PMC/PubMed Indexed Articles

Indexed In

- Open J Gate

- The Global Impact Factor (GIF)

- Open Archive Initiative

- VieSearch

- International Society of Universal Research in Sciences

- China National Knowledge Infrastructure (CNKI)

- CiteFactor

- Scimago

- Ulrich's Periodicals Directory

- Electronic Journals Library

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- Publons

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Research Article - (2023) Volume 13, Issue 5

Performance Evaluation of Sand Filter and Ultraviolet Disinfection Prototype on Treated Wastewater in Rafah, Gaza Strip

Samir Alnahhal*, Khaldoun Abualhin and Mohammed BarhoumReceived: 24-Apr-2023, Manuscript No. IJWR-23-21118; Editor assigned: 27-Apr-2023, Pre QC No. IJWR-23-21118 (PQ); Reviewed: 11-May-2023, QC No. IJWR-23-21118; Revised: 23-Jun-2023, Manuscript No. IJWR-23-21118 (R); Published: 30-Jun-2023, DOI: 10.35248/2252-5211.23.13.549

Abstract

The microbiological quality of wastewater is a key major issue in reclaimed water reuse in agricultural irrigation. This study evaluated the disinfection efficiency to improve the quality of Post-treatment Sand Filter Unit (PSFU) effluent for wastewater reuse by designing a Sand Filter Prototype (SFP) to increase the hydraulic retention time in the slow sand filter and by designing Ultraviolet (UV) prototypes. The study results showed that the highest disinfection efficiency of the UV prototypes was maintained for smaller effluent volumes. The SFP has also contributed to reducing the BOD5 concentrations and turbidity levels by about 49.28% and 71.08%, respectively. The BOD5 and turbidity concentrations were in line with the Palestinian Standards Institute (PSI) standard limits for irrigation reuse. The improvement in turbidity levels improved the penetration of UV light into the effluent and increased the UV disinfection efficiency. The UV disinfection decreased the Fecal Coliform (FC) concentrations were 525 FCU/100 ml and the effluent quality is suitable for reuse in agricultural irrigation based on the PSI standard.

Keywords

Experimental trail; Sand filters; Treated wastewater; Turbidity; Ultraviolet disinfection

Introduction

Climate induced changes and globally rapid population growth are noticeably increasing the demand for water for daily life uses and putting great pressure on both the quantity and quality of water supplies. This increasing demand has decreased the global per capita renewable internal freshwater resources from 13,407 m3 in 1962 to 5,658 m3 in 2018 [1]. Accordingly, finding alternative renewable water from non-conventional sources is a key significant need.

Reclaimed wastewater can be one of these sustainable sources used for other purposes rather than drinking, and can support crop production, either directly by irrigation or indirectly by recharging groundwater [2,3]. Other benefits can also be achieved by using reclaimed wastewater in agricultural irrigation, including human health and environmental protection, the economy development particularly, the agricultural sector is the largest consumer of more than 70% of available water [4]. Other environmental gains on the hydrological cycle, water reserves, green coverage, and climate [5]. However, such non-conventional water would require treatment before its practical reuse [6]. The quality of wastewater effluent should be ensured by wellcontrolled treatment and monitoring systems. National and international quality standards, regulations, and guidelines were developed to properly manage any potential impacts, and nowadays they undergo continuous research and updates, and they tend to have more restrictions.

The microbiological quality of wastewater is a key major issue in reusing treated effluent for agricultural irrigation [7]. Right now, wastewater effluent quality can be improved either by introducing new technologies in secondary wastewater processes, e.g., Membrane Bioreactors (MBRs), or by optimizing the performance of tertiary wastewater processes through single or combined disinfection processes (i.e., Peracetic Acid (PAA) and Ultraviolet (UV) radiation), or ozonation combined with ultrafiltration [8,9]. Further attention was paid to the wastewater quality by adopting several disinfection processes after the global Coronavirus disease 2019 (COVID-19) outbreak [10].

