Indexed In

- Open J Gate

- Genamics JournalSeek

- ResearchBible

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- Publons

- MIAR

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Research Article - (2023) Volume 12, Issue 4

Impact of Extraction Treatments on Physico-Chemical Functional Food Properties of Coconut Residue Dietary Fiber

D Amirtham1* and Anil Dahuja22Division of Biochemistry, ICAR-Indian Agricultural Research Institute, New Delhi, India

Received: 11-Aug-2023, Manuscript No. BABCR-23-22573; Editor assigned: 15-Aug-2023, Pre QC No. BABCR-23-22573 (PQ); Reviewed: 29-Aug-2023, QC No. BABCR-23-22573; Revised: 07-Sep-2023, Manuscript No. BABCR-23-22573 (R); Published: 15-Sep-2023, DOI: 10.35248/2161- 1009.23.12.504

Abstract

Coconut flour is a completely unique byproduct prepared from coconut milk residue obtained after the extraction of coconut milk. It is a wealthy healthy source of dietary fiber which can be used as bulking agents, filling agents and instead for wheat, rice and potato flour. The prevailing work objectives at the identity of suitable extraction techniques for obtaining dietary fiber from the underutilized coconut milk residue left unused within the coconut processing industries, with the aid of subjecting it to acid, alkali and enzyme extraction treatments. The exceptional characteristics of chemical extracted and enzyme extracted Coconut Residue Dietary Fiber (CRDF) were compared. An excessive yield of CRDF (44.3%) was received in the enzyme assisted extraction method than acid (20.3%) and alkali methods (15.1%).The enzyme extracted CRDF has got more Water Absorption Capacity (WAC) (16.3%), oil absorption potential (23.9%) and Swelling Capacity (SC) (83%) than chemical extracted CRDF. The findings found that enzyme extraction could improve the total carbohydrate content, SDF content, total phenolic content and minimize the protein presence in preference to acidic and alkali methods. Scanning electron microscopic studies explored that the fiber matrix of enzyme extracted CRDF are smoother and seem as lengthy slender fibrils compared to the chemical extracted CRDF as enzyme method leads to at most hydrolysis of cellulose and associated polysaccharides and makes the pore size wider and accountable for extra hydration properties.

Keywords

Coconut residue dietary fiber; Enzyme; Water absorption capacity; Swelling capacity; Scanning electron microscopy

Introduction

Coconut flour is a one-of-a-kind substance made from coconut waste following the extraction of coconut milk. It is a high-fiber source that can be used as a bulking agent, filling agent, and an alternative to wheat, rice, and potato flour and also can be integrated into various foods like baked products, snack and extruded foods and steamed products. Coconut flour is taken into consideration as a great supply of fiber and protein. It consists of about 60% overall dietary fiber/ kg wherein 56% insoluble and 4% soluble fiber/ kg. It was found that the glycemic index of coconut flour supplemented foods reduced with raising quantity of dietary fiber from coconut flour. As the coconut milk residue incorporates lignin, pectin, starch and proteins further to cellulose and hemicellulose, it is encouraged to use a multienzyme as an alternative to a single enzyme for hydrolysis. The degradation of cell wall and membrane, as a result accelerating the mass release of targeted compounds into extraction solvent and consequently enabling a higher release and an efficient extraction of bioactive compounds via enzymes together with cellulose, protease and amylase have been widely used for pretreatment of plant fiber prior to conventional techniques for extraction which can also drastically reduce the amount of solvent requirement. Enzymatic degradation of the coconut residue is influenced by means of pH, enzyme concentration, temperature and time. Optimization can be used to maximize the degradation of degradable solids to sugar using multi enzyme method for the extraction of crude polysaccharide isn’t always appreciably reported in any literatures. Therefore, the cutting-edge work is performed with the following targets i) To have a look at the effect of extraction methods on the yield and physicochemical homes of Coconut Residue dietary Fiber (CRDF) ii) To evaluate the physiochemical practical properties of CRDF extracted with chemical and iii) To discover the structural adjustments at the CRDF because of one of a kind extraction methods [1-5].

Materials and Methods

Coconut meal residue flour (raw material) of West coast tall variety, prevalent type of Tamil Nadu was procured from M/s. Apex Coco Products, Tirupur, Tamil Nadu. Papain, a-amylase, and cellulose of Sigma brand and other chemicals like cholesterol, sodium nitrite, and sodium acetate of analytical grade of SRL brand were used [6].

Defatted coconut meal residue preparation

One kilogram of desiccated coconut meal residue powder or flour was dried at 60°C to a moisture content of (2-3%) by means of weight and the defatted three volumes with food grade petroleum ether (40°C-60°C) and then washed with ethanol 3 times before drying at 60°C in an oven to a moisture content material of 2%- 3% by way of weight and saved in air tight containers for future processing [7].

Defatted extraction, acidic treatment and enzymatic hydrolysis

Acid and alkali extraction followed by precipitation with alcohol are the conventional techniques used for dietary fiber extraction. But, these strategies require long extraction methods and excessive temperatures giving low extraction yields. The high temperature could also have an effect on bioactivities of the extracted polysaccharides. Enzyme-Assisted Extraction (EAE) methods are gaining more interest because of the need for green extraction .and to improve the soluble fiber yield. Subsequently efforts had been made in the present study for the comparison of chemical extraction techniques (Acid and alkali extraction) and enzyme assisted extraction techniques as according to the following methodologies with reference to the yield and physic chemical, physiological and structural features of CRDF [8].

