Indexed In

- Open J Gate

- Genamics JournalSeek

- Academic Keys

- ResearchBible

- Cosmos IF

- Access to Global Online Research in Agriculture (AGORA)

- Electronic Journals Library

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- SWB online catalog

- Virtual Library of Biology (vifabio)

- Publons

- Geneva Foundation for Medical Education and Research

- Euro Pub

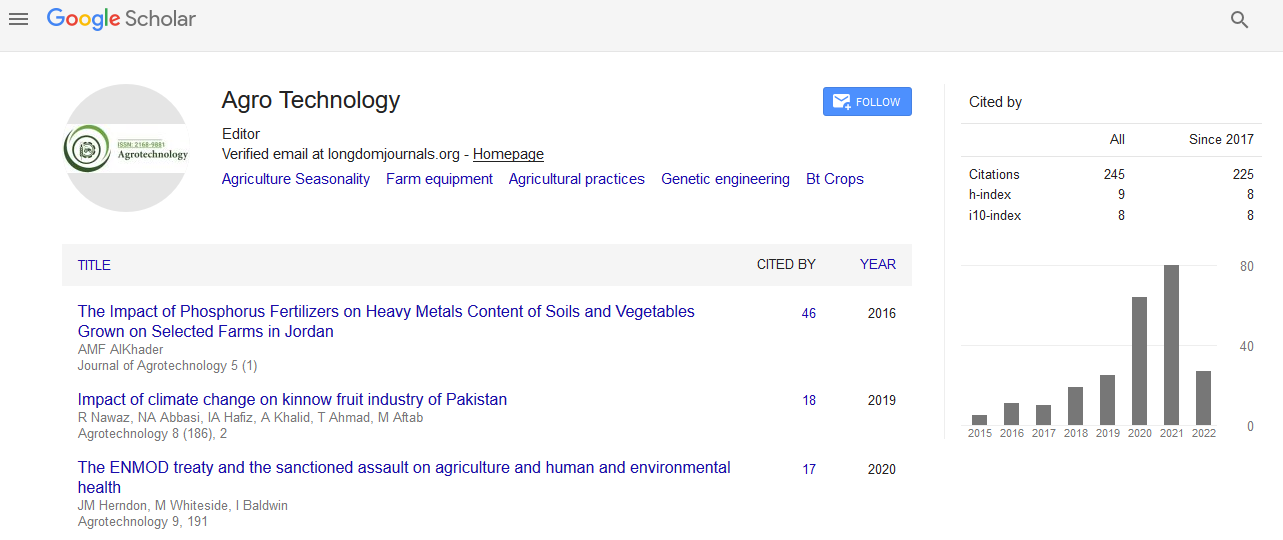

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Exploring the use of agro biowaste cellulosic fibers as a potential drywall panel board material for sustainable building use

International Conference on Agri Biotech & Environmental Engineering

September 11-12, 2017 San Antonio, USA

Jean Marie Villamor-Juanga and De La Cruz Patrick Deo

University of the Philippines, Philippines

ANCJA&IDI Inc., Philippines

Scientific Tracks Abstracts: Agrotechnology

Abstract:

This research explored the potential use biowaste cellulosic fibers as drywall panel board (DB) as construction material. The cellulosic fiber used in this study were primarily extracted from rice and banana crops agro-wastes which are highly cultivated in Philippines, other wastes used came from paper and carton boards. These biowaste products contribute to the environmental and climate change problems but can be mitigated by converting these wastes for productive reuse. In this experiment, the thermal conductivity (k value) and thermal resistivity (R-value) were determined. The materials tested were plaster of Paris as binder and perlite powder as fillers with respect to plaster/perlite/fiber ratio using percentage by weight, there were six (6) formulations used in the study, namely plaster of Paris (P-1), plaster of Paris and perlite (P-2), waste paper and rice straw (WR), waste paper and banana fiber (WB), rice straw and banana fiber (RB) and waste paper, rice straw and banana fiber (WRB). The R-following values were obtained for each formulation during testing: P-1 (0.36 h-ft2-°F/BTU), P-2 (0.49 h-ft2-°F/ BTU), WR (0.83 h-ft2-°F/BTU), WB (0.67 h-ft2-°F/BTU), RB (0.88 h-ft2-°F/BTU), and WRB (0.68 h-ft2-°F/BTU). Moisture and water absorption were also determined. Among six (6) formulations, RB showed significant results having an R value of 0.88 h-ft2-°F/BTU when compared with commercially available drywall boards. The common drywall boards in the market have the following R-values: fiber-cement board (0.19 h-ft2-°F/BTU), hardboard (0.69 h-ft2-°F/BTU), ordinary plywood (0.62 h-ft2- °F/BTU), medium-density particle board (0.52 h-ft2-°F/BTU) and gypsum wallboard (0.45 h-ft2-°F/BTU). In theory, a higher R-value means that the material can lower the amount of heat gain inside the room. Hence, the material is energy efficient. Moreover, properties of the material such as acoustical capacity, fire resistivity and water absorption can be further explored.

Biography :

Jean Marie Villmaor-Junaga is a Professor at the Department of Architecture at the University of the Philippines and is also a practicing Architect since 20 years. She has been actively attending international conferences on research related to housing, planning and material development. She has also made recent publications at the International Journal of Architecture and Urban Development (IJAUD) on vertical farming. Currently, she is more into researches related to material development of agricultural wastes in order to maximize potential use of waste while at the same time support waste valorization for a more sustainable and healthy environment.