Indexed In

- Genamics JournalSeek

- Academic Keys

- JournalTOCs

- China National Knowledge Infrastructure (CNKI)

- Access to Global Online Research in Agriculture (AGORA)

- Centre for Agriculture and Biosciences International (CABI)

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- SWB online catalog

- Publons

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Research Article - (2020) Volume 11, Issue 7

A Model of Food Security Management System for Edible Oil and Oil Based Products used for Cooking Purposes

A.M. Hettiarachchi1*, K.K.D.S. Ranaweera2 and D. Kuruppuarachchi22Department of Food Science and Technology, University of Sri Jayewardenepura, Sri Lanka

Received: 15-Jun-2020 Published: 21-Jul-2020, DOI: 10.35248/2157-7110.20.11.835

Abstract

Food safety and food security are interrelated concepts with a profound impact on the quality of human life. In 2009, the World Summit on Food Security introduced four pillars of food security namely; availability, access, utilization, and stability. However, the scope of food security is insufficiently addressed by the food safety standards. The purpose of this study is to develop an extended framework of standards opposed to food safety management standards considering one additional pillar in food security, which is food safety, with a special reference to edible oil and oilbased products in Sri Lanka. Among 745 Colombo Municipal Council (CMC) registered food preparation facilities, 75 facilities were selected as a stratified random sample. A self-administered online questionnaire was used to identify gaps in local food security practices in edible oil. Data analysis was performed using SPSS version 21 and the characteristics of the sample were analyzed using descriptive statistics. The results of the survey revealed that the Sri Lankan food preparation facilities are significantly behind in food security practices. Considering the deviated areas in the practice, which were identified through our questionnaire, a checklist was developed by giving more attention to the above mentioned deviated areas.

Keywords

Cooking oil; Cooking method; Food safety; Food security

Introduction

The concept of food security has emerged in the 20th century and many multilateral organizations have utilized the term “food security” to describe the global effort to eliminate hunger and malnutrition [1,2].

Food safety and food security are interrelated concepts with a profound impact on the quality of human life. In 2009, the World Summit on Food security is access to sufficient, safe, and nutritious food [1]. Food security consists of four pillars including availability, access, utilization, and stability. Food security could be substantially improved by increased investment and policy reforms [3,4]. Although international standards are one of the leading food safety security management systems that address food safety management the scope of food security is insufficiently addressed [5].

As per the literature review, it is commonly accepted theory at present is that the consumption of poly-unsaturated oil is healthy but it is not the case always. Because low temperatures are generally better for retaining the highest nutrient content of food and for reducing oxidation and its associated toxic byproducts. However, we do heavy cooking at high temperatures and unsaturated/poly-unsaturated oil is thermally very unstable and forms trans-fatty acids/peroxides which are not good for human health [6].

Food security policies and programs have the potential to play a role in reducing acute health care costs through preventative measures, support economic development, raise the quality of life of residents by increasing access to safe, nutritious food, and promote environmental well-being through sustainable agriculture techniques or the promotion of local food [7].

The purpose of this study is to develop a checklist for selfevaluation of Food Security Management System food preparation facilities considering a combination of food security practices and food safety practices, with a special reference to edible oil and oil-based products in Sri Lanka.

Methodology

Materials

With regard to the research framework presented, food security and food safety principles were modified where ever necessary applicable to local food preparation facilities. A selfadministered online questionnaire to assess the knowledge and practice of food security concepts under the indicators of procurement, distribution, and exchange, affordability, allocation, utilization, and safety was done. Responses to each indicator were used to identify gaps in local food security practices in edible oil. The basis for selecting each question under each indicator based on the literature survey (Table 1).

| Research construct | Concept variable | Reference number |

|---|---|---|

| Availability | Food availability relates to the supply of food through: | |

| 1. Procurement: is a process used to ensure the buyer receives goods, services, or works at the best possible price when aspects such as quality, quantity, time, and location are compared. | [8,9] | |

| 2. Distribution and exchange: Food distribution involves the storage, processing, transport, packaging, and marketing of food and food requires efficient trading systems and market institutions, which can affect food security. | [10,11] | |

| Access | Food access refers to the: | |

| 1. Affordability: Sufficient income to purchase quality products/raw materials | [12,13] | |

| 2. Allocation: Refers use of the most suitable oil for each cooking method. | [12] | |

| Utilization | Which refers to the using of different oils for different cooking methods. Nutritional values of the consumer determine food choice, and whether food meets cultural preferences is important to utilization in terms of psychological and social well-being. Access to healthcare is another determinant of food utilization, since the health of individuals controls how the food is metabolized | [8,9] |

| Stability | Food stability refers to the ability to obtain food over time. Food insecurity can be transitory, seasonal, or chronic. | [14] |

| Safety | Encompasses many facets of handling, preparation and storage of food to prevent food borne illness and injury. Food borne illnesses show an increasing trend, but still many go unreported. | [9] |

Table 1: List of literature references.

