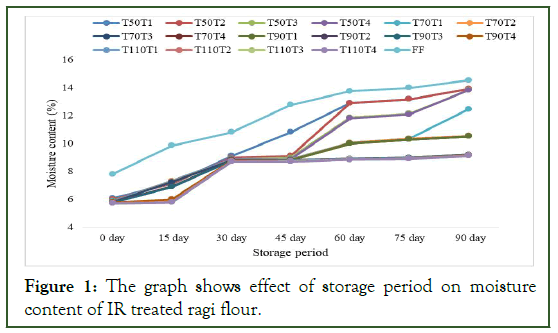

During the expansion in time of storage moisture content increases and affect the flour quality directly [14]. As per the treatment given the sample treated at 110℃ for 2, 3, 4 minutes shows minimum moisture content after 90 days of storage which indicate good flour quality. The graph and table below shows IR treatment at 110°C for 2 minutes is best for use followed by T100T3 and T110T1, treated at 110℃ for 3 and 1 minute (Figure 1) [15,16].

Figure 1: The graph shows effect of storage period on moisture content of IR treated ragi flour.

The effect of operating variables on the drying period using analysis of variance (ANOVA; Microsoft Excel) was carried out. According to the ANOVA results shown in table the moisture content was strongly influenced by temperature [17]. The analysis of variance for the effect of storage period on moisture content of IR treated ragi flour is given in Table 2 and 3. As per the above given table the F value calculated at α=0.05, the factor A in IR treated ragi flour shows significant variations in moisture content while no variation found in factor B [18].

| Treatment | 0 day | 15 days | 30 days | 45 days | 60 days | 75 days | 90 days |

|---|---|---|---|---|---|---|---|

| T50T1 | 6.1 | 7.1 | 9.1 | 10.8 | 12.9 | 13.19 | 13.9 |

| T50T2 | 5.98 | 7.13 | 8.98 | 9.1 | 12.9 | 13.19 | 13.93 |

| T50T3 | 5.89 | 7.23 | 8.89 | 8.98 | 11.86 | 12.15 | 13.85 |

| T50T4 | 5.87 | 7.31 | 8.87 | 8.89 | 11.81 | 12.1 | 13.83 |

| TT70T1 | 5.85 | 7.3 | 8.85 | 8.87 | 10.07 | 10.36 | 12.46 |

| TT70T2 | 5.81 | 7.29 | 8.81 | 8.85 | 10.05 | 10.34 | 10.56 |

| TT70T3 | 5.8 | 7.25 | 8.8 | 8.81 | 10.01 | 10.3 | 10.52 |

| TT70T4 | 5.8 | 6.9 | 8.8 | 8.8 | 10 | 10.29 | 10.51 |

| T90T1 | 5.79 | 6.89 | 8.79 | 8.8 | 10 | 10.29 | 10.51 |

| T90T2 | 5.79 | 6.87 | 8.79 | 8.79 | 8.91 | 8.97 | 9.19 |

| T90T3 | 5.76 | 6.87 | 8.76 | 8.79 | 8.91 | 8.97 | 9.19 |

| T90T4 | 5.75 | 6 | 8.75 | 8.76 | 8.88 | 8.94 | 9.16 |

| T110T1 | 5.71 | 5.81 | 8.71 | 8.75 | 8.87 | 8.93 | 9.15 |

| T110T2 | 5.73 | 5.8 | 8.73 | 8.73 | 8.85 | 8.91 | 9.13 |

| T110T3 | 5.7 | 5.75 | 8.7 | 8.71 | 8.83 | 8.89 | 9.11 |

| T110T4 | 5.7 | 5.76 | 8.7 | 8.7 | 8.82 | 8.88 | 9.1 |

| FF | 7.8 | 9.85 | 10.8 | 12.76 | 13.76 | 14.01 | 14.56 |

Table 2: Effect of storage period on moisture content of IR treated ragi flour.

| Source of variation | DF | Sum of squares | Mean squares | F-calculated | Significance | C.D. | SE (d) | SE (m) |

|---|---|---|---|---|---|---|---|---|

| Factor A | 3 | 71.762 | 23.921 | 5.623* | 0.00136 | 1.096 | 0.551 | 0.39 |

| Factor B | 3 | 3.131 | 1.044 | 0.245* | 0.86451 | N/A | 0.551 | 0.39 |

| A × B | 9 | 1.313 | 0.146 | 0.034* | 1 | N/A | 1.103 | 0.78 |

| Error | 96 | 408.419 | 4.254 | |||||

| Total | 111 | 484.624 | ||||||

Note: *F calculated at α=0.05, Factor A=Temperature, Factor B=Time

Table 3: ANNOVA for the effect of storage period on moisture content of IR treated ragi flour.

According to the findings, the original moisture content was 10.60% on average before radiation [19]. After one month of storage, the moisture content of irradiation foxtail millets ranged from 10.48 to 10.34 percent (d.b), while the control grain had the maximum moisture content (10.50 per cent). This can be attributed to the higher bed temperature of particles in the bed, which increased the intraparticle moisture diffusion to the surface of the solid, resulting in a higher drying rate and the drying was strongly influenced by air temperature (81.26% of the influence), followed by solids loading (16.98%). Air velocity had a very small influence on the drying period (3.2%) [20].

