Indexed In

- Genamics JournalSeek

- Academic Keys

- JournalTOCs

- China National Knowledge Infrastructure (CNKI)

- Access to Global Online Research in Agriculture (AGORA)

- Centre for Agriculture and Biosciences International (CABI)

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- SWB online catalog

- Publons

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Research Article - (2023) Volume 14, Issue 7

Assessment of Quality and Economic Viability of Small Dried Fish Produced under Sun and Heat Pump Drying Technologies

Rezaul Karim*, Rashadul Islam, Zahidul Islam, Rafiul Jannat, Yeamin Farabi Chowdhury, Debabrata Karmakar and Rakibul HasanReceived: 21-Jun-2023, Manuscript No. JFPT-23-21917; Editor assigned: 23-Jun-2023, Pre QC No. JFPT-23-21917 (PQ); Reviewed: 07-Jul-2023, QC No. JFPT-23-21917; Revised: 14-Jul-2023, Manuscript No. JFPT-23-21917 (R); Published: 21-Jul-2023, DOI: 10.35248/2157-7110.23.14.1034

Abstract

Two different methods, namely traditional sun drying and heat pump drying were employed to investigate the effect of drying on the quality of dried mola (Amblypharyngodon mola), kachki (Corica soborna) and chapila (Gudusia chapra). Results showed that the sensory characteristics of the dried fish produced under both sun and mechanical drying process found to be excellent in quality and overall acceptability scores. Sun dried fish products rehydrated more rapidly than mechanically dried products. The pH value of mechanically dried products found to be lower than the sun dried products ranged from 6.15% to 6.85%. The moisture, protein, lipid and ash content ranged from 9.52% to 10.62%, 59.41% to 70.31%, 9.86% to 22.55% and 7.80% to 11.68% respectively. The fatty acid profile showed no breakdown of the unsaturated fatty acids using heat pump dryer. The Total Volatile Base Nitrogen (TVB-N) value, acid value and per-oxide value ranged from 39.71 mg/100 g to 47.72 mg/100 g, 16.52 mg KOH/g to 17.41 mg KOH/g lipid and 15.05 meq/kg to 18.41 meq/kg lipid respectively the aerobic plate count of dried fish products ranged from 4.09 log CFU/g to 4.85 log CFU/g. Mechanically dried products were found to be more profitable than sun dried products. In conclusion, heat pump drying can be used as an environment friendly method for human consumption which enhances food security.

Keywords

Sun drying; Heat pump drying; Biochemical analysis; Free fatty acid; Cost benefit analysis

Introduction

Bangladesh positioned among the top five fish producing countries in the world with the productions of its vast aquatic resources including inland waters, river, brackish and marine water [1]. In the recent time, the fish production from marine sectors is increasing with a steady growth rate of above 5% annually. Unfortunately, a great loss has been observed with these huge productions because of its perishable nature and some procedural and preservation complexity of fishes. Globally, fish is known as a quick perishable item, immediately after harvest which start to lose its quality [2,3]. Because of that emergency it’s requires fast and rapid preservation after harvest. Post-harvest losses have an adverse effect on fishing communities that regularly rely upon post-gather exercises. The financial existence in addition, detrimentally affected by sun losses of the fishing communities and detract a considerable portion of the population’s access to protein [4].To recover such losses fish should be preserved immediately after harvest. There are many methods such as- freezing, drying, salting and smoking that have been practiced all over the world with aimed to extend the shelf life of fish. Sun-drying is the most commonly accepted method of fish preservation although it is the world’s oldest preservation methods [5]. It increases the shelf life, enhances the quality, provide ease of handling and further processing and sanitation [6]. Importantly dry fish is a great source of protein which is preferred most by many peoples of Asia and Europe because of its characteristic flavor, texture and taste and longer shelf life without refrigeration [7]. Because of dry fish such supremacy yearly 8% of the total world’s catch undergo dry fish processing industry [8].Mechanical drying is a modern method of fish drying that requires little or no sunlight for the drying process. It could be a revolution in the dry fish industry of producing a considerable amount of products. The ultimate benefits of the technique are that “one can produce dried fish any time of the day/year”. In addition, complete hygiene procedures, drying parameters and product processing steps can be maintained easily throughout the process. Moreover, the technology would not only reduce the risk of product spoilage but would also improve the quality of the dried fish products. Though, sun drying is the most cost effective drying process with various identical features of the dried products but several issues are faced by the producers during production. The most considerable cost regarding s un-drying is the huge loss of raw material during the rainy season and bad weather condition [9]. Moreover, in some cases it is found that the physical and sensory attributes of various traditional sun dried fish products for human consumption were unsatisfactory. There are frequent complaints from consumers about the quality of the products and the major problems associated with this drying procedure fish are the infestations by the house fly and insect larvae, poor sanitation and improper process that often lead to contamination and spoilage and ultimately the use of pesticide to prevent those [10]. Recently, the dried fish export market of Bangladesh is facing challenges because of unhygienic and traditional drying practices, and the use of prohibited chemicals during the drying of fish [11]. All those occur mainly because of the current climatic conditions, the procedural complexity of producing dried fish products, and the lack of modern drying methods. To improve the condition various drying methods have been applied by various researchers from the beginning. This study is aimed at applying a complete mechanical drying process to produce some improved dried fish products. A comparative evaluation will be performed for the mechanically dried products by producing the same products following the standard sun drying method. The perfect execution of the findings could be able to substitute the dry fish demand in the global market beside the sun dried products.

Materials and Methods

Sample collection

The study was carried out at Institute of Technology Transfer and Innovation (ITTI), Bangladesh Council of Scientific and Industrial Research (BCSIR), Dhaka, Bangladesh. Mola (Amblypharyngodon mola), Kachki (Corica soborna) and chapila (Gudusia chapra) fish were collected from the nearly available Kawran Bazar fish market (23°45'05.6"N to 90°23'50.4"E), Dhaka, Bangladesh.

