Indexed In

- Online Access to Research in the Environment (OARE)

- Open J Gate

- Genamics JournalSeek

- JournalTOCs

- Scimago

- Ulrich's Periodicals Directory

- Access to Global Online Research in Agriculture (AGORA)

- Electronic Journals Library

- Centre for Agriculture and Biosciences International (CABI)

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- SWB online catalog

- Virtual Library of Biology (vifabio)

- Publons

- MIAR

- University Grants Commission

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Method Article - (2025) Volume 16, Issue 10

Design and Construction of a Recirculating Aquaculture System without a constant water source

Nathan Huysman*, Eric Krebs and Michael E. BarnesReceived: 18-Nov-2025, Manuscript No. JARD-25-30333; Editor assigned: 20-Nov-2025, Pre QC No. JARD-25-30333 (PQ); Reviewed: 04-Dec-2025, QC No. JARD-25-30333; Revised: 11-Dec-2025, Manuscript No. JARD-25-30333 (R); Published: 18-Dec-2025, DOI: 10.35248/2155-9546.25.16.1037

Abstract

The use of Recirculating Aquaculture Systems (RAS) by governmental agencies to meet stocking needs is becoming commonplace. In South Dakota, the increasing need to grow cool and warm water species such as largemouth bass, bluegill, and channel catfish has necessitated the building of RAS. This paper describes the design, construction, and operation of a RAS built in a storage building at a cold water hatchery without a consistent water source. Each component of the RAS is described in detail and was designed to be cost effective while providing multiple years of service. During operation, the system successfully reared catfish, bluegill, and largemouth bass while maintaining acceptable water quality at 3-5% daily water exchange and minimal oxygen supply (during highest densities) at 2 L/ min of oxygen supply. The operational success of the system may encourage further development of RAS at state hatcheries.

Keywords

Recirculating Aquaculture System; RAS; Aquaculture

Introduction

The use of Recirculating Aquaculture Systems (RAS) by governmental agencies tasked with supporting conservation or sport fishery needs is becoming more commonplace [1]. In South Dakota, a greater emphasis has been placed on supporting urban and community fishery programs with warm and cool water fish (e.g., largemouth bass Micropterus nigricans, channel catfish Ictalurus punctatus, and bluegill Lepomis macrochirus). Without the proper infrastructure to grow these fish at cold water hatcheries, RAS must be developed to support these directives.

This paper describes the conversion of a metal storage building without a water supply into a RAS capable of holding up to 1500 kg of fish. Furthermore, budget constraints required the RAS to be designed with the most cost-effective strategy possible. We will highlight the selected system components, design of the various features of the RAS, how the system was plumbed, and rearing performance of the system.

System components

The following components were used in the construction of the RAS (prices circa 2023, USD):

• Four, 4542 L, 2.4 m diameter, polyethylene tanks (Polytank Inc., Litchfield, MN, $1403.00 each)

• One, 7949 L, 2.21 m diameter, 2.26 m height, reservoir tank (National tank outlet, Memphis, TN, $1864.99)

• One, 2460 L, 1.82 m diameter, 1.55 m height, reservoir tank (National tank outlet, Memphis, TN, $880.00)

• Two, 568 L, rectangular tanks (Pentair aquatic ecosystems, Apopka, FL, $449.48 each)

• One, 284 L, rectangular tank (United States Plastic Corp, Lima, OH, $421.00)

• Four, 132 L, inductor tank (United States Plastic Corp, Lima, OH, $311.69 each)

• One, 6435 L, cistern tank (United States Plastic Corp, Lima, OH, $3011.53)

• One, drum filter, Hydrotech model# HDF802-16 (Veolia water technologies, bought used $10,000.00)

• One, inline oxygen diffuser, GAIA model# UFB 300 (Gaia water, Victoria, British Columbia, Canada, $2190.00)

• Two, ultraviolet filter, Pentair model# E150S (Pentair aquatic ecosystems, Apopka, FL, $1285.27 each)

• One, 5-ton heater/chiller system (Delta Hydronics, Hudson, FL)

• 1.4 m3, Bio-elements media (Integrated Aqua Systems Inc, Vista, CA, $1794.00)

• 0.56 m3, De-gassing media (L S Enterprises LLC, East Earl, PA, $341.00)

• Four, automatic fish feeders (Arvotec, Integrated Aqua Systems Inc, Vista, CA, $668.43 each)

• Two, 2.67 HP pump, model# AP2.7N-HF-DAF-3 (PerformancePro Pumps, Hillsboro, OR, $1685.45)

• One, 1.5 HP pump, model# A2-11/2-HF (PerformancePro Pumps, Hillsboro, OR, $766.35)

• One, 0.25 HP pump, model# C1/4-49 (PerformancePro Pumps, Hillsboro, OR, $556.00)

• One, 0.5 HP Booster Pump (Dayton, grainger.com, $680.93)

• One, 1/10 HP Direct Drive Blower (Dayton, grainger.com, $179.95)

• One, Air Pump, Aquamiracle AP-160 (amazon.com, $129.99)

• One, 1/2 HP Shallow well jet pump (Flint and Walling, grainger.com, $747.39)

• One Sensaphone alarming system with cellular subscription (Sensaphone, $1796.05)

• Four Electronic flow meters with digital monitoring (h2 flow controls, $3563.00)

