Indexed In

- Academic Journals Database

- Open J Gate

- Genamics JournalSeek

- JournalTOCs

- China National Knowledge Infrastructure (CNKI)

- Scimago

- Ulrich's Periodicals Directory

- RefSeek

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

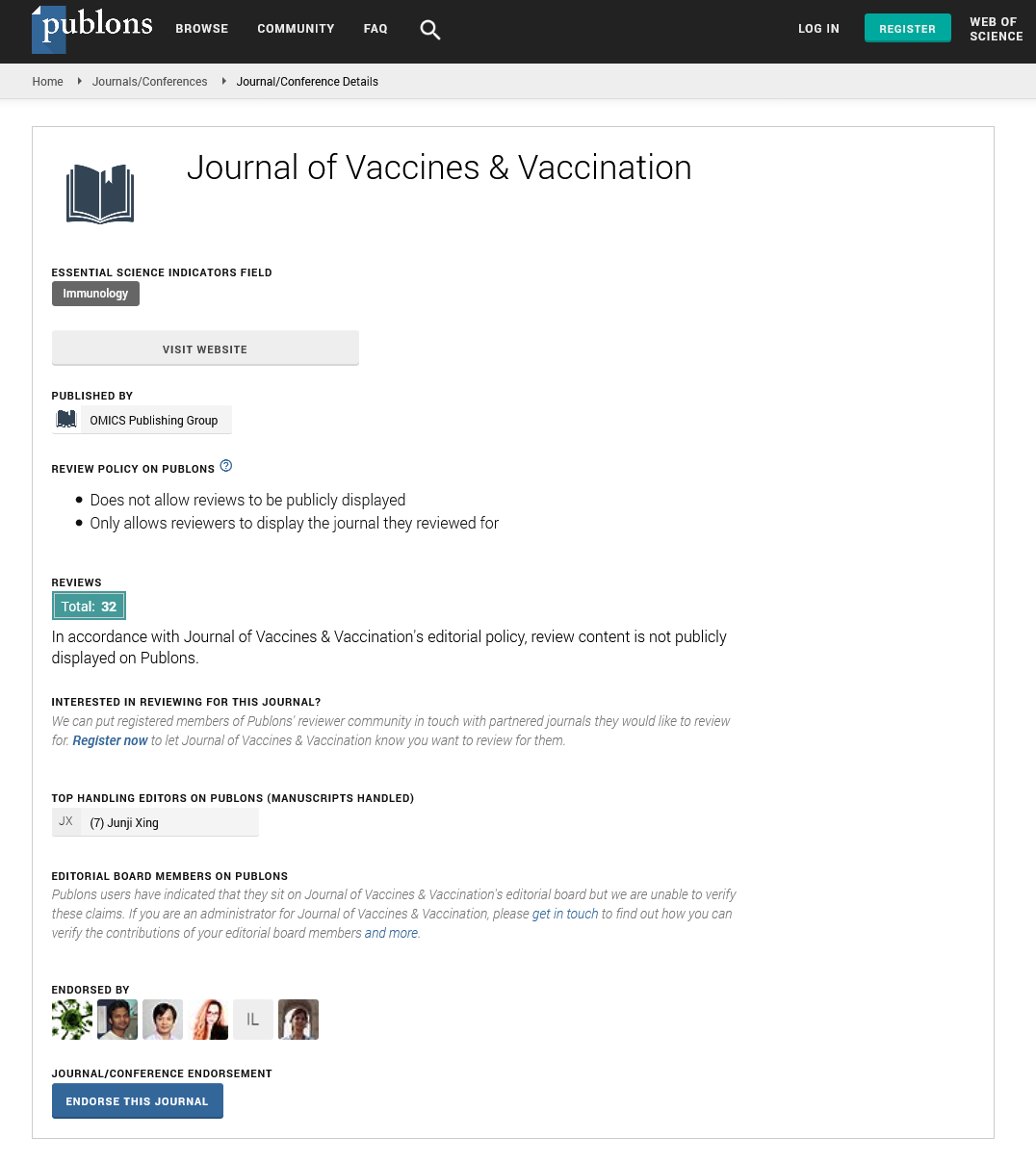

- Publons

- MIAR

- University Grants Commission

- Geneva Foundation for Medical Education and Research

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Emerging market challenges: Development of a thermostable and immunologically active solid HPV vaccine formulation

10th Euro Global Summit and Expo on Vaccines & Vaccination

June 16-18, 2016 Rome, Italy

Ramesh Chintala

Merck & Co. Inc., USA

Scientific Tracks Abstracts: J Vaccines Vaccin

Abstract:

This study describes a method of producing solid (frozen liquid or freeze-dried) aluminum adjuvant containing HPV vaccine formulations that are immunologically potent. Exposure of aluminum adjuvanted vaccines to sub-zero freezing temperatures or elevated temperatures during storage and transportation are two of the greatest challenges that often lead to substantial drop in vaccine potency, especially in emerging markets. In this study, HPV antigens bound to aluminum adjuvant were used in screening various formulations consisting of bulking agents, either independently or in combination, as well as various concentrations of salt in order to develop a stable formulation that could either be stored as a frozen liquid or as a freeze dried vaccine formulation. Results suggest that aluminum adjuvanted formulations containing a combination of bulking agents and or stabilizers in their formulations retain the physical as well as immunological characteristics of the liquid vaccine formulation upon thawing the frozen liquid formulation, after reconstitution of the dried formulation and after reconstitution of the dried formulations that were stored at elevated temperatures. This invention provides a method to address the cold chain issues that typically arise during storage and transportation of vaccines both in developing countries as well as developed nations through the development of stable vaccine that can either be freezedried or stored as a frozen liquid. These new formulations have the potential to significantly improve the handling, storage and thermal stability of aluminum containing vaccines and to reduce the costs associated with vaccine manufacturing and storage at the manufacturing facility.

Biography :

Ramesh Chintala has received his PhD in Chemistry from University of Madras, India (1997). He is currently an Associate Principal Scientist supporting vaccine formulation and drug product development within Vaccine Bioprocess R&D at Merck & Co., Inc, West Point, PA, USA. He has previously held positions at Enzon Pharmaceuticals working on Pegylation of proteins, downstream processing and analytical characterization. He has worked as a Postdoctoral Fellow at Kyoto Pharmaceutical University (Kyoto, Japan) and later moved to Rutgers University (Piscataway, NJ) for his second Postdoctoral fellowship. His areas of expertise include biologics and vaccine/adjuvant formulation development that employs the application of material sparing methods and surface characterization of pharmaceutical materials. He has several patents and publications in peer reviewed journals.

Email: ramesh_chintala@merck.com