Citations : 2345

Dentistry received 2345 citations as per Google Scholar report

Indexed In

- Genamics JournalSeek

- JournalTOCs

- CiteFactor

- Ulrich's Periodicals Directory

- RefSeek

- Hamdard University

- EBSCO A-Z

- Directory of Abstract Indexing for Journals

- OCLC- WorldCat

- Publons

- Geneva Foundation for Medical Education and Research

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Research Article - (2020) Volume 10, Issue 7

Comparative Evaluation and Correlation of Marginal Fit and Retention of Metal Copings Fabricated Using Two Different Designs of Die Spacer– An In Vitro Study

Komal C. Dave*, Asha M. Rathod, Gaurang Mistry and Omkar ShettyReceived: 17-Aug-2020 Published: 10-Sep-2020, DOI: 10.35248/2161-1122.20.10.566

Abstract

Introduction: The art and science of fixed prosthodontics is predicted on accomplishing precise and clinically accurate operative techniques based on sound biological and mechanical principles. Many factors have been demonstrated to influence the marginal seating and retention of crowns, such as size and shape of the prepared teeth, manipulation of the cement, retentive properties of the cement, cement film thickness, relieving space or venting for cement, cement application, and roughness of the dentinal surface. Optimum retention form is considered to be one of the most important principles of tooth preparation. The longevity of fixed prosthesis depends on the retention and marginal integrity of restoration. This study was done to evaluate, compare and correlate the marginal fit and retention for two different designs of die spacer.

Materials and Method: The samples to be studied were divided into 2 groups of 15 each. Each having a different die spacer design.

Results: The results showed no significant difference in marginal fit of group Ia and group IIa and retention was better in group IIb compared to group Ib. But no statistically significant differences were seen when correlating the marginal fit and retention between group Ia, group Ib and group IIa and group IIb.

Keywords

Die spacer; Retention; Marginal fit; Marginal adaptation

Introduction

Success of a fixed restoration depends to a large extent on the fit between the restoration and the prepared tooth surface [1]. Holmes JR, et al. [2] has stated that the fit of a casting can be defined best in terms of the “misfit” measured at various points between the casting surface and the tooth. Lack of adequate fit is potentially detrimental to both the tooth and the supporting periodontal tissues. Poor marginal adaptation in fixed prostheses causes microleakage which leads to increased plaque retention and subsequent changes in the subgingival microflora. The marginal fit of cemented restorations ranges from 25 μm to 40 μm, with some researchers suggesting that a marginal opening of ≤ 120 μm is clinically acceptable [3].

Perhaps the most important significant conclusion is that of Lorey and Myers [4]: “The retention values of uncemented casting gave no indications of the retention values obtained after cementation” [4].

In past, researchers believed better retention would be achieved with a frictional fit between the restoration and the tooth surface. This meant that during cementation process, a perfect fit could not be obtained due to lack of space for luting cement. Die spacers allow increased space for the cement between the tooth surface and the internal surface of the casting, reducing stress areas created during cementation, and thereby resulting in better fit and retention of the final restoration [5].

This study is designed to evaluate, compare, and correlate the marginal fit and retention of metal copings fabricated using two different designs of die spacer.

Materials and Methods

The method of the study was broadly divided into:

