Indexed In

- Open J Gate

- Genamics JournalSeek

- JournalTOCs

- China National Knowledge Infrastructure (CNKI)

- Electronic Journals Library

- RefSeek

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- SWB online catalog

- Virtual Library of Biology (vifabio)

- Publons

- MIAR

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Review Article - (2019) Volume 10, Issue 3

Quantitative Classification of Shallow Gas Blowout during Offshore Drilling Process

Shaoran Ren*, Yanmin Liu, Feng Huang and Panfeng ZhangReceived: 06-Jun-2019 Published: 01-Jul-2019

Abstract

Shallow gas is in form of natural gas accumulation at abnormal pressure, which may exist in shallow sediments below the seabed. Gas can blowout unexpectedly during well drilling that can pose a great hazard to drilling safety. In this paper, the occurrence and geological feature of shallow gas in offshore sediments are described and a quantitative classification of shallow gas hazards is given based on gas blowout rate, which can provide guidelines for the assessment and control of the shallow gas hazards. Several measures for prevention of shallow gas blowout in offshore drilling are described, including dynamic well killing technology.

Keywords

Shallow geologic hazards; Shallow gas; Deep water drilling; South China Sea; Gas blowout; Well kill

Introduction

There is abundant offshore oil and gas resource in the South China Sea and its prospective development has been speeded up in recent years [1-4]. In the last ten years, many large oil and gas fields have been discovered, and more than 60 percent of them are located in deep water areas of over 500m water depth [1,5,6]. Exploration of offshore oil and gas resources, especially in deep water areas, will take an important role in the future development of the South China Sea.

