Indexed In

- Open J Gate

- Genamics JournalSeek

- Smithers Rapra

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- Publons

- Geneva Foundation for Medical Education and Research

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Research Article - (2025) Volume 15, Issue 3

An Overview of the Conventional and Recent Trends in the Granulation Technologies

Sunil G. Shingade and Satish M. Mane*Received: 16-Aug-2025, Manuscript No. ACE-25-29491; Editor assigned: 19-Aug-2025, Pre QC No. ACE-25-29491 (PQ); Reviewed: 02-Sep-2025, QC No. ACE-25-29491; Revised: 18-Sep-2025, Manuscript No. ACE-25-29491 (R); Published: 25-Sep-2025, DOI: 10.35248/2090-4568.25.15.374

Abstract

Granulation is the particle enlargement by the agglomeration of fine particles. Granulation is necessary to avoid the segregation of powder mixture constituents. It is also needed to increase the compressibility and flow ability of the powder mixture. Dry (conventional and pneumatic) and wet are the two main types of the granulation technologies and would be selected on the physiochemical properties of the granulating materials. There are various types of advanced wet granulation technologies such as inverse wet granulation, steam granulation, moisture activated dry granulation, and thermal adhesive granulation, melt granulation, freeze granulation and foam granulation which are in current practices. High shear and low shear wet granulation technologies are considered as the conventional paths for carrying out the granulation. The present review article deals with the mechanism of the various granulation technologies with their merits and demerits.

Keywords

Granulation; Dry and wet; High and low shear; Melt; Freeze and steam granulation; Inverse wet granulation; Pneumatic dry granulation

Introduction

The process of particle enlargement by the agglomeration of fine particles is called as granulation [1]. It is mainly used in the production of pharmaceutical dosage forms, mostly tablets and capsules. Granulation process converts the fine powder into the free flowing, dust free granules which are easy to compress [1]. Granulation process is carried out to increase the flow ability, compressibility of the powder for the avoidation of segregation of the various powder excipients and to maintain the uniformity throughout the entire powder mixture. It means that granulation is carried out to enhance the uniformity of various powder excipients in the final product and to increase the density of the blend for better storage and shipment. Granulation is having the additional advantages like it facilitates metering, reduces dust formation, reduces toxic exposure to the environment and improves the appearance of the product also. Segregation occurs while storing and transportation of the powder mixture because the generally high dense and smaller particles get settle down easily which is not accepted because uniform composition is required while formulating the tablets and capsules. Granules are having inter and intra-granular porous structure and therefore, these are more compressible than normal powder mixture. The difference between the characteristics of the powder and the granules has been discussed inside the Table 1. Granulation is generally carried out after the initial dry mixing of the necessary powder excipients along with the active pharmaceutical ingredients. Granulation process is a difficult task to carry out because of the high quality requirement in terms of content uniformity and physical properties like size, bulk density, porosity, hardness, moisture content, compressibility of the formed granules because further these are processing for the formation of tablets and capsules [1]. The granules being used in pharmaceutical industries are having the size in the range of 0.2 to 4 mm.

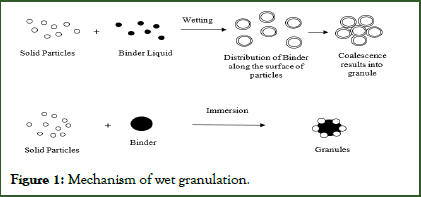

The mechanism of granules formation includes the nucleation and wetting of the fine powder particles followed by coalescence and consolidation along with attrition or breakage as shown in Figure 1.

Figure 1: Mechanism of wet granulation.

| Powder | Granules |

| Distinct particles having the size less than 1000 µm. | It is an agglomeration of the particles and having the size between 0.2 to 0.4 mm. |

| Powder particles are fine and having the large surface area per unit mass. Therefore, these are having high cohesive strength. | Granules are larger in size and having the comparatively less surface area per unit mass. Therefore, these are having comparatively less cohesive strength. |

| Flow properties are poor/low and not suitable for tablet compression. | Flow properties are high as compared to powder particles and suitable for tablet compression. |

|

Segregation of ingredients can occur during formulation or during storage or during transportation because, the powder mixture contains the ingredients of different sizes and densities. |

Segregation gets avoid and uniform composition of various ingredients inside the tablet can be achieved. |

|

Powder is less compressible because of the voidage existing between the powder particles is very less and therefore air may get in trap during the compression of tablets and does not escape easily which increases the capping tendency. |

Granules possesses the large inter and intra granules porosity which increases the compressibility and air entrapped gets release out easily during the tablet compression and finally it reduces the chances of air getting entrapped. |

|

Powder particles are smaller in size and therefore they get blown from the dye and also causes the sticking problems frequently during the tablet compression. |

Granules are larger in size and possesses high flowing ability and therefore there are less chances of causing sticking problems during compression. |

|

Powder particles are fine and having the large surface area per unit mass which generates more and more friction between them and therefore they are having poor flowing properties. |

Granule are comparatively larger in size and therefore the surface area per unit mass is less. Therefore, friction generating between them in flowing condition is less. Therefore, they are having high flowing properties. |

|

Powder particles are fine and bulk powder consists of the large number of particles and therefore large number of collisions occur in flowing condition which resists the flow of particles. Therefore, powder is having less flowing characteristics. |

Granules are larger in size and bulk granules consists of comparatively less number of granules and therefore the number of collisions occurring in flowing condition are comparatively less. Therefore, resistance to the flow of granules is very less which enhances the flowing characteristics of the granules. |

|

Powder is having less flowing characteristics and therefore stepper hopper angle is required to improve the flowing capability of the powder particles. |

As the flowing characteristics of the granules are high and therefore there is no need of stepper angle and it can flow easily in any kind of hopper. |

Table 1: The difference between the characteristics of the powder and the granules.

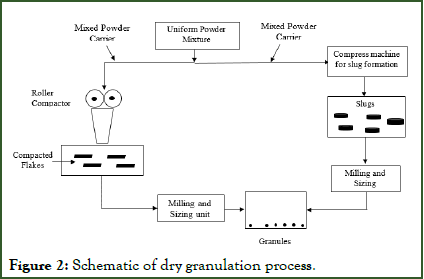

There are basically 2 types of granulation techniques such as dry granulation and wet granulation. The selection of the suitable process technology for forming the granules depends upon the physicochemical properties of the excipient powder particles. Dry granulation is basically carried out where, the product is sensitive to moisture or heat or does not compress well. The dry granulation is basically carried out without using any kind of liquid solution. Dry granulation technology involves the operations of compacting and size reduction of mixed powder to form the granules. Dry granulation could be achieved either by roller compaction or by slugging as shown in Figure 2 [1]. Dry granulation technology is easy to operate and the operating cost is comparatively less but it is not applicable where the formation of low dose formulations is necessary. The granules formed via dry granulation technique are friable in nature and possesses less hardness. Therefore, segregation of excipients occurs easily which is not acceptable. Therefore, wet granulation technology is preferred generally in which the problems associated with dry granulation get overcome.

Figure 2: Schematic of dry granulation process.

Wet granulation technology basically uses liquid with or without binder to hold the different excipients particles together. The objective of the review is to summarize the various granulation technologies which are in current practices with their merits and demerits.