These statements were converted to questions in the questionnaire and also a set of general questions about the category of food preparation facility, current certified standard, and usage of cooking oil were also included in the questionnaire.

There were research limitations such as only food processing facilities registered under Colombo Municipal Council were recruited, only the food security concept and hazards developing during the cooking process were considered for the study.

There were 745 Colombo Municipal Council (CMC) registered food preparation facilities and 75 (10% of the total population) food preparation facilities were randomly selected. This 75- sample size consists of the following way; out of 77 hotels sample size was 08, out of 538 eating houses sample size was 54, out of 108 restaurants sample size was 11, and out of 22 guest houses, the sample size was 2. The list of food preparation outlets was traced from CMC and was randomly selected according to the alphabetical order.

Descriptive and inferential statistics were used to measure the variables and assess the conceptual model. Parametric tests as well as nonparametric tests were used in the analysis. Data were entered and analyzed by using the Statistical Package for Social Sciences (SPSS 21).

Data analysis

During the data analysis, the following demographic factors were considered (Table 2).

| No. | Demographic factories | Percentage (%) | Number of responses |

|---|---|---|---|

| 1 | Profession | ||

| a) Chef | 60 | 45 | |

| b) Manager | 40 | 30 | |

| 2 | Working experience in the current profession | ||

| a) <2 years | 8 | 6 | |

| b) 2-5 years | 36 | 27 | |

| c) 6-10 years | 38.7 | 29 | |

| d) 11-15 years | 8 | 6 | |

| e) >16 years | 9.3 | 7 | |

| 03a | Awareness about the food safety management system-Chef | ||

| a) <2 years | 13.3 | 6 | |

| b) 2-5 years | 55.6 | 25 | |

| c) 6-10 years | 17.8 | 8 | |

| d) >11 years | 13.3 | 6 | |

| 03b | Awareness about food safety management system-Manager | ||

| a) <2 years | 10 | 3 | |

| b) 2-5 years | 56.6 | 17 | |

| c) 6-10 years | 16.7 | 5 | |

| d) >11 years | 16.7 | 5 | |

| 4 | Categories of facility registered | ||

| a) Eating house | 73.3 | 55 | |

| b) Guest house | 2.7 | 2 | |

| c) Hotel | 10.7 | 8 | |

| d) Restaurants | 13.3 | 10 | |

| 5 | System standards being certified by the facility | ||

| a) GMP | 30 | 3 | |

| b) HACCP | 20 | 2 | |

| c) ISO 22000:2005 | 50 | 5 | |

| 6 | Types of cooking oil mostly used in the facility for the cooking purpose | ||

| a) Palm oil | 54.6 | 41 | |

| b) Soybean oil | 28 | 21 | |

| c) Sunflower oil | 10.7 | 8 | |

| d) Coconut oil | 6.7 | 5 | |

| 7 | Reason for the selection of mostly used cooking oil | ||

| a) easily available | 10.7 | 8 | |

| b) cheap in price | 34.7 | 26 | |

| c) healthier than other oil | 5.3 | 4 | |

| d) as a routine | 37.3 | 28 | |

| e) popular in the market | 12 | 9 | |

| 8 | Different modalities of cooking oil usage | ||

| a) Cooking | 48 | 36 | |

| b) Frying | 30.7 | 23 | |

| c) Stir frying | 1.3 | 1 | |

| d) Deep frying | 20 | 15 | |

Table 2: List of demographic factories.

The validity and consistency of measures are very important to evaluate the credibility of the items in order to move ahead with the rest of the analysis. The adequacy of the measures was calculated by using Kaiser-Meyer-Olkin (KMO). KMO values between 0.5 and 1 indicate the sampling is adequate. KMO values less than 0.5 indicates the sampling is not adequate (Table 3).

| Variable | KMO | Bartlett’s test of Sphericity | Number of indicators |

|---|---|---|---|

| Procurement | 0.565 | 0 | 6 |

| Distribution and exchange | 0.844 | 0 | 8 |

| Affordability | 0.551 | 0 | 3 |

| Allocation | 0.601 | 0 | 4 |

| Utilization | 0.693 | 0 | 14 |

| Stability | 0.625 | 0 | 5 |

| Safety | 0.572 | 0 | 8 |

Table 3: KMO and Bartlett’s Test of sphericity.

Bartlett’s test of Sphericity tests the null hypothesis that the correlation matrix is an identity matrix, which indicates that variables are unrelated and thus unsuitable for structure detection. Values less than 0.05 of the significance level indicate that factor analysis is useful with our data (Table 3).

