Indexed In

- Open J Gate

- The Global Impact Factor (GIF)

- Open Archive Initiative

- VieSearch

- International Society of Universal Research in Sciences

- China National Knowledge Infrastructure (CNKI)

- CiteFactor

- Scimago

- Ulrich's Periodicals Directory

- Electronic Journals Library

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- Publons

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Research - (2020) Volume 10, Issue 3

Plastic Wastes as a Raw Material in the Concrete Mix: An Alternative Approach to Manage Plastic Wastes in Developing Countries

Yalemsew Adela1*, Mohamed Berhanu2 and Biruk Gobena22Centeral Ethiopia Environment and Forest Research Center,33042 Addis Ababa, Ethiopia

Received: 18-May-2020 Published: 20-Jun-2020, DOI: 10.35248/2252-5211.20.10.382

Abstract

The twenty-first century can be marked as a “plastic era” where different sectors are producing and consuming a huge amount of plastic. Concurrently, the plastic waste generation rate has been increasing and causing serious problems on the public health and ecosystem. Hence, recycling of plastic wastes can be one alternative management option for this peculiar waste stream. This study aims to evaluate the technical feasibility of plastic wastes as a partial replacement of coarse aggregate in a concrete mix using volcanic pumice as an admixture. Concrete test specimens prepared with standard M20 mix design were measured for a compressive and split tensile strength. Plastic aggregate made from plastic bags and bottles has shown a different degree of workability to replace the concrete mix. The compressive and split tensile strength tends to decrease with increasing the ratio of plastic aggregates for both types of plastics. However, the curve based operational cut-off value shows that the plastic bag and bottle aggregates can replace coarse aggregate from 11-14% and 35-37.5% respectively. Conclusively, utilizing the plastic aggregates as a partial replacement of coarse aggregate is technically feasible. However, applying the nominal concrete standard mix proportion is seemingly inappropriate while plastic aggregates used as an aggregate which in turn require a specific mix design. Despite the percent replacement is low, utilizing waste plastics in the concrete mix would help countries with the weak waste management system.

Keywords

Coarse replacement; Operational cut-off value; Plastic bag aggregate; Plastic bottle aggregate

Introduction

In the twenty-first century, the consumption of plastics has been increasing rapidly [1] and the generation of plastic waste has also become alarming [2]. In 2018, the total plastic production has reached to 359 million metric tons where 1.5 million metric tons of production were reported in the 1950s [3]. Ethiopia’s plastic industry is the fastest growing in Africa and the plastics consumption has grown by 15.6% per annum over the past years, from 44 kt in 2007 to 268 kt in 2018 and is estimated to be 386 kt in 2022. Similarly, the per capita consumption of plastics in Ethiopia has grown by about 13.1% annually from 0.6 kg in 2007 to 2.8 kg in 2018 and is estimated to be 3.8 kg in 2022 [3].

Despite the economic gain due to the emergence of plastic science is undeniable, the concurrent environmental problem occurring is also becoming a challenge to many parts of the world. According to D’ambrières [4], nearly half of all plastic produced since 1950 has ended up either in landfills or open dumped, and nine percent of the plastics have been recycled globally. Moreover, about 4 to 12 million metric tons of plastic waste ends up in the ocean. Different counties have different contributions to this phenomenon depending on the population size and status of the waste management system the countries possess. In the absence of well-organized waste management infrastructure, the quantity of plastic waste entering into the fluvial system is predicted to increase. Developing countries, in particular, would face a significant challenge concerning waste management due to the rapid population growth, increased urbanization and inconsistent consumption patter which particularly worsen the issue of plastic wastes [5].