System design overview

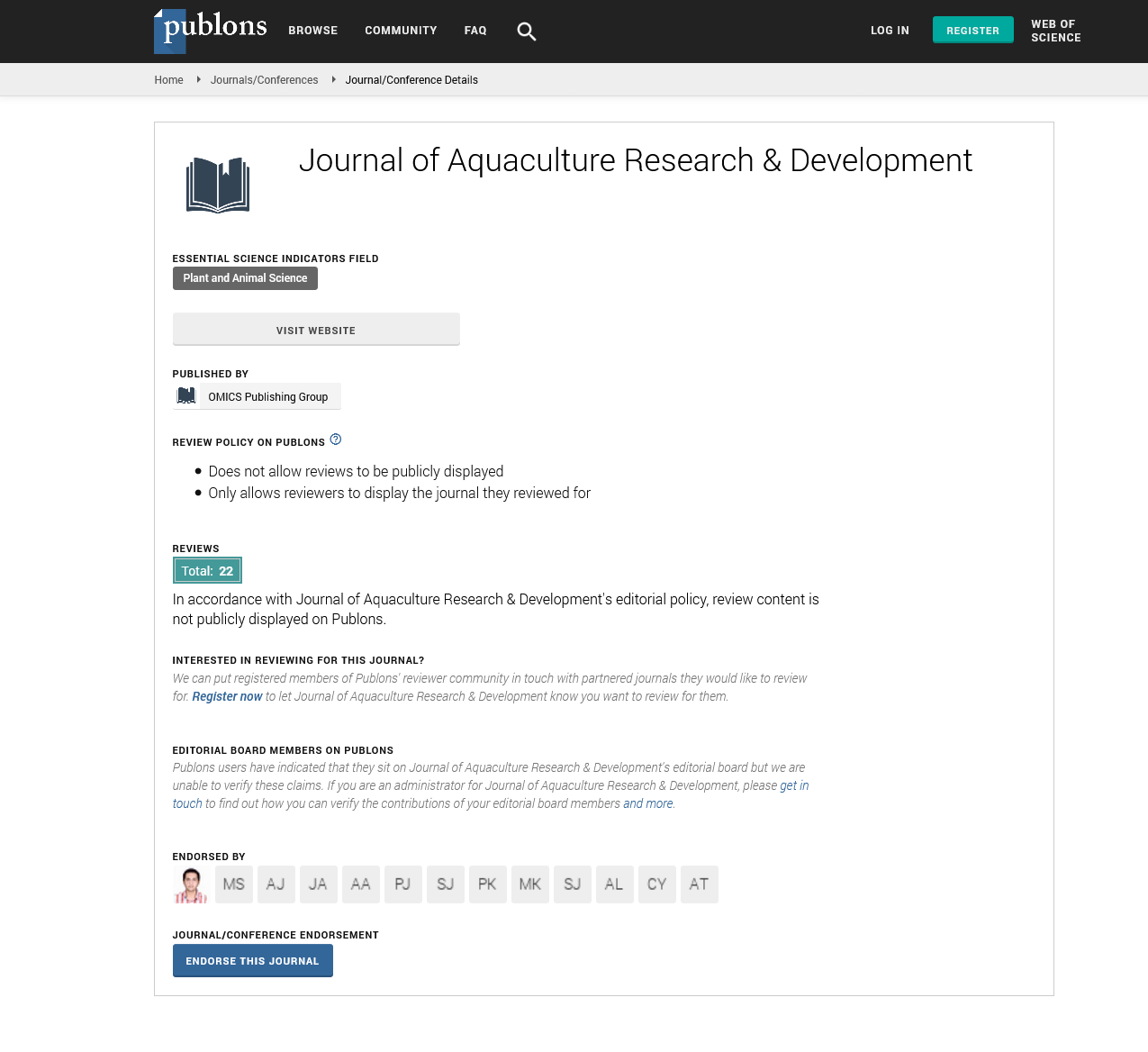

This RAS was designed and constructed to maximize the space available in an insulated 13.4 m long × 7.01 m wide metal building (Figure 1). The building was previously used for storage and did not have a water supply or drainage/sewer system. The only water available to bring into the building was from a 30.48 cm PVC aeration tower overflow line running adjacent to the building. The overflow line was diverted into a 6435 L flow-through cistern tank installed underground adjacent to the building. Inside the building, a 1/2 HP shallow well jet pump attached to a pressure tank was plumbed to the cistern to maintain constant water pressure in the building. The shallow well jet pump supplied water to a 7949 L reservoir tank, a spigot at each rearing tank, and a sink. The reservoir tank was outfitted with a manual float valve that kept the reservoir filled. From this reservoir, water is supplied to the RAS (primarily to the main sump) with a manually switched 1/4 HP pump.

Figure 1: Schematic of Recirculating Aquaculture System (RAS) built in an insulated 13.4 m long × 7.01 m wide metal building without water supply or sewer.

To maximize the available space, a 4-tank system was designed using 4542 L, 2.4 m diameter polyethylene tanks. Water was recirculated to these 4 tanks using a 2.67 HP Variable Frequency Drive (VFD) pump. This pump supplies at least 175 L/min water to each tank for a full tank water turnover rate of 30 minutes. The pump used a 7.62 cm suction line and a 10.16 cm discharge line plumbed along the wall of the building to each tank. At each tank, the 10.16 cm line was reduced to 7.62 cm where a ball valve was installed, and a dual-spray bar was plumbed in [2]. Each tank was converted into a Cornell-style dual drain tank [3]. The bottom 7.62 cm PVC drain from each tank was plumbed to a common waste line leading out of the building. The waste line from each tank could be diverted with a 7.62 cm ball valve into a 5.08 cm PVC line leading to a Radial Flow Settling tank (RFS). The top 10.16 cm PVC drain was plumbed into a common 15.24 cm PVC return line leading to a sump. This sump served as a collection point for all the main system return water. This collection sump then led to a drum filter and then into the main sump.

Bio-filtration was achieved by building a Moving Bed Bioreactor (MBBR) using a black 2460 L, 1.82 m diameter x 1.55 m height reservoir filled with 1.4 m3 of bio-media. This amount of bio- media would easily oxidize a Total Ammonia Nitrogen (TAN) load exceeding the upper limits of the system. The MBBR was continuously aerated with coarse bubble diffusers and the top access port was covered to eliminate light. Water was supplied with a 1.5 HP high flow pump on a separately plumbed loop originating from the main sump. Water was returned to the main sump with a 10.16 cm PVC line.

Another plumbing loop was designed to operate a carbon dioxide (CO2) de-gassing tower, heater/chiller, and Ultraviolet (UV) filter. Each component was plumbed separately by branching a 5.08 cm PVC line from the main 7.62 cm PVC line coming from a 2.67 HP VFD pump. Each return line from each component terminated into a common sump that the CO2 tower was built into and returned to the main sump via a 10.16 cm PVC line.

When needed, oxygen can be supplied to the system through a 7.62 cm inline oxygen diffuser plumbed just after the outlet from the main system pump. In the case of a power outage, the main system pump and CO2 loop pump can be plugged into a separate portable generator. Also, a normally closed solenoid attached to an oxygen bottle with a diffuser in each tank would supply direct oxygen to each tank in the event of a power outage. In full operation mode, the RAS held approximately 22,700 L of water. All system components were plumbed so they could be isolated and repaired in case of failure.

The next sections will discuss the design and build of each individual component of the RAS.