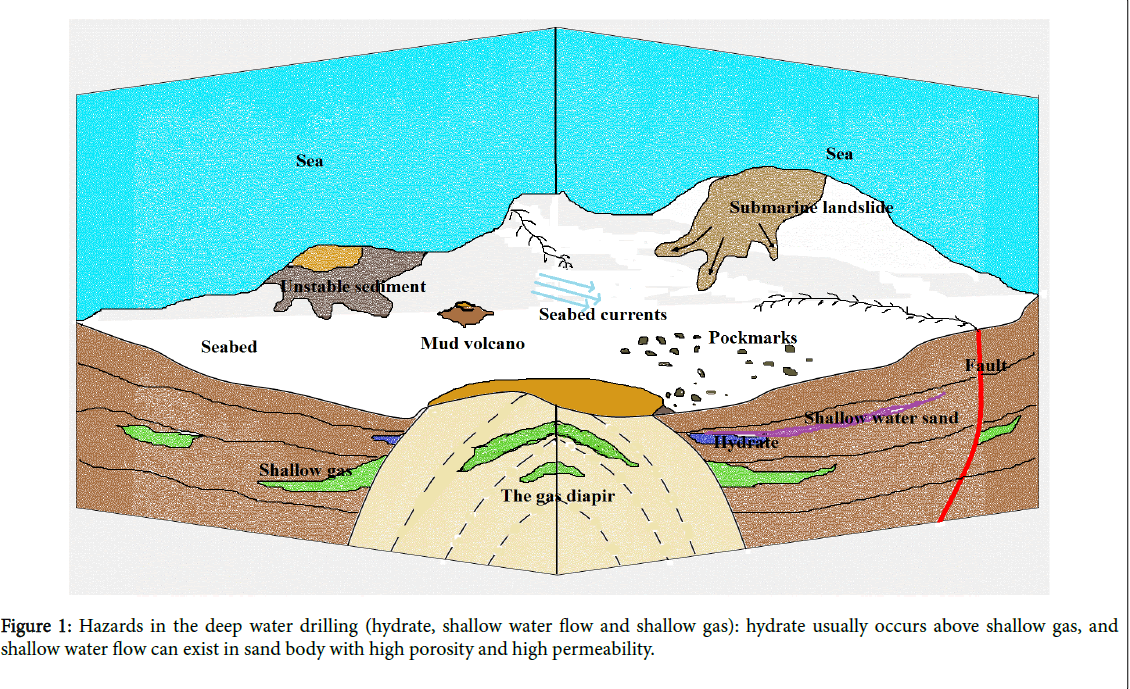

There are many technical and safety challenges in offshore drilling due to geologic hazards in shallow formations under the seabed as illustrated in Figure 1, including natural gas hydrate (NGH) [7], shallow water flow (SWF) and shallow gas (SG). Gas hydrate can exist in shallow sediments of deep-water regions, which may dissociate during drilling and induce problems of gas invasion and wellbore stability. Shallow water flow is of a sand body containing of unconsolidated sands and free water at abnormal overpressure, which exists typically at depths from 250 to 1000 meters below the seabed in areas of water depth ranging from 400 to 2500 meters [8-10]. High speed blowout of water and sands can occur when drilling through SWF zones, which can result in extensive wellbore enlargement and affecting wellbore and even seafloor integrity. Shallow gas is in the form of natural gas accumulation at abnormal pressure, similar to a small gas reservoir, which exists in shallow burial depth under the seabed and does not have the value for industrial exploitation, but gas can blowout unexpectedly during drilling that may pose a great hazard to drilling safety. Shallow gas can also occur in onshore sediments, but high density drilling fluid can be used to mitigate the gas invasion problem during drilling, while in offshore drilling, especially in deepwater drilling, the use of drilling fluids with high density is restricted due to a narrow difference between the hydro-static pressure in wellbore and the fracturing pressure of rocks in shallow sediments.

Figure 1: Hazards in the deep water drilling (hydrate, shallow water flow and shallow gas): hydrate usually occurs above shallow gas, and shallow water flow can exist in sand body with high porosity and high permeability.

A survey by ICES (International Council for the Exploration of the Sea) indicates that more than 20% blowouts in offshore drilling were caused by shallow gas, which resulted in a lot of disastrous accidents causing human losses and serious damage to drilling facilities. In 1975, an offshore drilling platform working in the Gulf of Mexico encountered a high pressure shallow gas zone when drilling to 300 m depth below the seabed. Gas blowout occurred suddenly and rapidly, resulting in fire and severe damage of the platform and drilling equipment [11]. In 1986, a gas blowout occurred during drilling of the SLB-5-4X well in Lake Maracaibo (Venezuela) due to shallow gas and caught in fire. The well killing operation failed because of the extensive heat of the fire, and the platform rig was burned off and fallen into the lake eventually [12,13].

In 1998, when drilling in Bekapir Oilfield of the Makassar Strait in Indonesia, the Viking Explorer drilling ship drilled through a shallow gas formation unexpectedly. A well blowout occurred, and then followed with explosion and fire. The drilling ship sank to the seabed 200 below the sea level and several hundred people were killed in this serious incident [14]. There are also many gas blowouts or well eruptions in drilling through shallow gas zones, but without serious or with minor accidents occurred. Well drilling in the Bohai Bay (China) also encountered SG zones in 1999. Overflow was firstly observed in Well PL19-3-3 when drilled to 374 m below the seafloor, and then a large amount of gas gush out of the well. The height of the gas column was up to 8m above the drilling platform [15]. Blowout preventer was operated successfully for the well killing.

Literature Review

Assessment of SG hazard and its prevention and control techniques in offshore drilling have received a lot of concerns, especially for well drilling in new development areas. Geologic identification and assessment of NGH, SWF and SG gas formations can be carried out before drilling via geological survey and seismic data analysis, but the common method adopted to prevent SG hazard is to avoid drilling in the suspected region due to the hazardous nature of the shallow gas. Consequently, there has been lack of quantitative description of the SG blowout, and its hazard classification has not been clarified yet.

In this study, a quantitative classification of shallow gas hazards is given based on gas blowout rate, which can provide guidelines for the assessment and control of the shallow gas hazards, and several measures for the prevention of shallow gas blowout in deep water drilling are described.