A. Preparation of teeth to receive metal copings

B. Fabrication of metal copings by DMLS

C. Evaluation of the marginal fit of metal copings before cementation

D. Cementation of metal copings on prepared teeth

E. Evaluation of metal copings for retention

Preparation of teeth to receive metal copings

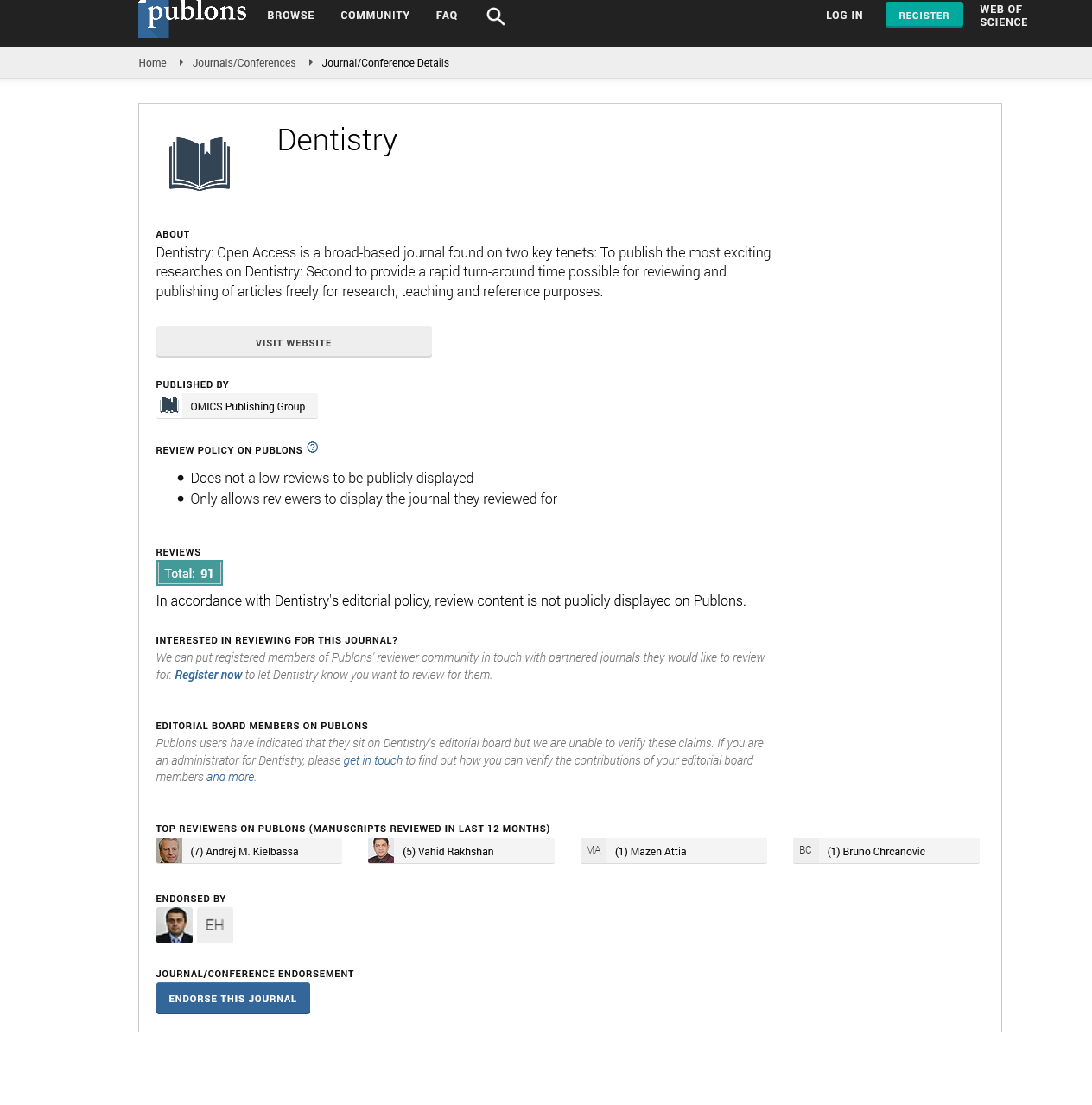

Thirty extracted first premolars were selected, from patients undergoing orthodontic treatment as sound tooth structure was available for principal source of retention. It was stored in tooth preservation solution. These teeth were notched in the root surface and mounted in acrylic blocks of uniform dimensions (3″ width and 2″ length), short of the cementoenamel junction. Standardised preparation for full porcelain fused to metal crown was made on the acrylic block with extracted first premolar tooth which was mounted on the model surveyor with a handpiece (Marathon 103, surveyor/milling machine). The model surveyor had a lock elbow joint that permitted orientation of the long axis of the bur parallel to the long axis of the tooth (Figure 1). The preparation convergence angle of 6 degrees and a shoulder margin 1 mm wide were produced using a tungsten carbide cutter (Bredent Germany F1372H07-10) occlusal reduction 5 mm in diameter. Care was taken to smoothen all line and point angles, after which this was duplicated into a jig prepared with polyvinyl sheet for a single tooth

Figure 1: Photograph showing preparation of tooth using model surveyor with hand piece.

The other teeth were prepared using this jig, to standardise all tooth preparations. Each of 30 prepared teeth were labelled with respective numbers on the acrylic block for easy identification (Figures 2 and 3).

Figure 2: Photograph showing prepared teeth for group I.