Mann-Whitney test was used to assess the significance between variables when comparing system certified and non-certified food preparation facilities and the significance value was taken as p<0.05.

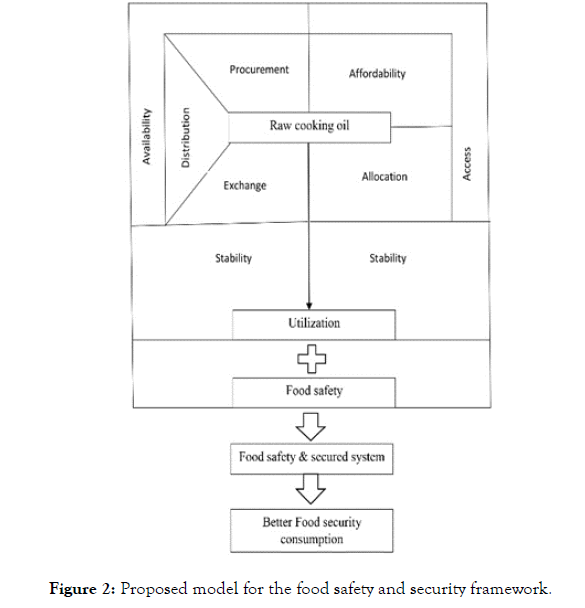

Referring to Figure 1, the mean values for seven indicators, carry an average mean greater than 3, which indicates that the responses were more toward agreeing to the questions based on involvement according to the Likert scale (Table 1).

Figure 1: Assessment of current awareness and practices in each variable.

Results and Discussion

According to Figure 1 and Table 1, in procurement indicators, 4 and 6 were less than 3, which indicates that the responses were more towards disagreeing to the questions based on involvement according to the Likert scale. This revealed that sample food preparation facilities were not considering the cooking oil buyer’s company system certification before purchasing and not requesting the next purchasing order before reaching the threshold volume of the buffer stock of the product. This could be due to their lack of knowledge of the importance of quality standard system and maintenance of buffer stock.

1, 2, and 5 indicators were less than 3, and this revealed that sample food preparation facilities were not giving much attention to the transporting vehicle condition, packing material during transportation and storing temperature and not considering them as impacting factors on food security.

Conferring to the Figure 1, in affordability pillar, indicator 1 was less than the test means, and this implies that price became the limiting factor when purchasing and in higher prices most of the time they have a shortage of quality edible oil so they go for much cheaper products to avoid the shortage.

In the allocation pillar, indicator 2 was less than the test mean, which implies that despite the above-mentioned limitations they believed a single oil type was not adequate for all cooking purposes.

Utilization pillar, indicator 2 was less than the test mean, which indicates that the shelf-life stability of the fried food was not the main reason behind the deep fat frying. Although indicators 1 and 8 were less than mean, those carried negative answers, which we were expecting, therefore the demand from customers and high-pressure vacuum, were actually not less than the mean. Further, most of the responders were unaware of the impact of high-pressure vacuum fryers on oil absorption.

The mean values for stability pillar, indicators 3 and 4 were less than the test mean, which implies that food preparation facilities usually did not calibrate all the monitoring equipment or keep monitoring records as well as not using equipment for monitoring the cooking temperature.

In finally safety pillar carried an average mean less than 3, indicator 5 was less than the test mean, which indicates that the responses were more towards disagreeing to the questions. This implies that food preparation facilities did not consider cooking temperature, pH level like critical points in designing the menu.

In our study population, the majority of the participants were aware of the safety measures recommended in the food safety standard. But the concern on the impact of physical parameters on nutritional status when preparing a menu was significantly poor among participant food outlets. It is known that cooking induces significant changes in chemical composition, influencing the concentration and bioavailability of bioactive compounds, especially in vegetables. But this fact was not evaluated in the current safety standard and most of the study population did not have a clear image of the importance of considering the impact of cooking conditions on the nutritional value of processed food when preparing food items.

Current consumer requirements are directed towards improving the quality of foodstuffs expecting that certain processed foods and the ones prepared by frying will exhibit in addition to sensorial attributes nutritional qualities as well. There is a constant concern towards the effects that the various factors involved in a thermal, industrial, or culinary process have on the nutritive value of the food that is processed. The knowledge on the impact of deep fat frying on food and its health impact was significantly higher among our study population but their selection of oil types was not complying with their knowledge during the day to day practice. Cost and unavailability of quality edible oil in the market were mentioned as common reasons behind using cheap poor-quality products by the current study population. This emphasizes the necessity of establishing proper, well-monitored in house industrial scheme to manufacture healthy cooking oil like virgin cooking oil to make healthy edible oil widely available in the local market. Further, the establishment of a monitoring process via including a check list of deep fat frying and other cooking methods with suitable oil type and comply with physical parameters of cooking oil is an important step to consider.