Occurrence and geologic classification of shallow gas

The source of the natural gas in offshore shallow gas zone can be from deep gas reservoirs, which migrated into and accumulated in shallow sediments under the seafloor along different types of channels, such as porous sand body, fractures and faults. In low permeability sediments, gas can migrate in vertical direction, and it can also flow along the formation dip in high permeability formations. The migrated gas can be gathered in a formation with cap layers of very low permeability, forming the so-called “stratified shallow gas”. If the pressure in a stratified shallow gas zone (or formation layer) is high over a long time, the gas will extrude into of the upper weak formation, and then a high pressure gas diapir can be formed. Many gas diapirs were evolved from stratified shallow gas, while some gas diapirs can be formed due to volcano-like sand or mud flow, accumulating with gas later on.

There are two kinds of shallow gas sources, namely the biogenic methane (over 96% of methane content) due to decomposition of organic matters in shallow silt formations and the thermally originated natural gas form deep formations. The shallow gas can be divided into 3 types depended on the nature of its occurrence and current state, including the stratified shallow gas, the mass shallow gas, and the high pressure gas diapir. The stratified shallow gas can be transformed from formations saturated with biogenic methane, which is layered and buried in different depth with a large area distribution. Due to the original content of organic matter in the sediments was not uniform because of different porosity and permeability, which can result in ununiformed gas distribution, and the so-called the mass or block shallow gas can be formed. A high pressure gas diapir usually has very low permeability upper layers, and gas can be trapped on the top of the diaper structure. The gas pressure or formation pressure coefficient of a shallow gas zone is dependent of the nature of its occurrence and geologic history. The shallow gas with thermal origin is normally featured of higher pressure than that of the biogenic methane. In general, there is no essential difference among different types of shallow gas in terms of geo-hazards for drilling operations, it all depends on its dimension, and pressure coefficient.

Shallow gas in the South China Sea

The South China Sea is located in the west of the Pacific Ocean. High water depth has been found in the south of the South China Sea, which can be over 5000 m. The water depth in the north of the South China Sea is between 1000-2000 m, and most of the region is of around 1500 m, where many oil and gas fields have been discovered [16-18]. Especially, some high pressure reservoirs have been found in depth of 3000-4000 m below the seafloor with high formation pressure coefficients (1.7-1.9), which may lead to the occurrence of shallow gas with high pressure in upper shallow sediments, posing a lot of fears on drilling safety. Actually, widely distributed shallow gas has been found in the northern parts of the region (Pearl River Mouth Basin and Yinggehai Basin), and the gas mainly came from biogenic methane. Shallow gas with thermally originated natural gas is suspected in the southern part of the region (e.g. the Qiongdongnan Basin), where oil and gas exploration is undergoing recently, but with less drilling experience. The occurrence nature of the shallow gas and its distribution in the northern part of the South China Sea are described in Table 1.

| Region | Source | Description | |

|---|---|---|---|

| North of the South China Sea | Pearl River Mouth Basin | Biogenic methane | Two large shallow gas zones and some small shallow gas formation have been identified, and the total area of the shallow gas region is over 900 km2 [19,20]. |

| Yinggehai Basin | Biogenic methane | Shallow gas can exist 5-10 m below the mudline, and shallow gas in large region of more than 1400 km2 is speculated [20,21] | |

| Qiongdongnan Basin | Thermogenic methane | Oil and gas reservoirs have been found in the basin, but with less drilling experience. At the bottom of the sea, there are micro pockmark and mud volcano [22,23] with high speculations of high pressure shallow gas. | |

Table 1: Occurrence and distribution of shallow gas in the northern part of the South China Sea.