Acid extraction of coconut residue dietary fiber: Both the experimental and theory of the protein structure and the drug designing will improve by the structural refinement and energy minimization which helps to moving towards more exact models are even including complex and large scaled simulations for energy free screening. Rather the properties of any atoms or the molecules can easily be calculated by some equations like Schrodinger equation for time dependent.

Alkali extraction of coconut residue dietary fiber: 100 grams of coconut milk residue flour was defatted with food grade petroleum ether 40°C-60°C (1:3 w/v) in an air tight vessel. Then it was filtered to eliminate fats and air dried. Defatted coconut milk residue turned into suspended in 500 mL of 0.1 N NaOH of pH 13(1:3 w/v) and stirred for 2 h, the suspension was filtered via linen and the residue was extracted with 80% ethanol (1:1.5 w/v) for 30 minutes at 80°C and finally washed with 80% ethanol for three times and dried at 50°C-55°C [9-11].

Enzyme assisted extraction of coconut residue dietary fiber: 100 g of defatted coconut milk residue flour was suspended in a thousand ml phosphate buffer (0.1 M). 1 g of a-amylase was added and the answer was stirred lightly at 90°C for two. The aggregate become cooled and adjusted to pH 7.0, and added with 0.5 g papain. After incubation at 50˚C for 2 h, the pH was made to 2 in the mixture combined with 0.5 g amylase and incubated at 60°C for two h. The mixture later incubated at a 100˚C for 10 min to inactivate the enzymes, and cooled to Room Temperature (RT) and filtered using a 100 meshe linen. The residue collected was washed with deionized water, dried at 50°C for 12 h,50 grams of TDF defined above were suspended in 500 mL of phosphate buffer (0.1 M, pH5.0) and mixed with 0.3 g cellulose/viscozyme and incubated at 50°C for 1 h. The mixture was heated at 100°C for 10 min and then cooled to RT and filtered through 100 meshe linen. The residue filtered was dried at 50°C for 12 h [12-15].

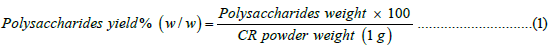

Further enzyme concentrations had been optimized through orthogonal array design primarily based at the yield of CRCP (%) and central composite experimental design has been made as mentioned in Table 1 and treatments have been done to optimize the enzyme assisted extraction conditions of CRDF, keeping the enzyme amount (X1), pH (X2), extraction time (X3), extraction temperature (X4), a four-aspect model at five levels has been decided on to assess their interactions. The extraction yield of crude polysaccharide (Y%) has been considered as dependent variable. To discover most desirable pH, temperature and extraction time for EAE, extractions at optimized enzyme quantities of cellulase 1%,amylase 2% and protease 2% had been carried out at varying pH (pH 4.0, 4.5, 5.0, 5.5 and 6.0),varying temperatures (40°C,50°C,60°C,70°C) and ranging extraction times ranging from 2 h to 6 h. 1 g of coconut milk residue raw material was extracted with 30 mL of compound enzymes mixture at the given amount. Water soluble crude polysaccharides have been isolated with the aid of precipitation of the intensified supernatant with four volumes of dehydrated alcohol and recovered with the aid of centrifugation. The polysaccharides content material was quantified with the aid of phenol sulfuric acid method with D-glucose as a reference at 490 nm and calculated as cited in equation [16-18].

| Treatment number | pH | Extraction time(h) | Temperature (° C) | Yield of CRDF (Y) (%) |

|---|---|---|---|---|

| E1 | 4.5 | 3 | 40 | 22.8 ± 0.16 |

| E2 | 5.5 | 3 | 40 | 26 ± 0.41 |

| E3 | 4.5 | 5 | 40 | 6 ± 0.30 |

| E4 | 5.5 | 5 | 40 | 5.5 ± 0.15 |

| E5 | 4.5 | 3 | 60 | 32 ± 0.56 |

| E6 | 5.5 | 3 | 60 | 36 ± 0.40 |

| E7 | 4.5 | 5 | 60 | 15±0.20 |

| E8 | 5.5 | 5 | 60 | 19 ± 0.15 |

| E9 | 5 | 4 | 50 | 25 ± 0.36 |

| E10 | 4 | 4 | 50 | 28 ± 0.40 |

| E11 | 6 | 4 | 50 | 26.3 ± 0.26 |

| E12 | 5 | 2 | 50 | 34.5 ± 0.25 |

| E13 | 5 | 6 | 50 | 44.3 ± 0.21 |

| E14 | 5 | 4 | 30 | 25 ± 0.10 |

| E15 | 5 | 4 | 70 | 13.5 ± 015 |

| Acid extraction | 3 | 8 | 60 | 24.2 ± 0.15 |

| Alkali extraction | 13 | 2.5 | 80 | 23.1 ± 0.11 |

Table 1: Different extraction treatments followed as per Central composite design for Enzyme treatments (E1-E15) to optimize the extracting conditions X2-pH, X3-Temperature and X4-Extraction time with the optimized enzyme concentration (X1)-cellulase 1%( 25ul), protease 2%(17 mg) and amylase 2%(12 mg) compared with Acid treatment and alkali treatments with respect to the yield of Coconut Residue Dietary Fiber (CRDF)

The yield of polysaccharides in the CR was calculated by the subsequent equation:

Physico-chemical properties

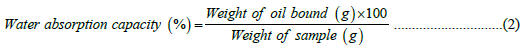

Water absorption capacity: The water absorption capability was determined primarily based at the approach described by Adeleke and Odedeji (2010) with moderate change. 10 ml of distilled water was taken into a pre-weighed centrifuge tube. The centrifuge tube was agitated though a vortex mixer at a velocity 2,200/min for 2 min and centrifuged at 8,000 g for 25 min at 25°C. The clean supernatant was decanted and discarded. The excess moisture built in the aggregate was eliminated by means of draining for 10 min at room temperature. The water absorption ability become expressed as weight of water bound by using 100 g of flour using equation 2 below.