Materials and Methods

Types of granulation technologies

Dry granulation and wet granulation are the two main types of granulation technologies and these are classified on the basis of the processing methodologies as follows [2]:

Conventional methods

• Dry granulation

• Novel advanced method of dry granulation: Pneumatic dry granulation

• Conventional wet granulation techniques: These techniques are classified further on the basis of operating procedure as follows: a) High shear wet granulation: Rotating high shear forces at high power consumption per unit mass with the addition of the liquid. b) Low shear wet granulation: Rotating low shear forces at low power consumption with the addition of liquid. c) Fluidized bed granulation which is one of the low shear wet granulation techniques.

• Novel advanced methods of wet granulation: a) Moisture activated dry granulation, b) Steam granulation, c) Melt granulation, d) Thermal adhesion granulation, e) Freeze granulation, f) Reverse wet granulation

These dry and wet granulation techniques are elaborated briefly as follows:

Dry granulation

Conventional dray granulation: Dry granulation could be achieved either by roller compaction or by slugging in which particles get adhered to each other either by cohesive or adhesive forces existing between them. It is generally carried out at high pressure of roller compaction and during roller compaction particles get entrapped/packed between each other at high compacting pressure. The schematic of dry granulation technology has been shown in Figure 2. Dry granulation technique is preferred for carrying out the granulations of those materials which are moisture sensitive and thermolabile because this process is carried out without using any kind of liquid solution and therefore there is no need to heat and carry out the drying operation. If the liquid solution is not used then the contact of moisture with granulating material could be avoided completely [3].

The tablet press can be used for carrying out the dry granulation to produce large tablets called slugs, but the limitation with this technique is that the powder may not possess the flow ability to feed the product uniformly inside the die cavity which finally results into varying degrees of densification [3].

The roller compactor can be used generally for carrying out the dry granulation, because the powder mixture can be delivered uniformly between the two pressure rollers and the powder mixture gets compact between these pressure rollers and gets exit out in the form of ribbon or small pellets which further passes through the milling and sizing operations before going to make its final use [3]. These are the conventional techniques for carrying out the dry granulation. The advanced technique for carrying out the dry granulation is also found in the literature and it has been elaborated as follows.

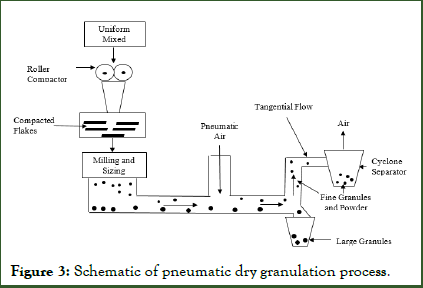

Advanced dry granulation: Pneumatic Dry Granulation (PDG): It is an innovative and advance dry granulation technique. It is a roller compaction process followed by air classification to produce granules with having the properties of good flowing ability and compressibility [4,5].

This method involves the production of granules by roller compaction and the intended granules could be separated from both the fine particles as well as fine granules in a fractionating column by passing the air stream, whereas the fine particles/fine granules get carried over with air stream. The schematic of PDG as shown in Figure 3. The air stream with fine particles fed to cyclone separator where the solid material gets separate out from air stream and recycled back to the input of the roller compactor or stored in a separate vessel for reprocessing. Dry granulation is a time efficient and economically feasible technique with minimum loss of granulating material. Granules formed via pneumatic granulation are having comparatively larger size than the normal dry granulation because in PDG the fine granules or remaining powder gets remove with the air stream. Therefore, intra-granular porosity of the granules obtained via PDG is high and it increases the compressibility of the granules. The disintegration of the granules formed via PDG takes place at the faster rate because the particles are going to hold together by the weak cohesive and adhesive forces existing between them.

Figure 3: Schematic of pneumatic dry granulation process.

But PDG are having some limitations because the particles are going to hold together by cohesive and adhesive forces which are not so strong and therefore the granules formed are friable in nature. As the granules are friable in nature then disintegration takes place easily and results into segregation of their excipients [1]. This technology is not suitable for low dose formation because the granules formed are larger in size. One more disadvantage is that it requires specialized heavy duty tablet press and it does not permit uniform colour distribution 1]. It tends to create more dust as compared to wet granulation and it increases the probability of cross contamination also [1], and because of all these limitations wet granulation is preferred generally for carrying out the granulation for small dosses and to improve the strength or hardness inside the granules which are going to form.

The wet granulation is carried out to overcome the limitations of dry granulation and these techniques of wet granulation have been elaborated as follow.

Wet granulation

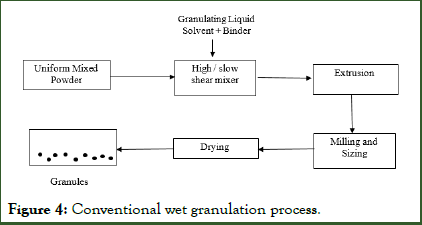

Wet granulation is generally carried out in the presence of solvent and or binder. Solvent containing binder causes the wetting of solid particles by capillary action and these wetted particles get agglomerate together due to the cohesive forces existing between the binder molecules. The granulating fluid is the mixture of solvent and binder and the solvent must be volatile so that it can be recovered easily by carrying out the drying of formed granules at lower temperature. Both the solvent and binder must be non-toxic in nature. Water, ethanol and isopropanol, either alone or in combination are generally going to use as a solvent for carrying out the wet granulation process. If only solvent without binder is used, then it gets mixed with the powder and the bonds gets form between the solid particles. These bonds should be strong enough, otherwise once the solvent gets removed, then the solid particles get apart from each other. Therefore, if the solvent alone is not sufficient to form enough strong bonds between the particles, then the specific binder is needed so that even after the removal of solvent the binder holds the solid particles together and prevents them from getting separate out from each other. The process of wet granulation may be or may not be simple. In the traditional wet granulation methods, the wet mass is generally forced through the sieve to produce wet granules and those granules can be dried subsequently [1]. Mechanism of the granulation has been shown schematically in Figure 1 and it is applicable for wet granulation technique [6]. Conventional wet granulation has been presented schematically in Figure 4 [1].

Various types of binders being used for carrying out the wet granulation and some of these have been listed here. Sugars, natural polymers like starch, synthetic and semi-synthetic polymers like polyvinylpyrrolidone, polymethacrylates, polyethylene glycol and cellulose based polymers like ethyl cellulose, hydroxypropyl methylcellulose, methylcellulose, hydoxyprolpylcellulose, etc. can be used as a binder in carrying out the wet granulation. But the selection of the suitable binder is important task and it depends upon the properties of the binder and granulating materials [7]. The selection of the suitable binder is an important task in carrying out the wet granulation and the selection criteria has been discussed briefly as follows.

Selection of the suitable binder

Binders are selected on the basis of the specific properties which are needed in the final dried product. For example: Sugars, sorbitol, mannitol or maltodextrins are generally added into the poorly tasting and bitter drugs so that their taste can be improved and in this case binder concentration should be more than that of the concentration required for carrying out the granulation. Binder is also selected on the basis of its physicochemical properties. For example: Starch is highly viscous and if it is used as a binder then its homogeneous distribution throughout the powder mixture does not take place properly. Therefore, it is pre-gelatinized and used as a binder of having the composition in between 5 to 10% w/w and later on water is added as a solvent and the pre-gelatinized starch gets soluble in cold water easily and get distribute uniformly throughout the entire mass of the granulating material. During the selection of the binder it is necessary to take the note that the selected binder should not react with any drug excipient. Therefore, both binder as well as solvent should be inert in nature. For example: Polyvinlypyrrolidone (PVP) is an inert and used as a binder in the formulation and having the composition in the in between 0.5 to 5% w/w on dry basis and one more advantage with PVP is that it is soluble in both water and alcohol. The polymethacrylates are a group of about 20 inert polymers and they can be used as a binder in pharmaceutical granulation processes in the presence of water or any alcoholic solvent. They can be used as a binder in solid oral dosage forms such as capsules, beads and tablets. They can be used specifically in high dose drugs because of having solubility in water. If the dried ingredients are moisture sensitive then ethyl cellulose is used as a binder with alcohol as a solvent.