There are several R & D efforts to avert or minimize the problem happening due to waste plastic. Among this recycling of plastic into different valuable materials is one stage in the integrated waste management principle. In recent years there are various scientific reports in using waste plastics in the construction sector as a sole construction material and as an aggregate (fine and coarse) [6-25]. Wangmo et al., [1], with M20 mix designed and a volumetric mix proportion of 1:1.72:3.169 obtained 20% replacement of coarse aggregate gave the highest compressive strength at 28 days with only 2% lower value than that of nominal concrete and a split tensile strength for concrete with 15% percentage replacement showed the highest value and it increased at every curing age. Several findings carried out in different methods reported that increasing the ratio of plastic fraction decreases the compressive and split tensile strength [1,2,7,14,15,17,20,21,24,26]. Almost all reported papers in this arena used different mix design proportions which makes the findings difficult to utilize for real practical application. Conclusively, most of the research undertakings ignored the use of a standard concrete mix design ratio to determine the workable range in real practice. Therefore, this study aims to investigate the technical feasibility of plastic bags( polyethylene) and plastic bottles(polyethylene terephthalate) under the nominal standard M20 grade mix design ratio using volcanic pumice as an admixture and identify curve based operational cut-off value for practical application.

Materials and Methods

Materials

In this study the portland Pozala cement of 32.5R grade confirming to IS 8112- 1989 with a specific gravity of 3.21, standard consistency of 28 %, initial setting time of 50 minutes and final setting time of 245 minutes. The fine and coarse aggregate used were natural river sand with a specific gravity of 2.63 and crushed granite stone with a specific gravity of 2.6 respectively. The maximum size of the coarse aggregate used was two cm. Tap water that is used for drinking purposes was used for the mix. As the main part of the study, waste plastic bags(polyethylene) and plastic bottles (polyethylene terephthalate) were also used. Similarly, the plastics were cut to an approximate maximum size of 2cm for the intended purpose to replace the coarse aggregate. Moreover, a natural volcanic rock (i.e. pumice with a size of < 2μm) was used as an admixture.

Experimental Design

The experimental design employed evaluated the effect of twofactor variables, i.e. the quantity of coarse aggregate replaced and effect of pumice as an admixture. The response variables measured were comprehensive and split tensile strength of the concrete specimens prepared. Five experimental and three control groups were designed as shown in Table 1.

Table 1: Experimental Design.

| Test | Experimental Blocks | Experimental Groups | Control Groups | |||

|---|---|---|---|---|---|---|

| Compressive Strength | Block 1 (B1) | 25 % Plastic bottle |

50 % Plastic bottle |

75 % Plastic bottle |

Control group for B1 and B3 with M20 concrete mix ratio | Control group for B2 and B4 M20 concrete standard mixtures + 10% pumice admixture |

| Block 2 (B2) |

10% Pumice admixture to B1 | 10% Pumice admixture B1 | 10% Pumice admixture B1 | |||

| Block 3 (B3) |

15 % Plastic bag |

25% Plastic bags |

35% Plastic bags |

|||

| Block 4 (B4) |

10% Pumice admixture to B3 | 10% Pumice admixture B3 | 10% Pumice admixture B3 | |||

| Split Tensile Strength |

Block 5 (B5) |

25% plastic bottle | 35% plastic bottle | 50% plastic bottle | Control group for B5 with M20 mix design | |

A total of 108 test specimens for a standard concrete grade of M20 were prepared as per the Indian IS-456-2000 standard for both the experimental and control groups. The percent of plastic bags and plastic bottle aggregate replacement range from 0-35% and 0-75% respectively. The variation on the percent replacement between the plastic bag and bottle was made based on the preliminary experimentation done to investigate the degree of workability of the specimens upon increasing the plastic fraction in the mix. Other experimental groups that contain pumice as an admixture (10% of the cement ratio) were also designed for a compressive test. In the case of split tensile strength, two approaches were differently addressed in designing the experiment, the first one is there no experimental group which contain pumice admixture and the second is the percent replacement of plastic aggregate is different from the experimental groups designed for a compressive strength test (Table 1). The mixing was done manually based on a volumetric basis and the mix design was 1:1.5:3 according to Indian Standard IS 456-2000. The casts were cured on open-air and subsequent strength measurements were taken on days 7, 14 and 28.