Sample preparation for drying

After collecting the fishes were immediately brought to the study area for sorting according to size and quality and washing carefully to remove waste and unwanted particle. After processing fish were spread on wire mesh trays and the trays were kept in an organized way into drying rack for mechanical drying. For sun drying trays were placed in an open place under sun for drying and covered by fine meshed net to avoid flies and insect infestation.

Mechanical drying: Heat pump dryer was used for mechanically fish drying process. The temperature was controlled at 45 ± 3°C for 6 hours (drying). The relative humidity was maintained 50.20 ± 0.5% during the drying time. The fish were turned over after 4 hours from the beginning for better drying.

Sun drying: The fish were kept under proper monitoring to avoid over drying and turned over after 3 hours of placing. The average temperature was 34 ± 2 (8 hours daylight) and relative humidity was 60.28 ± 3.5% during the experimental time.

Quality analysis

Physical characteristics: Acceptance test was conducted with ten trained panelist of ITTI sensory panel. Each panelist was asked to evaluate the colour, odor, texture, and insect infestation of each sample by using ten point hedonic scales according to the method described by Roy (2013) [12].

Determination of water reconstitution behavior: Water reconstitution behavior of the products was investigated following the method described by Hasan et al., (2016).

Determination of pH: Initially 10 g of sample were weighed and placed in a beaker. Then 10 times of distilled water was added and homogenized properly using tissue homogenizer. Finally, the pH of the mixture was measured using CRM multi-parameter (HQ40d,Hach).

Biochemical composition

Biochemical composition of the traditionally sun-dried and mechanical dried fishes was determined through following standard method of each.

Moisture content determination: Moisture content was determined by using Moisture Analyzer Shimadzu, Japan (Moc63u).

Protein determination: Analysis of protein was done by using the method of Dumas JBA (1831) [13].

Lipid determination: Crude fat was determined by following Twisselmann (1923) using petroleum ether as solvent through Fat Extractor E-500 ECE [14].

Ash content determination: The determination of ash content of dry fish samples were made according to the method described in the AOAC official method AOAC, (1995) [15].

Measurement of free fatty acid

The determination of Free Fatty Acid (FFA) of fish oil samples were made according to the method described in the AOAC official method O’keefe and Pike, (2010) using GCMS-2014 (Shimadzu) [16].

Determination of TVB-N

The method of Antonopoulos and Vyncke (1989) was followed to estimate total volatile base nitrogen (TVB-N). The value was expressed as mg/100 g of muscle [17].

Lipid oxidation determination

Determination of peroxide value: Standard procedure AOAC (1995) was followed to determine peroxide value. Initially 0.5 g of fat sample was mixed with 30 mL of acetic acid: Chloroform solution (3:2) into a conical flask. Then 0.5 mL potassium iodides mix into the solution and kept in dark condition for 10 minutes. Then the mixture was diluted with 30 mL distilled water and added 0.5 mL of freshly prepared 1% starch. Finally, mix the sample vigorously and titrated with 0.01 N sodium thiosulfate. The peroxide value was expressed as meq/kg of lipid.

Determination of acid value: Standard method AOAC (1995) was followed to determine the acid value. Initially 0.5 g of fat sample was mixed with 100 mL of ethanol: Diethyl ether solution (1:1 v/v) into a conical flask. A drop of phenolphthalein was used as an indicator. Finally, the mixture was titrated with 0.01 N potassium hydroxide. The results were expressed as mg KOH/g lipid.

Microbiological analysis

Plate Count Agar (PCA) (Hi media, Mumbai, India) and physiological saline solution (0.85% NaCl) was used to perform aerobic plate count according to the methods given in Cowan and Steel’s manual.

Benefit-Cost Ratio (BCR) analysis

The Benefit Cost-Ratio (BCR) was calculated considering the products monetary facts. In addition the qualitative and quantitative factors were also considered of the products. The formula used for calculate BCR is

Net benefit (NB)=PVB-PVC

Where,

BCR=Benefit cost ratio

PVB=Present value of all qualitative and quantitative benefits

PVC=Present value of all types of costs

NB=Net benefit

Statistical analysis

All the experimental data were analyzed by computer software SPSS (version 21.0). One-way analysis of variance (ANOVA) and values were presented as the mean ± Standard Deviation (SD) of triplicate determinations by t test and the test of significance was defined at p<0.05.

Results

Drying of fishes

The traditional sun drying method took almost 8 hours to dry the A. mola, C. soborna and G. chapra fishes respectively where the average air temperature was 34 ± 2°C and relative humidity was 60.28 ± 3.5% as the system was totally dependent on environment the time range will vary dependent on the weather condition. On the other hand, the mechanical drying method took almost 6 hours to dry A. mola, C. soborna and G. chapra fishes where the average temperature was maintained at 45 ± 3°C and relative humidity was 50.20 ± 0.5%. The product quality was found excellent in condition after drying.