Oil absorption capacity: The oil absorption ability was acquired consistent with the technique defined by Kaur and Singh (2005). One gram of sample was carefully added into a pre-weighed centrifuge tube and 10 ml of maize oil was poured, stirred every 5 minutes in vortex at pace 2,500/min for a period of 30 min and centrifuged for 25 min at 8,000 g. The fats absorption is expressed as weight of oil certain by means of 100 g of flour in line with the equation 3.

Swelling power: The swelling power was evaluated according to the method described Leach et al. (1959) with changes. 0.0.5 g of sample was added to a pre weighted Eppendorf containing 1.5 ml of distilled water. The Eppendorf was closed and manually shaken and was heated for 30 min at 65°C using a thermo-shaker at 1,000 rpm. The samples were then centrifuged for 20 min at 25°C with a RCF of 8000. Upon completion of centrifugation, the supernatant become decanted and the weight of the Eppendorf and pellet was determined. The swelling capacity was decided by means of dividing the weight of pellet produced (residue) by means of the weight of sample and multiplying by means of 100.

Foaming capacity: Foaming capacity was calculated according to the method described by Kaur and Singh (2005). 3 g/100 ml of distilled water of flour samples was taken in a beaker and homogenized at 13,500 rpm for 2 min. The mixture was immediately disposed into a 2 hundred ml graduated cylinder and the content of the beaker was emptied using a spatula. The foam level was measured, and the foaming capacity was calculated as the percentage of level increase because of whipping according to equation 5.

For the foaming capacity, changes in the foam volume were recorded at 60 min.

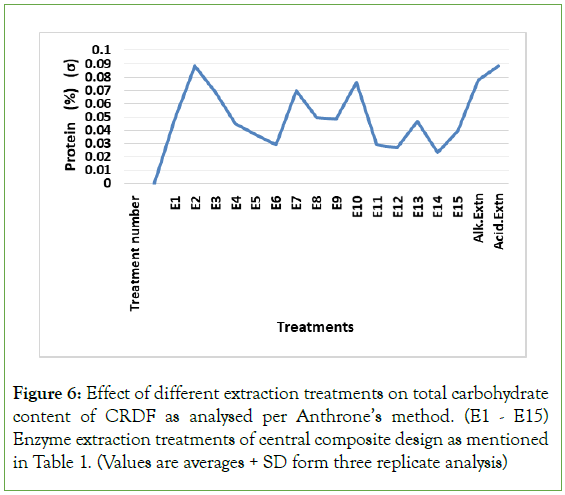

Determination of total carbohydrate contents: Anthrone’s method was used to determine total carbohydrate contents the usage of glucose as a reference. Briefly, 1 mL of sample solution was added to 900 ml of water and 5 ml of Anthrone’s reagent was added and mixed thoroughly, measured at 620 nm in UV–VIS spectrophotometer. Total carbohydrate content was calculated the usage of a standard curve of D-glucose.

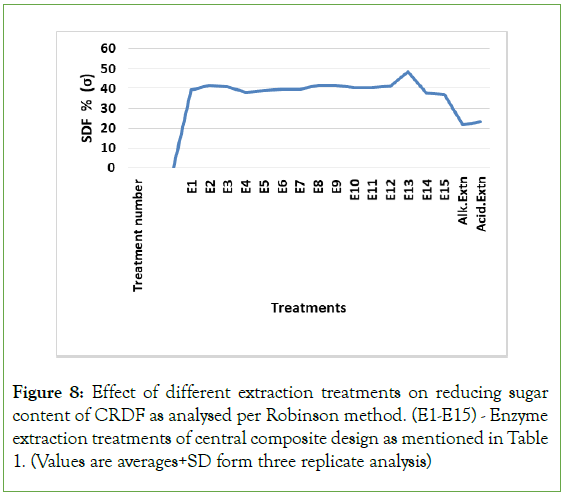

Determination of reducing sugar of crude polysaccharides: The technique of Robertson et al. (2001) was used to determine reducing sugar content. In short 1 mL of sample solution was introduced into two ml of 3,5 Dinitrosalicylic Acid (DNS), boiled for five min and cooled at room temperature. The aggregate was then topped up with 7 mL of distilled water. Absorbance was measured at 540 nm using UV–VIS spectrophotometer. Total reducing sugar was determined with D-glucose as a reference [19-21].