Compressive strength test

The compressive strength test is the common test conducted in concrete science to understand the overall qualitative characteristics of the concrete since many of the characteristics are related to compressive strength [23]. The compressive test was carried out on a specimen of cubical shape using the ASTM C39 procedure. Standard concrete cubes of size 150mm x 150mm x 150mm were tested for the compressive strength test. The test was repeated for two specimens and the average value was taken as the mean strength. The value for the compressive strength then computed using:

(1)

(1)

Where, C=compressive strength, MPa

P=Maximum applied load indicated by test machine, N

B=Width of a specimen, mm

L=Length of a specimen, mm

Split tensile strength test

Tensile strength is one of the fundamental and crucial properties of concrete. Experiences showed that concrete could have very good in compressive strength but weak in tensile strength and this is one of the drawbacks of concrete [2]. Split tensile strength test was carried out on a cylindrical specimen 15cm in diameter and 30 cm long as per the IS 5816 testing method. Load at which the specimen failed is recorded and the splitting tensile stress is obtained using the formula indicated below:

(2)

(2)

Where, T= splitting tensile strength, MPa

P=Maximum applied load indicated by test machine, N

D=diameter os specimen, mm

L=Length of specimen

Results and Discussion

Density

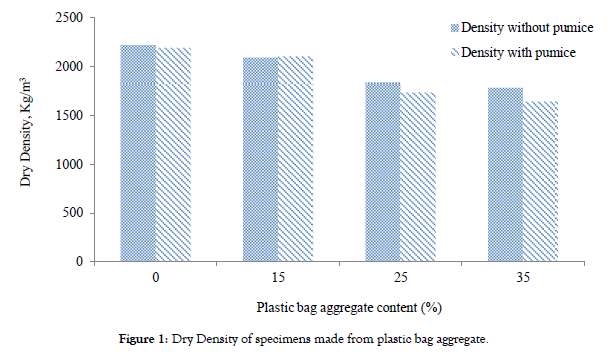

The behavior of concrete is dependent on several parameters where the density is among the others. In this study, the test specimens were prepared using volcanic pumice as an admixture and without admixture. Theoretically, the presence of pumice is believed to produce lightweight concrete [26,27]. Generally, the density of the concrete decreases with increasing the percent replacement of plastic aggregate made from both plastic bottles and bags aggregate as shown in Figures 1 and 2. The density of the concrete without pumice ranged from 2222 kg/m3 to 1780 kg/m3 whereas concrete consisting of pumice had a density that ranges from 2190 kg/ m3 to 1644 kg/m3 for zero and 35 percent plastic bag aggregate replacement respectively for both groups. The density of concrete with and without pumice has shown no observed difference at a percent replacement of less than 25% of plastic bag aggregate (Figure 1). However, the density at 35% replacement of plastic bag aggregate with (1644kg/m3) and without (1780kg/m3) has indicated a difference between the two categories.

Figure 1: Dry Density of specimens made from plastic bag aggregate.

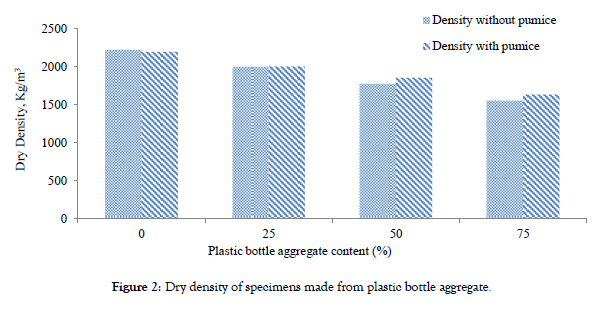

Figure 2: Dry density of specimens made from plastic bottle aggregate.

Similarly, the density of the concrete decreased upon the increment of the plastic bottle aggregate in the mix as indicated in Figure 3.

Figure 3: Operational cut-off value for plastic bag aggregate replacement with pumice.

In the case of concrete comprising plastic bottle aggregate with no pumice, the density ranged from 2222 kg/m3(0% replacement) to 1556 kg/m3(75% replacement)as shown in Figure 3. In the presence of pumice, the density was found to be 2195 kg/m3 at 0% replacement and 1630 kg/m3 at 75% replacement (Figure 2). Unlike the concrete mixed with plastic bag aggregate, the density of the concrete mixed with plastic bottle aggregate and pumice showed a slight increase than that of concrete with no pumice. In both types of plastic aggregates used in this study, the density of the concrete was observed to decrease in comparison with the control specimens that do not contain plastic aggregate. The density of the concrete specimens (plastic bag aggregate + with no pumice) had shown a 20% decrease in the specified replacement range whereas the density decreased by 25% upon addition of pumice as an admixture. The density of the specimen that comprises plastic bottle aggregate without pumice decreased by 30% and 25% decrease in the presence of pumice in the replacement range. Comparing the two plastic aggregate categories, a relative decrease of density is observed for the plastic aggregate made from bottles. These would be probably due to the texture of the plastic, which increases the volume. In general, the reduction of the density of the concrete containing plastic aggregate is mainly associated with the difference in the specific gravity of gravel and the plastic aggregates.