Methodology

System construction

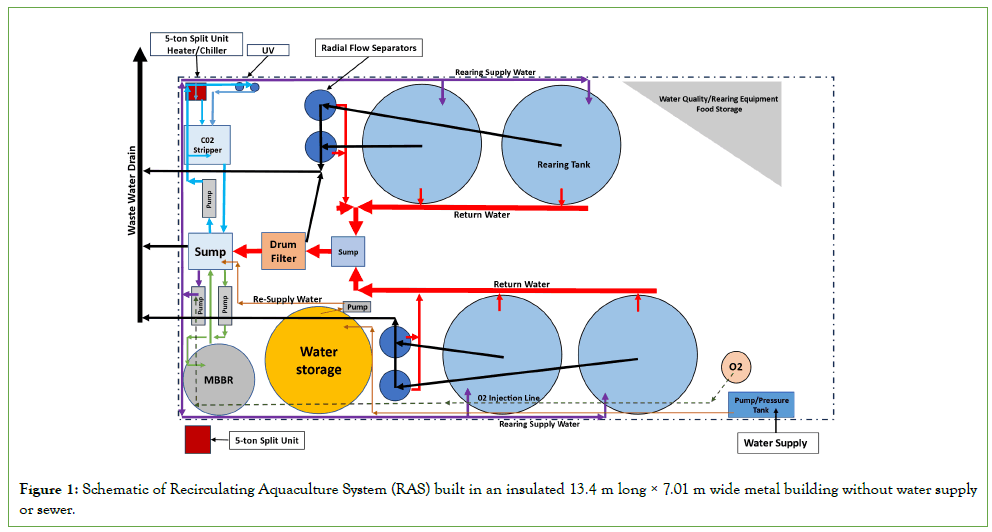

Culture tank set-up: Because the polyethylene culture tanks lacked drainage or inlet structures, the tanks were manually converted into Cornell-style dual drain tanks. Cornell-style dual drain tanks are designed with two separate drains, a top and bottom drain, to reduce solids loading into the drum filter [2]. For the top drain, a 10.16 cm uni-seal was installed with a 10.16 cm PVC open ended pipe extending approximately 10.16 cm into the tank at the estimated top water level. A perforated aluminum structure was inserted into the open-ended pipe of the top drain to maximize surface area into the drain and prevent overflow due to clogging (Figure 2).

Figure 2: Culture tank top drain perforated aluminum structure.

For the bottom drain, a 7.62 cm bulkhead fitting was installed in the center of the tank with the flat portion facing up into the tank. A 30.48 cm long, 7.62 cm PVC standpipe was press fit into the bulkhead. To facilitate draining from the standpipe, a saw blade width slit was cut into the standpipe every 1.9 cm with the first slit occurring right above the level where the standpipe sleeved into the bulkhead fitting. Slits were made every 1.9 cm for a total of 10 slits on three different sides of the pipe. The standpipe was capped with a 7.62 cm PVC slotted drain cap.

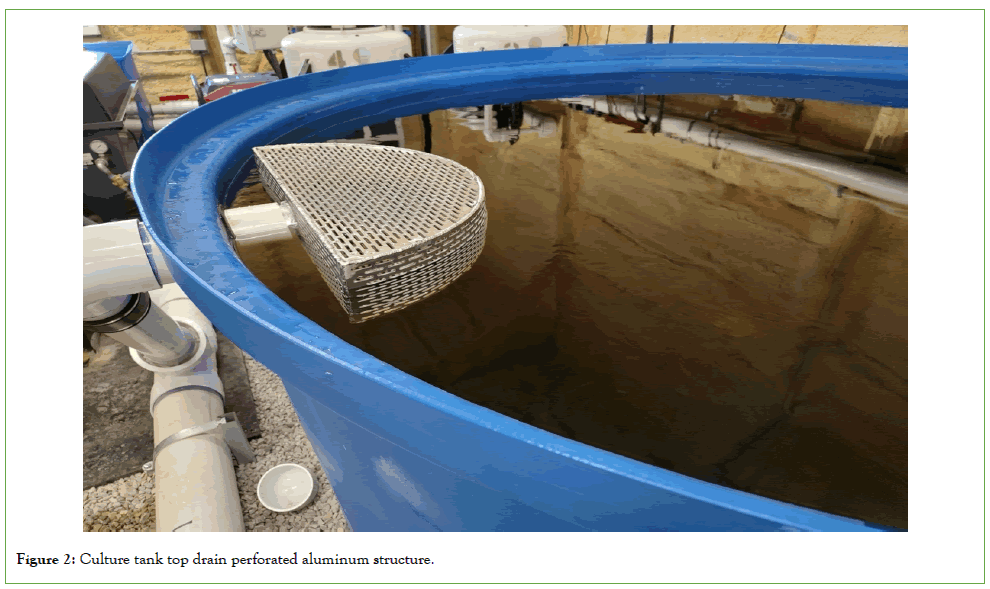

To help support the weight of each tank and facilitate drain plumbing under each tank, a metal support structure was built and buried under each tank (Figure 3). Each structure was 2.44 m × 2.44 m made from 5.08 cm × 0.31 cm thick slotted steel square tubing. Structures consisted of six 2.44 m horizontal supports running lengthwise and bolted onto two 2.44 m supports running perpendicular, and below, the horizontal supports. The perpendicular supports were elevated 25.4 cm by bolting 35.56 cm legs to another 2.44 m support bar running directly below the perpendicular support. The bottom support bars acted as the feet of the structure, maximizing contact area with the ground.

Figure 3: Culture tank support frame, exposed (left) and buried (right).

To maximize tank circulation and self-cleaning properties, a dual spray bar system with directional adjustment capabilities was built onto the main water line (Figure 4) [4]. Each spray bar was attached to the main water line with a 7.62 cm PVC union for removal and maintenance. Both the vertical and horizontal portion of the spray bars were cut so that they extended 50.8 cm out from a central 7.62 cm PVC tee. A rounded 7.62 cm PVC cap was used to close the ends of the spray bars. Twelve 0.95 cm holes were drilled equidistant apart on each spray bar. To facilitate directional control, each spray bar was plumbed with a 7.62 cm PVC male adapter that was threaded into a 7.62 cm PVC female adapter that was attached to the central PVC tee. A 0.95 cm stainless rod was drilled through the front end of each spray bar to act as a handle and to visualize water direction during orientation.

Figure 4: Culture tank dual spray bar with directional control.