In the Gaza Strip, the experience of wastewater reuse is nonsystematic and limited by a few casual initiatives donated by international institutions and external donors in the recent three decades. Most of the main wastewater treatment plants are old and overloaded and produce poor-quality effluents most times, linked to some administrative and socio-economic impediments [11].

In April 2019, a Post-treatment Sand Filter Unit (PSFU) was constructed after the secondary treatment process at Rafah Wastewater Treatment Plant (WWTR), and which recent performance evaluation showed that its effluent quality is not suitable for reuse in agriculture [12]. Therefore, the PSFU aims to improve the effluent quality for agricultural reuse according to the Palestinian Standard Institute (PSI) guidelines [13].

The PSFU was designed mainly based on Slow Sand Filtration (SSF) technology, which would be a promising technology for additional wastewater effluent treatment and reuse of wastewater effluents for agricultural and recreational purposes in developing countries, as concluded by many previous studies [14]. The SSF constructed after the secondary treatment process in the Gaza WWTP has significantly improved the effluent quality for agricultural reuse [15]. The SSF performance evaluation revealed that further effluent quality improvements could be achieved by increasing the hydraulic retention time in the sand filter [16-18].

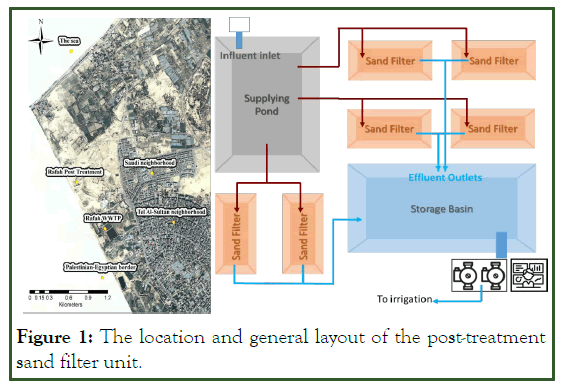

The general objective of the PSFU is to adopt innovative environmental and agricultural solutions that strengthen integrated water resource management by providing more sustainable water for agricultural purposes and reducing dependency on groundwater in Southern Gaza (Rafah and Khan Younis governorates). The PSFU is located in the Southwest of Rafah nearby the Egypt border. The PSFU consists of one supplying pond, six sand filter basins, and one effluent storage basin. The volume capacity of each sand filer basin is 600 m3. The PSFU was not provided by any disinfection system. The location and general layout of the PSFU are presented in Figure 1.

Figure 1: The location and general layout of the post-treatment sand filter unit.

The PSFU effluent does not currently undergo any disinfection treatment and relies solely on sand filters to meet the Palestinian Standard Institute (PSI) limits for agricultural reuse [19]. However, the concentration of pathogens in the effluent exceeds the recommended limits.

To address this issue, this study aims to investigate the effectiveness of a two-stage treatment process in improving the water quality of PSFU effluent. The first stage involves testing the effectiveness of a Lab-scale Sand Filtration Prototype (LSFP) in filtering the effluent. The second stage involves disinfection treatment using UV prototypes. The LSFP and UV prototypes are designed to study the feasibility of upscaling the natural filtration and disinfection treatment, respectively, in the PSFU.

The study seeks to propose a solution to the poor quality of the PSFU effluent by increasing the hydraulic retention time in the current slow sand filter and exposing the effluent to openchannel UV irradiation. The investigation will provide decisionmakers with insights into the feasibility of the proposed twostage treatment process as a means of achieving the recommended PSI limits for agricultural reuse of the effluent.

Materials and Methods

The research methodology consisted of designing and developing four UV Disinfection Prototypes (UVDPs) inside the PSFU premise to disinfect the PSFU effluent and test which UV dose and exposure time can provide better quality for reuse in agricultural irrigation. This effluent quality must match the Palestinian Standard Institute (PSI) recommended guidelines.