The observed density in this study shows that the concrete density of those specimens that contain plastic aggregate (bags and bottles) and pumice admixture is in the range of 2093 kg/m3 to 1630 kg/m3. Accordingly, the concrete can be classified as lightweight concrete as per the American Concrete Institute(ACI) classification guide [28]. However, several density-based classifications categorize the present finding into different classes depending on the sub-criteria of density classification.

Compressive strength

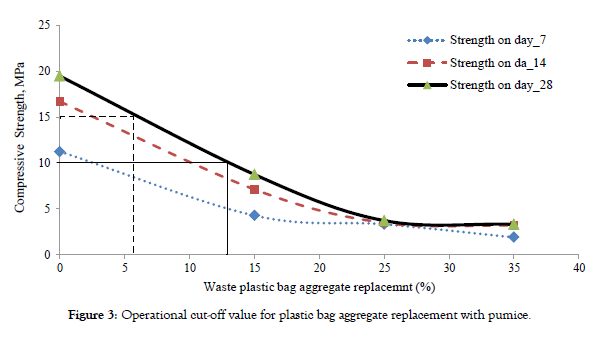

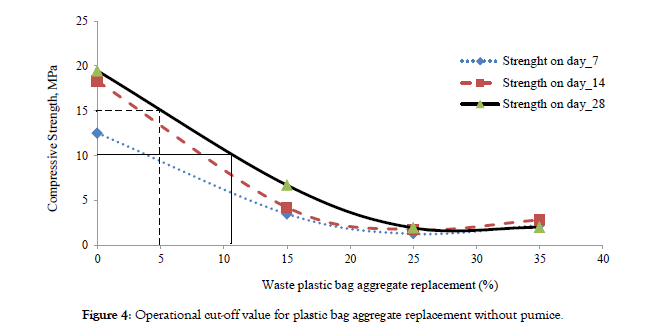

The strength of concrete is dependent on the ratio and quality of the ingredients composited. In different cases, the addition of admixture also determines the behavior of concrete. In this study, the test specimen made from standard cement concrete, concrete containing plastic aggregates and concrete containing pumice as an admixture have shown various results in terms of the strength test. As it is shown in Figure 4 and Table 2, the compressive strength of the cast specimens replaced with plastic aggregates decreases significantly(p-value=0.000) in comparison with the control standard M20 grade concrete cast. The replacement of coarse (gravel) aggregate made from plastic bags without pumice shows the lower compressive strength upon increasing the percent replacement of the plastic aggregates. In the second test group of the same percent replacement of plastic bag aggregates but containing pumice, a relative increment of the strength is observed as clearly indicated in Figure 3. This could be related to the synergetic effect of the pumice and plastic bag aggregate where the high iron oxides, aluminum oxides and silicon oxides in pumice, and the thin thickness of the plastic play a role.

Figure 4: Operational cut-off value for plastic bag aggregate replacement without pumice.

Table 2: Split tensile strength.