Quality analysis

Physical characteristics: The dried fish produced by the both drying method was found excellent in quality according to the sensory properties, such as color, odor, texture and insect infestation (Table 1). Significantly (p<0.05) highest value in case of odor was found in sun dried A. mola, C. soborna and G. chapra than mechanically dried products but no significant difference (p>0.05) was found between these two methods in case of other sensory parameters and overall acceptability.

| Fish | Drying method | Color | Odor | Texture | Insect infestation | Overall acceptability |

|---|---|---|---|---|---|---|

| A. mola | SD | 1.37 ± 0.09 | 1.25 ± 0.13 | 1.49 ± 0.10 | 1 | 1.28 ± 0.08 |

| MD | 1.23 ± 0.11 | 1.18 ± 0.10 | 1.38 ± 0.13 | 1 | 1.20 ± 0.09 | |

| C. soborna | SD | 1.28 ± 0.010 | 1.29 ± 0.09 | 1.31 ± 0.11 | 1 | 1.22 ± 0.08 |

| MD | 1.22 ± 0.07 | 1.19 ± 0.06 | 1.27 ± 0.09 | 1 | 1.17 ± 0.03 | |

| G. chapra | SD | 1.26 ± 0.12 | 1.22 ± 0.11 | 1.41 ± 0.14 | 1 | 1.22 ± 0.09 |

| MD | 1.20 ± 0.0 | 1.16 ± 0.07 | 1.33 ± 0.13 | 1 | 1.17 ± 0.07 | |

| Note: Each value is expressed as a mean (scoring 1-10) ± SD (n=10); SD: Sun Dried; MD: Mechanically dried. | ||||||

Table 1: The sensory properties of A. mola, C. soborna and G. chapra dry products produced through mechanically drying and sun drying.

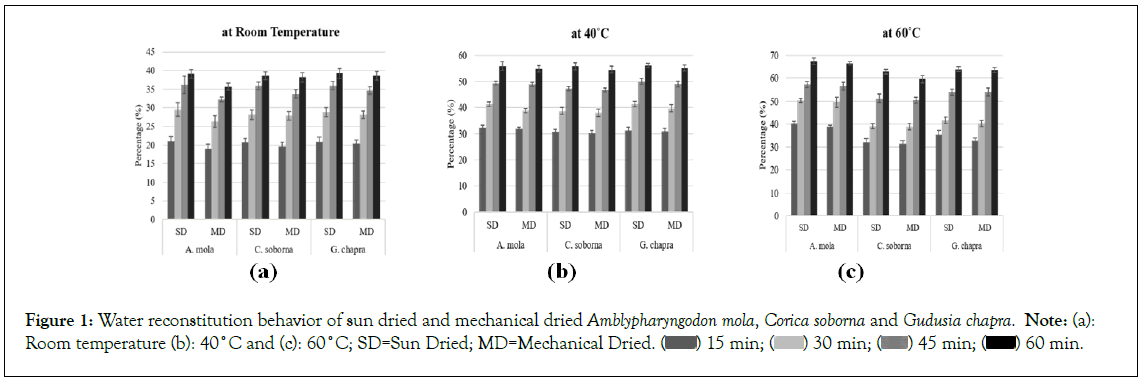

Determination of water reconstitution behavior: The water reconstitution percentage of the produced dried fishes is shown in Figure 1. The results showed that the sun dried A. mola, C. soborna and G. chapra held 39.11%, 38.65% and 39.22% moisture at room temperature, 55.95%, 55.90% and 56.13% at 40°C and 67.26%, 62.82% and 63.90% moisture at 60˚C after 60 minute respectively. On the other hand mechanically produced dried A. mola, C. soborna and G. Chapra held 35.67%, 38.18% and 38.58% moisture at room temperature, 54.97%, 54.60% and 55.23% at 40˚C and 66.36%, 59.47% and 63.47% moisture at 60˚C after 60 minute respectively. The reconstitution level was not significantly (p>0.05) increased with the increment of time and temperature.

Figure 1: Water reconstitution behavior of sun dried and mechanical dried Amblypharyngodon mola, Corica soborna and Gudusia chapra. Note: (a):

Room temperature (b): 40˚C and (c): 60˚C; SD=Sun Dried; MD=Mechanical Dried. ( ) 15 min; (

) 15 min; ( ) 30 min; (

) 30 min; ( ) 45 min; (

) 45 min; ( ) 60 min.

) 60 min.

pH value of dried fish products: The pH values of the dry fish products produced by the different drying methods are shown in Table 2. The pH value ranged from 6.15 to 6.85. The pH was significantly (p<0.05) higher pH value was observed in sun dried A. mola than the mechanically dried fish. No significant difference (p>0.05) in pH was found between sun dried and mechanically dried products of C. soborna and G. chapra.

| Fish | Drying method | pH |

|---|---|---|

| Mola | Sun dried | 6.85 ± 0.18 |

| (A. mola) | Mechanically dried | 6.41 ± 0.11 |

| Kachki | Sun dried | 6.46 ± 0.10 |

| (C. soborna) | Mechanically dried | 6.15 ± 0.14 |

| Chapila | Sun dried | 6.61 ± 0.20 |

| (G. chapra) | Mechanically dried | 6.24 ± 0.15 |

| Note: Each value is expressed as a mean ± SD (n=3); SD: Sun Dried. | ||

Table 2: The pH value of A. mola, C. soborna and G. chapra dry products produced through mechanical and sun drying process.

Proximate analysis of dried fish products

The proximate analysis of dried A. mola, C. soborna and G. chapra was performed on a dry weight basis (Table 3). Comparatively the dried products obtained from mechanical and sun drying showed no significant difference. The moisture content of dried fish ranged from 9.52% to 10.62%. The protein content of dried products ranged from 59.81% to 70.31%. The lipid content of dried fish products ranged from 9.86% to 22.55%. The ash content of dried fish products ranged from 7.80% to 11.68%. Significantly (p<0.05) the highest moisture content in sun dried, highest ash content in mechanically dried G. chapra and highest lipid content was found in sun dried A. mola compared with the associated drying method and no significant difference (p>0.05) was found in other parameters obtained from two different drying methods.

| Fish | Drying Method | Moisture | Protein | Lipid | Ash |

|---|---|---|---|---|---|

| Mola | Sun dried | 10.24 ± 0.61 | 59.41 ± 2.24 | 22.55 ± 1.13 | 7.80 ± 1.16 |

| (A. mola) | Mechanically dried | 10.12 ± 0.52 | 59.81 ± 2.11 | 21.93 ± 1.35 | 8.14 ± 1.19 |

| Kachki | Sun dried | 9.91 ± 0.3 | 70.15 ± 1.68 | 9.86 ± 0.93 | 10.08 ± 1.05 |

| (C. soborna) | Mechanically dried | 9.52 ± 0.26 | 70.31 ± 2.25 | 10.02 ± 0.77 | 10.15 ± 1.11 |

| Chapila | Sun dried | 10.62 ± 0.45 | 64.35 ± 1.59 | 14.34 ± 1.52 | 10.69 ± 1.32 |

| (G. chapra) | Mechanically dried | 10.26 ± 0.39 | 64.49 ± 1.42 | 13.57 ± 1.21 | 11.68 ± 1.13 |

| Note: Each value is expressed as a mean ± SD (n=3); SD: Sun Dried. | |||||

Table 3: Effect of drying methods on the proximate composition (%) of A. mola, C. soborna and G. chapra.