The methodology also consisted of conducting field measurements and laboratory analyses for some water quality parameters, including chemical, biological, and health concern parameters before and after the disinfection in the four UVDPs. The PSFU influent was used to fill the four prototypes. The water quality samples were collected eight times in the period from March 28, 2022 to June 28, 2022. The quality parameters were selected based on the capacity of local technical laboratories in the Gaza Strip. Field measurements were conducted at the PSFU site and laboratory analyses were performed at the institute of water and environment Al-Azhar university in the Gaza Strip. The field measurements included turbidity, pH, and temperature. Turbidity was measured using a HACH 2100 Q portable turbidity meter following the nephelometric method. The pH and temperature were measured using a digital meter ADWA AD11. Laboratory analyses for quality parameters included Fecal Coliform (FC) and Biochemical Oxygen Demand (BOD) using the American standard methods for the examination of water and wastewater [20].

The methodology also consisted of designing and developing the LSFP inside the PSFU premise to carry out additional treatment for the PSFU effluent because the UV disinfection of PSFU effluent in the four UVDPs alone did not provide quality water matches the PSI guidelines for reuse in irrigation.

Experiment trails

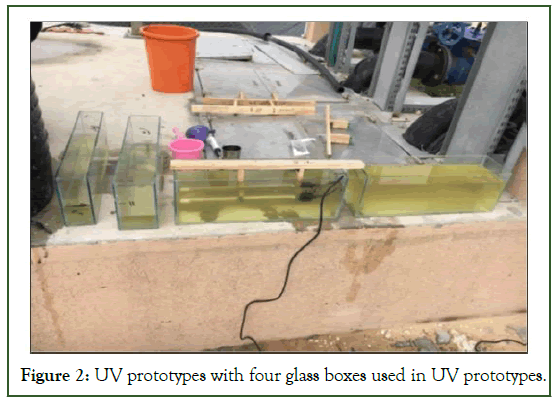

The study involved two experimental trials. In the first trial, the disinfection of PSFU effluent was carried out in four UVDPs without any additional treatment. The performance of UV irradiation for the PSFU effluent was measured using four opentop glass boxes, each equipped with a 254 nm wavelength UV bulb and a wooden holder, as shown in Figure 2.

Figure 2: UV prototypes with four glass boxes used in UV prototypes.

The width dimensions of the four boxes were different, while the height dimensions were equal and the length dimensions are also equal at 60 cm, which is the length of the UV bulb, as shown in Table 1. To evaluate the efficiency of each UVDP, the four prototypes were filled with the same PSFU effluent and exposed to an identical dose of UV irradiation.

| UV prototype # | Water volume (gallon) | Water volume (liter) | Length (cm) | Width (cm) | Height (cm) |

|---|---|---|---|---|---|

| 1 | 1 | 3.78 | 60 | 7.9 | 7.9 |

| 2 | 2 | 7.56 | 60 | 11.2 | 11.2 |

| 3 | 3 | 11.34 | 60 | 13.8 | 13.8 |

| 4 | 4 | 15.12 | 60 | 15.9 | 15.9 |

Table 1: Water volumes and dimensions filled in for four UV prototypes.

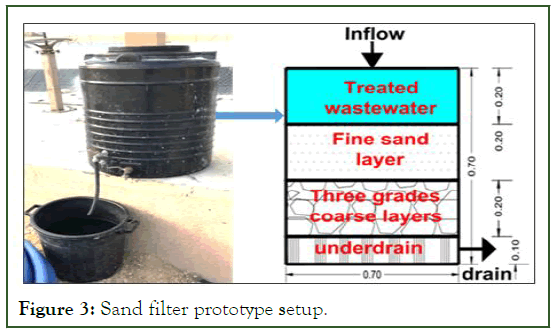

In the first experimental trial, the efficiency of UV disinfection in the four UVDPs was undermined by the high turbidity of the PSFU effluent, highlighting the need for additional treatment. The second experimental trial, therefore, evaluated the effectiveness of a Lab-scale Sand Filter Prototype (LSFP) in reducing turbidity and improving UV disinfection in the UVDPs. The LSFP was designed to simulate the sand filters used in the PSFU and consisted of a 270 liter water tank filled with clean sand (mean grain size of 0.08 cm) and graduated gravels (mean grain sizes of 0.4, 0.8, and 1.2 cm) arranged in three layers, as shown in Figure 3. The sand was placed on top, followed by the graduated gravels arranged from smaller to larger grain sizes. After the PSFU effluent was filtered through the LSFP, the filtered effluent was collected and used to fill the UV prototypes for UV disinfection. The study investigated the performance of LSFP and UV disinfection.