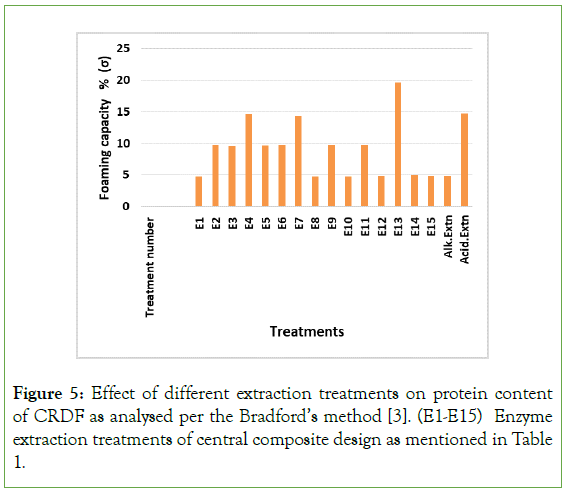

Determination of protein content of crude polysaccharides: Bradford reagent with albumin as a reference protein was used to determine overall protein concentration. A volume of 20 μl of the sample solution was added to 200 μl of Bradford reagent in a μ titer plate and incubated at 37°C for 15 min. Absorbance changed into measured at 590 nm.

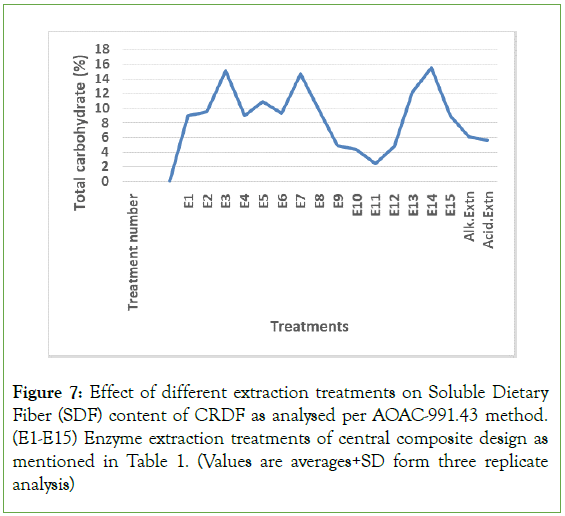

Determination of soluble dietary fiber content: Estimation of soluble and insoluble dietary fiber and total dietary fiber content in coconut was determined by means of the enzyme-gravimetric technique. Dry material was suspended in phosphate buffer (pH 6.0) and dealt with distinct enzymes such as alpha amylase (pH 1.5), pepsin (pH 6.8) and pancreatin (pH 4.5) for 1 h at unique pH, as provided within the brackets. Which will determine insoluble dietary fiber, the fiber was separated after enzymatic digestion, washed with ethanol and acetone, Soluble dietary fiber was measured by means of precipitating the filtrate using ethanol. The precipitate was washed with ethanol and acetone, dried, incinerated and eventually weighed.

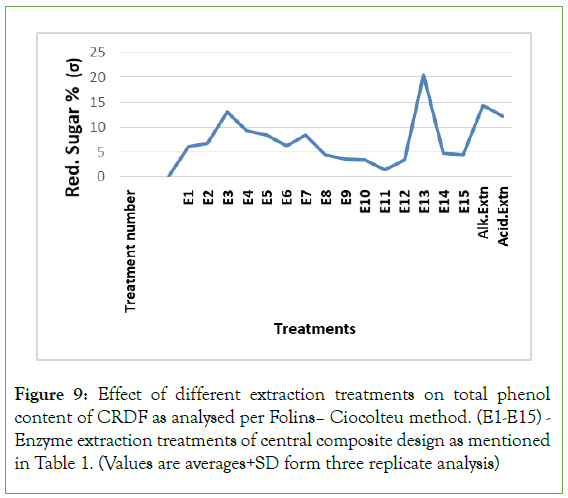

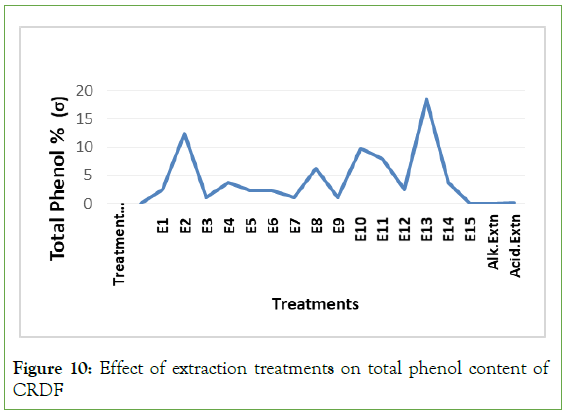

Determination of total phenol content: Folin’s ciocolteu method was used to determine overall phenol content 0.0.2 mL of sample was added to 3.3 ml of water, 0.5 ml of Folin’s reagent,mixed properly and incubated for 5 minutes. Then added 1 ml of 20% sodium carbonate, blended well and incubated for 10 minutes. Absorbance was estimated at 660 nm in UV–VIS spectrophotometer. Total phenolic content was measured using pyrocatechol as a reference.

Structural research; Scanning Electron Microscopy (SEM)

The micro structure of CRDF was examined as described by using Niu, Hou, Wang, and Chen (2014) with a scanning electron μscope (Quanta three-D twin Beam, FEI Co, Tokyo, Japan) available at Department of Nano Sciences and technology, TNAU, Coimbatore. Dried samples have been mounted on an aluminum stub with double-sided stick tape, coated with gold, after which examined at an accelerating voltage of 15 kV. The micrographs were taken at 700 and 3000 magnification, respectively.

Statistical analysis

The results obtained from the diverse above analysis are given as followed. All measurements have been accomplished in triplicate. All statistical analyses were done by the use of SAS 8.0 software and data’s had been expressed as mean values with standard deviation.