Discussion

Quantitative classification of shallow gas hazards

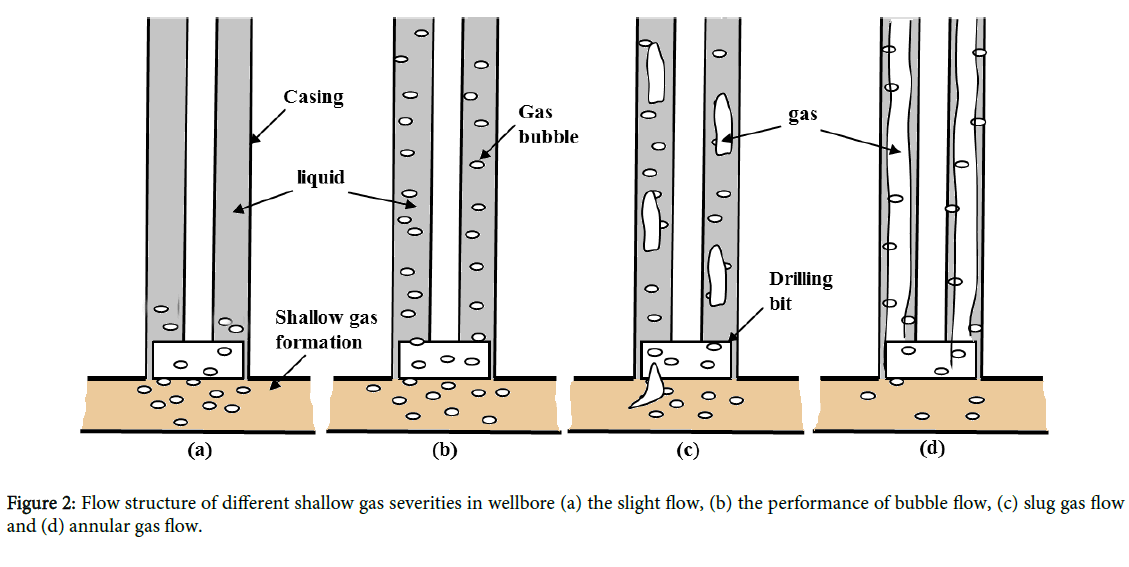

In the studies of offshore shallow hazards on drilling, well blowout has been classified into 5 grades as miner flow, low flow, moderate flow, strong flow and severe flow [24-26] but without quantitative description. For gas-liquid two phase flow, the effect of liquid compressibility can be negligible under normal oil and gas field operations (2-50 MPa, 5-150ºC) while gas can have huge volume change when the pressure and temperature change during its flow and migration from bottom of the hole to wellhead. Therefore the volume of gas at both wellhead and well bottom conditions needs to be calculated. According to the field operation experience of the China National Offshore Oil Corp (CNOOC) in offshore drilling, shallow gas and hydrate were encountered in the South China Sea, in which gas invasion can be observed as an obvious drilling fluid overflow at the wellhead. Normally 1-2 m3 volume of the mud overflow from the annulus can be obviously identified by the drilling personnel on platform along with gas bubbles coming out from the well, as an early indication of gas kick. In this study, based on the gas-liquid flow state in the wellbore (27,28) and the available volume of the wellbore space for liquid displacement by gas during gas blowout, 4 grades of the SG blowout are proposed, including slight gas invasion (slight flow), early gas kick (bubble flow), gas kick (slug gas flow) and major well blowout (annular gas flow), and the gas inflow rate in wellbore and their corresponding drilling mud overflow at wellhead are illustrated in Table 2 and their graphical illusions are shown in Figure 2.

| Gas Inflow State | Slight Flow | Bubble Flow | Slug Gas flow | Annular Gas Flow | |

|---|---|---|---|---|---|

| Gas inflow rate in wellbore |  in sm3/s | <10 | 10-100 | 100-270 | >270 |

| or in 103 sm3/h | <36 | 36-360 | 360-980 | >980 | |

| Corresponding mud flow volume at wellhead (m3) | <0.1 | 0.1-1 | 1-2.7 | >2.7 | |

| SG hazard classification | Slight gas invasion | Early gas kick | Gas kick | Serious well blowout | |

Table 2: Corresponded gas inflow in wellbore and drilling mud overflow at wellhead for the quantitative shallow gas hazard classification.

Figure 2: Flow structure of different shallow gas severities in wellbore (a) the slight flow, (b) the performance of bubble flow, (c) slug gas flow and (d) annular gas flow.

The characteristics of the 4 shallow gas hazards can be described below

Slight flow (slight gas invasion): Gas start to inflow into wellbore but it is difficult to monitor at wellhead. Less than 0.1 m3 of drilling mud can be overflowed at the wellhead during gas invasion time. This may occur in drilling through a small size shallow gas zone with formation pressure coefficient less than 1.15.