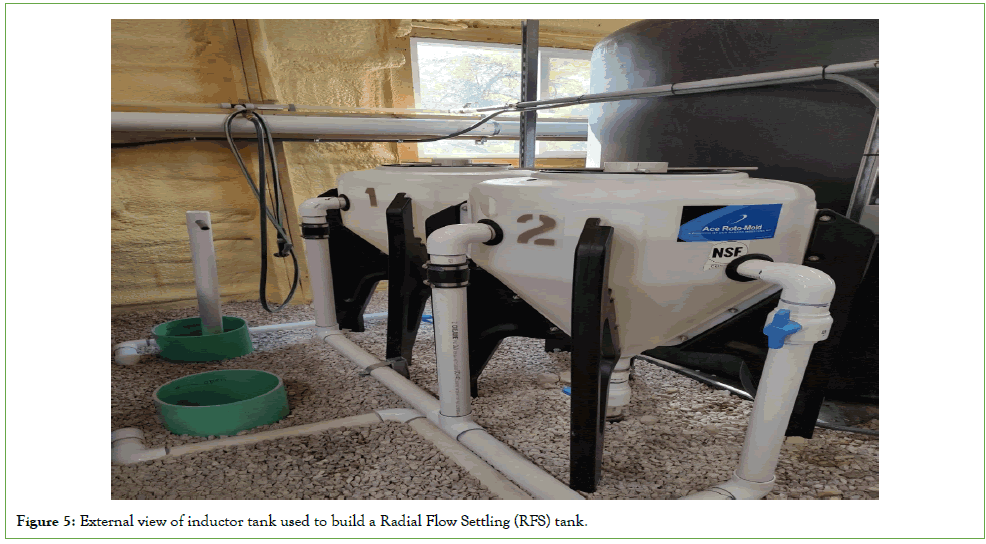

Radial Flow Settling (RFS) tank build: Each RFS was built using a 132 L inductor tank with a 60o slope for improved drainage and collection of solids (Figure 5) [5]. Water entered the inductor tank horizontally from the side using 5.08 cm PVC pipe inserted through a 5.08 cm uni-seal fitting (Figure 6). This pipe was then extended into the middle of the tank where it was directed to up-flow with a 90o PVC elbow. Water up-flow into the tank is controlled by using various lengths of 5.08 cm PVC pipe inserted into the PVC elbow. A longer PVC piece would result in less flow while a short piece would result in increased flow. Flow was set for a minimum 30 second hydraulic retention time [6]. Water exited the RFS from a 5.08 cm PVC pipe inserted through a 5.08 cm uni-seal just above the level where the water entered the RFS.

Figure 5: External view of inductor tank used to build a Radial Flow Settling (RFS) tank.

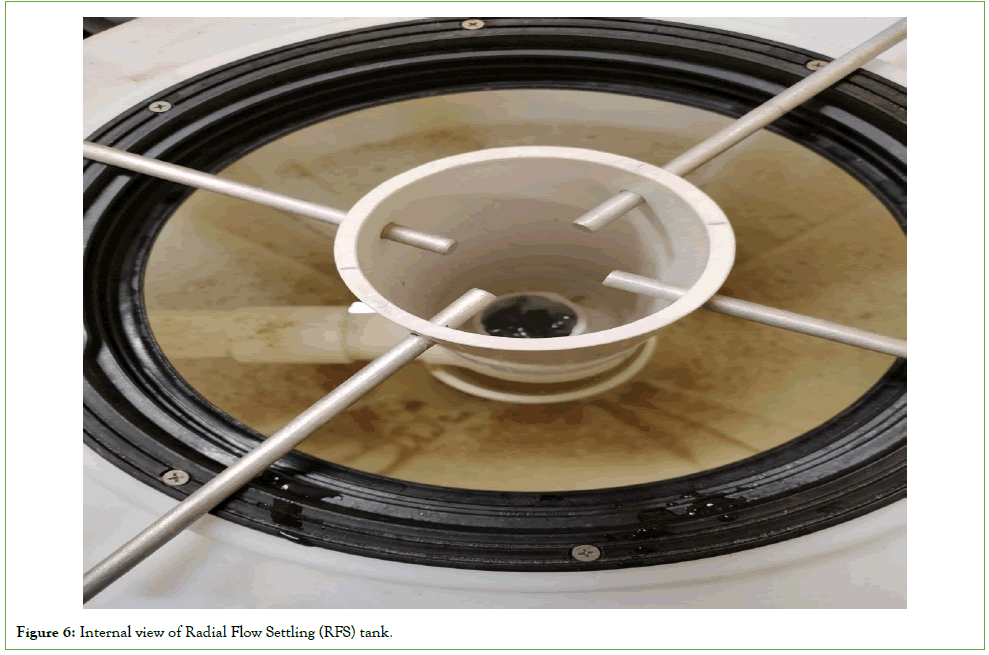

To create the quiescent zone inside the RFS, a 7.62 cm piece of PVC was suspended over the inflow pipe by inserting aluminum rods through the top of the pipe and hanging the pipe from the rim of the RFS, extending to the level of the pipe bringing water into the RFS. Since this pipe could not be extended further down the inside of the RFS, a 30.48 cm long piece of 10.16 cm PVC pipe was placed under the inlet pipe, resting on the sloped portion of the tank. The 10.16 cm PVC pipe had 4 triangular cuts made at the base for solids to drain through. The insertion of the 10.16 cm pipe greatly increased solids capture inside the RFS.

Moving Bed Bioreactor (MBBR) build: A MBBR was selected for system nitrification due to its ease of use, simplicity in design, and effective ammonia removal rates [7]. To properly size the biofilter, two parameters had to be calculated: 1) The maximum TAN produced per day, and 2) The total media volume needed to convert that amount of TAN to nitrate.

To calculate the TAN that could be produced in our system we used the following formula [8]: Total Ammonia Nitrogen (TAN, kg/day)=Max kg feed/day × %Protein in Feed × %Nitrogen Wasted × 0.16 g Nitrogen/g Protein × 1.2 g TAN/g Nitrogen

Based on previous experience, we assumed that at max densities of fish we would feed up to 12 kg/day of feed up to 50% protein. The percent nitrogen wasted is a constant set at 50%. The 0.16 g Nitrogen/g Protein and 1.2 g TAN/g Nitrogen are also feed constants. At 12 kg of 50% protein feed, we could produce up to 0.58 kg of TAN/day.