Fatty acid profile

The fatty acid profile of both fish products obtained from sun and mechanical dryer are presented in Table 4. Total Saturated Fatty Acids (SFA) percentage of the total lipid from sun dried and mechanically dried A. mola, C. soborna and G. chapra ranged from 59.618% to 60.144%, 78.718% to 78.754% and 69.354% to 70.674% respectively. Mono Unsaturated Fatty Acids (MUFA) percentage of the total lipid from sun dried and mechanically dried A. mola, C. soborna and G. chapra ranged from 32.486% to 32.924%, 15.87% to 16.595% and 22.214% to 23.055% respectively. Poly Unsaturated Fatty Acids (PUFA) percentage of the total lipid from sun dried and mechanically dried A. mola, C. soborna and G. chapra ranged from 7.37% to 7.458%, 4.649% to 5.41% and 7.112% to 7.59% respectively. Thirteen fatty acids in muscle lipids from A. mola, C. soborna and G. chapra were classified and evaluated. Important fatty acids found were myristic acid (C14:0, 4.394%-6.744%), palmitic acid (C16:0, 28.624-35.356%), palmitoleic acid (C16:1n7, 6.584%- 13.106%), margaric acid C17:0, 1.099%-21.960%), stearic acid (C18:0, 4.827%-10.362%), oleic acid (C18:1n-9, 9.286%-19.458%), linoleic acid (C18:2n-6, 3.242%-5.212%), alpha linolenic acid (C18:3n3, 1.287-3.114%), arachidic acid (C20:0, 3.564%-8.926%) and behenic acid 246 (C22:0, 1.444%-5.399%).

| Fatty acid (%) | Mola (A. mola) | Kachki (C. soborna) | Chapila (G. chapra) | ||

|---|---|---|---|---|---|

| SD | MD | SD | MD | SD | |

| C12:0 | - | - | - | - | 1.097 |

| C13:0 | 1.214 | 1.209 | - | - | - |

| C14:0 | 6.557 | 6.581 | 4.394 | 4.493 | 6.26 |

| C15:0 | 4.968 | 5.025 | 1.108 | 1.024 | 1.686 |

| C16:0 | 28.624 | 29.07 | 33.795 | 34.247 | 33.074 |

| C16:1 | 13.028 | 13.106 | 7.259 | 6.584 | 8.765 |

| C17:0 | 2.328 | 2.399 | 21.694 | 21.96 | 6.882 |

| C18:0 | 4.827 | 4.964 | 9.545 | 9.339 | 9.704 |

| C18:1n9 | 19.458 | 19.818 | 9.336 | 9.286 | 13.449 |

| C18:2n6 | 4.283 | 4.344 | 3.362 | 3.242 | 4.881 |

| C18:3n3 | 3.087 | 3.114 | 1.287 | 2.168 | 2.231 |

| C20:0 | 8.86 | 8.926 | 3.725 | 3.564 | 6.873 |

| C22:0 | 2.766 | 1.444 | 4.493 | 4.091 | 5.098 |

| Note: *SD=Sun Dried; MD= Mechanically dried. | |||||

Table 4: Effect of drying methods on the free fatty acid composition (%) of A. mola, C. soborna and G. chapra.

Changes of Total Volatile Base Nitrogen value (TVB-N)

The TVB-N values of the dry fish products produced by the different drying methods are shown in Table 5. The TVB-N value ranged from 35.01% to 47.72%. Significantly (p<0.05) the highest TVB-N value was found in mechanically dried A. mola than sun dried A. mola and sun dried C. soborna than mechanically dried C. soborna, A. mola. No significant difference (p>0.05) was found between the sun and mechanical dried G. chapra.

| Fish | Drying Method | Acid value (mg KOH/g lipid) | Per-oxide value (meq/kg lipid) | TVB-N (mg/100g) |

|---|---|---|---|---|

| Mola | Sun dried | 17.41 ± 0.72 | 15.05 ± 0.93 | 46.21 ± 0.51 |

| (A. mola) | Mechanically dried | 16.52 ± 0.78 | 15.21 ± 0.84 | 47.72 ± 1.19 |

| Kachki | Sun dried | 10.32 ± 0.87 | 12.34 ± 1.02 | 36.71 ± 0.71 |

| (C. soborna) | Mechanically dried | 10.11 ± 0.93 | 12.03 ± 0.96 | 35.01 ± 0.76 |

| Chapila | Sun dried | 11.59 ± 0.79 | 14. 41 ± 1.12 | 40.35 ± 1.14 |

| (G. chapra) | Mechanically dried | 10.94 ± 0.57 | 14.33 ± 0.92 | 39.91 ± 1.06 |

| Note: Each value is expressed as a mean ± SD (n=3); SD: Sun Dried. | ||||

Table 5: Acid value, peroxide value and TVB-N value of dried fish products produced through mechanically drying and sun drying.