| Replacement % | Split tensile strength MPa | ||

|---|---|---|---|

| Day 7 | Day 14 | Day 28 | |

| 0 | 2.40 | 2.53 | 3.10 |

| 25 | 1.60 | 1.78 | 2.83 |

| 35 | 1.60 | 1.76 | 2.17 |

| 50 | 1.60 | 1.76 | 2.19 |

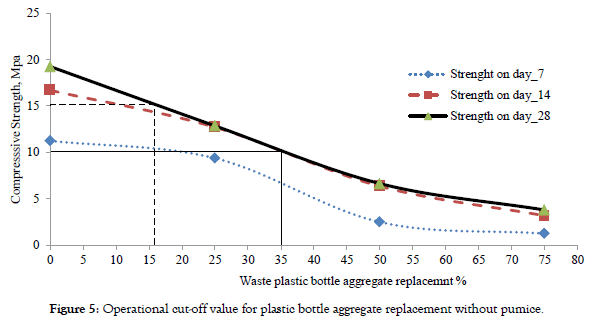

In general, in both groups, the compressive strength decreases by more than 50% with increasing the plastic bag aggregate content than the nominal concrete mix so that the operational cut-off value is required to use plastic bags in lightweight construction activity. Accordingly, the operational cut-off plastic bag aggregate replacement is determined using the 10MPa and 15Mpa load (Figures 3 and 4). For the concrete specimens without pumice under M20 grade mix design, the operational cut-off value for percent plastic replacement is found to be 5% and 11% for 15MPa and 10MPa compressive strength respectively (Figure 5). For those test specimens containing pumice, 6% and 14% replacement can be made for the 15MPa and 10MPa compressive strength (Figure 4). In other words, 11% and 14% plastic bag aggregate replacement can be operational for 10MPa load requiring construction. This implies that plastic bags can be consumed in concrete to the specific lightweight construction that requires the particular strength in the operational cut-off value range so that the cost associated with gravel can be reduced. Since the behavior of the cast against fire was not studied, the use of such concrete is highly recommended for the construction of pedestrian pavement, compound floor tiles, room partitioning, and others.

Figure 5: Operational cut-off value for plastic bottle aggregate replacement without pumice.

Despite the operational cut-off value is viewed from the meaningful load(10MPa and 15MPa) experienced in the construction sector, under special cases where the concrete load lowers to 5MPa the use of plastic bag aggregate increases up to 27% that indicates that such amount of dumped plastic can be removed.

Plastic bottles differ from plastic bags in chemical, physical and mechanical properties that in turn affect their properties in the same application for similar activity. This study has also shown this in terms of physical property (density) and mechanical property (compressive strength). The compressive strength of the test specimens containing the plastic aggregate made from plastic bottles has shown that its compressive strength decreases by 35% when the plastic replacement increases.

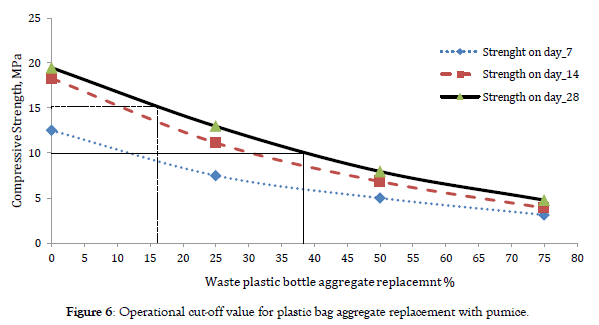

As can be seen from Figures 5 and 6, there is a difference between the control specimens and the experimental specimens (p-value= 0.065). The effect of pumice is not yet significant to affect compressive strength. Unlike the effect observed in specimens containing plastic bags, its presence in the specimens containing plastic bottles caused a slight decrease in the compressive strength. Moreover, the compressive strength tends to increases at each curing age for both plastic aggregate types and similar findings are reported [29-32].

Figure 6: Operational cut-off value for plastic bag aggregate replacement with pumice.

Similarly, the operational cut-off value for plastic bag aggregate replacement in the absence of pumice to maintain 15MPa and 10MPa compressive strength is 16% and 35% respectively (Figure 5). For the test specimen with pumice the percent replacement of 16% and 37.5% is operational to maintain 15MPa and 10 MPa compressive strength respectively (Figure 6). Therefore, the operational cut-off value ranges from 16% to 37.5% for the desired compressive strength. In the economic term, 37% of the gravel cost can be reduced if the plastic bottles are used as coarse aggregate in concrete that requires a 10MPa load.

However, an increase in percent replacement (~58 -75%) can be maintained for compressive strength of 5MPa though this type of concrete is commonly used. In general, using plastic bottles as an aggregate could be an alternative means to manage plastic wastes and economically viable.

Split tensile strength

For standard M20 mix design, the tensile strength is estimated to be 3.1Mpa based on equation 2. In this study, the tensile strength has also decreased with increasing the percent replacement of the plastic bottle aggregate. However, the measured tensile strengths are found in the operational workability range (3.10 – 2.19). Hypothetically, the incorporation of elastic materials such as plastics in the concrete mix could increase the tensile strength. However, the tensile strength tends to decrease with increasing the plastic content. Similarly, studies conducted [1,2] and reported the decrement of the tensile strength.