Next, to calculate the total media volume we would need to denitrify 0.58 kg of TAN to nitrate/day we used the following formula: Media Volume (m3)=TAN (g TAN/day)/VTR (g TAN/m3/day) According to manufacturer’s specifications, the Volumetric TAN conversion Rate (VTR) of our media was 532 g/m3/day. This resulted in a need for 1.1 m3 of total media to convert all the ammonia in the system.

To accommodate the 1.4 m3 of media we purchased (more than necessary but we wanted to aim on the side of caution), a black 2460 L, 1.82 m diameter, portable water containment tank was used as the reactor vessel. This size of tank would easily allow the media to not exceed 70% of reactor volume [7]. Water was recirculated through the MBBR with a 1.5 HP pump receiving water from the main sump with 7.62 cm PVC and uni-seal. This pump could supply 560 L/min to the MBBR. Water entered the MBBR through the manhole opening from a 7.62 cm PVC line. Water returned to the main sump from a 10.16 cm PVC line plumbed to the bottom of the tank. This line was inserted approximately 30.48 cm into the tank through a 10.16 cm uni-seal fitting. The 30.48 cm portion inside the tank received multiple 0.95 cm holes (just smaller than the media) drilled into it and was capped with a 10.16 cm PVC drain cap. Overflow protection was provided for by plumbing in a secondary 10.16 cm PVC drain at just above the water line (Figure 7).

Figure 6: Internal view of Radial Flow Settling (RFS) tank.

Figure 7: Overflow protection drain for Moving Bed Bioreactor (MBBR).

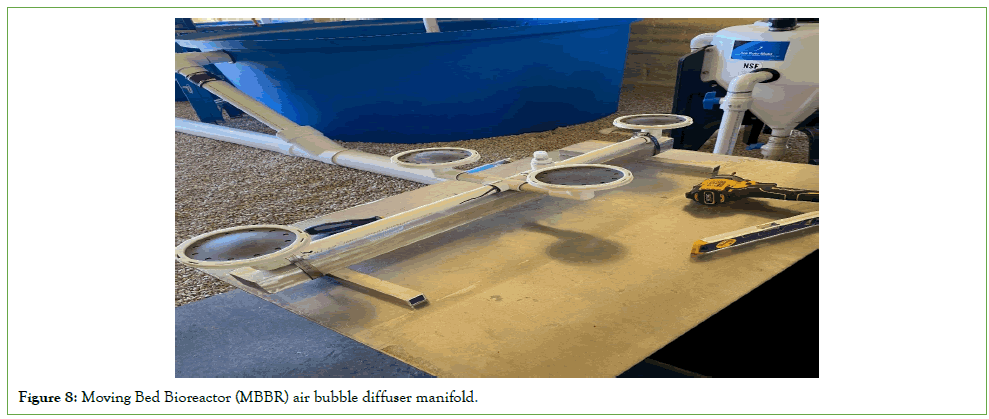

This drain was connected to the main drain from the MBBR leading into the main sump. To keep the bio-media aerated, a course bubble diffuser manifold with four diffusers was built and placed onto the bottom of the tank before adding in the media (Figure 8).

Figure 8: Moving Bed Bioreactor (MBBR) air bubble diffuser manifold.

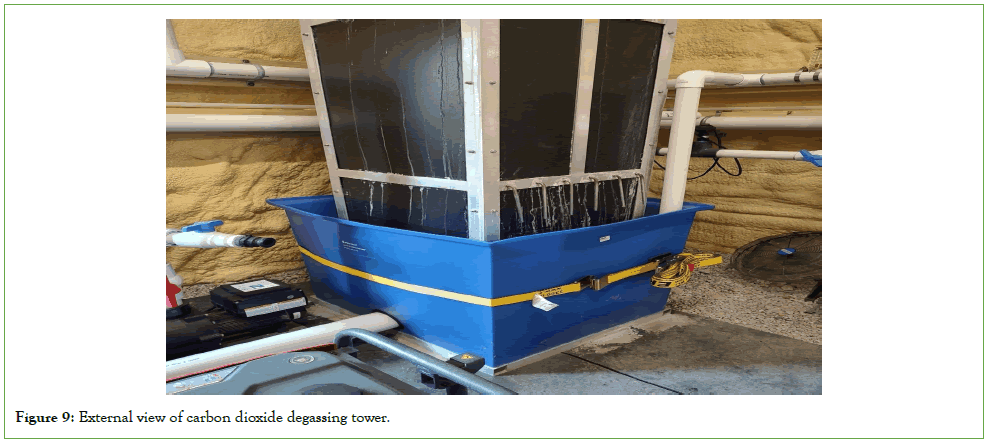

Carbon dioxide de-gassing tower build: CO2 removal was achieved with a media filled degassing tower (Figure 9). The overall dimensions of the tower were 64.77 x 64.77 x 274.32 cm. This accommodated 0.56 m3 of de-gassing media. For this design, total media surface area was 126.56 m2/m3. With a total flow rate of approximately 575 L/min, and a blower supplying 10.9 m3/min of airflow, this tower will easily maintain CO2 levels below 10 mg/L, even under heavy loadings of fish (Figure 10).

Figure 9: External view of carbon dioxide degassing tower.

Figure 10: Blower used to supply air to carbon dioxide degassing tower.

Water reservoir build: The only water available to bring into the building was from a 30.48 cm PVC overflow line from an artesian well de-gassing tower. A 7.62 cm diversion line was plumbed into the 30.48 cm overflow line. The 7.62 cm diversion line lead into a 6435 L cistern tank that was buried 122 cm deep next to the RAS building. A 7.62 cm PVC line was run from the buried cistern to an overflow channel so that water could continuously run through the cistern.