Results and Discussion

Physico functional properties

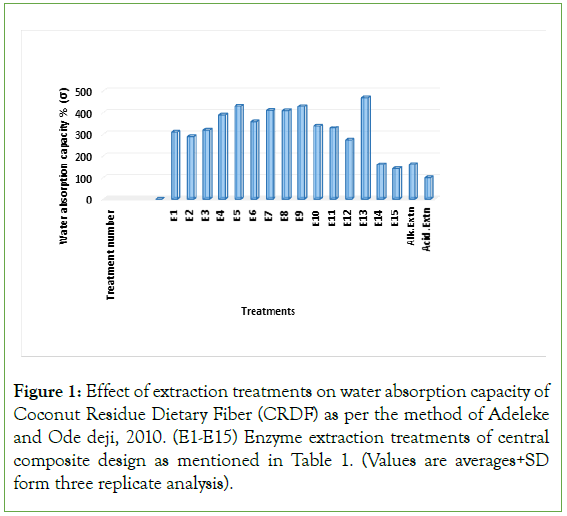

The capacity of fiber to bind with water is known as Water Absorption Potential (WAC). Carbohydrates and proteins are the essential chemical ingredients that enhance water adsorption capacity of fiber because of their hydrophilic components. The dietary fiber helps in bounding with water. Furthermore, the presence of polar amino acids can have an impact on the hydrophilic nature of the protein. The high content of SDF (Table 1), and the honeycomb structure (Figure 1) of enzyme extracted CRDF with particle size of 157.5 nm is responsible for the maximum water absorption potential (469.6+0.57%).The SDF content was positively correlated with WAC of DFs, and cellulose hydrolysis may weaken the intermolecular hydrogen bonds of cellulose and hemicelluloses, improve the exposure of hydrated hydroxide, carboxyl companies and capillary motion of fiber, which leading to increment in WAC. The higher water absorption potential of enzyme extracted CRDF in evaluation to other fibers recommend that it is able to be utilized in food method which include sausages and different bakery products. Water absorption potential plays mainly responsible for bulkiness and consistency of food products.

Figure 1: Effect of extraction treatments on water absorption capacity of Coconut Residue Dietary Fiber (CRDF) as per the method of Adeleke and Ode deji, 2010. (E1-E15) Enzyme extraction treatments of central composite design as mentioned in Table 1. (Values are averages+SD form three replicate analysis).

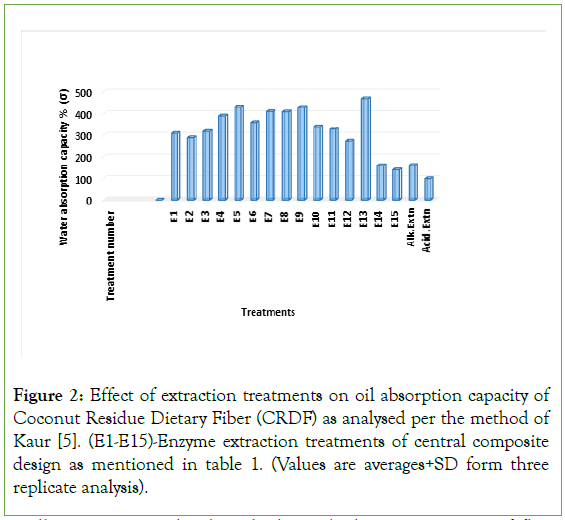

Oil Absorption Capability (OAC) describes the potential of a food material to be bound to oil. This parameter can also be affected by properties of the elements of fiber in terms of their hydrophobic nature which helps in the absorption of oil. OAC of the fiber samples confirmed a slightly different nature from that of the water absorption capacity. It ranged from 200% to 390% OHC of CRDF is associated with a few functional properties inclusive of the capacity to prevent fats loss during food processing and the ability to lessen serum levels of cholesterol. Alkali extracted CRDF exhibited the best OHC (239.2 ± 0.2%) as compared with other samples, due to the surface properties (Figure 2), and the removal of polar groups, uronic acid groups due to the elimination of starch and hemicelluloses. Moreover, the presence of non-polar amino acid side chains may could have helped in an efficient hydrophobic interaction with the hydrocarbon chains of the lipid. The oil absorption function of food products enables the development of mouth experience and retention of flavour. Therefore, coconut fiber will be probably beneficial in production of some bakery foods in which palatability and flavour retention are vital. Similar scenario was noticed in rice bran fiber.

Figure 2: Effect of extraction treatments on oil absorption capacity of Coconut Residue Dietary Fiber (CRDF) as analysed per the method of Kaur [5]. (E1-E15)-Enzyme extraction treatments of central composite design as mentioned in table 1. (Values are averages+SD form three replicate analysis).