Conclusion

IR heating is a unique process; however, presently, the application and understanding of IR heating in food processing is still in its infancy. It is further evident that IR heating offers many advantages over convection heating, including greater energy efficiency, heat transfer rate, and heat flux that results in time-saving as well as increased production line speed.

As per the experiments conducted for the investigation of effect on physico-chemical and nutrient properties of ragi flour during storage after IR heat treatment in designed and developed Infrared batch heating chamber, finally it can be concluded that as per the treatment given to all the samples the sample treated at 110℃ for 2 minutes shows minimum changes over the period of 90 days storage which is good for flour and the IR treatment at 110℃ for 2 minutes i.e. T110T2 is best for use.

References

- Onigbinde AO, Akinyele IO. Biochemical and nutritional changes in corn (Zea mays) during storage at three temperatures. J Food Sci. 1988;53(1):117.

- Abdul-Kadir, Bargman T, Rupnow J. Effect of infrared heat processing on rehydration rate and cooking of Phaseolus vulgaris (Var. Pinto). J Food Sci. 1990;55(5):1472-1473.

- Abioye VF, Olatunde SJ, Elias G. Quality attributes of cookies produced from composite flours of wheat, germinated finger millet flour and African yam bean. Int J Res Granthaalayah. 2018;6(11):172-183.

- Stephen AK, Emmanuel S. Improvement on the design of a cabinet grain dryer. Am J Eng Appl Sci. 2009;2(1):217-128.

- Afzal TM, Abe T, Hikida Y. Energy and quality aspects during combined FIR-convection drying of barley. J Food Eng. 1999;42(4):177-182.

- Chibuzo NS, Osinachi UF, James MT, Chigozie OF, Dereje B, Irene CE. Technological advancements in the drying of fruits and vegetables: A review. Afr J Food Sci. 2021;15(12):367-379.

- Gull A, Prasad K, Kumar P. Evaluation of functional, antinutritional, pasting and microstructural properties of millet flours. J Food Meas Charact. 2016;10:96-102.

- Desai AD, Kulkarni SS, Sahoo AK, Ranveer RC, Dandge PB. Effect of supplementation of malted ragi flour on the nutritional and sensorial quality characteristics of cake. Advance J Food Sci Tech. 2010;2(1):67-71.

- Chandrasekara A, Shahidi F. Content of insoluble bound phenolics in millets and their contribution to antioxidant capacity. J Agric Food Chem. 2010;58(11):6706-6714.

[Crossref] [Google Scholar] [PubMed]

- Dagerskog M, Osterstrom L. Infra-red radiation for food processing: A study of the fundamental properties of infra-red radiation. Lebens Wissen Technol. 1979;12(4):237-242.

- Das I, Das SK, Bal S. Drying performance of a batch type vibration aided infrared dryer. J Food Eng. 2004;64(1):129-133.

- Datta A, Ni H. Infrared and hot air assisted microwave heating of foods for control of surface moisture. J Food Eng. 2002;51(4):355-364.

- Dharmaraj U, Malleshi NG. Changes in carbohydrates, proteins and lipids of finger millet after hydrothermal processing. LWT-Food Sci and Technol. 2011;44(7):1636-1642.

- Tanhuanpaa E, Lindberg P. The fat content and fatty acid composition of grain during storage. Acta Agric Scand. 1965;15(2):171-180.

- Gabel MM, Pan Z, Amaratunga KS, Harris LJ, Thompson JF. Catalytic infrared dehydration of onions. J Food Sci. 2006;71(9):E351-E357.

- Hadimani NA, Malleshi NG. Studies on milling, physicochemical properties, nutrient composition and dietary fiber content of millets. J Food Sci Technol. 1993;30:17-20.

- Hood-Niefer SD, Tyler RT. Effect of protein, moisture content and barrel temperature on the physicochemical characteristics of pea flour extrudates. Food Res Int. 2010;43(2):659-663.

- Kanchana S, Shurpalekar KS. Effect of different levels of ragi (Eleusine coracana) husk in semisynthetic diet on the growth of albino rats. Nutr Rep Int. 1988;38(5):1067-1071.

- Jalgaonkar K, Jha SK, Sharma DK. Effect of thermal treatments on the storage life of pearl millet (Pennisetum glaucum) flour. Indian J Agr Sci. 2016;86:762-769.

- Jones JM, Engleson J. Whole grains: Benefits and challenges. Annu Rev Food Sci Technol. 2010;1:19-40.

[Crossref] [Google Scholar] [PubMed]

Citation: Sharma RK, Khokhar D (2023) Design and Development of Infrared Batch Heating Chamber for Reduction of Moisture Content to Enhance the Storability of Ragi (Eleusine coracana) Flour. J Food Process Technol. 14:1072.

Copyright: © 2023 Sharma RK, et al. This is an open access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.