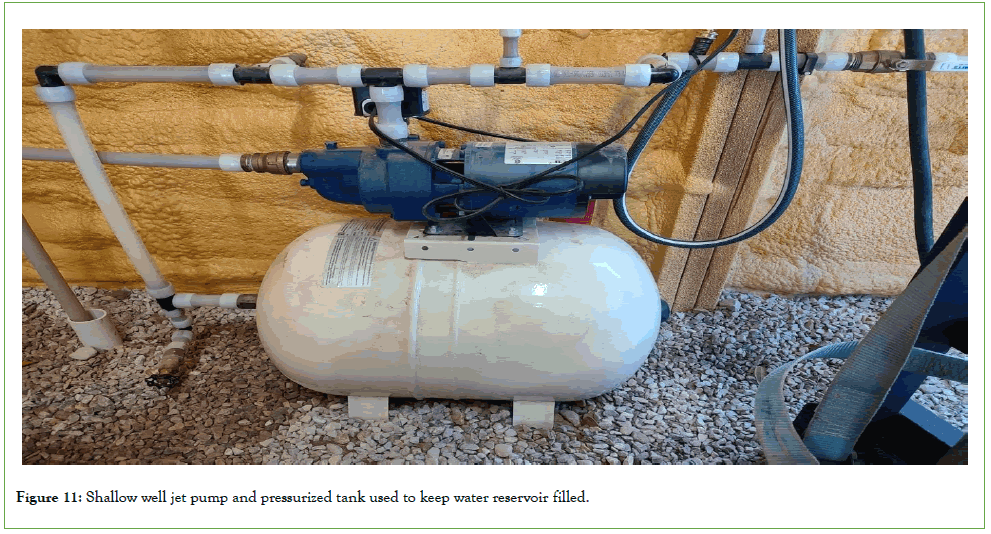

To get water into the building from the cistern, a 3.81 cm PVC line was plumbed through the top of the cistern and angled 90º so that the bottom of the pipe was near the bottom of the cistern. This line ran underground until it penetrated the RAS building and was attached to a 1/2 HP shallow well jet pump with a pressure tank (Figure 11). The shallow well jet pump supplied water to a 7949 L reservoir tank located inside the building (Figure 12). The reservoir tank was outfitted with a manual float valve that kept the reservoir filled with water from the shallow well jet pump. From this reservoir, water is supplied to the RAS with a 1/4 HP pump.

Figure 11: Shallow well jet pump and pressurized tank used to keep water reservoir filled.

Figure 12: Water reservoir with ¼ HP pump used to supply water to the system.

Plumbing design

Three separate plumbing loops were designed to facilitate proper flow of water to rearing tanks and each piece of equipment. Each loop began and returned to the main sump using a dedicated pump for each individual loop.

Main culture tank loop: A 2.67 HP variable flow pump was selected for the main culture loop to have better control of flow rates to the tanks. Water was supplied to the pump from the main sump with a 7.62 cm PVC pipe. On the outlet side of the pump, a 7.62 cm PVC in-line oxygen diffuser system was plumbed into the line. From there, the line was split into two 10.16 cm PVC legs, each supplying water to two tanks on either side of the building. An electronically monitored flow meter was installed onto each leg to measure flow and alert if there was stoppage in flow due to pump failure or power outage. Water was supplied to each tank with a vertical and horizontal spray bar. Water returned to the system from the top drains of both tanks via a 15.24 cm PVC line on the floor that carried the water to a pre- sump installed before the drum filter. Likewise, the bottom drains were diverted through the RFS’s where they were drained back into the 15.24 cm PVC line via a shared 5.08 cm PVC drain line. This water would then run through the drum filter and into the main sump where it would be redistributed across the system.

Bio-filter loop: Since variable flow was not needed for the bio- filter, a simple 1.5 HP high flow pump was selected for the bio-filter loop. This pump received water from the main sump, after solids filtration, via a 5.08 cm PVC line. Water was then pumped into the top of the bio-filter with a 7.62 cm PVC line. Water returned to the main sump from a 10.16 cm PVC line plumbed into the bottom of the reservoir. A 10.16 cm overflow line was plumbed into the reservoir just above the water line and draining down into the main 10.16 cm drain line. The overflow drain handled any fluctuations in water level. This system easily supplied 750 LPM of water to the bio-filter for an approximate 3-minute water retention time.

Carbon dioxide de-gassing tower, Heater/Chiller, Ultraviolet filter loop: This plumbing loop was designed to simultaneously supply water to the CO2 de-gassing tower, heater/chiller, and Ultraviolet (UV) filter. The CO2 tower required 575 L/min while both the heater/chiller and UV filter required 150 L/min each for a total requirement of 875 L/min. The 2.67 HP variable speed pump selected would deliver approximately this amount of water at the calculated head pressure of the plumbing system. The pump received water directly from the main sump from a 7.62 cm PVC line. The outlet of the pump was a 7.62 cm PVC line that branched off into 3 separate 5.08 cm PVC lines, each feeding an individual component of the system. Each component had a 5.08 cm ball valve installed with an in-line flow meter following to control flow. All components terminated into the sump that the CO2 tower was located in. The water returned to the main sump via a 10.16 cm PVC line connecting the two together.

Waste lines: The main sump and each half of the building all had 10.16 cm PVC waste lines plumbed in that would exit the building underground from the back. Each of these 10.16 cm lines penetrated a 30.48 cm black corrugated pipe that was buried in the ground outside the building. This pipe would direct all the waste into a solids retention pond.