Figure 3: Sand filter prototype setup.

UV disinfection systems' efficacy is determined by the UV dose, which can be calculated from the desired inactivation rate of microorganisms. Several parameters govern a UV reactor's performance, including lamp power, arrangement, diameter, fluid flow rate, and properties. Understanding how these parameters affect the UV reactor's performance is crucial for designing an efficient UV reactor.

The UV dose produced by a UV disinfection system is the primary factor that determines its efficacy, and it depends on the UV light intensity and exposure time. The UV light intensity is determined by the lamp size, type, and power provided to the lamp, while the system's exposure time is determined by the flow rate. Water with high levels of turbidity, and organic matter is unsuitable for UV radiation because it reduces disinfection effectiveness.

The UV exposure time for experimental trials can be determined based on the time it takes for the effluent to flow from the inlet to the outlet of the box culvert. The UV dose can then be calculated using the UV intensity and exposure time. Therefore, to ensure accurate results, it was necessary to calculate the UV exposure time in the two experimental trials. The UV intensity was determined based on the time needed to flow the PSFU effluent from the inlet to the outlet of the box culvert, which connects the storage basin and the wet well where two pumps are installed in series. The box culvert, which has dimensions of 18.5 m long, 1 m width, and 1 m height, was assumed to be full of water and the existing two hydraulic pumps were working simultaneously. The calculated UV exposure time was 68 seconds, as shown in Table 2. This information was crucial in determining the UV dose using the following equation:

UV does=UV intensity × Exposure time

The purpose of this calculation was to study the disinfection efficiency of a UV system if installed in the box culvert.

| Pumps | Flow discharge (m3/h) | Area (m2) | Velocity (m/s) | Distance (m) | Time (sec) |

|---|---|---|---|---|---|

| Pump 1 | 225 | 1 | 0.063 | 8.5 | 136 |

| Pump 2 | 225 | 1 | 0.063 | 8.5 | 136 |

| Total | 450 | 1 | 0.125 | 8.5 | 68 |

Table 2: Time determination based on the box culvert dimensions and PSFU hydraulic pumps.

Results and Discussion

The findings present treatment and disinfection performance efficiency, given relevant water quality parameters, which are explored in this section.

Biochemical oxygen demand removal

Removal of organic material from wastewater is significant to meet the acceptable quality standards for safe reuse. Biological Oxygen Demand (BOD) is a traditional parameter to measure the organic material by determining the oxygen used for oxidizing part of the organic material based on the principle that if sufficient oxygen is available, aerobic biological decomposition by microorganisms will continue until all organic material is consumed. The BOD analysis is very useful in the control of wastewater effluent.

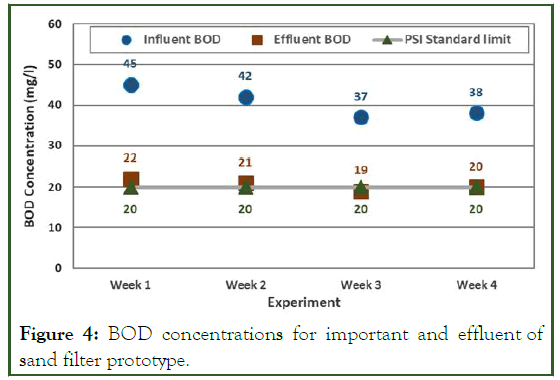

In the second experimental trial, a filtration process using the LSFP was developed to reduce the BOD concentration and improve the efficiency of UV disinfection. As shown in Figure 4, the BOD5 concentrations of the LSFP influent and effluent were measured for four weeks. The findings showed that the LSFP contributed to reducing the BOD5 concentrations by about 49.28% on average. Compared to the PSI standard limits for irrigation reuse (20 to 60 mg/l), the BOD5 concentrations in the effluent were in line with these PSI standard limits. It is important to note that the reduction of BOD5 concentration was found to be beneficial in improving the efficiency of UV disinfection.