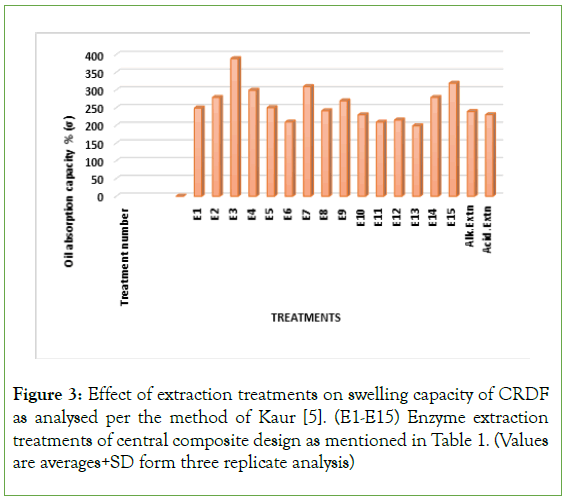

Swelling power can be described as a hydration property of flour after dispersing it in extra water for a designated period. Moreover, it is used to determine the ability of undisrupted granules to bind water at high temperature. According to, fiber carries free polar groups which lead them to bind effortlessly with water and swells. But, the quantity of swelling turned into affected by way of the fats composition of the flour that could have blocked the matrix of the fiber, thereby reducing admission to water. Swelling capacity of enzyme extracted CRDF was found to be greater (319+0.2%) than acid and alkali extracted CRDF. This is can be due to less fat content in the enzyme extracted CRDF which allows the access of water molecules within the fiber matrix.

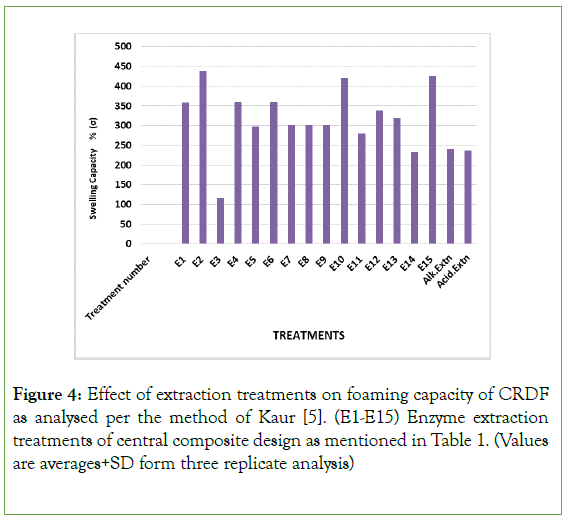

Foam may be defined as a colloidal of numerous fuel bubbles which can be trapped in a liquid or semi-solid medium. As a result, foaming potential and stability are a function of surface binding substance such as protein which can be quantified upon the application of whipping. They are critical parameters that are more advantageous because of protein-protein interactions and the concentration of those surface binding solutes (Kaur and Singh, 2005). In this regard, Foaming Capacity (FC) describes how strong the surfaceactive substance may be inside the presence of gravitational stresses. The foaming capacity of the CRDF samples is ranged from 4.7% to 19.9% with alkali and enzyme extracted having the lowest and the highest values, respectively. A likely reason for the variant in foaming ability is the kind of protein contained in the flour. Flexible protein molecules triggers a more potent interaction on the air–water interface to produce foams at the same time as wellestablished globular proteins offer a vulnerable air–water interface which results in low foamability .The excessive foaming capability of enzyme extracted CRDF lead them to be more applicable in food systems requiring excessive FC inclusive of breads, desserts and sponges.

Chemico functional properties

All CRDF samples exhibited more glucose due to the reduction of pectin substances and hemicelluloses of CRDF by the acidic and cellulase hydrolysis. Similar result was acquired by other researchers, as referred by Q. Jing, 2015, in comparison to chemical treated CRDF, the TDF content of the enzyme extracted CRDF turned into more even as the fats and protein content become decrease, which was in accordance with the record of Yalegama et al. CRDF produced with the aid of alkali treatment, exhibited a lower SDF content (21.5+0.2%) than that of CRDF of enzyme extracted method indicating that the acidic treatment caused reduction in SDF. In comparison, the SDF content of enzyme extracted turned into much higher (48.9+0.41%) than that of chemical extracted suggesting that cellulase could lead to the degradation of hemicelluloses and cellulose, enhancing the SDF content material. Furthermore, the TDF content of coconut milk residue turned into more than that of DFs from rice bran (27.04 g/100 g), sesame coat (42.00 g/100 g) and deoiled cumin (46.01 g/100 g) indicating that they can be used as functional component.