Figure 3: Photograph showing prepared teeth for group II.

Fabrication of metal copings by DMLS

The 30 prepared teeth were digitized using the extraoral scanner (LavaTM Scan ST Design System (3MTM ESPE) with Dental Wings Software). The 30 prepared teeth were divided into two groups for different die spacer design of 15 metal coping samples each of which had the die spacer thickness of 25 μm, the groups were evaluated for both marginal fit and retention individually as follows:

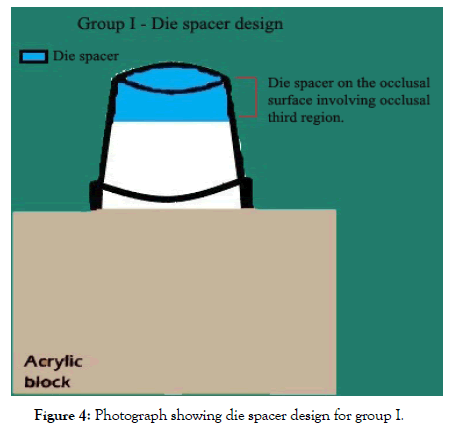

Group I: Metal copings were fabricated using die spacer on the occlusal surface involving occlusal third region (Figure 4).

Figure 4: Photograph showing die spacer design for group I.

Group Ia: Metal copings were fabricated using die spacer on the occlusal surface involving occlusal third region to evaluate the marginal fit.

Group Ib: Metal copings were fabricated using die spacer on the occlusal surface involving occlusal third region to evaluate retention.

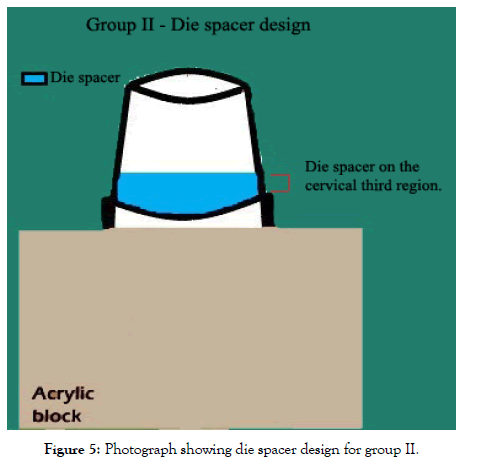

Group II: Metal copings were fabricated using die spacer on the cervical third region (Figure 5).

Figure 5: Photograph showing die spacer design for group II.

Group IIa: Metal copings were fabricated using die spacer on the cervical third region to evaluate the marginal fit.

Group IIb: Metal copings were fabricated using die spacer on the cervical third region to evaluate the retention.

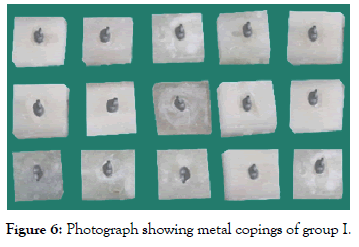

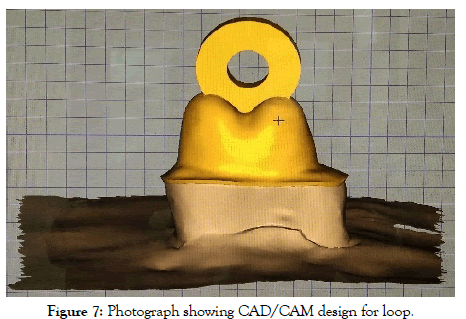

Group I (Figure 6): After the extraoral digital impressions were taken for 15 prepared teeth, the .stl files (scans) which were obtained were used to fabricate the copings by Direct Metal Laser Sintering (DMLS) (EOSINT M 270). With the help of Lava CAD software, the finish line was marked. The thickness of the metal copings was decided to be kept at 0.4 mm with the die spacer design applied on the occlusal surface involving the occlusal third. After the designing was done, the command was sent to the EOS laser sintering machine (EOSINT M 270). The copings were fabricated increment by increment (20 μm each) from EOS cobalt chrome SP2 metal alloy powder using the high-powered focused laser beam. When every layer had been built up, the solid copings were taken out from the machine, sandblasted, finished, inspected, and ultrasonically cleaned. Every metal coping had a special loop of 4 mm designed on the occlusal surface to facilitate connection of the crown to universal testing machine (ACME, India, UNITEST model no. 1) (Figure 7).