The binder is also selected on the basis of achieving expected drug releasing rate, because the drug has to disintegrate in stomach properly. The generally preferred binders should have solubility either in water or in alcohol or in both [7].

The binder should have large interfacial tension with air so that it can wet the granulating material properly. The binder should have the optimum viscosity because if the viscosity is very high then it could not distribute uniformly throughout the entire

powder mixture which is not acceptable from the granulation point of view. If the viscosity is too low then it could not wet the granulating material properly. Therefore, the viscosity of the binder and the viscosity of the solution containing binder should be optimum and it can be optimized on the experimental trial and error basis.

In brief, the binder should be selected on the basis of various criteria and these are listed here. The first criteria are that the desired properties should be achieved in the final dried granulated product. The second criteria are that the selected binder should be inert and does not react with any granulating excipient. The third criteria is that the granulated drug should get disintegrate in the stomach properly. The fourth criteria are that the selected binder should have optimum physico-chemical properties.

Conventional wet granulation techniques

Conventional wet granulation is carried out either at high shear or at low shear. Therefore, it is classified in two types as high shear wet granulation and low shear wet granulation.

High shear wet granulation: High shear granulation assembly consists of a cylindrical or conical bowl assembled with 3 blade impeller, an auxiliary chopper and discharge port. A motor is used to rotate the impeller and chopper. Impeller is used to carry out the mixing so that granulating liquid and binder get spread uniformly throughout the entire powder mixture and the wet solid mass gets generate. As the solid particles get wetted then they agglomerate together and granules get form. The granules formed at high shear are smaller in size and less porous because particles going to hold together are more compact due to high shear force. Therefore, the granules formed are having larger density, low compressibility and less friable in nature. As the compressibility is less, then the hardness of tablets formed from such granules decreases.

Generally, the mass wetted inside the high shear mixer is extruded and then passed through the milling operation to obtain the granules with the proper shape and size and the schematic of wet granulation has been shown in Figure 4. Once the granules of proper shape and size are obtained, then they are generally shifted further for carrying out the drying inside the fluidized bed dryer.

Figure 4: Conventional wet granulation process.

The mixing rate (Impeller speed), addition rate of the binder, quantity of the binder and Mixing time are the process variables of high and low shear granulation techniques.

The two most important process variables in a high shear wet granulation technique are the impeller speed and wetting time. As the impeller speed increases then the granulation size decreases, intra-granular porosity decreases and granulation density increases. If the wetting time increases, then the binder gets distribute more uniformly which affects both the particle size distribution as well as the hardness of granules. High shear wet granulator requires less quantity of binder and granulating solvent as compared to low shear wet granulator, but the compressibility of granules found from high shear wet granulator is less than those formed from the low shear wet granulator.

Low shear wet granulation: Low shear wet granulation is carried out at low speed of impeller means at lower mixing rate. Therefore, it requires more processing time as compared to high shear granulation. The quantity of binder required for low shear granulation is 50-60% higher than that of the high shear granulation. The compacting force at low shear mixing is less and therefore the granules formed are larger in size and more porous. Therefore, the density of the granules formed by low shear is less as compared to those formed by high shear granulation. The granules formed by low shear granulation technique are more compressible than those formed by high shear granulation technique because the intra-granular porosity of granules formed by low shear granulation technique is comparatively high. The granules formed by low shear granulation technique are more friable because of having high intra-granular porosity and less hardness, but the hardness of the tablet formed from such granules is comparatively high because the granules possess high compressibility.

As the quantity of granulating liquid being used in conventional high shear as well as low shear granulation technique is large and therefore these granulating processes are generally carried out in 4 stages. Stage 1 includes the wetting of granulating mass with the granulating liquid. The 2nd stage associated the extrusion of wetted solid mass through the small orifice. The extruded mass is then shifted to the milling operation where the required shape and size of the granules can be achieved and it is considered as 3rd stage. The 4th stage involves the drying of the wet granules and it is generally carried out inside the fluidized bed dryer. The low shear granulation technique requires 50-60% more granulating liquid as compared to high shear granulation technique and therefore extensive drying operation is needed to be carried out during the low shear granulation.

Advanced granulation techniques

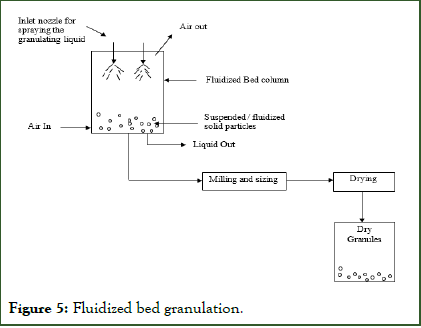

Fluidized bed granulation: It is one of the wet granulation techniques operating at low shear rate and it consists of the column in which the powder particles which are need to be granulated are fluidized by passing the air stream and the granulating liquid containing binder is going to spray from the top side of the column as shown in Figure 5. It is low shear granulation and therefore, granules formed are larger in size of having large intra-granular porosity. The density of the granules formed is less and having high compressibility. The process variables such as liquid droplet size, rate of liquid addition and air to liquid mass ratio play a key role in controlling the properties of the granules which are going to form. If the air to liquid mass ratio increases, then initially the size of granules may increase because of the increasing rate of solvent evaporation which makes the binder more viscous and as a result wetting property of the binder get enhances. Therefore, the strength/ hardness of the agglomerated particles increases and not going to break down due to the attrition occurring between themselves or between them and the wall of the column. If the air to liquid mass ratio increases beyond its optimum limit then attrition strength between the agglomerated particles increases and break down the large agglomerated particles into smaller size and as a result the granules of smaller sizes get form. The auto-mization air pressure is also one of the important parameter to control the size of granules inside the fluidized bed granulator. Some researchers found that, if the auto-mization air pressure increases, then the granulation size decreases and that might be due to the occurrence of intense collisions between the agglomerated particles. Some authors found that if the addition rate of the binder solution increases, then the size of the granules also increases and that might be due to that the wetting rate of solid particles at high input liquid rate is comparatively high than the agglomeration rate. If the wetting rate is higher than the agglomeration rate then the particles get wetted uniformly before going to adhere each other which increases the strength/hardness of the agglomerated particles and therefore, these agglomerated particles are not going to break down easily due to their internal collisions and it finally results into the larger size of the granules. Some authors observed that if the droplet size of the spraying binder solution decreases then, the granule size also increases and this might be due to the high inter-facial tension existing between the air and binder solution allowing the proper wetting of binder solution along the surface of powder particles which finally leads to the proper growth of the granules and resulting into larger size.

Figure 5: Fluidized bed granulation.