Tank feeding

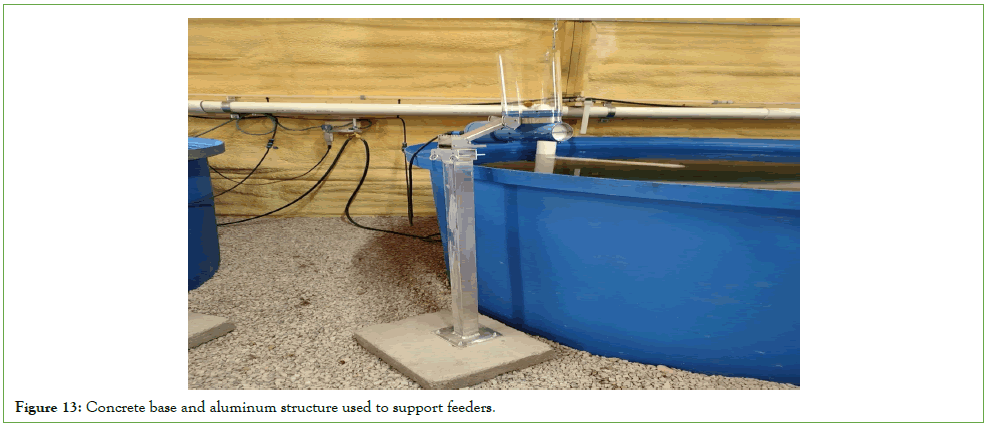

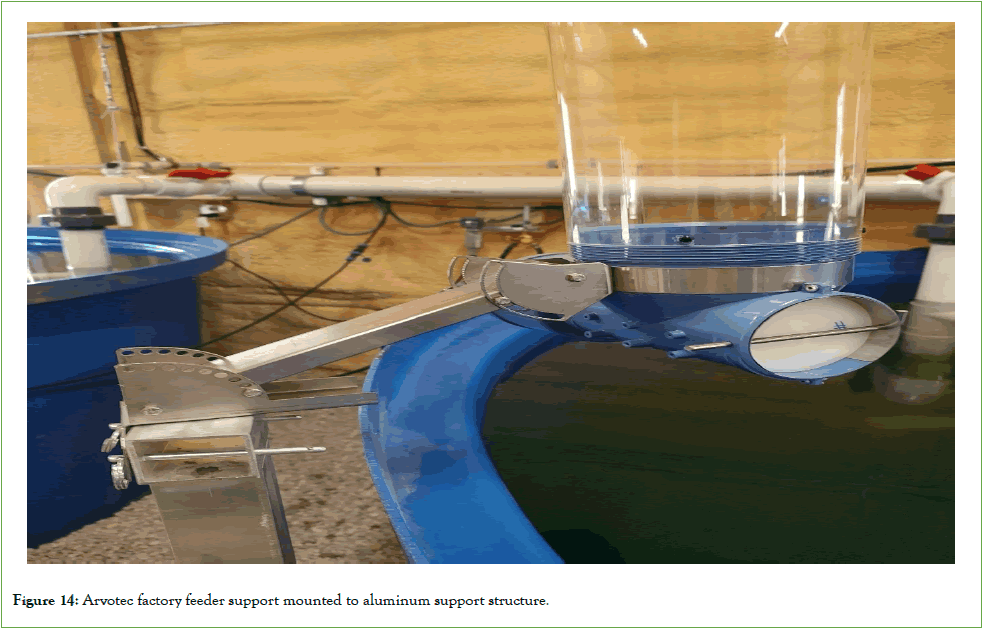

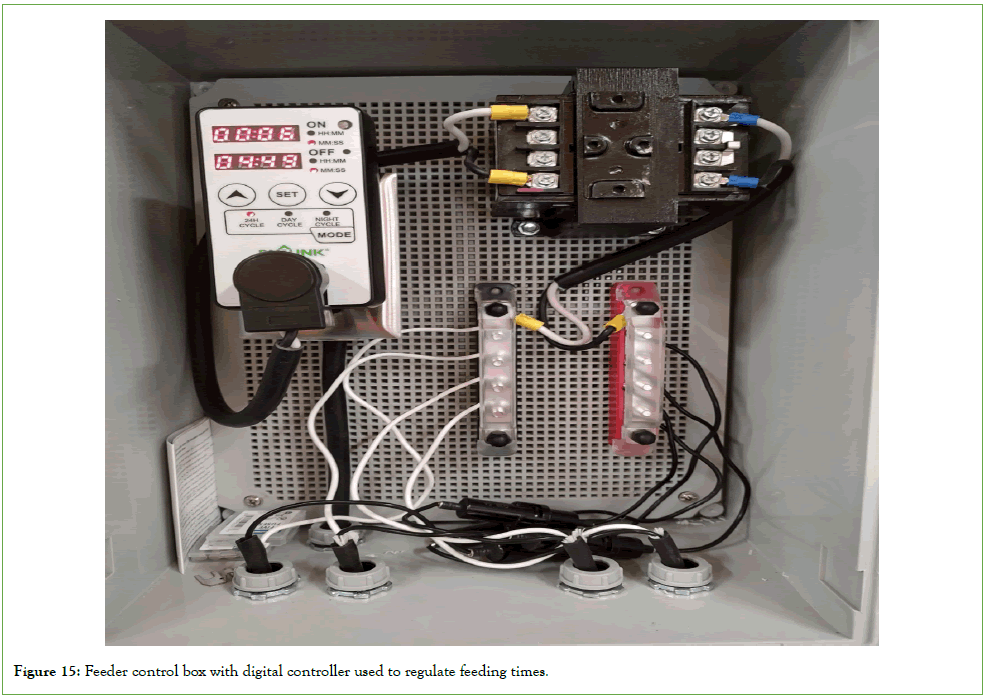

Due to the polyethylene tank rims not being able to support an Arvotec feeder, a specialized feeder mount system had to be designed. The base of the feeder support was anchored into a poured concrete square; 45.7 × 30.5 × 5.1 cm (Figure 13). The feeder support base was 15.2 × 15.2 × 0.64 cm aluminum square. A 106.7 cm long 5.1 × 5.1 × 0.3 cm aluminum square tube was welded to the base. An 8.9 cm long 5.1 × 5.1 × 0.3 cm piece of aluminum square tube was welded to the top of the aluminum riser in a perpendicular orientation. From this point, the factory mounting system for Arvotec feeders could be utilized by mounting to the perpendicular piece of aluminum with an 8.9 × 0.5 cm metal pin (Figure 14). Feeder control was designed similar to the system built by Stromberg et al. (Figure 15) [9]. In short, a duplex outlet was installed inside a weatherproof electrical box. A BN-LINK digital interval timer (BN- LINK Sante Fe Spring, California, and USA) was plugged into the duplex outlet. From the timer, a 12-gauge wire was taken to a 120 × 24 VAC transformer. On the 24 VAC side of the transformer, a 12-gauge set of wires was taken to a common bus bar, one for each leg. From the bus bars, individual outdoor rated 18 gauge 2-wire cords were run to each feeder. The timer allowed for either 24-hour, daylight, or night feedings for each tank.

Figure 13: Concrete base and aluminum structure used to support feeders.

Figure 14: Arvotec factory feeder support mounted to aluminum support structure.

Figure 15: Feeder control box with digital controller used to regulate feeding times.