Lipid oxidation determination

The degree of lipid oxidation in dried fish products was measured by determining the acid value and peroxide value. The acid value of dried A. mola, C. soborna and G. chapra ranged from 10.11 mg KOH/g to 17.41 mg KOH/g lipid. Significantly (p<0.05) the highest acid value was found in sun dried A. mola but other products obtained from sun and mechanically drying process were found not significant (p>0.05). The per-oxide value of dried fish ranged from 12.03 meq/kg to 15.21 meq/kg lipids (Table 5). No significant difference (p>0.05) was found between sun dried and mechanically dried products of A. mola, C. soborna and G. chapra.

Microbiological load of dried fish products

The aerobic plate count of dried fish products obtained from mechanical and sun drying method ranged from 4.01 log CFU/g to 4.85 log CFU/g (Table 6). Significantly (p<0.05) the highest microbial load was observed in sun dried A. mola, C. soborna and G. chapra compared with the products produced by the mechanical dried method.

| Fish | Drying method | Aerobic plate count (log CFU/g) |

|---|---|---|

| Mola | Sun dried | 4.76 ± 0.16 |

| (A. mola) | Mechanically dried | 4.09 ± 0.06 |

| Kachki | Sun dried | 4.62 ± 0.05 |

| (C. soborna) | Mechanically dried | 4.18 ± 0.15 |

| Chapila | Sun dried | 4.85 ± 0.09 |

| (G. chapra) | Mechanically dried | 4.59 ± 0.16 |

| Note: Each value is expressed as a mean ± SD (n=3); SD: Sun Dried. | ||

Table 6: Effect of the drying methods on microbial load of A. mola, C. soborna and G. chapra.

Benefit-Cost Ratio (BCR)

The shape and size of the dryer was compact and durable with ease of handling and installation. Though the size and shape of the dryer was small, the tray area can accommodate 80 kg of raw fish per batch. In addition, the size and shape of the dryer could be increased and modified to accommodate higher number and weight of fish which increased the viability of the project cash flows. BCR is directly dependent on raw and final products price and species types. The production cost varies only depending on the time needed for drying. It is the type of fish and its market demand mainly has direct effect on BCR. But, considering the production cost the technology is not effective for low valued fish. Therefore, the production technology is suitable for high market priced fishes. Table 7 comprises the BCR of the freshwater and marine mola produced under heat pump dryer.

| SI No. | Characters | Mola (A. mola) |

Kachki (C. soborna) |

Chapila (G.chapra) |

|||

|---|---|---|---|---|---|---|---|

| SD | MD | SD | MD | SD | MD | ||

| 1 | Raw materials cost (BDT/kg dry fish production) | 500 BDT/Kg | 800 BDT/Kg | 500 BDT/Kg | 800 BDT/Kg | 500 BDT/Kg | 800 BDT/Kg |

| 2 | Other Cost (Depreciation cost, Electricity cost, Labor cost, Packaging cost etc.) | 15 BDT/Kg | 60 BDT/Kg | 15 BDT/Kg | 60 BDT/Kg |

15 BDT/Kg | 60 BDT/Kg |

| 3 | Present value of all types of costs (PVC) | 515 BDT/Kg | 860 BDT/kg | 515 BDT/Kg | 760 BDT/kg | 515 BDT/Kg | 860 BDT/Kg |

| 4 | Selling price of the final product (PVB) | 650 BDT/Kg | 1250 BDT/Kg | 650 BDT/Kg | 1250 BDT/Kg | 650 BDT/Kg | 1250 BDT/Kg |

| 5 | Net benefit (NB) | 135 BDT/Kg | 390 BDT/Kg | 135 BDT/Kg | 390 BDT/Kg | 135 BDT/Kg | 390 BDT/Kg |

| 6 | Benefit-cost ratio | 1.26 | 1.45 | 1.26 | 1.45 | 1.26 | 1.45 |

Table 7: Benefit Cost Ratio (BCR) of Mola (A. mola), Kachki (C. soborna) and chapila (G. chapra) produced under heat pump dryer and traditional sun dried process.

Discussion

Quality analysis

Physical characteristics: In this study, the products obtained from sun dried and mechanical dried process found excellent in case of sensory characteristics except the odor. But the mechanical drier produced mild flavor products and the sun dried products found containing their characteristics flavor slightly. The difference of odor was not so high between the products produced from these two methods because of the size of the experimental species. Oven dried C. punctatus produced an excellent quality product in terms of odor, color, texture and insect infestation [18]. In another study, traditionally sun-dried fish products showed objectionable color, odor, and texture but comparatively better quality fish products produced through solar tunnel dryer [19]. Solar tunnel dryer showed comparatively better result than the traditional and improved dryer for dried fish production [20].

Water reconstitution: In this study water reconstitution behavior of both mechanical dried and sun dried fish products showed a positive relationship between water absorption and increasing water temperature. Overall, the dried fish produced by sun drying method were rehydrated more rapidly than the dried fish produced by the heat pump drying method. Water temperature opens the internal structure of fish muscle and stimulates the chance of rapid rehydration which indicates that a positive relationship is sustained between physical properties and rehydration ability of dried fish products [21-23]. Hasan (2006) showed that the maximum reconstitution capacity in some small indigenous species ranged from 30.69% to 56.66%, 35.62%to 66.24% and 48.46% to 78.94% soaked after 60 min on solar tunnel drier at 30˚C, 40˚C and 60˚C temperature respectively, which were more or less similar with the present study [24]. Moreover, the variation of species along with time and temperature are the possible parameters which influences the rehydration ability of dried fish products [22,25].

pH: In this study it has been found that the mechanically dried fish products (A. mola, C. soborna and G. chapra) showed lower pH value than sun dried fish products which denied with Jahan and Akhtar, 2019 who found the highest pH content in oven dried and the lowest in sun dried C. punctatus products [18]. The acceptable fish pH range is 6-8 but is considered to be spoiled above 7 and the quality of dried fish improved at low pH value [26,27].In this study, the initial pH value of dried fish were ranged from 6.15 to 6.85 immediately after drying which indicated the better product quality.