Bubble flow (early gas kick): Moderate gas invasion occurs, which can be as an early gas kick, and around 0.1-1 m3 drilling mud overflow in a short time from the wellbore annulus can be observed at wellhead At this state, around 10-100 sm3/s of gas can flow into wellbore, mixing and dispersing in drilling fluid and reducing the density of the mud. This can occur when drilling through a moderate size of shallow gas zone with formation pressure coefficient over 1.2, which can lead to major gas kick or well blowout to occur if no well killing measures to be taken.

Slug gas flow (gas kick): Relatively large gas volume (e.g. 100-270 sm3) blows into wellbore, which can effectively displace the liquid in the wellbore and can induce gas slugs and gas kicks.

Annular gas flow (major or serious well blowout): This occurs when the velocity of gas inflow into wellbore is greater than 270 sm3/s, and nearly all the drilling fluid in the wellbore can be is displaced by the invaded gas. The gas is in a continuous flow state, which can catch fire or cause other serious accidents. This can occur when a large size of shallow gas zone with high formation pressure coefficient is drilled.

In summary, three critical gas rates or ranges can be defined to quantitatively classify the severity of the shallow gas hazards, namely the gas invasion rate, the well kick rate and the blowout rate. The critical gas invasion rate indicates the start of gas invasion into wellbore, and it can be in the range up to 10 sm3/s, in which slight gas invasion can occur that can be readily controlled via normal well killing techniques, such as increasing the circulation rate or density of drilling fluid. The simulation results indicate, when seawater is used as drilling fluid, there is a corresponding formation pressure coefficient (1.15) of the SG zone that can trigger gas invasion. The critical gas kick rate is identified as 100 sm3/s, and that for the critical well blowout rate is of 270 sm3/s.

Prevention measures of shallow gas hazards

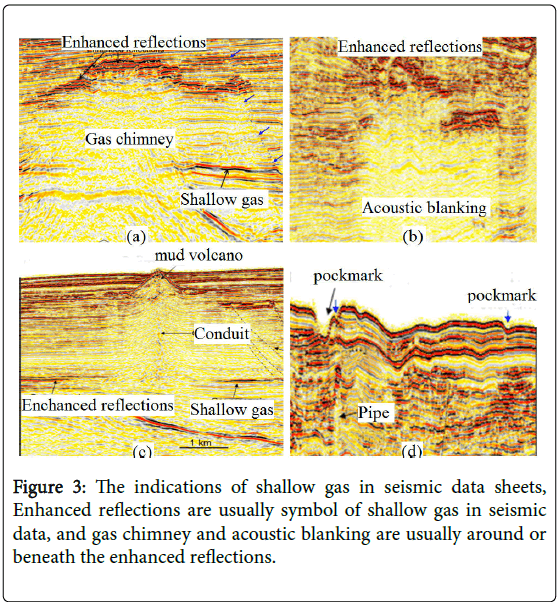

Identification of shallow gas before drilling: Shallow gas can be identified via seismic and acoustic data analysis [27-29]. Some typical SG characteristics in converted seismic profiles are shown in Figure 3 to indicate the occurrence of shallow gas in subsea sediments [18] Enhanced reflections, a pile of high amplitude seismic reflections in seismic data sheet (Figures 3a and 3b) are obvious signals of shallow gas, which can usually exist at the crest of a gas chimney. Acoustic blanking can be a zone of severely dimmed or acoustically opaque reflections, which can occur beneath enhanced reflections. As shown in Figures 3a and 3b, two features that gas chimney and acoustic blanking occur beneath the shallow gas formation (expressing as “ enhanced reflections ” ). They penetrate through the enhanced reflections and stop below an enhanced reflections. Furthermore, the mud volcanoes and pockmarks (Figure 1, Figures 3c and 3d) represent shallow gas escaping from high pressure gas diapirs. They connect the shallow gas formation by conduits or seepages and can be directly observed on the seabed as shown in Figure 1.

Figure 3:The indications of shallow gas in seismic data sheets, Enhanced reflections are usually symbol of shallow gas in seismic data, and gas chimney and acoustic blanking are usually around or beneath the enhanced reflections.

