Indexed In

- Open J Gate

- Genamics JournalSeek

- Academic Keys

- JournalTOCs

- China National Knowledge Infrastructure (CNKI)

- Ulrich's Periodicals Directory

- RefSeek

- Hamdard University

- EBSCO A-Z

- Directory of Abstract Indexing for Journals

- OCLC- WorldCat

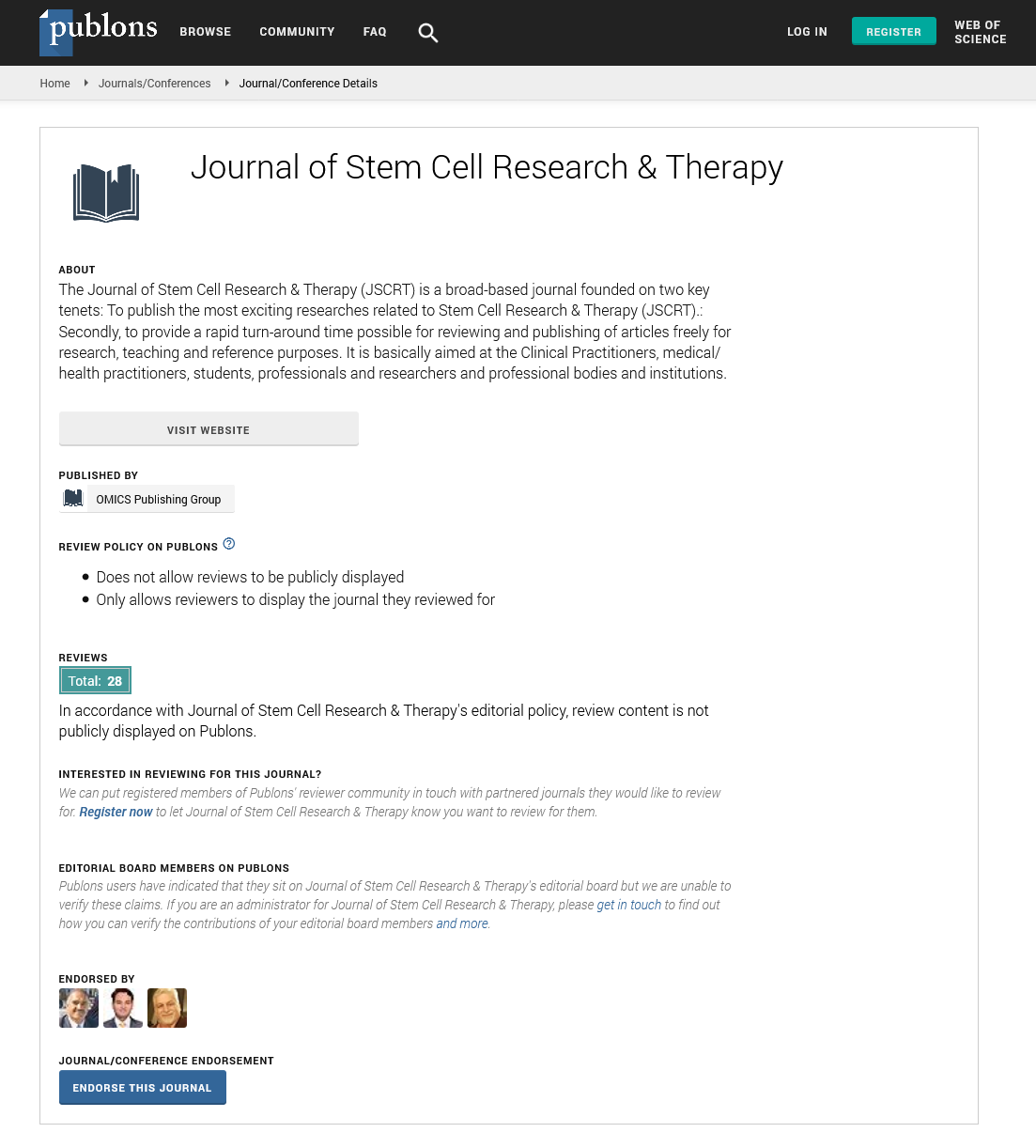

- Publons

- Geneva Foundation for Medical Education and Research

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Pullulan hydrogel-immobilized bacterial cellulose membranes for wound dressing

Joint Event on 12th Annual Conference on Stem Cell and Regenerative Medicine & 4th Annual Conference on Biomaterials

June 04-06, 2018 | Prague | Czech Republic

Deniz Atila, Ayten Karatas, Dilek Keskin and Aysen Tezcaner

Middle East Technical University, Turkey

Istanbul Technical University, Turkey

Posters & Accepted Abstracts: J Stem Cell Res Ther

Abstract:

When a full-thickness skin is lost due to trauma or diseases, wound bed cannot be immediately repaired. Coverage of damaged tissue with a material other than patient???s own skin to prevent dehydration and infection can be an alternative. Thus, bilayer membranes may be candidates for satisfying requirements of top and sub layers of a potential wound dress. For instance, top layer should be dense and strong whereas sublayer should be porous and cytocompatible. Moreover, both layers should have high-waterabsorbing capability. Membranes composed of bacterial cellulose (BC) produced by Acetobacter species have been widely utilized for different purposes owing to its excellent mechanical properties and pronounced water retention capacity. Pullulan (PUL) is another extracellular polysaccharide produced by Aureobasidium species possessing water solubility and gelation ability. Therefore, a membrane system composed of these materials can be formed by crosslinking PUL and attaching it onto BC layer to prevent delamination. Actually, PUL can effectively be immobilized on BC since it adheres to cellulose in nature. In this study, BC/PUL bilayer membranes were fabricated as a wound dressing composite for the first time in a simple and practical manner. BC produced by bacteria was purified and used in original form. PUL solution (20(w/v)%) was prepared in distilled water including trisodium trimetaphosphate (STMP) as a ???green??? crosslinking agent (STMP/PUL(w/w):1/3) and NaOH was added into the PUL solution (NaOH/STMP(w/w):1/10) as an initiator prior to pouring the solution onto BC membranes. Crosslinking occurred within 12min. Optimizations for manufacturing membranes were completed and characterizations are under study.

Biography :

Deniz Atila has completed MSc Degree in Department of Engineering Sciences from Middle East Technical University and has been working on PhD studies in the same department. She has published 3 papers in reputed journals.

E-mail: atila.deniz@metu.edu.tr