Proximate analysis

In this study, the moisture content was ranged from 9.52% to 10.62%. Lower moisture content cease the mould growth and increase the shelf life of dried products. In a study, it has been reported that when the moisture content of a fish is reduced to 25% is seemed well dried and mould growth will cease and shelf life will increase if the moisture content reduce to 15% [28]. The protein content of this study ranged 59.48% to 71.31% which supported the results of other researcher. In a study, it has been reported that the sun dried fish products normally contain 60% to 80% protein [29]. The protein content in dried fish ranges from 55.75% to 64.49% and 49.23% to 62.85% in three selected dried fish species and 40.69% to 66.52% in fourteen selected dried fish species [30,31]. The lipid content of this study was ranged from 9.86% to 22.55%. In freshwater A. mola the lipid content found higher which supports the results of other researchers 18.45% in A. mola and 14.03% [32]. The Ash content of this study was ranged from 7.80% to 11.68%. The presence of minerals in any sample is described by the ash content which qualitatively indicates the importance of the species and this study matches comparatively with other findings [33,34].

Fatty acid

Among the saturated fatty acids, palmitic acid (C16:0), margaric acid (C17:0), stearic acid (C18:0) found predominant in dried fish products which supports Islam et al., 2018. Important unsaturated fatty acids obtained from the products were Palmitoleic acid (C16:1n7), oleic acid (C18:1n-9), linoleic acid (C18:2n-6), linolenic acid (C18:3n-3). Palmitic acid (C16:0) was found as a dominant saturated fatty acid in fish [35-37]. In case of MUFAs oleic acid (C18:1n-9) found as dominant in freshwater fish and Palmitoleic acid (C16:1n-7) and oleic acid (C18:1n-9) found as a dominant MUFAs in marine fish [38-42]. Freshwater microalgae contain plenty of Palmitic acid, oleic acid, Linoleic acid, alpha-linoleic acid [43]. Freshwater fish require linoleic acid (18:2 n‐6), linolenic acid (18:3 n‐3) or both [44].These fatty acids then accumulate in the fish via the food chain and abundantly found in fish.

TVB-N content

The increasing amount of TVB-N in fish indicates progressing the spoilage. It has been reported that the TVB-N value of dried tilapia fillets ranged between 44.27 and 64.39 mg/100 g of muscle. In another study, oven dried and sun dried C. punctatus products TVB-N value found 3.85 mg/100 g and 4.02 mg/100 g respectively, in different marine fish products TVB-N value ranged from 1.9-25.2 mg/100 g which were obtained using solar tunnel dryer [18,44]. In this study, TVB-N value found lower than the recommended value (100 mg-200 mg/100 g) which determined the freshness of the products [45,46].

Lipid oxidation

Acid value: Sun drying products showed higher acid values compared with dried fish produced by the heat pump drying method. Lower acid values determined the better quality products. In this study, the acid values were ranged from 10.11 mg KOH/g to 17.41 mg KOH/g of lipid which supported [47,48]. Free fatty acids breakdown by lipid hydrolysis might be the cause of increasing amount of acid value of dried fish products. The oxidative deterioration of polyunsaturated fatty acids in fish muscle which causes lipid peroxidation, shortening the shelf-life of food products followed by the production of off-flavor and off-odor [49].

Peroxide value: In this study, the peroxide values were observed within acceptable limits (PV ≤ 20 meq/kg fish lipid) and ranged from 12.03 meq/kg to 15.21 meq/kg lipids which was more or less similar with the results reported by Majumdar et al., (2017). No significant (p>0.05) difference had found regarding the peroxide value between the drying methods [46].

Microbial content

The total bacterial count (CFU/g) of the dried C. punctatus found higher in sun dried sample than in oven dried sample which is agreed with this study. In this study the mechanically dried A. mola, C. soborna and G. chapra showed lower bacterial count than sun dried fish products [18,23]. The APC of some marine dried fish ranges between 3.27 and 4.49 log CFU/g and between 1.84 log CFU/g and 5.3 log CFU/g for some sun dried fish and bacterial load of traditional dried SIS products ranged from 1.43 × 108 CFU/g to 2.89 × 108 CFU/g [5,24]. The bacterial count of this study were ranged from 4.01 log CFU/g to 6.83 log CFU/g. and the acceptable limit of total plate count for fresh fish is 7 log CFU/g and 1 × 105 at 37˚C temperature for dried fish [50,51].

Benefit cost ratio

Ali et al., (2008) observed that rural farmers made an appreciable surplus from marketing smoked fish. Most of the bonga fish marketers (42.50%) found more fruitful yield selling dry fish [52-59].This indicates that dried fish is more profitable than raw fish. Hence, the authors worked on fish drying process where the products had been found more acceptable and profitable using mechanical drier than traditional sun drying process.

Conclusion

The results demonstrated that the dry fish products produced by mechanical dryer and sun drying methods are more or less similar in terms of sensory characteristics. It was also observed that no changes in proximate composition were occurred in the final products due to the mechanical drying process. The microbial load, TVB-N value, peroxide value and acid value were found in acceptable limit in case of both methods. Fatty acid percentage of the final products obtained from mechanically dried products found more or less similar compared to sun dried products. During the drying process, no insect infestation was occurred in dried fish products and so that shelf life of products might be increased. It can be concluded that the physical and chemical properties of the final products of mechanical dryer remained identical to sun drying products so that mechanical drying method can replace the traditional method of sun drying.

Conflict of Interest

The authors declare that they have no personal relationships or known competing financial interests that could have appeared to influence the work reported in this paper.

Ethical Clearance

The ethical clearance for the use of animals in the present research is not applicable.

Acknowledgments

The authors are grateful to the Bangladesh Council of Scientific and Industrial Research (BCSIR) and the Ministry of Science and Technology, Bangladesh.