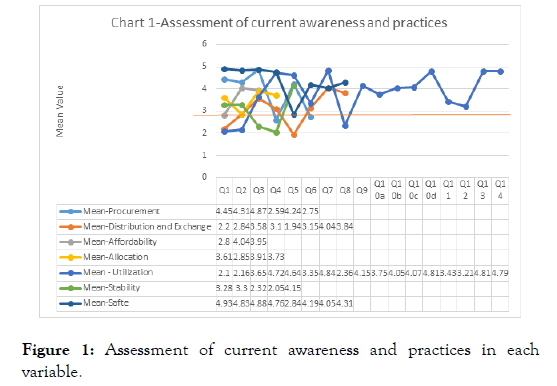

Therefore, in addition to food safety management system, we suggest to include four pillars in food security systems into the standard because of significantly food security practices are lacking in our current system. Therefore, our recommended model for food safety and security system is illustrated in Figure 2.

Figure 2: Proposed model for the food safety and security framework.

The key factors which determine the fulfilment of each category of food security concept must be evaluated and analyzed via a check list during standard certification of food selling outlets. Unfortunately, current food safety standard certification has a significant vacant space in terms of assessing food security in food preparation facilities.

Our conceptual model (Figure 2) adopts and expands the existing food safety concept into much comprehensive and realistic by integrating the food security concept to develop a novel concept called food safety and security system. Our model is grounded in the assumption that it is essential to map the food system as an integrated set of processes to more fully understand the influencing environmental, social, economic, and human factors that shape access to adequate food resources.

Conclusion

The results of the survey revealed that the Sri Lankan food preparation facilities are significantly behind in food security practices because they match more considerable about food safety management principles. Proposed model identifies points of vulnerability in the food system in general and the consumer subsystem in particular to provide greater conceptual clarity to protect against food insecurity. Because of that, this proposed model will be a road to integrate conceptual work in food safety and security to create a framework to guide research, practice and policy relevant to increase the population food security. Focusing on food system vulnerabilities and system- and individual-level barriers influencing the consumer subsystem facilitates a more systematic and organized conceptual framework to guide research, practice, and policy relevant to food systems and food security.

REFERENCES

- Food and Agriculture Organisation FAO. Agricultural and Development Economics Division. “Food Security”. 2012.

- FAO, The food system and factors affecting household food security and nutrition. Agriculture, food and nutrition for Africa: a resource book for teachers of agriculture. Rome: Agriculture and Consumer Protection Department. 2012.

- Bryan FL. Risks of practices, procedures and processes that lead to outbreaks of foodborne diseases. J Food Prot. 1988;51:663-673.

- Ecker O, Breisinger C. The food security system: A new conceptual framework. IFPRI Discussion Paper 1166. Washington, D.C.: International Food Policy Research Institute (IFPRI), 2012.

- FAO, Declaration of the World Food Summit of Food Security. Rome: Food and Agriculture Organization of the United Nations: 2009.

- Shahbandeh M. Consumption of vegetable oils worldwide from 2013/14 to 2019/2020, by oil type (in million metric tons). Consumer Goods and FMCG, 2020.

- Kennedy MS . Alcohol, gambling and fast food outlets within the Bay of Plenty and Lakes Region. Toi Te Ora-Public Health Service. 2006.

- Bouchon P. Understanding oil absorption during deep fat frying. Adv Food Nutr Res. 2009;57:209-234.

- ISO/FDIS 22000. Food safety management systems-requirements for any organization in the food chain. 2005.

- Kochhar SP, Henry CJ. Oxidative stability and shelf-life evaluation of selected culinary oils. Int J Food Sci Nutr. 2009;60:289-296.

- World Health Organization, Regional Office for South-East Asia. Food safety: What you should know. World Health Organization. 2015.

- Gunstone F. Vegetable oils in food technology: composition, properties and uses. John Wiley and Sons. 2011.

- Gregory PJ, Ingram JS, Brklacich M. Climate change and food security. Philos Trans R Soc B Biol Sci. 2005;360:2139-2148.

- Boskou D. 21 Frying Fats. Chemical, biological, and functional aspects of food lipids. 2nd Edition. CRC Press. 2010:429.

Citation: Hettiarachchi AM, Ranaweera KKDS, Kuruppuarachchi D (2020) A Model of Food Security Management System for Edible Oil and Oil Based Products used for Cooking Purposes. J Food Process Technol 11:835. doi: 10.35248/2157-7110.20.11.835

Copyright: © 2020 Hettiarachchi AM, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.