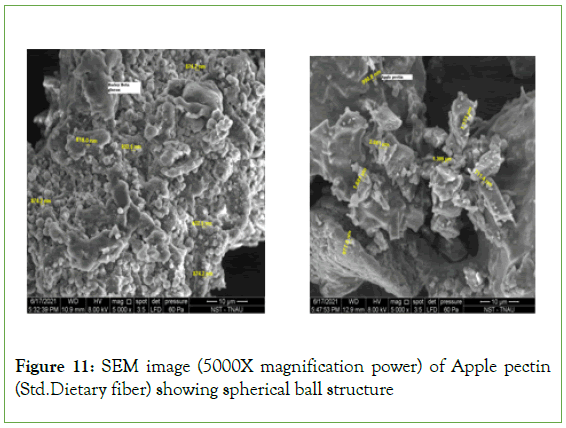

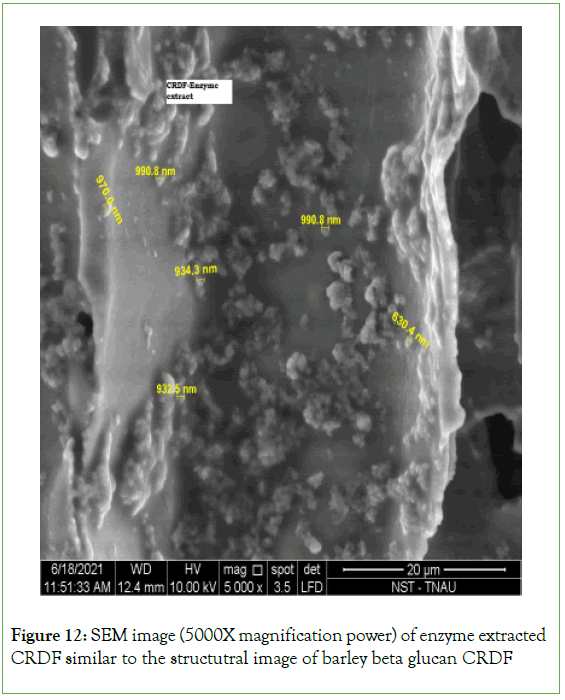

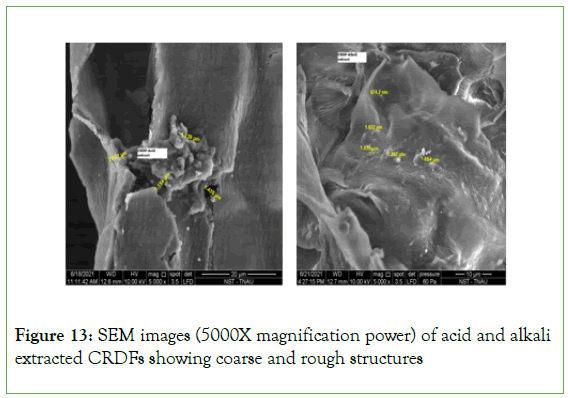

Structural studies; Scanning Electron microscopic studies

SEM photographs of DFs are given in Figures 3-9. In comparison to CRDF of acidic and alkali treatment and enzyme extracted CRDF exhibited a typical honeycomb structure with a greater quantity of holes and cracks (Figures 10-13) much like barley beta glucan (probably because that the acidic method and enzymatic hydrolysis eliminated the proteins or starch across the DF bundles, which was also contributed to the modifications in surface region of the DFs. In addition SEM pictures shown that the fiber surface of enzyme extracted CRDF are smoother and appear as long slender fibrils compared to the chemical treated CRDF. The rough and dispersed fiber surface of alkali treated CRDF suggests the partial elimination of the outer non-cellulosic layer composed of hemicelluloses, lignin, pectin, wax and other impurities found inside the desiccated coconut meal residue whereas enzyme extraction leads to most hydrolysis of cellulose and related polysaccharides and makes the pore wider and accountable for more hydration. Similar result was observed by different researchers.

Figure 3: Effect of extraction treatments on swelling capacity of CRDF as analysed per the method of Kaur [5]. (E1-E15) Enzyme extraction treatments of central composite design as mentioned in Table 1. (Values are averages+SD form three replicate analysis)

Figure 4: Effect of extraction treatments on foaming capacity of CRDF as analysed per the method of Kaur [5]. (E1-E15) Enzyme extraction treatments of central composite design as mentioned in Table 1. (Values are averages+SD form three replicate analysis)

Figure 5: Effect of different extraction treatments on protein content of CRDF as analysed per the Bradford’s method [3]. (E1-E15) Enzyme extraction treatments of central composite design as mentioned in Table 1.

Figure 6: Effect of different extraction treatments on total carbohydrate content of CRDF as analysed per Anthrone’s method. (E1 - E15) Enzyme extraction treatments of central composite design as mentioned in Table 1. (Values are averages + SD form three replicate analysis)

Figure 7: Effect of different extraction treatments on Soluble Dietary Fiber (SDF) content of CRDF as analysed per AOAC-991.43 method. (E1-E15) Enzyme extraction treatments of central composite design as mentioned in Table 1. (Values are averages+SD form three replicate analysis)

Figure 8: Effect of different extraction treatments on reducing sugar content of CRDF as analysed per Robinson method. (E1-E15) - Enzyme extraction treatments of central composite design as mentioned in Table 1. (Values are averages+SD form three replicate analysis)

Figure 9: Effect of different extraction treatments on total phenol content of CRDF as analysed per Folins– Ciocolteu method. (E1-E15) - Enzyme extraction treatments of central composite design as mentioned in Table 1. (Values are averages+SD form three replicate analysis)

Figure 10: Effect of extraction treatments on total phenol content of CRDF

Figure 11: SEM image (5000X magnification power) of Apple pectin (Std.Dietary fiber) showing spherical ball structure

Figure 12: SEM image (5000X magnification power) of enzyme extracted CRDF similar to the structutral image of barley beta glucan CRDF

Figure 13: SEM images (5000X magnification power) of acid and alkali extracted CRDFs showing coarse and rough structures

Conclusion

As compared to chemical extracted, enzyme extracted CRDF observed to incorporate excessive water absorption, swelling capability and foaming capability, less oil absorption ability which is the most desirable parameter for the physical functionality of soluble dietary fiber. The findings proved that enzyme extraction would improve the total carbohydrate, SDF content and WHC of CRDF as compared to acid and alkali methods. Based on the above findings soluble CRDF has been found to major applications in food and health products as promising low-calorie functional constituent for fiber enrichment.

Acknowledgment

We duly acknowledge the financially support rendered by ICAR (Indian Council of Agricultural Research) for the Post-Doctoral Research work at Indian Agricultural Research Institute, New Delhi, India and supported by Tamil Nadu Agricultural University, Coimbatore, India.

Conflict of Interest

The authors declare that they have no competing interests.

