Indexed In

- Open J Gate

- Genamics JournalSeek

- Academic Keys

- JournalTOCs

- China National Knowledge Infrastructure (CNKI)

- Ulrich's Periodicals Directory

- RefSeek

- Hamdard University

- EBSCO A-Z

- Directory of Abstract Indexing for Journals

- OCLC- WorldCat

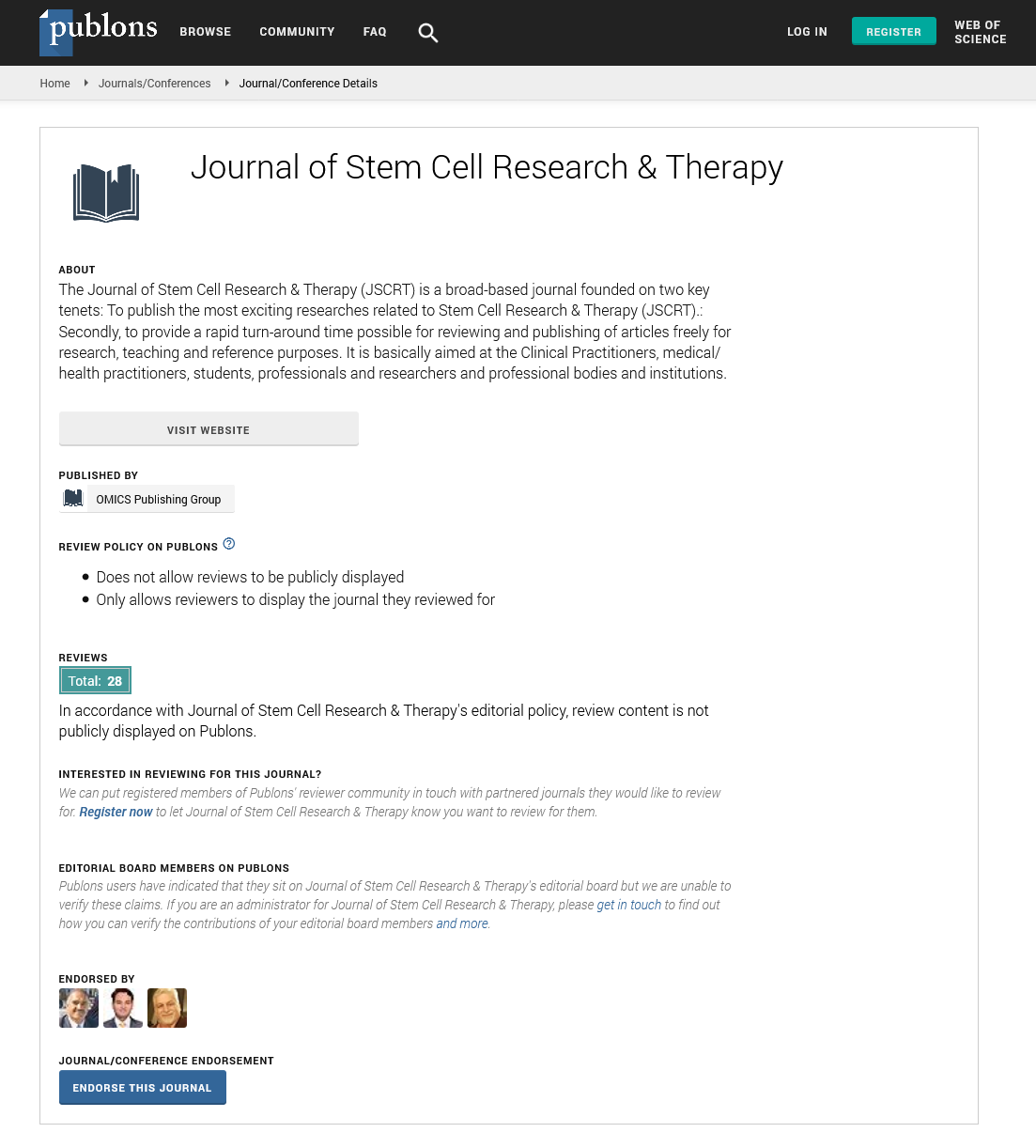

- Publons

- Geneva Foundation for Medical Education and Research

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

3D printing and characterization of scaffolds for stem cells

Joint Event on 12th Annual Conference on Stem Cell and Regenerative Medicine & 4th Annual Conference on Biomaterials

June 04-06, 2018 | Prague | Czech Republic

Annett Dorner-Reisel

Schmalkalden University of Applied Sciences, Germany

Keynote: J Stem Cell Res Ther

Abstract:

Calcium phosphate (CaP) scaffolds are superior materials for stem cell differentiation into bone cells. CaP materials are similar to the mineral component of natural bone, which favors stem cell differentiation into bone cells. Doping the calcium phosphates with suitable elements regulates protein and cell reactions further. In CaP, Mg2+ promotes angiogenesis and Sr2+ favors osteogenesis. Si4+ creates charge imbalance, if PO4 are replaced with SiO4, which leads to a more electronegative surface. 3D printing is a method for CaP scaffold production offering excellent possibilities for control of macroscopic geometry, micro and macro porosity, mechanical integrity as well as special demand for patient individual scaffold designs. Ceramic powders can be processed by several additive manufacturing methods. In the presentation, additive manufacturing of scaffold biomaterials is reviewed, shortly. Special information is given for CaP scaffold production by powder faded printing (PFP) using hydroxyapatite powder. For successful and precise printing by the PFP, ceramic powders need to fulfill several requirements, like grain and agglomerate size distribution or chemical composition for demanded binder-powder interactions. In the present study, CO3 and flour substitution are proven by FT-IR and Raman spectroscopy. The microstructure of the 3D printed scaffolds is further characterized by X-ray diffraction before and after sintering. Special highlight of the study is first testing with additional lignin. Dissolved lignin was infiltrated into the porous structure of two different 3D printed geometries. Tests with ST-2 mouse cells confirm a slightly better biocompatibility in comparison to 3D printed scaffolds without lignin treatment.

Biography :

Annett Dorner-Reisel worked as scientific staff after completing her training as Technician for Ceramic Processing in 1989 and studies in Process and Materials Engineering. She received her PhD from TU Chemnitz. She specialized in biomaterials and hybrid structures- biomedical and functional materials for transportation and energy sector, i.e. sensor/actor applications or high performance carbon allotropes. She carried out Post-doctoral studies at UC Santa Barbara, USA and Nagoya Institute of Research, Japan. Following second Doctoral degree at the Bergakademie Freiberg, she worked several years in industry before engaging 2011 in a professorship position at the Schmalkalden University HS SM. Since 2017, she is Head of the research group “Bio-STEP” at HS SM, which clusters several researchers from different working directions like materials, production technology electronics and signal transfer. Bio-STEP focuses on biomaterials, biogenic materials for energy and light weight sectors, bionics and biomimetics.

E-mail: AnnettDornerReisel@web.de