In addition, well logging data can have obvious characteristics of high acoustic time difference, high resistivity and low density from SG zones. Therefore, early detection of SG zones can be carried out using a LWD (logging while drilling) technique during drilling process. Early and careful overflow monitoring of drilling fluid and ROV (remote control submersible) for real-time monitoring on subsea wellhead is also recommended in drilling through speculated SG zones.

Well killing techniques in drilling process: Dynamic well killing techniques can be in place and used in drilling in speculated shallow gas regions with small size and low pressure formations. Dynamic well killing is an unconventional solution for well control in drilling high pressure and low fracturing pressure formations. Its principle is to adjust the density and viscosity of killing fluid, and to increase delivery volume (or circulation rate) of drilling fluid in order to increase the bottom well pressure and balance the pressure difference between the wellbore and the formation. Increasing the density of drilling fluid is an effective solution in practice. Once a shallow gas zone is encountered (e.g. with early gas kick signs), the drilling operation should be stopped immediately, and a well killing fluid with an estimated density should be injected into the wellbore using a higher circulation rate. After the well is killed and gas in well bore is discharged, cementing can be used to seal the shallow gas formation. And then drilling operation can be restored to drill through the shallow gas formation using heavier drilling fluid. It is an effective method via mixing seawater with a heavy mud to increase the density of drilling fluid [30]. Meanwhile, the density of mud must be adjusted precisely to ensure no formation fracturing.

Conclusion

In this study, a quantitative classification of shallow gas hazards is given based on gas blowout rate, including slight flow (with gas inflow rate of less than 10 sm3/s), bubble flow (10-100 sm3/s), slug gas flow (100-270 sm3/s) and annular gas flow (more than 270 sm3/s), which can provide guidelines for the assessment and control of the shallow gas hazards. Once a shallow gas zone is encountered (e.g. with early gas kick signs), several measures can be taken to prevent the SG hazards in offshore drilling, such as dynamic well killing technology.

Acknowledgements

Financial supports by the 973 National Research Project of China (No. 2015CB251201), the Program for Changjiang Scholars and Innovative Research Team in University (IRT_14R58) and the Fundamental Research Funds for the Central Universities (15CX05036A) are gratefully acknowledged.

REFERENCES

- Yang J, Shijing C (2008) Current situation and development trend of petroleum drilling technologic in deep water. J Oil Dril Petroleum Tech 30: 10-13.

- Shiguo W, Wenhai W, Xingxun J (2011) South China sea deepwater drilling Challenges and solutions. J Petroleum Drill Techn 39: 50-55.

- U.S Energy Information Administration. Assessment Report of Oil and gas resource in the South China Sea http://www.eia.gov/countries/regions-topics.cfm?fips=SCS

- Baojiang S, Zhennan Z (2015) Challenges and countermeasures for the drilling and completion of deepwater wells in the South China Sea. Petroleum Drill Techn 43: 1-7.

- Zhiming Y, Jianliang Z, Shiquan J, Jian L (2011) Deepwater drilling risk analysis and countermeasure strategy. 13th China Association for Science and Technology - Proceedings of the Ocean Engineering Equipment Development Forum. Tianjin.

- Zhichuan G, Tinggen C (2006) The theory and technology of Drilling Engineering, China University of Petroleum Press, DongYing, China pp: 150-203.

- McConnell DR, Zhang Z, Boswell R (2012) Review of progress in evaluating gas hydrate drilling hazards. Mar Petroleum Geol 34 : 209-223.

- Furlow W (1998) Shallow water flows: How they develop; what to do about them. Offshore, Accessed on: 1 September 1998.

- Cameron C (2005) Controlling Shallow Water Flows in Deep Water: Offshore Mediterranean Conference and Exhibition in Ravenna, Italy.

- Tinggen C, Zhichuan G, Xisheng L (2000) Drilling engineering theory and technology. China University of Petroleum.

- Shiguo W, Haiqing Z, Xiangyang W, Haibin S, Dongdong D(2007) The research of geohazards estimation technique on deep-water wells. J Mar Sci. 31: 77-80.