References

- FAO.The State of World Fisheries and Aquaculture. Contributing to food security and nutrition for all. Rome, pp. 200.2016.

- Dewi RS, Nurul H, Ahmad R. Changes in the physico-chemical properties, microstructure and sensory characteristics of shark depending using different drying methods. Am J Food Technol. 2011;6(1):149-157.

[Crossref]

- Musa U, Hati SS, Adamu YI, Mustapha A. Pesticides residues in smoked fish samples from north-eastern Nigeria. J Appl Sci. 2010;10(11):975-80.

- Adeyeye SA. Smoking of fish: A critical review. J Cul Sci Technol. 2019;17(6):559-575.

- Mansur MA, Rahman S, Khan MN, Reza MS, Uga S. Study on the quality and safety aspect of three sun-dried fish. Afr J Agric Res. 2013;8(41):5149-5155.

- Mujumdar AS. Handbook of Industrial drying. Taylor and Francis group, UK.2007.

- Immaculate K, Sinduja P, Velammal A, Patterson J. Quality and shelf life status of salted and sun dried fishes of Tuticorin fishing villages in different seasons. Int Food Res J. 2013;20(4):123-124.

- Patterson J, Kailasam S, Giftson H, Immaculate JK. Effect of drying technologies on the biochemical properties of Stolephorus commersonnii. Food Qual Saf. 2018;2(3):153-158.

- Mazid MA, Kamal M. Development of low cost solar dryer for the production of improved quality dried fish. Final Report. BFRI. Marine Fisheries and Technology Station and Bangladesh Agricultural University, Mymensingh. 2005;65.

- Kamruzzaman AK. Qualitative evaluation of some commercial dried fish products of Bangladesh. Mymensingh: Department of Fisheries Technology, Bangladesh Agricultural University. 1992.

- Hasan MM, Rasul MG, Ferdausi HJ, Trina BD, Sayeed A, Shah AK. Comparison of organoleptic and chemical characteristics of some traditional and improved dried fish products. Res J Animal Vet Fishery Sci. 2016;4(2):1-6.

- Roy VC. Improvement of food quality of dried Bombay duck (Harpodon nehereus) product using salt and herbal substances (Doctoral dissertation).2013.

- Dumas JBA. Procedes de l’analyse organic. Annales de Chimie et de Physique. 1831;247 (1):198-213.

- AOAC. Official methods of analysis, 16th ed.; Association of official analytical chemists: Arlington, VA, USA.1995.

- Twisselmann HAT (1923). Chem-Ztg 47:506; D.R.P. 519371 (1931).

- O’keefe SF, Pike OA. Fat characterization. Food analysis. 2010;4(1):117-132.

[Crossref]

- Antonacopoulos N, Vyncke W. Determination of volatile basic nitrogen in fish: A third collaborative study by the West European Fish Technologists' Association (WEFTA). J Food Res Technol. 1989;189(4):309-316.

- Jahan SN, Akhtar S. Quality assessment of oven dried and traditional sun dried Channa punctatus. Int J Food Sci Biotechnol. 2019;4(1):94-95.

- Rahman MJ, Karim E, Uddin MS, Zaher M, Haque MA. Development of low-cost emergency fish dryer in Bangladesh to use in absence of sunlight. Bangladesh Res Public J. 2012;7(1):267-276.

- Rasul MG, Majumdar BC, Afrin F, Bapary MA, Shah AA. Biochemical, microbiological, and sensory properties of dried Silver carp (Hypophthalmichthys molitrix) influenced by various drying methods. Fishes. 2018;3(3):25.

- Brennan JG, Butters JR, Cowell ND, Lilly AE. Food engineering operations. Appl Sci. 1976.

- Tunde-Akintunde TY. Effect of soaking water temperature and time on some rehydration characteristics and nutrient loss in dried bell pepper. Agric Eng Int: CIGR Journal. 2008.

- Reza MS, Bapary MA, Azimuddin KM, Nurullah M, Kamal M. Studies on the traditional drying activities of commercially important marine fishes of Bangladesh. Pak J Biol Sci. 2005;8(1):1303-1310.

- Hasan MM, Shikha FH, Hossain MI, Kamal M, Islam MN, Wahab MA. Quality assessment of traditional, rotary and solar tunnel dried small indigenous fish species products. Bangladesh J Fish Res.2006; 10 (1): 73-84.

- Nurullah M. Quality assessment and improvement of traditionally dried small indigenous fish of Bangladesh. Mymensingh: Department of Fisheries Technology, Bangladesh Agricultural University. 2005.

- Huss HH. Fresh Fish-quality and quality changes, FAO Fihs. Series 29, FAO DANINAQ, Rome, Italy.1988;132.

- Farid FB, Latifa GA, Nahid MN, Begum M. Comparison of the changes in physico-chemical characteristics of dry salted Snake-head shoal (Channa striatus Bloch, 1801) and Taki (Channa punctatus Bloch, 1793) at room temperature (27˚C to 31˚C). Res J Animal Vet Fishery Sci. 2014;2(9):18-23.

- Clucas IJ. Fish handling preservation and processing in the tropics part. 1982;1(1):144-145.

- Haque E. Bangladesher Chhoto Machh (A book on small fishes of Bangladesh). Published by Graphic Sign, Mymensingh. 2004;2200:81-84.

- Rahman MA, Gheyasuddin H, Rasid MH, Choudhury MF. Proximate composition and native quality of freshwater Zeol fishes of Bangladesh. Bangladesh J Fish. 1982;2(5):34-43.

- Azam K, Basher MZ, Asaduzzaman M, Hossain MH, Ali MY. Biochemical quality assessment of fourteen selected dried fish. J Zool Rajshahi Univ. 2003;22(1):23-26.

- Ullah N, Hazarika P, Handique PJ. Biochemical quality assessment of ten selected dried fish species of north east India. Int adv res J Sci Eng Technol. 2016;3(1):30-33.

