Indexed In

- Genamics JournalSeek

- RefSeek

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Publons

- Euro Pub

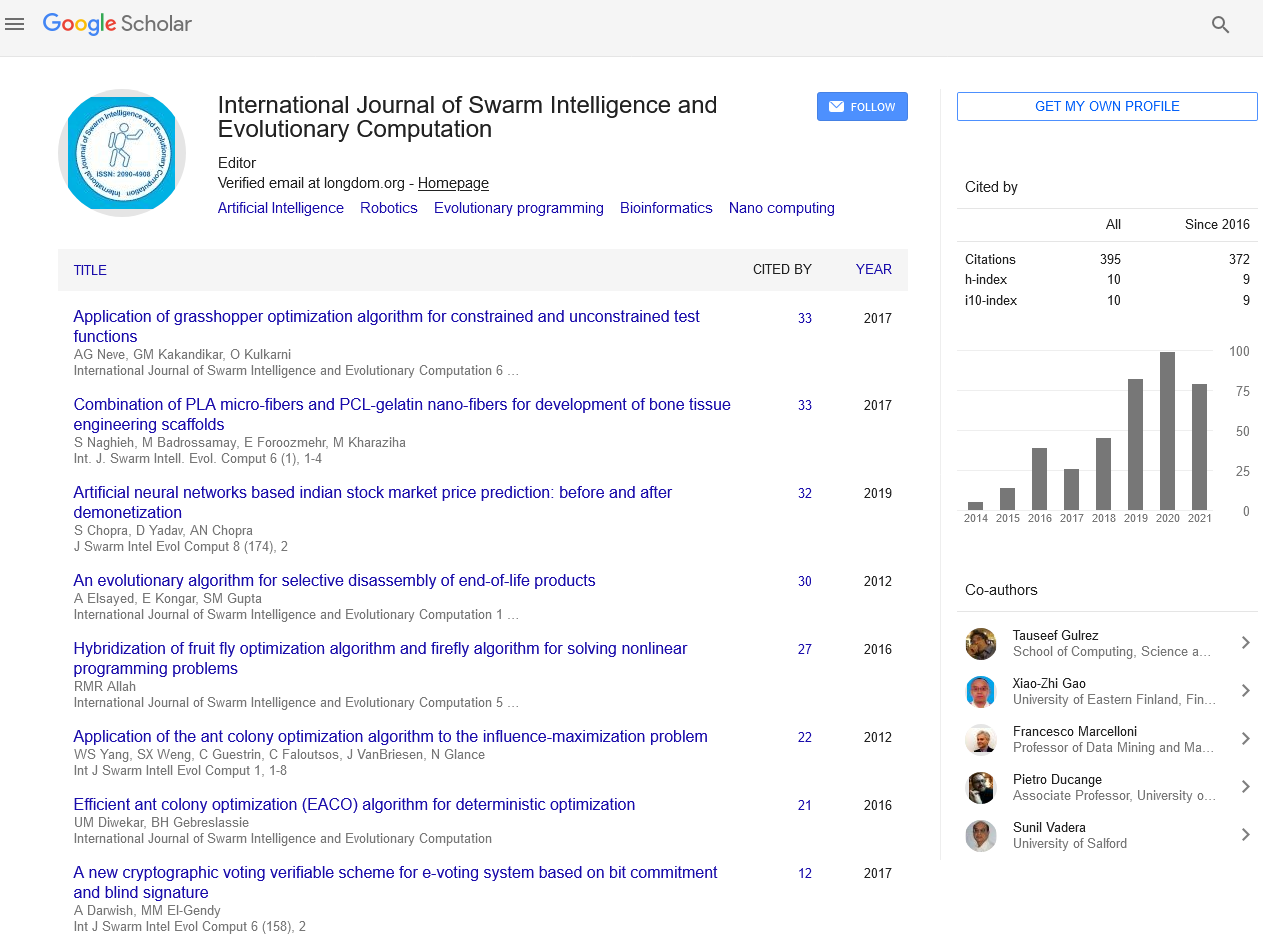

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Abstract

Groove Location for Optimum Performance of Two-Lobe Bearing Using Genetic Algorithm

Lintu Roy , Kakoty SK

This paper presents the various arrangements of grooving location of two lobe oil journal bearing for optimum performance. An attempt has been made to find out the effect of different configurations of two lobe oil journal bearing by changing groove locations. Various groove angles that has been considered are 10°, 20° and 30°. The Reynolds equation is solved numerically in a finite difference grid satisfying the appropriate boundary conditions. Determination of Optimum performance is based on maximization of non dimensional load, flow coefficient and mass parameter and minimization of friction variable using Genetic Algorithm. The results using Genetic Algorithm are compared with Sequential quadratic programming (SQP). At optimum position there is a significant improvement in the optimum value of friction variable, flow coefficient, load and mass parameter value than that of two-lobe bearing with grooves position along horizontal direction and 1800 apart. The optimum groove locations arrived at are not diametrically opposite, which is the current practice. The present analysis is carried out and results are obtained for ellipticity ratio equal to 0.5.