The fluidized bed granulation is a low shear wet granulation and therefore the granules formed are larger in size and more porous in nature. The intra-granular porosity is dependent on the cumulative effects imparted by the quantity of binder being used, thermos-physical properties of the binder being used, the addition rate of the binder solution and the shear rate. The comparison between the high shear and low shear wet granulation techniques has been made inside the Table 2.

| Granule characteristic | High shear wet granulation | Low shear wet granulation |

| Impeller speed | High | Low |

| Uniform distribution of the binder | Comparatively more | Comparatively less |

| Processing time | Comparatively less | Comparatively more |

| Hardness | Comparatively more | Comparatively less |

| Intra-granular porosity | Comparatively less | Comparatively more |

| Compressibility | Comparatively less | Comparatively more |

| Friability | Comparatively less | Comparatively more |

| Tablet hardness | Comparatively less | Comparatively more |

Table 2: The comparison between the conventional high shear wet granulation and the conventional low shear wet granulationusing the same quantity of binder solution in both cases.

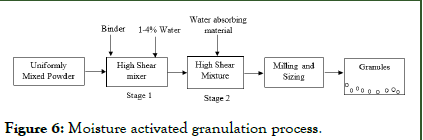

Moisture activated dry granulation (MADG): This technique was invented in 1987 [8] and it is one sort of wet granulation technique but uses very little amount of water to activate the binder and initiate the agglomeration. This technique generally carried out in two stages, the first stage involves the occurrence of agglomeration of the wetted powder particles, while the second stage involves the addition of the moisture absorbing material like microcrystalline cellulose, silicon dioxide to absorb excess water from the formed agglomerates and distribute it to the remaining powder mixture to continue the granulation of remaining portion. The overall process has been shown schematically inside the Figure 6. Initially agglomeration is facilitated by adding small amount of water, usually in the range of 1-4% by wt. This technique leads to the formation of dry granules because water used is very less in quantity. As the water used is very less, then heat required for carrying out the drying of formed granules is also very less, which makes this technique more energy and time efficient [9-11]. During redistribution of the moisture some agglomerates remain intact in size without change but large agglomerates may break down and uniform size distribution of the agglomerates may occur, this technique does not lead to the formation of large lumps because the quantity of water being used initially is very less as compared to conventional wet granulation techniques. The agglomerates formed by this technique are having the size in the range of 150-500 μm [1]. The granules formed by this technique contains very little amount of water because water used initially is very less and therefore the formed granules are almost dry. Therefore, this technology is named as MADG or Moist granulation. The agglomerates going to form almost maintain the uniformity among themselves in size and therefore granules formed by this technique possesses better flowing ability and compressibility [10,11]. This technique is having some limitations such as it could not use where the drug is moisture sensitive or hygroscopic in nature. As the granules formed are smaller in size and therefore, this technique could not be used where high drug loading is required [1]. The high shear mixer is generally used for carrying out the mixing of granulating powder and granulating liquid for carrying out the granulation by the technique MADG [1]. The equipment assembly for carrying out the granulation by this technique should consist of the high shear mixer followed by low shear mixer. This typical type of hardware is necessary because in high shear mixer uniform spreading and wetting of the binder occurs but the agglomerated particles may get break down due to high attrition at high shear. Therefore, additional low shear mixer is necessary to grow the agglomerated particles by avoiding the effect of attrition. If only high shear mixer is used, then it has to provide with the provision of controlling the speed of rotation/rate of mixing.

Figure 6: Moisture activated granulation process.

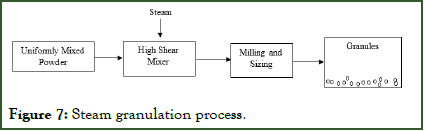

Steam granulation: This technique uses steam as a binder instead of water. The steam is at a higher temperature than the liquid water and therefore it diffuses inside the powder particles and distribute uniformly throughout the powder mixture. As the temperature of the steam drops down, then it gets condense and hot liquid gets coated on the surface of powder particles and that hot water can be removed easily by evaporation [11-13]. High shear mixer coupled with steam generator is necessary for carrying out the agglomeration by this technique as shown in Figure 7. This technique is having some limitation such as it could not be used where the drugs are moisture sensitive and thermolabile in nature. This technique is limited to those drugs whose particles of various excipients get adhered together even after the complete removal of the moisture. This technique is useful to form fine spherical granules. As the formed granules are fine then the surface area per unit granulating mass is large and therefore dissolution occurs at the faster rate than that of the granules formed by conventional wet granulation technique [13-17].

Figure 7: Steam granulation process.

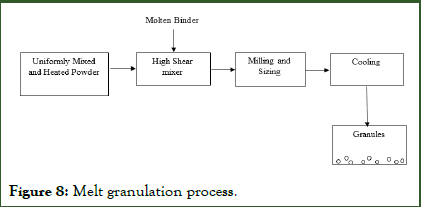

Melt granulation: It is one of the wet granulation techniques in which melted binder facilitates the agglomeration of particles. Melted binder gets coated on the surface of the particles and the particles get adhere to each other. The binder should get melt or soften at relatively low temperature [18]. Cooling of the agglomerated powder and the solidification of the molten or soften binder completes the granulation process [19,20]. Melt granulation can be carried out in two ways either by adding solid binder which get melt during granulation or by adding already molten liquid to heated particles as shown in Figure 8 [11,21,22]. This granulation technique is carried out without any solvent and at elevated temperature and therefore, it is suitable for those drugs which are moisture sensitive. As this granulation technique is carried out without any kind of solvent and therefore the operations like drying and recycling of the solvent are avoided which makes the process more energy and time efficient [12,19,20,22-24]. The selected binder should have melting point in the range of 50-90°C [18] because if the melting point of the binder is very low then it becomes troublesome in storage and transfer operations and if the melting point of binder is very high then degradation of dry excipients may occur and therefore, this technique is not suitable for thermolabile drugs. Melt granulation could be carried out either in high shear granulator or in fluidized bed granulator in which molten binder could be sprayed on the fluidized bed of the heated particles. The binder should be such that even after getting its solidification its wetting properties could be maintained and it should be capable for adhering the particles together in the agglomerated form.

Figure 8: Melt granulation process.

Thermal Adhesion Granulation (TAG): TAG involves the addition of small amount of granulating liquid consists of the mixture of solvent and binder to the mixture of particles to be granulated and followed by heating the entire mixture to the temperature of 32 to 130°C in a closed system under tumble rotation to facilitate the agglomeration of particles. Granules of the required particle size can be achieved after cooling and sieving [25,26]. The granulating liquid being used in this technique is the mixture of organic solvent and water. The drying operation is avoided in TAG because the granulating liquid being used in this technique is very less in quantity.

