Indexed In

- Academic Journals Database

- Open J Gate

- Genamics JournalSeek

- JournalTOCs

- China National Knowledge Infrastructure (CNKI)

- Scimago

- Ulrich's Periodicals Directory

- RefSeek

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

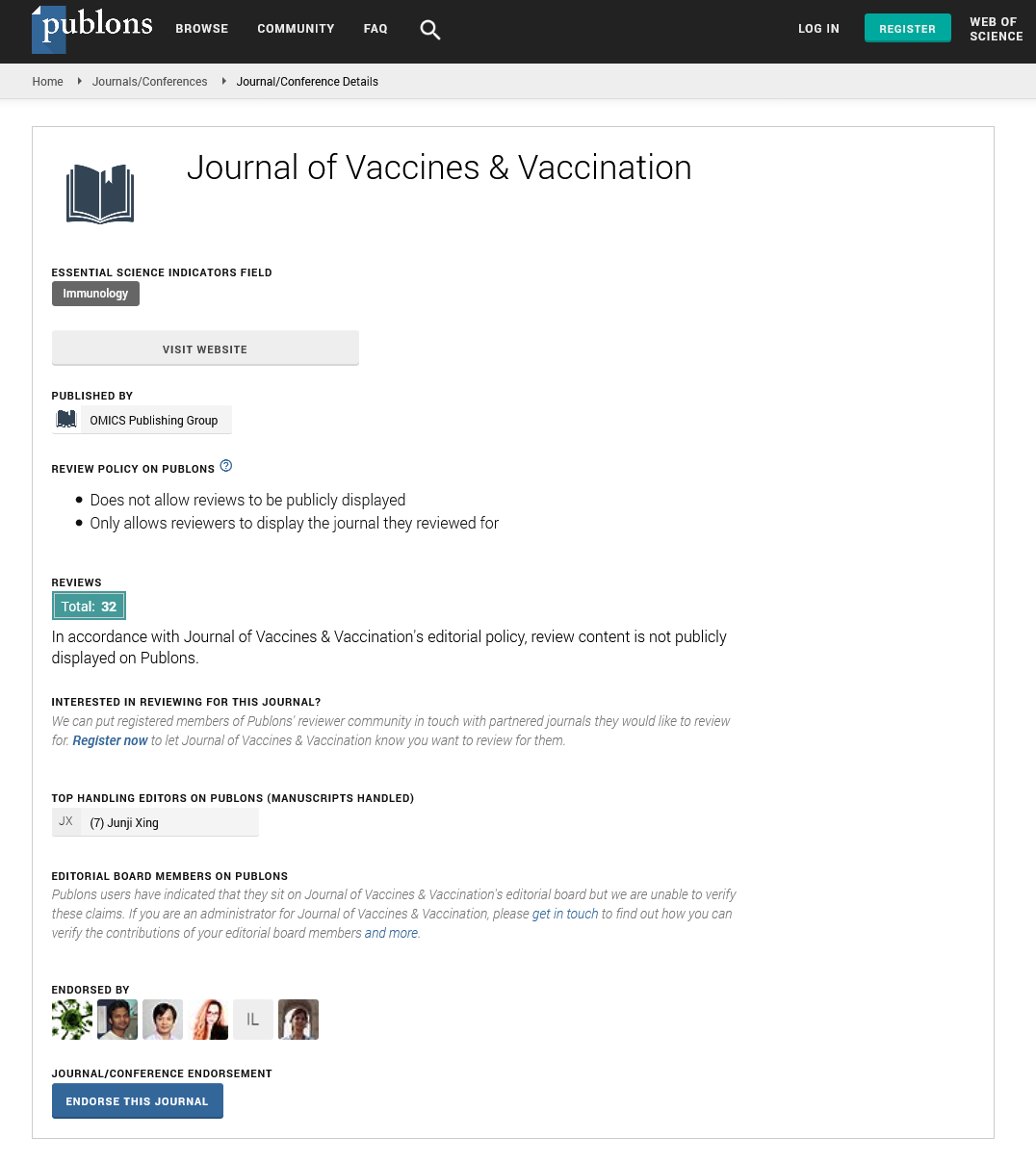

- Publons

- MIAR

- University Grants Commission

- Geneva Foundation for Medical Education and Research

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Supra AntigenTM technology platform: Manufacturing and development of vaccines for the treatment of Alzheimer disease

3rd International Conference on Vaccines & Vaccination

July 29-31, 2013 Embassy Suites Las Vegas, NV, USA

Pedro Reis, P. Donati, A. Pfeifer, and A. Muhs

Scientific Tracks Abstracts: J Vaccines Vaccin

Abstract:

A lzheimer?s disease (AD), the most common form of dementia, is characterized by pathological Amyloid beta (Aβ) deposition into plaques and neurofibrillary tangles due to aggregation of hyperphosphorylated Tau protein in the brain. The benchmark for AD vaccines targeting Aβ, is the generation of antibodies without the introduction of antigen specific T-cells, which have been reported to cross the blood-brain-barrier and cause encephalitis in 6% of AD patients receiving anti-Aβ vaccine. We developed a liposome vaccine platform technology that combines (i) antigens lacking T-cell epitopes, (ii) adjuvant signaling via TLR stimulation and (iii) B-cell receptor cross-linking by repetitive assembly of epitopes. AC Immune has developed its own vaccine manufacturing technology in order to make it easily up-scalable and compatible with cGMP principals. Our present work highlights AC Immune?s development approach for bringing an AD vaccine under clinical environment. The rationale for process development was to simplify the process, improve the homogeneity of the liposomes, reduce manufacturing time and make it easier to scale the process. Our data indicates that AC Immune?s manufacturing strategy is suitable for the preparation of drug product for preclinical and clinical studies at 100-1,000 mL scale. The following additional comments can be made. i. The preparation of the liposomes appears flexible and robust, and should be readily scalable ii. It is likely that the quality of the peptide raw material, and perhaps its tendency to aggregate may have an impact on the level of protein incorporation into the vesicles, the homogeneity of the liposomes and presence of aggregates. The level of peptide incorporation into the liposomes was generally quite high and the level of unincorporated peptide was low iii. The current manufacturing strategy appears suitable for preparation of intermediate (100-1,000 mL) batches; however, large scale batches may use an in-line mixing system to mix the protein with the vesicles. Studies to optimize the detergent to protein ratio, detergent to lipid ratio, and lipid concentration at the time of peptide reconstitution may also be required at this time iv. Clarifying filtration provides a useful strategy to improve the sterile filtration process, and remove some of the aggregates and/or larger particles that are present in the formulation

Biography :

Pedro Reis pursued his Ph.D. on Biophysics in 2008 at Chalmers University of Technology, Sweden. Afterwards, he was appointed as Primer Researcher at Baylor College of Medicine, Houston and at UNIL?s Biochemistry Department, Switzerland. Since August 2009, Pedro Reis has been working as a project leader of vaccine manufacturing at AC Immune SA, which is a Swiss-based biopharmaceutical company and a leader in Alzheimer?s disease drug development. AC Immune SA has been developing innovative therapeutics with ?best in class? potential against Alzheimer?s disease and other conformational diseases along three axes: vaccines, antibodies and small molecules