Figure 6: Photograph showing metal copings of group I.

Figure 7: Photograph showing CAD/CAM design for loop.

Group II (Figure 8): 15 prepared teeth were scanned using an extraoral scanner (LavaTM Scan ST Design system (3MTM ESPE) with Dental Wings software). The .stl files (scans) which were obtained, were used to fabricate the copings in a similar manner as that of group I, except that the die spacer design is applied on the cervical third of the respective sample.

Figure 8: Photograph showing metal copings of group II.

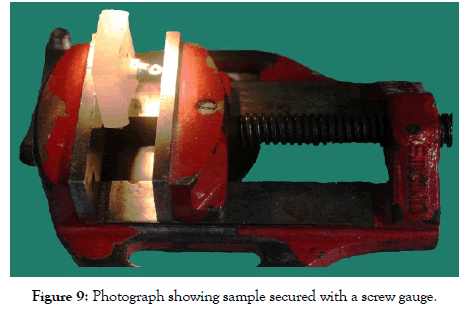

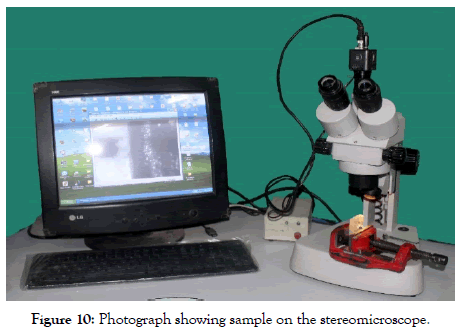

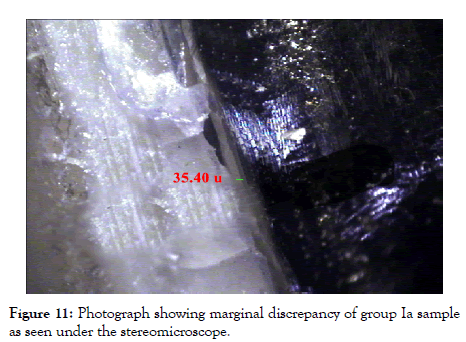

Evaluation of the marginal fit of metal copings before cementation

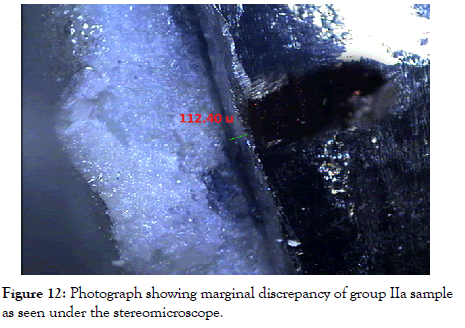

The metal copings of both the groups were placed on their respective prepared teeth. They were secured in position with the help of a screw gauge to prevent displacement (Figure 9). The fit was assessed by checking the discrepancy between the margins of the metal coping and the prepared tooth. Marginal discrepancy was measured under 40X magnification with a stereomicroscope (Model- XTL 3400 E; Wuzhou New Found Instrument Co. Ltd., China) with Image Analysis System (Model- MVIG 2005; Chroma Systems Pvt. Ltd., India) (Figure 10). Measurements were made in micrometer (μm) at the 4 predetermined points which were marked on the prepared metal copings i.e. at the midbuccal, midmesial, midlingual and middistal surfaces. All measurements were executed by the same operator. No cement or other medium was used to fix the metal coping onto the prepared tooth. The image of the marginal discrepancy between the metal coping and the prepared tooth was focused under the microscope and then captured on the computer screen. The Image Analysis System, with the help of a digital scale, facilitated the measurement of the discrepancy between the metal coping and the prepared tooth (Figures 11 and 12). The results obtained were tabulated and then subjected to statistical analysis using the test of normality and independent t-test.

Figure 9: Photograph showing sample secured with a screw gauge.

Figure 10: Photograph showing sample on the stereomicroscope.

Figure 11: Photograph showing marginal discrepancy of group Ia sample as seen under the stereomicroscope.

Figure 12: Photograph showing marginal discrepancy of group IIa sample as seen under the stereomicroscope.