- Adams NJ, Hansen A, Stone AD, Voisin JA, Quiroz GA, et al. (1987) A case history of underwater wild well capping: Successful Implementation of New Technology on the SLB-5-4X Blowout in Lake Maracaibo, Society of Petroleum Engineers, Venezuela.

- Voisin JA, Quiroz GA, Pounds R, Wright J, Bierman K (1987) Relief Well Planning and Drilling for SLB-5-4X Blowout, Lake Maracaibo, SPE Technical Conference and Exhibitio, Venezuela.

- Shiguo W, Yangbing X, Qin Q, Qingping L (2014) Shallow drilling geological disasters of oil and gas in deepwater. Exploration Engineering Rock & Soil Drilling and Tunneling. 41: 38-42.

- Yang H (2004) Well blowout precaution and control technology for shallow gas in Bohai oilfield. China Oilfield Services Ltd.,CNOOC,Beijing.

- Sun Q, Wu S, Hovland M, Luo P, Lu Y, et al. (2011) The morphologies and genesis of mega-pockmarks near the xisha uplift, South China Sea. Mar Petroleum Geol 28: 1146-1156.

- Yanchao W (2014) Research of enhance heavy oil recovery by air injection assisted cyclic steam stimulation. Thesis for the Master degree.

- Sun Q, Wu S, Cartwright J, Dong D (2012) Shallow gas and focused fluid flow systems in the Pearl River Mouth Basin, northern South China Sea. Mar Geol 315: 1-14.

- Can YY, Ren CJ, Fu PG, Liu K (2003) A study of formation cause, existing characteristics of the shallow gas and its danger to engineering. Donghai Mar Sci 96: 950-957.

- Ping L, Jun D, Lejun L, Chengxiao C, Yuanqin X (2010) Distribution characteristics of the shallow gas in Chinese offshore seabed. Chinese. J Geol Hazard & Control 21: 69-74.

- Ning F, Qing L, Yingli L (2011) Analysis on potential gas source of gas hydrate from the original characteristics of shallow gas in the north of the South China Sea. Geoscience 25: 332-339.

- Shuyang G, Bingzhong S, Xin Z (2013) Research on deep-water drilling fluid system in southeast of Hainan. J Drilling Fluid & amp Completion Fluid 30: 5-8.

- Shouquan L, Xiqing L, Shengjie W, Yugui G (2000) Kinds of hazardous geology and division in South China Sea. Chinese Journal of Geological Hazard & Control.

- Ellis TB, Acorda EPR (2013) Mitigation of deepwater shallow hazards with simplified cement system: South China Sea Case Study. International Petroleum Technology Conference, Beijing, China.

- Thomas J, Weiland R (2003) Shallow Water Flow Severity Diagram. BP / E&P Technology Group.

- Zehui D, Weiping L, Wenho M, Zhujun L, Chong Z, et al. (2015) Analysis of Cause of reservoir damage in Lingshui 17-2 gas field and selection of test fluid for reservoir protection in deep water area. Drilling Fluid & Completion Fluid 32: 39-42.

- Yonghai G (2007) Study on multi-phase flow in wellbore and well control in deep water drilling. China University of Petroleum. Thesis for the Master degree.

- Gao YH, Sun BJ, Zhao XX, Wang ZY (2010) Dynamic simulation of kicks in deepwater drilling’, Journal of China University of Petroleum 34: 66-91.

- Schroot BM, Schfittenhelm RTE (2003) Shallow gas and gas seepage: Expressions on seismic and other acoustic data from the Netherlands North Sea. Journal of Geochemical Exploration. 78: 305- 309.

- Shengmin Z (1999) A new advance of gas hydrate research. Marine Geology & Quaternary Geology. 19: 39-4

Citation: Ren S, Liu Y, Huang F, Zhang P (2019) Quantitative Classification of Shallow Gas Blowout during Offshore Drilling Process. J Pet Environ Biotechnol 10:393. DOI: 10.35248/2157-7463.19.10.393

Copyright: © 2019 Ren S, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.