Figure 4: BOD concentrations for important and effluent of sand filter prototype.

Turbidity removal

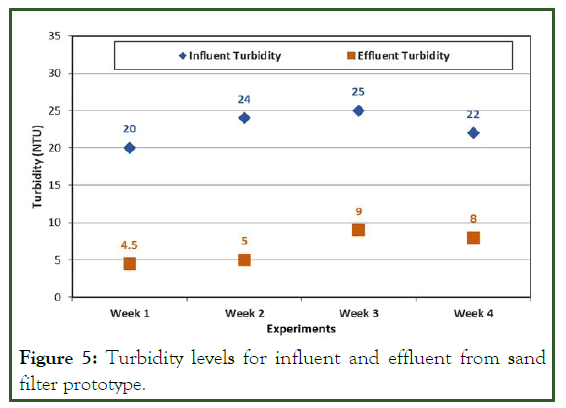

Turbidity and microbial contamination of the wastewater can undermine the effectiveness of disinfection. Therefore, the level of turbidity needs to be reduced to improve the efficiency of UV disinfection as the turbidity can decrease the UV transmittance and affect UV dose delivery, or can shield microorganisms from UV light. The turbidity of treated wastewater can be reduced by filtration through sand filters. Therefore, the SFP in the second experimental trial was developed and used to reduce the turbidity in the PSFU effluent. The turbidity levels of the LSFP influent and effluent were measured for four weeks, as shown in Figure 5.

Figure 5: Turbidity levels for influent and effluent from sand filter prototype.

As shown in Figure 5, the findings revealed that LSFP has contributed to reducing turbidity levels by 71.08%, on average. This improvement in the turbidity levels would improve the penetration of UV light into the effluent and improve the disinfection efficiency of the UV system.

Fecal coliform removal

Pathogen removal is a significant process in wastewater treatment and reuse, as pathogens can pose severe health and environmental risks. Fecal Coliform (FC) is an indicator of pathogenic contamination in treated water effluent. Table 3 represents the FC removal by UV light for different volumes of glass boxes in the first experimental trial.

| Glass box volume | Fecal coliform | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Week 1 | Week 2 | Week 3 | Week 4 | ||||||

| (Gallon) | (Liter) | (CFU/100 ml) | LOG | (CFU/100 ml) | LOG | (CFU/100 ml) | LOG | (CFU/100 ml) | LOG |

| 1 | 3.78 | 9,000 | 3.95 | 5,000 | 3.70 | 6,000 | 3.78 | 4,000 | 3.60 |

| 2 | 7.56 | 14,000 | 4.15 | 14,000 | 4.15 | 16,000 | 4.20 | 11,000 | 4.04 |

| 3 | 11.34 | 39,000 | 4.59 | 19,000 | 4.28 | 21,000 | 4.32 | 18,000 | 4.26 |

| 4 | 15.12 | 43,000 | 4.63 | 37,000 | 4.57 | 43,000 | 4.63 | 38,000 | 4.58 |

Table 3: Fecal coliform results of different volumes of treated water exposed to UV irradiation.

As shown in Table 3, the efficiency of the UV bulb in disinfecting the effluent depends on the distance that the UV light can penetrate around the bulb within the glass box. The UV intensity is inversely proportional to the square of the distance of which UV light can penetrate. The results showed that the highest disinfection efficiency of the UV bulb was achieved for smaller volumes, with a one-gallon volume showing the best results. However, the results of the fecal coliform concentration in the effluent of the PSFU revealed that the UV disinfection alone was insufficient in reaching the PSI standard limits for irrigation reuse (<1000 CFU/100 ml). The findings revealed that the PSFU effluents required further treatment to reduce the presence of low particulates (turbidity) and organic materials (BOD) to improve UV disinfection.