Cementation of metal copings on prepared teeth

Glass ionomer cement (GC Corporation, Tokyo, Japan) powder and liquid was dispensed onto the pad. The standard powder to liquid ratio is (1.8/1.0 g) 1 level scoop of powder to 2 drops of liquid. Using the plastic spatula, all the powder was added to the liquid, which was mixed rapidly for 20 seconds according to the manufacture’s specifications. The mixed cement was placed along the walls of the metal coping and was seated on the respected prepared tooth till the final seating of the metal coping. The excess cement was cleaned along the margins. The luted crown along with the tooth and acrylic block was placed under a pressure ridge for application of seating force of 25 N till the cement set (Figure 13).

Figure 13: Photograph showing pressure rig.

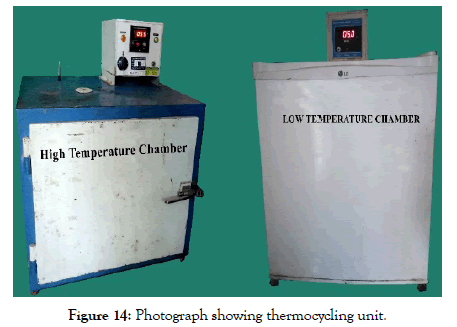

All metal copings, on each of the respective prepared tooth were cemented sequentially and were tested for retention after they were thermocycled by dwelling in 5°C and 55°C bath for 700 alternating 1/min immersion (Figure 14).

Figure 14: Photograph showing thermocycling unit.

Evaluation of metal copings for retention

The samples were individually fixed to the rigid lower member of the Universal testing Machine (ACME, India, model no. 10). A stainless- steel wire, 5″ in length and 4 mm in diameter was fixed to the upper member and passed through the loop on the metal coping (Figure 15). The machine was set to apply a uniaxial tensile force to the sample with a cross head speed of 1 mm/min. The load was applied from zero reading then gradually increased. The loading was continued until the cemented metal coping showed first dislodgment and the readings were recorded in Newtons and tabulated (Figures 16 and 17). They were then subjected to statistical analysis using the test of normality and independent t-test.

Figure 15: Photograph showing sample being tested with the universal testing machine.

Figure 16: Photograph showing dislodged metal copings of group I.

Figure 17: Photograph showing dislodged metal copings of group II.

Results

An in vitro study was carried out to evaluate, compare and correlate the marginal fit and retention of metal copings fabricated using two different designs for die spacer.

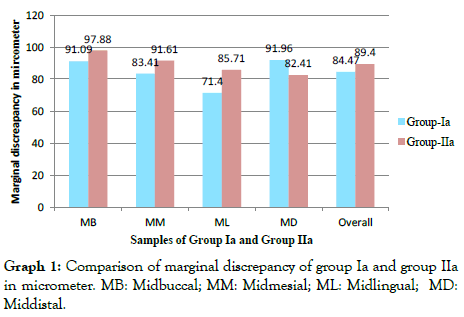

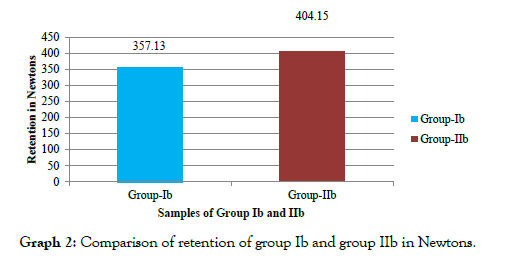

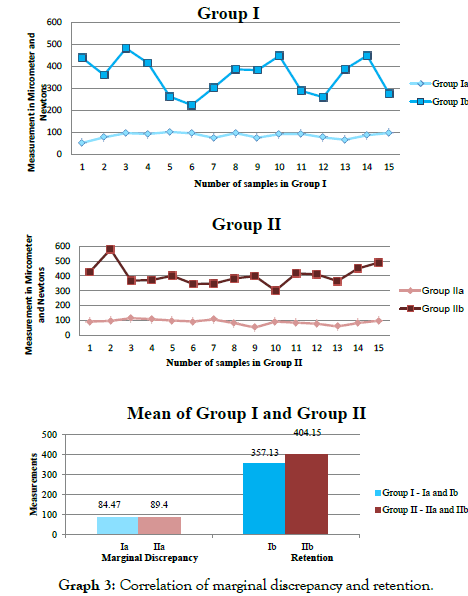

The readings obtained were then tabulated as shown in Tables 1-5 and Graphs 1-3.

