Indexed In

- Open J Gate

- Genamics JournalSeek

- Academic Keys

- JournalTOCs

- China National Knowledge Infrastructure (CNKI)

- Ulrich's Periodicals Directory

- RefSeek

- Hamdard University

- EBSCO A-Z

- Directory of Abstract Indexing for Journals

- OCLC- WorldCat

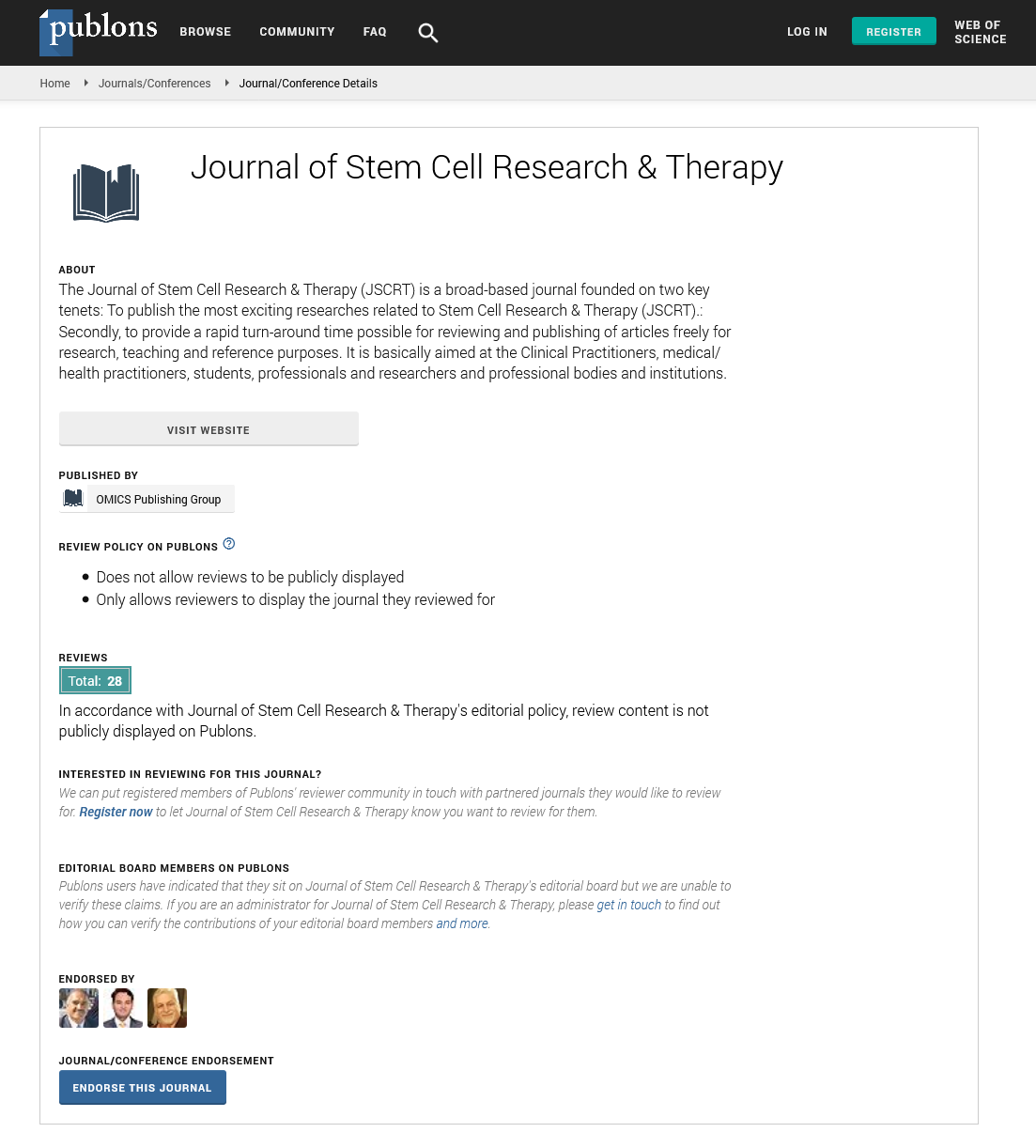

- Publons

- Geneva Foundation for Medical Education and Research

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Serum-free expansion, harvest and preservation of mesenchymal stem cells from a scalable microcarrier process

3rd International Conference and Exhibition on Cell & Gene Therapy

October 27-29, 2014 Embassy Suites Las Vegas, USA

Thomas R J Heathman

Scientific Tracks Abstracts: J Stem Cell Res Ther

Abstract:

The use of animal-derived serum is common in MSC culture but has many drawbacks such as limited supply, lot-to-lot variability, possibility of pathogen transmission and reduced scope for process optimisation. These constraints have the potential to impact the development of a consistent large-scale process and therefore must be addressed. In this work, we have demonstrated the successful end-to-end production of MSCs from a potentially scalable serum-free process. Human MSCs have been expanded on fibronectin coated, non-porous plastic P-102L microcarriers (Solohill, USA) in 100 mL stirred spinner flasks at a density of 3x105 cells/mL in serum-free medium with monitoring of key metabolites. MSCs were successfully detached and separated from microcarriers using our recently-developed protocol with a post-harvest viability of 99.63 ? 0.03%, demonstrating full ISCT characterisation and maintaining MSC outgrowth and colony-forming potential. MSCs were held post-harvest for four hours in suspension to simulate a typical pooling time for a scaled expansion process and cryopreserved in a serum-free vehicle solution using our developed controlled-rate freezing process. Post-thaw viability was 75.8 ? 1.4% with a similar three hour attachment efficiency of 75.2 ? 13.1%, demonstrating successful MSC recovery and attachment. MSCs were able to form an F-Actin containing cytoskeleton following attachment and demonstrated five-fold expansion after seven days in culture post-thaw. This study has demonstrated for the first time that MSCs can be expanded, harvested, cryopreserved and recovered from a potentially scalable serum-free microcarrier process. Demonstrating the successful integration of multiple unit operations in a serum-free MSC production process from expansion through to cryopreservation provides an important pilot study in the development of an end-to-end MSC manufacturing process.

Biography :

Thomas Heathman is a PhD student at Loughborough University?s EPSRC Doctoral Training Centre in Regenerative Medicine, with a focus on the scalable manufacture of cell-based therapies. He has a First Class Master?s Degree in Chemical Engineering from the University of Bath and has previously worked in the oil & gas industry as a process engineer. He has currently published 5 papers in reputable journals, holds positions on 6 committees and leads multiple contract research projects with industry partners.