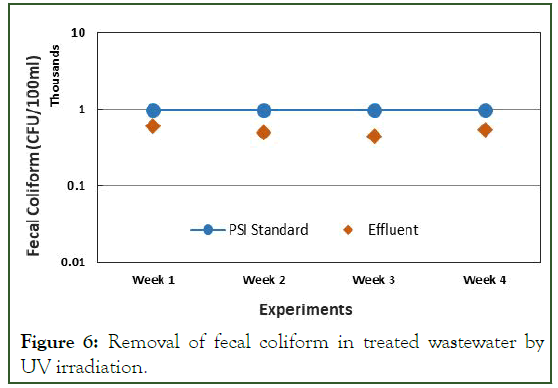

In the LSFP filtration process, effluents were passed through sand filters before exposure to UV irradiation, and FC concentrations were monitored for four weeks, as shown in Figure 6. The results indicated that the average FC concentration was 525 FCU/100 ml, which falls below the PSI standard limits (1000 FCU/100 ml). As a result, the effluent quality is now suitable for reuse in agricultural irrigation, demonstrating the effectiveness of the LSFP in increasing UV irradiation in reducing pathogenic contamination.

Figure 6: Removal of fecal coliform in treated wastewater by UV irradiation.

Conclusion

This study provides valuable insights into the dynamics and efficacy of using sand filtration as demonstrated by the LSFP for further treatment of post-treated effluent in the wastewater treatment process after secondary treatment and before Ultraviolet (UV) irradiation. The experimental results demonstrate the following points:

• UV irradiation is effective for pathogen destruction.

However, its disinfection efficiency is constrained by the

low particulates (turbidity) and organic materials BOD

concentrations in the water effluent.

• The purpose of LSFP development with a similar

filtration medium to the current sand filter in the

post-wastewater treatment unit was to increase the

hydraulic retention time from 24 hours to 48 hours and

provide further removal of turbidity and BOD.

• Resendable removal efficiencies for turbidity and BOD

would be achieved using the sand filtration process,

which reached 50% and 71%, respectively.

Recommendation

The following recommendations can be drawn from this study to inform future research and upscaling of the open channel UV disinfection model, particularly when adopting sand filters as a post-wastewater treatment process.

Continuous monitoring and performance evaluation should be regularly implemented to ensure the effective and safe reuse of wastewater in irrigation.

Further studies are needed to develop a robust open-channel UV disinfection process to improve the quality of treated effluent and ensure the safe reuse of reclaimed wastewater for agricultural purposes.

Additional research is needed to better understand the disinfection dynamics when using UV irradiation for treated wastewater effluent, by examining other performance parameters such as heavy metals, chemical oxygen demand, nutrients, detergents, and other biological contaminants.

Acknowledgment

The authors thank the Oxford committee for famine relief "Oxfam" which has funded this research and made this work possible.

References

- Ait-Mouheb N, Bahri A, Thayer BB, Benyahia B, Bourrie G, Cherki B, et al. The reuse of reclaimed water for irrigation around the Mediterranean Rim: A step towards a more virtuous cycle?. Reg Environ Change. 2018;18:693-705.

- Mateo-Sagasta J, Raschid-Sally L, Thebo A. Global wastewater and sludge production, treatment and use. Wastewater: Economic asset urbanizing world. 2015:15-38.

- Al-Haddad A, Rashid T, Al-Salman B. Optimum soil depth for removal of coliphage viruses from treated wastewater, Kuwait. Desalination Water Treat. 2015;53(10):2727-2731.

- Hussain MI, Muscolo A, Farooq M, Ahmad W. Sustainable use and management of non-conventional water resources for rehabilitation of marginal lands in arid and semiarid environments. Agr water Manag. 2019;221:462-476.