In both test measurements (i.e compressive and split tensile strength), the results were below the obtained results [2,7,10,12,17,24] by other researchers who used a different mix design ratio and type of replacement which shows that applying the nominal concrete mix design to plastic containing concrete mix doesn’t achieve maximum plastic replacement. This implies that another specific mix design could better improve and manage the issue of plastic waste [30,31].

Conclusion

Both plastic bottles and bags showed some potential to be used as a partial replacement of coarse aggregate in the concrete mix. Due to the major physical properties difference between bags and bottles, workability property and the amount of coarse aggregate replacement capacity is also different. The workability of the concrete cast made from the plastic bags aggregate is feasible up to 35% replacement for consecutive test measurements whereas up to 75% replacement of plastic bag aggregate is practical. The compressive strength tends to decrease with increasing the plastic aggregate ratio at all curing age for both types of plastics. This may be due to the different adhesive strength characteristics, unlike the standard concrete mix where the adhesive strength between the waste plastic and cement paste decrease. However, the ratio of plastic bottle aggregate replaced in the concrete mix is significantly greater than the plastic bag aggregate. This could be probably associated with the density and texture difference between the two types of plastics where the aggregate made from plastic bottles has a relative similarity to gravel than made from plastic bags. The effect of the admixture (pumice) on compressive strength showed some positive change though it is not statistically significant. Even though the standard M20 mix with a maximum of 20Mpa load is employed, the meaningful operational cut-off value obtained was at 10MPa. Similarly, the split tensile strength decreases with increasing the plastic aggregate ratio. Therefore, a further study that focused on the specific mix design that could maximize the percent replacement of coarse aggregate and serve as a standard should be done. Provided all the above findings and limitations to be filled by research, consuming plastic wastes in the construction sector would help to manage plastic wastes in countries which have poor waste management system and facilities.

Acknowledgment

This research is funded by the Federal Democratic Republic of Ethiopia, Ethiopian Environment and Forest Research Institute (EEFRI). Therefore, the authors are highly thankful to the research institute and other stakeholders such as Ethiopian Institute Architecture, Building Construction, and City Development(EiABC) for the necessary support.

REFERENCES

- Tamang LW, Wangmo T, Darjay KT, Phuntsho KS, Namgyal P, Wangchuk U. Use of plastics in concrete as coarse aggregate. Int J Educ Appl Res. 2017;7:9-13.

- Raghatate Atul M. Use of plastic in a concrete to improve its properties. International journal of advanced engineering research and studies. 2012;1(3):109-11.

- https://www.statista.com/statistics/282732/global-production-of-plastics-since-1950/

- d’Ambrières W. Plastics recycling worldwide: current overview and desirable changes. Field Actions Science Reports. The journal of field actions. 2019 (Special Issue 19):12-21.

- Godfrey L. Waste plastic, the challenge facing developing countries—ban it, change it, collect it?. Recycling. 2019;4(1):3.

- Koide H, Tomon M, Sasaki T. Investigation of the use of waste plastic as an aggregate for lightweight concrete. InChallenges of Concrete Construction: Volume 5, Sustainable Concrete Construction: Proceedings of the International Conference held at the University of Dundee, Scotland, UK on 9–11 September 2002 2002 (pp. 177-185). Thomas Telford Publishing.

- Ismail ZZ, Al-Hashmi EA. Use of waste plastic in concrete mixture as aggregate replacement. Waste management. 2008;28(11):2041-7.

- Asokan P, Osmani M, Price AD. Assessing the recycling potential of glass fibre reinforced plastic waste in concrete and cement composites. Journal of Cleaner Production. 2009;17(9):821-9.

- Kim SB, Yi NH, Kim HY, Kim JH, Song YC. Material and structural performance evaluation of recycled PET fiber reinforced concrete. Cement and concrete composites. 2010;32(3):232-40.

- Rai B, Rushad ST, Kr B, Duggal SK. Study of waste plastic mix concrete with plasticizer. ISRN civil engineering. 2012.