References

- Albalasmeh AA, Berhe AA, Ghezzehei TA. A new method for rapid determination of carbohydrate and total carbon concentrations using UV spectrophotometry. Carbohydr Polym. 2013;97(2):253-261.

[Crossref] [Google Scholar] [PubMed]

- Amandikwa C, Iwe MO, Uzomah A, Olawuni AI. Physico-chemical properties of wheat-yam flour composite bread. Niger Food J. 2015;33(1):12-17.

- Bradford MM. A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem. 1976;72(1-2):248-254.

[Crossref] [Google Scholar] [PubMed]

- Zhu F, Du B, Zheng L, Li J. Advance on the bioactivity and potential applications of dietary fibre from grape pomace. Food chem. 2015;186:207-212.

[Crossref] [Google Scholar] [PubMed]

- Kaur M, Singh N. Studies on functional, thermal and pasting properties of flours from different chickpea (Cicer arietinum L.) cultivars. Food chem. 2005;91(3):403-411.

- Korakli M, Gänzle MG, Vogel RF. Metabolism by bifidobacteria and lactic acid bacteria of polysaccharides from wheat and rye, and exopolysaccharides produced by Lactobacillus sanfranciscensis. Journal of applied microbiology. 2002;92(5):958-965.

[Crossref] [Google Scholar] [PubMed]

- Cheng L, Zhang X, Hong Y, Li Z, Li C, Gu Z, et al. Characterisation of physicochemical and functional properties of soluble dietary fibre from potato pulp obtained by enzyme-assisted extraction. Int J Biol Macromol. 2017;101:1004-1011.

[Crossref] [Google Scholar] [PubMed]

- Yalegama LL, Karunaratne DN, Sivakanesan R, Jayasekara C. Chemical and functional properties of fibre concentrates obtained from by-products of coconut kernel. Food Chem. 2013;141(1):124-130.

[Crossref] [Google Scholar] [PubMed]

- Lee SC, Prosky L. DeVries JW. Determination of insoluble, soluble, and total dietary fiber (CODEX definition) by enzymatic-gravimetric method and liquid chromatography: Collaborative study. J Assoc Off Anal Chem. 1992;75:395-416

- Ma MM, Mu TH. Effects of extraction methods and particle size distribution on the structural, physicochemical, and functional properties of dietary fiber from deoiled cumin. Food chem. 2016;194: 237-246.

[Crossref] [Google Scholar] [PubMed]

- Mohammed B, Gabel M, Karlsson LM. Nutritive values of the drought tolerant food and fodder crop enset. Afr J Agric Res. 2013;8(20):2326-2333.

- Niu M, Hou GG, Wang L, Chen Z. Effects of superfine grinding on the quality characteristics of whole-wheat flour and its raw noodle product. J. Cereal Sci. 2014;60(2):382-388.

- Adeleke OR, Adiamo OQ, Fawale OS. Nutritional, physicochemical, and functional properties of protein concentrate and isolate of newly-developed Bambara groundnut (Vigna subterrenea L.) cultivars. Food Sci Nutr. 2018;6(1):229-242.

[Crossref] [Google Scholar] [PubMed]

- Mei C, Park SH, Sabzikar R, Callista Ransom CQ, Sticklen M. Green tissue-specific production of a microbial endo-cellulase in maize (Zea mays L.) endoplasmic-reticulum and mitochondria converts cellulose into fermentable sugars. J Chem Technol. 2009;84(5):689-695.

- Peerajit P, Chiewchan N, Devahastin S. Effects of pre-treatment methods on health-related functional properties of high dietary fibre powder from lime residues. Food Chem. 2012;132(4):1891-1898.

- Raghavendra SN, Raghavarao KS. Effect of different treatments for the destabilization of coconut milk emulsion. J Food Eng. 2010; 97(3):341-347.

- Robertson JA, Ryden P, Botham RL, Reading S, Gibson G, Ring SG, et al. Structural properties of diet-derived polysaccharides and their influence on butyrate production during fermentation. LWT-Food Sci Technol. 2001;34(8):567-573.

- Suresh HG, da Silveira dos Santos AX, Kukulski W, Tyedmers J, Riezman H, Bukau B, et al. Prolonged starvation drives reversible sequestration of lipid biosynthetic enzymes and organelle reorganization in Saccharomyces cerevisiae. Mol Biol Cell. 2015;26(9):1601-1615.

[Crossref] [Google Scholar] [PubMed]

- Raghavendra SN, Rastogi NK, Raghavarao KS, Tharanathan RN. Dietary fiber from coconut residue: Effects of different treatments and particle size on the hydration properties. Eur Food Res Technol. 2004;218:563-567.

- Liu X, Zhang M, Guo K, Jia A, Shi Y, Gao G, et al. Cellulase-assisted extraction, characterization, and bioactivity of polysaccharides from Polygonatum odoratum. Int J Biol Macromol. 2015;75:258-265.

[Crossref] [Google Scholar] [PubMed]

- Zheng Y, Li Y. Physicochemical and functional properties of coconut (Cocos nucifera L) cake dietary fibres: Effects of cellulase hydrolysis, acid treatment and particle size distribution. Food chem. 2018;257:135-142.

[Crossref] [Google Scholar] [PubMed]

Citation: Amirtham D, Dahuja A (2023) Impact of Extraction Treatments on Physico-Chemical Functional Food Properties of Coconut Residue Dietary Fiber. Biochem Anal Biochem. 12:504.

Copyright: © 2023 Amirtham D, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.