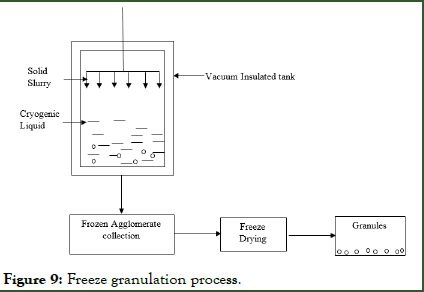

Freeze granulation: This granulation technique was invented by Swedish ceramic institute in 1980 [12,27,28]. This technique includes the spraying of the liquid slurry into the cryogenic liquid like nitrogen of having the boiling below 0°C as shown in Figure 9. The liquid slurry consists of the mixture of powder in solvent with suitable binder. Once the slurry spread into the cryogenic liquid, then the droplets gets solidify and frozen. These frozen droplets are separated from the cryogenic liquid and freeze drying is carried out [29]. The granules are dried in freeze drying via the process of the direct sublimation of ice into gas. Therefore, segregation effect is avoided and the granules formed are spherical in shape. Therefore, this technique leads to the formation of spherical shape free flowing granules and the solvent being used for making slurry could be either organic or aqueous in nature. This technology is useful for making the granules in which particle size and homogeneity need to be preserved because this technology is enable to maintain the structure and homogeneity inside the formed granules [27-29]. Therefore, the quality of slurry determines the quality of formed granules in terms of homogeneity. This technique is also having some additional advantages such as the density of granules could be managed by controlling the concentration of powder particles inside the spraying slurry. As it is carried out at low temperature then it is useful for the thermolabile drugs and for achieving high yields as compared to the other technologies. There are some technical challenges are associated with the implementation of this technology on a large scale and these are listed here. The 1st challenge might be in maintaining the viscosity of the binder in an optimum range because of the operating temperature is very low, otherwise the binder does not wet properly along the surface of solid particles once it gets solidify. One more technical limitation is that if the concentration of powder particles inside the slurry is too high then it causes the choke up of spraying nozzles. On the other side if the concentration of powder particles inside the slurry is very less then, in frozen condition, density of ice decreases and large voidage gets develop inside the granules which may lead to the friable granules. The selected cryogenic liquid should have sufficient interfacial tension with granulating liquid so that the granules of uniform shape will get form. Cryogenic liquid exhibit high vapour pressure and therefore it is a challenging task to maintain the vapour pressure of such liquids at the atmospheric level. One more technical challenge is that if the slurry of room temperature is sprayed inside the cryogenic liquid, then heat gets transfer from the slurry to the cold cryogenic liquid and as a result the boil off gas gets generate and therefore, it is difficult to maintain the pressure inside the closed vessel at the level of open atmospheric pressure.

Figure 9: Freeze granulation process.

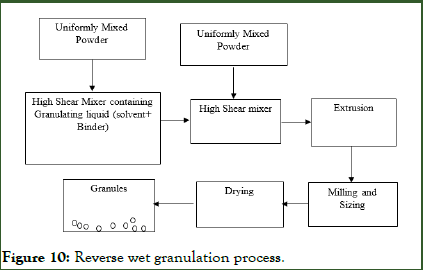

Reverse wet granulation: Reverse wet granulation is the technique of the immersion of mixed dry powder to the granulating liquid under mixing conditions. Once the wet mass gets generate then 2nd lot of the same dry powder is added and granulation is carried out as shown in Figure 10. The granulating liquid consists of the hydrophilic polymer/binder [30] and the resulted granules are dried and milled. The formed granules are having good flowing ability. Further it was found that the formed granules erode uniformly as compared to those formed by conventional wet granulation technique. If the granulation is carried out by this technique, then uniform distribution of the binder takes place which improves the water dissolution rate and uniform erosion of the granules. Therefore, this granulation technique is suitable for those drugs which have poor water solubility. As the binder gets distribute uniformly, then the granules formed are larger in size with less intragranular porosity as compared to the conventional wet granulation techniques [31,32]. Fluidized bed granulation technique is also capable for distributing the granulating liquid uniformly but it requires 5 to 6 times more liquid than conventional wet granulation technique [33].

Figure 10: Reverse wet granulation process.

Some of the advanced wet granulation techniques operate at very low level of the solvent quantity and considered as almost dry. Therefore, there is a need of comparison between the dry and wet granulation is necessary.

Therefore, the brief comparison of the dry granulation with the wet granulation has been made and shown inside the Table 3.

| Granule characteristic | Dry granulation | Wet granulation |

| Use of binder liquid | No use of binder | Use of binder |

| Hardness | Comparatively less | Comparatively more |

| Granule size | Comparatively large | Comparatively small |

| Intra-granular porosity | Comparatively more | Comparatively less |

| Compressibility | Comparatively more | Comparatively less |

| Friability | Comparatively more | Comparatively less |

| Dosage | Comparatively high | Comparatively low |

Table 3: The comparison between dry and wet granulation.

The summary of the above mentioned advanced granulation techniques has been tabulated in Table 4.

|

Granulation techniques |

Description |

Granule | Merits | Limitation |

|

Pneumatic dry granulation

|

1. Dry granulation |

1. High porosity 2. Highly compressible due to high porosity 3. Highly friable due to high porous texture 4. High dosage |

1. It is useful for thermolabile drugs 2. It is useful for moisture sensitive drugs 3. Fast disintegration |

1. Need of recycling the separated fine granules powder particles 2. Excipient separation occurs due to high friability and less hardness |

|

Steam granulation

|

1. Steam used as a binder

|

1. Uniform wetting 2. Uniform evasion 3. Granules due to high shear 4. Large surface area per unit mass 5. Spherical granules due to uniform wetting 6. Uniform size distribution due to high shear |

1. Fast dissolution 2. Uniform size reduction while dissolution 3. No need of carrying out extensive drying operation 4. No need of extrusion like convention wet granulation 5. Less processing time as compared to conventional wet granulation |

1. It is not useful for thermoliable drugs 2. Not useful for moisture sensitive drugs 3. High energy input for steam generation |

|

Techniques of moisture activated dry granulated

|

1. 1-4% water is needed to activate the binder |

1. Uniform size distribution due to high shear 2. Fine granules formed due to high shear 3. The quantity of added water is very less and it leads to formation of pores granules 4. As compressibility is high then compressibility increases |

1. Drying operation is avoided 2. Less energy consumption because of no need of drying 3. Time efficient |

1. Not applicable for moisture sensitive drugs 2. Not applicable to high dosing drugs due to fine granulation |

|

Thermal adhesion granulation

|

1. Low solvent/water addition

|

1. Fine granules due to high shear 2. Tensile strength because granulation occurs at elevated temperature |

1. No drying operation to be carried out because the solvent is already heated | 1. It is not useful for thermoliable drugs 2. Not useful for moisture sensitive drugs 3. High energy input for steam generation 4. Viscosity of binder should get maintained during heating 5. Viscosity and wetting characteristics of solvent should get maintained during heating |

|

Melt granulation

|

1. Molten binder is used |

1. Dissolution rate could be controlled due to selection of suitable binder 2. Releasing rate could be controlled due to the selection of suitable binder |

1. No water and solvent 2. Drugs operation is avoided 3. Energy saving because of avoidation of drying operation 4. Applicable for moisture sensitive drugs |

1. Not applicable to thermolabile drugs 2. Limited binders |

|

Freeze granulation

|

1. Addition of slurry inside the cryogenic liquid |

1. Spherical granules get formed due to the frozen of droplets 2. Morphology gets maintained due to freeze drying 3. Uniform size gets maintained due to uniformity in spraying droplet slurry 4. Wet granulation |

1. Uniform size gets maintained due to uniformity in spraying droplet slurry 2. Morphology gets maintained due to freeze drying 3. Granule homogeneity gets maintained |

1. Limited cryogenic liquid 2. Limited binders 3. Binders should maintain their viscosity and hold its properties after getting frozen 4. Applicable to solvent slurry only |

|

Reverse wet granulation

|

1. Wet granulation |

1. Uniform wetting due to reverse addition 2. Fine granules due to high shear |

1. Spherical shape due to uniform wetting 2. Fine granules due to high shear |

1. Low porosity due to uniform wetting 2. Less compressible due to less porosity 3. Large amount of heat is necessary to remove the solvent 4. Applicable to poorly water soluble drugs otherwise get soluble in water during reverse addition |

Table 4: Comparison of various granulation techniques.

Results and Discussion

Characteristics of the granules

The granules formed via above both dry and wet granulation techniques should posse some specific measurable characteristics which are listed here.