- Bonetta S, Pignata C, Gasparro E, Richiardi L, Bonetta S, Carraro E. Impact of wastewater treatment plants on microbiological contamination for evaluating the risks of wastewater reuse. Environ Sci Eur. 2022;34(1):20.

- Albolafio S, Marin A, Allende A, Garcia F, Simon-Andreu PJ, Soler MA, et al. Strategies for mitigating chlorinated disinfection byproducts in wastewater treatment plants. Chemosphere. 2022;288(Pt 2):132583.

[Crossref] [Google Scholar] [PubMed]

- Clem V, de Mendonca HV. Ozone reactor combined with ultrafiltration membrane: A new tertiary wastewater treatment system for reuse purpose. J Environ Manage. 2022;315:115166.

[Crossref] [Google Scholar] [PubMed]

- Luan X, Liu X, Fang C, Chu W, Xu Z. Ecotoxicological effects of disinfected wastewater effluents: A short review of in vivo toxicity bioassays on aquatic organisms. Environ Sci: Water Res Tech. 2020;6(9):2275-2286.

- Afifi SA, Elfari AA, Alnahhal S. Evaluation of nutrient removal dynamic in post treatment slow sand filter unit. Int J Waste Resour. 2021;11:431.

- Tyagi VK, Khan AA, Kazmi AA, Mehrotra I, Chopra AK. Slow sand filtration of UASB reactor effluent: A promising post treatment technique. Desalination. 2009;249(2):571-576.

- Bendida A, Tidjani AE, Badri A, Kendouci MA, Nabou M. Treatment of domestic wastewater from the town of Bechar by a sand filter (sand of Beni Abbes Bechar Algeria). Energy Procedia. 2013;36:825-338.

- Maharjan N, Kuroda K, Dehama K, Hatamoto M, Yamaguchi T. Development of slow Sponge Sand Filter (SpSF) as a post-treatment of UASB-DHS reactor effluent treating municipal wastewater. Water Sci Technol. 2016;74(1):65-72.

[Crossref] [Google Scholar] [PubMed]

- Verma S, Daverey A, Sharma A. Slow sand filtration for water and wastewater treatment-a review. Environ Technol Rev. 2017;6(1):47-58.

- Omran, ED. Performance Evaluation of Sand Filter in Improvement of Effluent Wastewater from Gaza Wastewater Treatment Plant. Master of Science in Environmental Science. Islamic University–Gaza; 2014.

- Li HY, Osman H, Kang CW, Ba T. Numerical and experimental investigation of UV disinfection for water treatment. Appl Therm Eng. 2017;111:280-291.

- Gibson J, Drake J, Karney B. UV Disinfection of wastewater and combined sewer overflows. Adv Exp Med Biol. 2017;996:267-275.

[Crossref] [Google Scholar] [PubMed]

- Gehr R, Wagner M, Veerasubramanian P, Payment P. Disinfection efficiency of peracetic acid, UV and ozone after enhanced primary treatment of municipal wastewater. Water Res. 2003;37(19):4573-4586.

[Crossref] [Google Scholar] [PubMed]

- Henze M, Concha L. Wastewater characterization. In Biological wastewater treatment: Principles, modelling and design. IWA Publishing; 2008: 33-52 [Crossref] [Google Scholar] [PubMed]

- Passantino L, Malley Jr J, Knudson M, Ward R, Kim J. Effect of low turbidity and algae on UV disinfection performance. J Am Water Work Assoc. 2004;96(6):128-137.

- Tchobanoglous G, Kreith F. Handbook of solid waste management. 2nd edition. McGraw-Hill: New York, London, 2002.

Citation: Alnahhal S, Abualhin K, Barhoum M. (2023) Performance Evaluation of Sand Filter and Ultraviolet Disinfection Prototype on Treated Wastewater in Rafah, Gaza Strip. Int J Waste Resour. 13:549.

Copyright: © 2023 Alnahhal S, et al. This is an open access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.