- Ghernouti Y, Rabehi B. Strength and durability of mortar made with plastics bag waste (MPBW). International Journal of Concrete Structures and Materials. 2012;6(3):145-53.

- Saikia N, Brito JD. Waste polyethylene terephthalate as an aggregate in concrete. Materials Research. 2013;16(2):341-50.

- Sojobi AO, Owamah HI. Evaluation of the suitability of low-density polyethylene (LDPE) waste as fine aggregate in concrete. Nigerian Journal of Technology. 2014;33(4):409-25.

- Chen CC, Jaffe N, Koppitz M, Weimer W, Polocoser A. Concrete mixture with plastic as fine aggregate. International Journal of Advances in Mechanical and Civil Engineering. 2015;2(4):49-53.

- Arivalagan S. Experimental investigation on partial replacement of waste plastic in concrete. International Journal of Engineering Sciences & Research Technology. 2016;5(11):443-9.

- Jibrael MA, Peter F. Strength and behavior of concrete contains waste plastic. Journal of Ecosystem & Ecography. 2016;6(2):2-5.

- Hossain MB, Bhowmik P, Shaad KM. Use of waste plastic aggregation in concrete as a constituent material. Progressive Agriculture. 2016;27(3):383-391.

- Ahirwar SK. Strength Analysis of Concrete by Using Plastic Waste. International Journal for Research in Applied Science and Engineering Technology. 2017; 5:566–570.

- Jassim AK. Recycling of polyethylene waste to produce plastic cement. Procedia Manufacturing. 2017;8:635-42.

- Muthadhi A, Mohamed Basid A, Madivarma R, Satheesh Kumar J, Raghuvarman R. Experimental Investigations on Concrete with E-Plastic Waste. International Journal of Scientific & Engineering Research. 2017;8(6):50–54.

- Thosar CP, Husain M. Reuse of plastic waste as replacement of sand in concrete. International Journal of Innovative Research in Science, Engineering and Technology. 2017;6:789-94.

- Venkatesh N. Plastic Mix Concrete By Using Waste Plastic Powder and Plastic Granules With Compressive Strength. 2017;3(1): 40–44.

- Kumar RR, Venkatadinesh M. Mechanical Properties of M 25 Grade Concrete Made With Pumice as A Partial Replacement Of Coarse Aggregate. 7(8), pp. 42–52.

- Sangal GS. Study the effect of plastic waste on strength of concrete. International Journal for Advance Research and Development. 2018;3(7):36-9.

- Babafemi AJ, Šavija B, Paul SC, Anggraini V. Engineering properties of concrete with waste recycled plastic: a review. Sustainability. 2018;10(11):3875.

- Albano C, Camacho N, Hernandez M, Matheus A, Gutierrez A. Influence of content and particle size of waste pet bottles on concrete behavior at different w/c ratios. Waste Management. Elsevier Ltd. 2009;29:2707–2716.

- Anwar Hossain KM. Properties of volcanic pumice based cement and lightweight concrete. Cement and Concrete Research. 2004;34:283–291.

- Bate SC. Guide for structural lightweight aggregate concrete: report of ACI committee 213. International Journal of Cement Composites and Lightweight Concrete. 1979;1(1):5-6.

- Silva RV, de Brito J, Saikia N. Influence of curing conditions on the durability-related performance of concrete made with selected plastic waste aggregates. Cement and Concrete Composites. 2013;35(1):23-31.

- Ghernouti Y, Rabehi B, Safi B, Chaid R. Use of recycled plastic bag waste in the concrete. Journal of International Scientific Publications: Materials, Methods and Technologies. 2011;8:480-487.

- Jambeck JR, Geyer R, Wilcox C, Siegler TR, Perryman M, Andrady A, et al. Plastic waste inputs from land into the ocean. Science. 2015;347(6223):768-771.

Citation: Adela Y, Berhanu M, Gobena B (2020) Plastic Wastes as a Raw Material in the Concrete Mix: An Alternative Approach to Manage Plastic Wastes in Developing Countries, Int J Waste Resour 10: 382. doi: 10.35248/2252-5211.20.10.382

Copyright: �©2020 Adela Y, et al. This is an open access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.