The characteristics of the granules (agglomerated particles) can be measured in the same way as that of the powder. Flow ability, intergranular porosity and cohesiveness are the major physical properties of the granules. Carr index is the measurement of flow ability and Hausner ratio is the measurement of cohesiveness. The density of the granules resulted after tapping is called as the tapped density and before tapping it is considered as the bulk density.

Carr index is given by

Carr index= (ρtap-ρbulk)/ρtap × 100

If the value of Carr index is large then it means that the large difference is exist between the tapped and bulk densities. Further it means that, the volume of the mixture of the granules is reducing significantly after carrying out the tapping and it is possible when the difference between the size of large granules and tiny granules is large and the mixture of granules getting more compact after carrying out the tapping and therefore, the free space available for taking place the movement of granules decreases. In such cases smaller granules getting packed inside the space available between the larger granules and resist the flow and as a result the flow ability of the granules decreases. Therefore, if the Carr index is large then, the flowing ability is less and vice versa. Flowing ability is classified on the basis of obtained Carr index as follows.

If the Carr index is less than 15%, then the flowing ability is considered as very good. If the Carr index is in between 15 and 20%, then the flowing ability is considered as good. If the Carr index is in between 20 and 35%, then the flowing ability is considered as fair. If the Carr index is in between 35 and 45%, then the flowing ability is considered as bad. If the Carr index is more than 45%, then the flowing ability is considered as very bad [34].

Hausner ratio is defined as the ratio of the tapped density to the bulk density.

HR=ρtap/ρbulk

The flowing nature of the granules is classified on the basis of Hausner ratio which is defined as the ratio of the density of the granules after carrying out the tapping to the density before carrying out the tapping.

If Hausner ratio is less than 1.2, then the granules are free flowing. If the Hausner ratio is 1.2 to 1.4, then the flow ability is intermediate. If the Hausner ratio is greater than 1.4, then the granules are non-flowing and highly cohesive in nature [34].

The intergranular porosity of the granules is given by [35].

ε=(ρgranule-ρtapped)/ρgranule

Granules size distribution

Granules size distribution is defined on the basis of span index. Span index is given by [35]

Span=(D90-D10)/D50

Where, D90 is such a diameter that, the 90% of the granules are having the diameter less than or equal to D90. Similarly, D10 is such a diameter that 10% of the granules are having the diameter less than or equal to D10 and D50 is such a diameter that 50% of the granules are having the diameter less than or equal to D50.

The granulation of the gellan gum has been carried out inside the fluidized bed granulator and the effect of the concentration of various binders on the properties of the granules has been listed inside the Table 5 [35]. From this study, it is observed that the diameter of the granules increases with the increase in concentration of binder and span index decreases continuously. It means that, the difference between D90 and D10 increasing at the slower rate than the rate of increasing D50. Further it is also observed that, as the concentration of binder increases then, the Carr index and Hausner ratio also increases because of the increase in the difference between the tapped density and the bulk density of the granulated mass. It may happen due to the increase in difference between the size of the large granules and the size of tiny granules which makes the granulated mass more compact after carrying out the tapping.

| Sample | pbulk (g/cm3) | ptapped (g/cm3) | Carr Index (CI) | D0.1 | D0.5 | D0.9 | Span index |

| GG_P | 0.48 | 0.61 | 21.2 | 48.29 | 301.71 | 721.2 | 2.23 |

| GGA_W | 0.49 | 0.59 | 17.1 | 50.25 | 309.54 | 651.04 | 1.55 |

| GGA_2.5% MD | 0.72 | 0.84 | 14.3 | 56.85 | 392.5 | 828.77 | 2.1 |

| GGA_5% MD | 0.66 | 0.78 | 14.7 | 80.29 | 420.36 | 754.56 | 1.6 |

| GGA_10% MD | 0.67 | 0.79 | 14.9 | 99.33 | 453.54 | 798.67 | 1.54 |

| GGA_2.5% L | 0.64 | 0.76 | 15.1 | 60.41 | 317.77 | 636.5 | 1.81 |

| GGA_5% L | 0.53 | 0.66 | 19.5 | 78.19 | 466.34 | 852.35 | 1.66 |

| GGA_10% L | 0.44 | 0.57 | 23.8 | 103.98 | 488.69 | 827.99 | 1.48 |

| GGA_2.5% G | 0.48 | 0.67 | 28.5 | 55.83 | 342.01 | 629.36 | 1.68 |

| GGA_5% G | 0.28 | 0.39 | 28.8 | 74.76 | 419.3 | 734.67 | 1.56 |

| GGA_10% G | 0.27 | 0.4 | 32.5 | 78.82 | 435.1 | 782.74 | 1.47 |

Table 5: The effect of the concentration of various binder on the physical property of granules.

Yong-hwan kim et al. carried out the granulation of xanthan gum using the fluidized bed granulator. This study provides the impact of maltodextrin (binder) concentration on the flowing properties of the formed granules. According to this study, the Carr index and Hausner ratio varies with the concentration of the binder as shown in Table 6. From this study it is observed that as the concentration of the binder increases, then the Carr index and Hausner ratio decreases. It means that, the flowing properties get improved with the increase in concentration of binder and it is due the difference between the tapped and bulk densities is increasing with the increase in binder concentration and it may occur up to the optimum concentration of the binder get reaches. The optimum value of the binder concentration depends upon the physical properties of the granulating material, the type of the binder being used and the shear rate of granulation equipment.

| Sample | MD concentration (%) | CI (%) | HR |

| Non-granulated XG | 15.3 | 1.18 | |

| Granulated XG | 0 | 15.3 | 1.18 |

| 5 | 14.2 | 1.16 | |

| 10 | 12.5 | 1.14 | |

| 15 | 11 | 1.12 |

Table 6: The variation in Carr index and Hausner ratio with the variation in the concentration of binder.

The concentration of the binder used in carrying out high shear or low shear granulation should be in optimum range. If it is beyond optimum, then it leads to the formation of lumps and therefore the difference between the size of large and tiny granules increases which gives negative impact on the flow ability of the granules. On other side, if it is too below the optimum value, then the granules formed are friable in nature and get break down easily which finally causes the segregation of the various powder ingredients. The size of the large granules obtained in high shear granulator is comparatively small than that of the low shear granulator. Therefore, the difference between the size of largest granules and tiny granules is less in high shear granulator than the low shear granulator. Therefore, Carr Index and Hausner ratio are less for high shear granulator than the low shear granulator. It means that, the granules formed via high shear granulation technique possesses better flowing ability as compared to those formed via low shear granulation technique. Therefore, generally high shear granulation technique is preferred over the low shear granulation for carrying out the granulation via the recent granulation techniques where the binder solution being used is very less in quantity. If the low shear granulator is used with the less quantity of binder solution, then the uniform distribution of binder solution does not take place properly and therefore, the difference between the size of large and tiny granules gets increase and uniform granulation does not occur. Therefore, in such cases high shear granulation is preferred. If the low shear wet granulation techniques are considered, then low shear fluidized bed granulation is preferred because a single fluidized bed column is sufficient to carry out both granulation and drying operation [36]. If the conventional high shear wet granulation technique is used for carrying the granulation, then high shear mixer is required to mix the granulating mass followed by the extruder and extruder is followed by the shredder and sizer and the wet granules being dried inside the fluidized bed dryer. Therefore, all these auxiliary equipments need to be installed which increases both the capital as well as operating cost. All these technical hurdles are associated with the high shear wet granulation technique and therefore, fluidized bed wet granulation is preferred widely in industries instead of high shear wet granulator. One more technical aspect with the fluidized bed granulation is that, the granules formed are having high inter and intra granule porosity and therefore, these are more compressible in nature.