Emergency back-up preparations

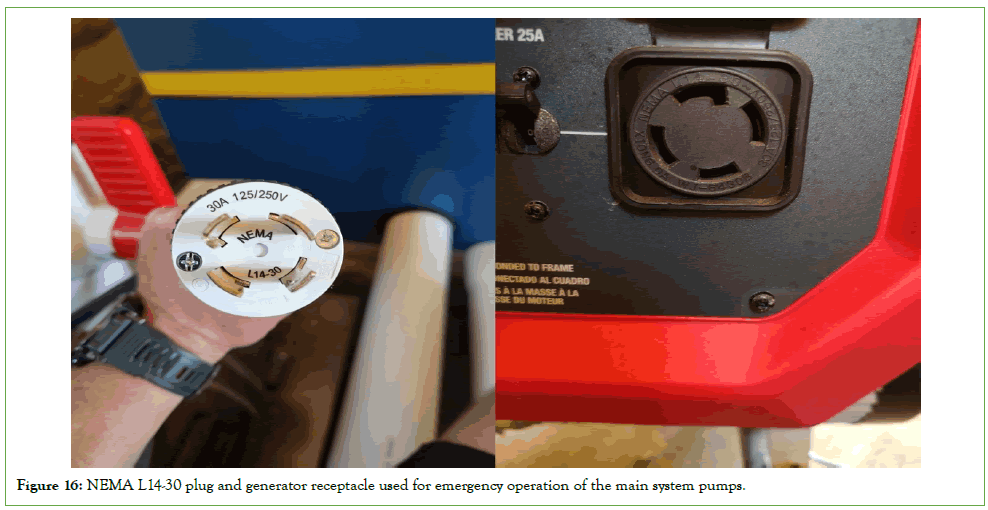

Without an external building generator for backup power, a straightforward method to quickly convert to portable generator power was designed. In the event of a power outage, the main pump and CO2 pump could be quickly transferred to a portable generator that was stored next to the pump. A NEMA L14-30 male plug was wired to the pump and could be easily plugged into either a weatherproof wall outlet of the same configuration, or the portable generator (Figure 16).

Figure 16: NEMA L14-30 plug and generator receptacle used for emergency operation of the main system pumps.

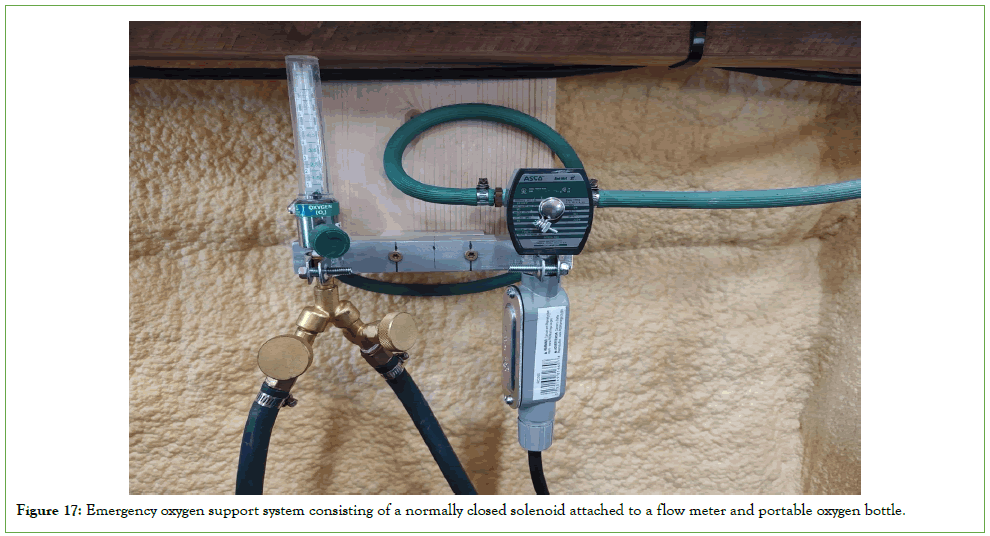

Also, a simple automatic oxygen injection system was installed, similar to the system described by Timmons and Vinci [6]. A normally open 120 VAC solenoid was wired into a 120 VAC duplex outlet and attached to an oxygen cylinder (Figure 17). In the event of a power outage, the solenoid would deactivate, sending oxygen to an oxygen flow meter where it was split into a 609 mm diffuser placed into each tank. This emergency oxygen system supplied enough oxygen to allow time to be able to turn on generators and restore water flow to each tank. Lastly, a sensaphone system with a cellular subscription was installed that could alert in power outages or low water flows for the main pump and CO2 pump. For main power outages, the sensaphone was plugged into a 120 V outlet inside the building. To detect pump failure, an electronic flow meter was installed into the outlet side of the main pump and CO2 pump. This flow meter would alert the sensaphone if flows fell below a pre-set limit.

Figure 17: Emergency oxygen support system consisting of a normally closed solenoid attached to a flow meter and portable oxygen bottle.

Conclusion

Overall, the RAS Please process the article processing charges within 24-48 hours from the date of invoice was effectively designed and successfully reared fish. The RAS held approximately 375 kg of channel catfish in two tanks and 120 kg of bluegill in the other two tanks at time of harvest without compromising water quality and minimal oxygen supply (2 L/min of oxygen continuously supplied to system). The system design is easily maintained with minimal maintenance and daily labor requirements.

Acknowledgement

We would like to thank the numerous interns that helped with the daily chores and maintenance of the RAS. We would also like to thank Analuisa Larson for her assistance with manuscript editing and formatting.

References

- Meerbeek JR. Short-term stocking survival of yearling Muskellunge raised in a recirculating aquaculture system. Iowa Department of natural resources. Federal aid in sport fish restoration, Study. 2021;7060.

- Timmons MB, Summerfelt ST, Vinci BJ. Review of circular tank technology and management. Aquacult Eng. 1998;18(1):51-69.

- Summerfelt ST, Davidson J, Timmons MB. Hydrodynamics in the ‘Cornell-type’dual-drain tank. In the third international conference on recirculating aquaculture. 2000;22:160-166.

- Tvinnereim K, Skybakmoen S. Water exchange and self-cleaning in fish-rearing tanks. 1989;2:1041-1047.

- Davidson J, Summerfelt ST. Solids removal from a cold water recirculating system-comparison of a swirl separator and a radial-flow settler. Aquacult Eng. 2005;33(1):47-61.

- Timmons MB, Vinci BJ. The Yellow book of recirculating aquaculture (5th edn), Ithaca Publishing Company LLC, Ithaca.2022.

- Rusten B, Eikebrokk B, Ulgenes Y, Lygren E. Design and operations of the Kaldnes moving bed biofilm reactors. Aquacult Eng. 2006;34(3):322-331. [Crossref]

- Losordo TM, DeLong DP. Controlling total ammonia-nitrogen (TAN) concentration is imperative. Global Seafood Alliance. 2015.

- Stromberg M, Huysman N, Barnes ME. Design of a novel control panel for 24-Volt automatic fish feeders. J Eng Technol Res.

Citation: Huysman N, Krebs E, Barnes ME. (2025). Design and Construction of a Recirculating Aquaculture System without a Constant Water Source. J Aquac Res Dev. 16:1037.

Copyright: © 2025 Huysman N, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.