- Hussain MM, Karim A, Alam Z, Islam MS, Khan A, Hossain A. Effect of pre-treatment on the drying of ghonia fish Labeo gonius in the open sun and in a solar tent. Bangladesh J Zool. 1992;20(2):231-238.

- Islam MA, Hossain BB, Bhuiyan AS, Absar N. Biochemical composition and nutritional value of Cirrhina reba (Hamilton-1822) of Bangladesh. J bio sci. 2003;11(1):127-130.

- Visentainer JV, Noffs MD, de Oliveira Carvalho P. Lipid content and fatty acid composition of 15 marine fish species from the southeast coast of Brazil. J Am Oil Chem Soc. 2007;84(6):543-547.

- Guler GO, Kiztanir B, Aktumsek A, Citil OB, Ozparlak H. Determination of the seasonal changes on total fatty acid composition and ω3/ω6 ratios of carp (Cyprinus carpio L) muscle lipids in Beysehir Lake (Turkey). Food Chem. 2008;108(2):689-694.

- Li G, Sinclair AJ, Li D. Comparison of lipid content and fatty acid composition in the edible meat of wild and cultured freshwater and marine fish and shrimps from China. J Agric Food Chem. 2011;59(5):1871-1881.

- Gutierrez LE, Silva RC. Fatty acid composition of commercially important fish from Brazil. Scientia Agricola. 1993;50(1):478-483.

- DURMUŞ M. Fish oil for human health: Omega-3 fatty acid profiles of marine seafood species. Food Sci Technol. 2018;39:454-461.

- Hasan Koizumi K, Hiratsuka S. Fatty acid compositions in muscles of wild and cultured ocellate puffer Takifugu rubripes. Fish Sci. 2009;75(5):1323-1328.

- Tanakol R, Yazici Z, Şener E, Sencer E. Fatty acid composition of 19 species of fish from the Black Sea and the Marmara Sea. Lipids. 1999;34(3):291-297.

- Aydın M, Tufan B, Sevgili H, Köse S. Seasonal changes in proximate composition and fatty acid profile of pufferfish (Lagocephalus sceleratus Gmelin, 1789) from the Mediterranean Sea of Turkey. J Aquat Food Prod Technol. 2013;22(2):178-191.

- Othman FS, Jamaluddin H, Ibrahim Z, Hara H. Production of α-linolenic acid by an oleaginous green algae Acutodesmus obliquus isolated from Malaysia. J Pure Appl Microbiol. 2019;13(3).

- National Research Council Nutrient requirements of fish. Washington, DC: National Academies Press.1993.

[Crossref]

- Reza MS, Bapary MA, Islam MN, Kamal MD. Optimization of marine fish drying using solar tunnel dryer. J Food Process Preserv. 2009;33(1):47-59.

- Connell JJ. Control of fish quality, 4th edn Hoboken fishing news books: Oxford, UK. 1995.

- Shah AA, Tokunaga C, Kurihara H, Takahashi K. Changes in lipids and their contribution to the taste of Migaki-nishin (dried herring fillet) during drying. Food Chem. 2009;115(3):1011-1018.

- Majumdar BC, Afrin F, Rasul MG, Khan M, Shah AK. Comparative study of physical, chemical, microbiological and sensory aspects of some sun dried fishes in Bangladesh. Brazilian J Biol Sci. 2017;4(8):323-331.

- Ramanathan L, Das NP. Studies on the control of lipid oxidation in ground fish by some polyphenolic natural products. J Agric Food Chem. 1992;40(1):17-21.

- Ojagh SM, Rezaei M, Razavi SH, Hosseini SM. Effect of chitosan coatings enriched with cinnamon oil on the quality of refrigerated rainbow trout. Food chem. 2010;120(1):193-198.

- Surendran P, Nirmala TKV, Lalitha KV. Laboratory manual on microbiological examination of seafood, (2nd ed), CIFT, Cochin. 2006.

- Ali EA, Gaya HI, Jampada TN. Economic analysis of fresh fish marketing in Maiduguri Gamboru market and Kachallari Alau dam landing site of Northeastern Nigeria. J Agric Soc. 2008; 4(1).

- Antonacopoulos N, Vyncke W. Determination of volatile basic nitrogen in fish: A third collaborative study by the West European Fish Technologists' Association (WEFTA). J Food Res Technol. 1989;189(4):309-316.

- Lee MH. Official methods of analysis 16th Ed. Association of official analytical chemists. Washington DC, USA. Sci Educ. 1995.

- Cowan ST. Cowan and Steel's manual for the identification of medical bacteria. Cambridge University press UK. 1993.

- Mohamed GF, Hegazy EM, Abdellatef M. Physicochemical properties and mycotoxins contents of Tilapia fish-fillets after solar drying and storage. Glob Vet. 2011;7(2):138-148.

- Islam MT, Ahmed S, Sultana MA, Tumpa AS, Flowra FA. Nutritional and food quality assessment of dried fishes in Singra upazila under Natore district of Bangladesh. Trends Fish Res. 2013;2(1):2319-4758.

- Islam R, Islam MD, Shoeb M, Nahar N. Fatty acid compositions in marine fish samples of Bangladesh. J Nutr Food Sci. 2018;8(5):1-3.

- Siddhnath, Ranjan A, Mohanty BP, Saklani P, Dora KC, Chowdhury S. Dry fish and its contribution towards food and nutritional security. Food Rev Int. 2022;38(4):508-536.

Citation: Karim R, Islam R, Islam Z, Jannat R, Chowdhury YF, Karmakar D et al., (2023) Assessment of Quality and Economic Viability of Small Dried Fish Produced under Sun and Heat Pump Drying Technologies. J Food Process Technol.14:1034.

Copyright: © 2023 Karim R, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.