The percentage of the porosity depends upon the type of granulating material and the type of binder being used in granulation because each and every binder possesses the different particle wetting characteristics [37-44]. The effect of various binders on the physical properties of xanthan gum granules has been listed in Table 7 [37]. From this study it was observed that, the diameter of the formed granule depends upon the binding strength of the binder, viscosity of binder solution, the quantity of binder solution and the shear rate [45]. If the viscosity increases, then wetting takes place properly and particles get adhered together strongly and result into the larger granules. As the size of the granules increases then, the intergranular porosity increases and as a result compressibility increases. If the viscosity of the binder solution is less then, the granulation process follows the mechanism of crushing and layering and if the viscosity is high then, the granulation occurs through coalescence and growth mechanism [46].

| Binder type | pbulk (g/cm3) | ptapped (g/cm3) | Porosity (%) | CI (%) | HR |

| Control (no sugar) | 0.46 | 0.61 | 46 | 25.0 | 1.33 |

| Glucose | 0.35 | 0.46 | 62.9 | 24.1 | 1.32 |

| Lactose | 0.39 | 0.50 | 55.0 | 22.7 | 1.29 |

| Sucrose | 0.38 | 0.49 | 55.8 | 22.5 | 1.29 |

| Sorbitol | 0.37 | 0.49 | 55.2 | 22.7 | 1.30 |

Table 7: The effect of various binders on the physical properties of xanthan gum.

The granules formed via freeze granulation technique are almost having the same size and the difference between the size of largest granules and tiny granules is very less. Therefore, the difference between the tapped and bulk density of these granules is negligible which makes the granules free flowing and Carr index as well as the Hausner ratio lies in the lower range.

The difference between the characteristics of the granules obtained from the conventional high shear wet granulation techniques and fluidized bed granulation technique has been tabulated inside the Table 8. Fluidized bed granulation is one sort of low shear wet granulation and carry out under the fluidizing conditions. Therefore, there are chances of some of the fine particles either remain as it is without agglomerating together or get agglomerate in the form of tiny granules. Therefore, granule size distribution obtained from the fluidized bed granulation technique is comparatively wider than that of the high shear wet granulation technique. The high shear wet granulation carries out at high shear mixing of the granulating liquid with the granulating mass and then it is extruded and passes further to shredder and spheronizer which results into the spherical shape of the granules. But if the case of fluidized bed granulation is considered, then the particles get agglomerate together randomly and the granules formed are having irregular shape. High shear wet granulation is carried out at high impacting force and therefore, intra-granular porosity could be lower. But the fluidized bed granulation is carried out at low shear means at comparatively lower impacting force which increases the intra-granular porosity. The granules formed via high shear wet granulation could be in spherical shape with narrow size distribution and therefore, they possess good flowing properties [47-50]. But the granules formed via fluidized bed granulation technique could be in irregular shape with wide size distribution and therefore, these granules possess comparatively less flowing properties. The high shear wet granulation is carried out generally at high shear and therefore, the mean granule diameter could be smaller than that of the low shear fluidized bed granulation. The high shear wet granulation is having many merits over the fluidized bed granulation but even after that the fluidized bed granulation is generally preferred in industry because of having comparatively less capital investment.

| Granule characteristics | High shear granulation technique | Fluidized bed granulation technique | Ref |

| Size distribution | Narrow | Wide | 47 |

| Granule shape | Spherical | Irregular | 48 |

| Granule porosity | Low | High | 49 |

| Tapped/Bulk density | Low | High | 47, 48, 50 |

| Flow ability | Good | Low | 50 |

| Mean size | Small | Large | 47 |

Table 8: Comparison of granule characteristics between high shear wet granulation and fluidized bed granulation.

Conclusion

The review article has been designed through the perspective of getting insight into the granulation technologies. The review highlights the importance of granulation, the mechanism of granulation process and the various granulation techniques with their merits and demerits. The review article has been penned in such a way that it discloses the pictorial view of the overall process of the various granulation techniques for the better understanding. Conventional granulation techniques such as dry and wet have been presented briefly with their advantages and limitations. The advanced dry and wet granulation techniques such as pneumatic air dry granulation, steam granulation, melt granulation, moisture activated dry granulation, freeze granulation, reverse wet granulation have been discussed briefly with the pictorial representation of their process paths. The statistical analysis of the granule characteristics with the proper scientific reasoning has beenpresented briefly.

Authors Contribution

All authors are equally contributed.

Acknowledgement

Authors are thankful to Lupin Pharmaceutical Ltd. for the financial support for this work through the fund assigned on the project entitled as “Powder Processing”.

References

- Shanmugam S. Granulation techniques and technologies: Recent progresses. Bioimpacts. 2015;5(1):55-63.

- Saikh MA. A technical note on granulation technology: A way to optimize granules. Int J Pharm Sci Res. 2013;1:55-67.

- A comparison of granulation technologies: GEA, An industrial report.

- Politi G, Heilakka E. Granules, tablets and granulation. 2008.

- Politi G, Heilakka E. Methods and apparatus for dry granulation. 2017.

- Liu T, Kittikunakorn N, Zhang Y, Zhang F. Mechanisms of twin screw melt granulation. J Drug Deliv Sci Technol. 2020;55:102150.

- Cantor SL, Augsburger LL, Hoag SW, Gerhardt A. Pharmaceutic granulation processes, mechanisms, and the use of binders. CRC Press. 2008.

- Ullah I, Corrao R, Wiley G, Lipper R. Moisture activated dry granulation: A general process. Pharm Technol. 1987;11:48-54.

- Railkar AM, Schwartz JB. Evaluation and comparison of a moist granulation technique to conventional methods. Drug Dev Ind Pharm. 2000;26:885-889.

- Railkar AM, Schwartz JB. The effects of formulation factors on the moist granulation technique for controlled release tablets. Drug Dev Ind Pharm. 2001;27:893-898.

[Crossref] [Google Scholar] [PubMed]

- Railkar AM, Schwartz JB. Use of a moist granulation technique (MGT) to develop controlled release dosage forms of acetaminophen. Drug Dev Ind Pharm. 2001;27:337-343.

[Crossref] [Google Scholar] [PubMed]

- Panda RR, Tiwary AK. Hot melt granulation: A facile approach for mono-lithic osmatic release tablets. Drug Dev Ind Pharm. 2012;38:447-461.

[Crossref] [Google Scholar] [PubMed]

- Rodriguez L, Cavallari C, Passerini N, Albertini B, González-RodrıÌguez ML, Fini A, et al. Preparation and characterization by morphological analysis of diclofenac/PEG 4000 granules obtained using three different techniques. Int J Pharm. 2002;242:285-289.

[Crossref] [Google Scholar] [PubMed]

- Albertini B, Cavallari C, Passerini N, González-RodrıÌguez ML, Rodriguez L. Evaluation of beta-lactose PVP K12 and PVP K90 as excipients to prepare piroxicam granules using two wet granulation techniques. Eur J Pharm Biopharm. 2003;56:479-487.

[Crossref] [Google Scholar] [PubMed]

- Cavallari C, Abertini B, González-RodrıÌguez ML, Rodriguez. Improved dissolution behaviour of steam-granulated piroxicam. J Pharm Biopharm. 2002;54:65-73.