Graph 1: Comparison of marginal discrepancy of group Ia and group IIa in micrometer. MB: Midbuccal; MM: Midmesial; ML: Midlingual; MD: Middistal.

Graph 2: Comparison of retention of group Ib and group IIb in Newtons.

Graph 3: Comparison of retention of group Ib and group IIb in Newtons.

Discussion

Marginal fit is considered an important criterion for clinical quality and success of fixed restorations [6]. Accuracy of fit is the most important characteristic related to the longevity of a restoration [7,8]. An unacceptable marginal discrepancy could result in cement washout and microleakage, creating a biofilm that leads to subsequent biological complications such as secondary caries, periodontal problems and pulpitis [8]. Poor marginal adaptation between the tooth and the restoration increases plaque retention and changes the distribution of the microflora, which can induce the onset of periodontal disease [9]. The retention and seating of restoration is a complex phenomenon related to several factors including: Preparation of variables such as convergence angle, axial wall height and diameter, surface area, margin configuration and additional retentive features, surface finish of the preparation, and of the fitting surface of the casting, and use of preparation sealing agents. Cementation variables such as type of cement, physical properties of luting agent, placement techniques, seating force, and environmental conditions, use of techniques designed to improve seating such as die spacing and fabrication of restoration. Changes to any of these factors may result in changes in retention [10].

Measurement of mean of the marginal discrepancy of metal copings is 84.15 μm for group Ia and 89.13 μm for group IIa (Tables 1 and 2).

| Sample number | MB | MM | ML | MD | Mean |

|---|---|---|---|---|---|

| 1 | 35.4 | 58.5 | 63.4 | 48.5 | 51.45 |

| 2 | 85 | 101.6 | 36.8 | 85 | 77.1 |

| 3 | 125.1 | 81.7 | 52.6 | 125.1 | 96.13 |

| 4 | 108.4 | 69.8 | 80.3 | 108.4 | 91.73 |

| 5 | 109.9 | 107.3 | 77.8 | 109.9 | 101.23 |

| 6 | 110.3 | 90.4 | 68.9 | 110.3 | 94.98 |

| 7 | 69.8 | 80.4 | 76.5 | 69.8 | 74.13 |

| 8 | 122.4 | 87.1 | 51.8 | 122.4 | 95.93 |

| 9 | 68.4 | 79.3 | 85.1 | 68.4 | 75.3 |

| 10 | 89.4 | 96.8 | 88.4 | 89.4 | 91 |

| 11 | 90.2 | 93.3 | 96.4 | 90.2 | 92.53 |

| 12 | 69.8 | 71.3 | 94.2 | 69.8 | 76.28 |

| 13 | 85.5 | 53.2 | 40.1 | 85.5 | 66.08 |

| 14 | 95.2 | 88.9 | 65.4 | 95.2 | 86.18 |

| 15 | 101.5 | 91.6 | 93.3 | 101.5 | 96.98 |

| Mean | 91.09 | 83.41 | 71.4 | 91.96 | 84.47 |

MB: Midbuccal; MM: Midmesial; ML: Midlingual; MD: Middistal

Table 1: Values of marginal discrepancy of group Ia in micrometer (μm).

| Sample number | MB | MM | ML | MD | Mean |

|---|---|---|---|---|---|

| 1 | 122.4 | 89.9 | 75.4 | 80.3 | 92 |

| 2 | 136.8 | 98.3 | 71.6 | 80.9 | 96.9 |

| 3 | 139.5 | 125.1 | 96.8 | 99.2 | 115.15 |

| 4 | 136.5 | 111.5 | 90.2 | 95.2 | 108.35 |

| 5 | 95.8 | 99.3 | 101.6 | 100.2 | 99.23 |

| 6 | 98.3 | 103.9 | 89.7 | 80.3 | 93.05 |

| 7 | 114 | 99.7 | 103.2 | 110.4 | 106.83 |

| 8 | 90.6 | 92.8 | 84.2 | 60.1 | 81.93 |

| 9 | 52.3 | 50.1 | 46.3 | 61.41 | 52.53 |

| 10 | 82.9 | 80.6 | 103.4 | 100.9 | 91.95 |

| 11 | 101.4 | 92.6 | 77.8 | 65.4 | 84.3 |

| 12 | 77.6 | 81.41 | 84.9 | 70.5 | 78.6 |

| 13 | 50.2 | 55.6 | 61.8 | 70.4 | 59.5 |

| 14 | 61.8 | 91.4 | 79.8 | 100.5 | 83.38 |

| 15 | 108.1 | 102 | 119 | 60.41 | 97.38 |

| Mean | 97.88 | 91.61 | 85.71 | 82.41 | 89.4 |

MB: Midbuccal; MM: Midmesial; ML: Midlingual; MD: Middistal

Table 2: Values of marginal discrepancy of group IIa in micrometer (μm).