[Crossref] [Google Scholar] [PubMed]

- Vialpando M, Albertini B, Passerini N, Bergers D, Rombaut P, Martens JA, et al. Agglomeration of mesoporous silica by melt and steam granulation. Part 1: A comparison between disordered and ordered mesoporous silica. J Pharm Sci. 2013;102:3966-3977.

[Crossref] [Google Scholar] [PubMed]

- Vialpando M, Albertini B, Passerini N, Vander Heyden Y, Rombaut P, Martens JA, et al. Agglomeration of mesoporous silica by melt and steam granulation. Part 2: Screening of steam granulation process variables using a factorial design. J Pharm Sci. 2013;102:3978-3986.

[Crossref] [Google Scholar] [PubMed]

- Haramiishi Y, Kitazawa Y, Sakai M, Kataoka K. Study on fluidized melt granulation. I. Examination of the factors on the granulation. Yakugaku Zasshi. 1991;111:515-523.

[Crossref] [Google Scholar] [PubMed]

- Maejima T, Kubo M, Osawa T, Nakajima K, Kobayashi M. Application of tumbling melt granulation (TMG) method to prepare controlled release fine granules. Chem Pharm Bull (Tokyo). 1998;46:534-536.

[Crossref] [Google Scholar] [PubMed]

- Maejima T, Osawa T, Nakajima K, Kobayashi M. Application of tumbling melt granulation (TMG) method to prepare controlled release fine granules. Chem Pharm Bull (Tokyo). 1998;46:531-533.

- AleksiÄ? I, Äuriš J, IliÄ? I, IbriÄ? S, ParojÄiÄ? J, SrÄiÄ S. In silico modelling of in situ fluidized bed melt granulation. Int J Pharm. 2014;466:21-30.

- Passerini N, Calogerà G, Albertini B, Rodriguez L. Melt granulation of pharmaceutical powders: A comparison of high-shear mixer and fluidized bed processes. Int J Pharm. 2010;391:177-186.

- Kowalski J, Kalb O, Joshi YM, Serajuddin AT. Application of melt granulation technology to enhance stability of a moisture sensitive immediate-release dry product. Int J Pharm. 2009;381:56-61.

- Lakshman JP, Kowalski J, Vasanthavada M, Tong WQ, Joshi YM, Serajuddin AT. Application of melt granulation technology to tabletting properties of poorly compatible high dose drugs. J Pharm Sci. 2011;100:1553-1565.

- Yeh TS, Yeh DH. Subjecting mixture of diluent excipients and pharmaceutically active ingredient, binder excipients, optionally with disintegrant excipient, to heating under condition of low moisture and tumble rotation to form tablets. Google Patents. 2004.

- Yeh TS, Yeh DH. Process for the preparation of direct tabletting formulation and aids. USA Patent 6761905. 2004.

- Albertini B, Cavallari C, Passerini N, González-RodrıÌguez ML, Rodriguez L. Evaluation of beta-lactose PVP K12 and PVP K90 as excipients to prepare piroxicam granules using two wet granulation techniques. Eur J Pharm Biopharm. 2003;56:479-487.

- Rundgren K, Lyckfeldt O. Improving powders with freeze granulation. Ceramic Industry. 2003;153:40-44.

- Nyberg B, Carlstrom E. Granulation of ceramic powders for pressing by spray-freezing and freeze drying. Euro-Ceramics II. 1993;1:447-451.

- Li B, Reynolds TD. Granulating, process for preparing them and pharmaceutical products containing them. Google Patents. 2010.

- Wade JB, Martin GP, Long DF. Feasibility assessment for a novel reverse-phase wet granulation process: The effect of liquid saturation and binder liquid viscosity. Int J Pharm. 2014;475:450-461.

- Wade JB, Martin GP, Long DF. Controlling granule size through breakage in a novel reverse-phase wet granulation process; the effect of impeller speed and binder liquid viscosity. Int J Pharm. 2014.

- Abberger T. Influence of binder properties, method of addition, powder type and operating conditions on fluid bed melt granulation and resulting tablet properties. Pharmazie. 2001;56:949-952.

- Abdullah EC, Salam AM, Aziz AR. Cohesiveness and flowability properties of silica gel powder. Phys Int. 2010;1:16-21.

- Dev MJ, Warke RG, Warke GM, Mahajan GB, Singhal RS. Fluidized bed granulation of gellan gum: Investigation of binder effect on physical, structural, and rheological properties. Powder Technol. 2023;415:118199.

- Benali M, Gerbaud V, Hemati M. Effect of operating conditions and physio-chemical properties on the wet granulation kinetics in high shear mixer. Powder Technol. 2009;190:160-169.

- Lee H, Yoo B. Agglomerated xanthan gum powder used as a food thickener: Effect of sugar binders on physical, microstructural, and rheological properties. Powder Technol. 2020;362:301-306.

- Jinapong N, Suphantharika M, Jamnong P. Production of instant soymilk powders by ultrafiltration spray drying and fluidized bed agglomeration. J Food Eng. 2008;84:194-205.

- Srivastava S, Mishra G. Fluid bed technology: Overview and parameters for process selection. Int J Pharm Sci Dry Res. 2010;2:236-246.

- Jeong GY, Bak JH, Yoo B. Physical and rheological properties of xanthan gum agglomerated in fluidized bed: Effect of HPMC as a binder. Int J Biol Macromol. 2019;121:424-428.

- Kim YongHwan KY, Kim SungGun KS, Yoo ByoungSeung YB. Effect of maltodextrin on physical properties of granulated xanthan gum prepared by fluidized bed granulator. Int J Food Eng. 2017;13.

- Rajniak P, Mancinelli C, Chern RT, Stepanek F, Farber L, Hill BT. Experimental study of wet granulation in fluidized bed: Impact of the binder property on the granule morphology. Int J Pharm. 2007;334:92-102.

- Talar IA, Yazici F. Effect of different binders on reconstitution behaviors and physical, structural, and morphological properties of fluidized bed agglomerated yoghurt powder. Dry Technol. 2018.

- Morkhade DM. Comparative impact of different binder condition methods, binders and diluents on resistivity granule and tablet attributes via high shear wet granulation. Powder Technol. 2017;114-124.

- Ji J, Cronin K, Fitzpatrick J, Fenelon M, Miao S. Effects of fluid bed agglomeration on the structure modification and reconstitution behaviour of milk protein isolate powder. J Food Eng. 2015;167:175-182.

- Mangwandi C, Adams MJ, Hounslow MJ, Salman AD. Effect of impeller speed on mechanical and dissolution properties of high shear granules. Chem Eng J. 2010;164:305-315.

- Hausman DS. Comparison of low shear, high shear, and fluid bed granulation during low dose tablet process development. Drug Dev Ind Pharm. 2004;30:259-266.

- Flore K, Schoenherr M, Feise H. Aspects of granulation in the chemical industry. Powder Technol. 2009;189:327-331.

- Agnese T, Cech T, Geiselhart V, Wagner E. Comparing the wet granulating properties of PVA-PEG graft copolymer and different PVP grades in fluid bed granulation process applying different inlet air temperatures. 2nd Conference on Innovation in Drug Delivery, Aix-en-Provence. 2010.

- Gao JZ, Jain A, Motheram R, Gray DB, Hussain MA. Fluid bed granulation of a poorly water soluble, low density, micronized drug: Comparison with high shear granulation. Int J Pharm. 2002;237:1-14.

Citation: Shingade SG, Mane SM (2025) An Overview of the Conventional and Recent Trends in the Granulation Technologies. Adv Chem Eng. 15:374.

Copyright: © 2025 Shingade SG, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.