Although marginal adaptation is a fundamental factor in the clinical success of the fixed dental prostheses, there is no consensus on the maximum clinically acceptable marginal discrepancy. A wide range of values from 50 to 200 μm has been reported in the literature [11]. Christensen [12] found that an acceptable marginal fit was 34 μm to 119 μm. Abduo J et al., Ural Ç et al., and Ting SS et al. [13-15] also suggested that restorations with marginal discrepancies less than 120 μm were more likely to be successful and hence they stated that clinically acceptable marginal discrepancy is less than 120 μm. This difference in values may be attributed to lack of standardization in measurement methodology, making comparison among studies a challenge.

The results of group Ib shows force in Newtons to dislodge the crown which are present in (Table 3), the lowest being 223.15 N and the highest being 481.20 N. Force required to dislodge crowns in group IIb was presented in (Table 4), the lowest being 301.40 N and highest being 580.15 N.

| Sample number | Retention force (N) |

|---|---|

| 1 | 438.55 |

| 2 | 360.5 |

| 3 | 481.2 |

| 4 | 414.6 |

| 5 | 261.9 |

| 6 | 223.15 |

| 7 | 302.8 |

| 8 | 385.5 |

| 9 | 382.7 |

| 10 | 447.6 |

| 11 | 288.1 |

| 12 | 259.05 |

| 13 | 386.85 |

| 14 | 448.45 |

| 15 | 276 |

| Mean | 357.13 |

Table 3: Values of retention of metal copings for group Ib in Newtons (N).

| Sample number | Retention force (N) |

|---|---|

| 1 | 428 |

| 2 | 580.15 |

| 3 | 367.8 |

| 4 | 372.95 |

| 5 | 401 |

| 6 | 346.15 |

| 7 | 348 |

| 8 | 382.8 |

| 9 | 399.2 |

| 10 | 301.4 |

| 11 | 417.95 |

| 12 | 410.48 |

| 13 | 365.5 |

| 14 | 450.5 |

| 15 | 490.5 |

| Mean | 404.15 |

Table 4 : Values of retention of metal copings for group IIb in Newtons (N).

Jorgensen and Esbensen [16] in a study designed to investigate the relationship between film thickness of cement and crown retention, found a decrease in retention with increasing cement film thickness, which closely corresponds to crown elevation, and thus, a decrease in retention with increase crown elevation was seen. Die spacers allow increased space for the cement between the tooth surface and the internal surface of the casting, reducing stress areas created during cementation, and thereby resulting in better fit and retention of the final restoration [11].

The result in Table 5 shows correlation of the overall mean marginal discrepancy and retention where since p-value greater than 0.05 no significant difference is seen in group I, and in group II since p-value is greater than 0.05 there is no significant difference. Where, the non-significances mean that the retention and marginal discrepancy have indirect correlation i.e. increase retention with decrease marginal discrepancy.

| Group-Ib | Group-IIb | |

| Correlation value | -0.234315 | 0.008795 |

| p-value | 0.4005921 | 0.9751834 |

Table 5: Correlation of overall mean marginal discrepancy and retention.

Geagauff and Rosenstiel [17] used a dynamic seating force of 49 N applied via the orangewood stick that was “rocked back and forth”. This experiment design resulted in over-seating for all castings following cementation. They observed tooth surfaces that were nearly free of cement and slightly discoloured and suggested that the slight abrasion and deformation had occurred during the dynamic loading. It also may be possible that dynamic loading results in increased frictional fit between the tooth surface and the fitting surface of the restoration, increasing the retention of the unspaced crowns.

Wilson et al. [18] has shown that increased seating force resulted in increased crown deformation and found strain levels under some conditions near to the fracture strains for porcelain. Wilson [19] has demonstrated that crowns with a reduced axial spacing shows an increased seating time. Many of these potential problems may be overcome by producing a crown that demonstrates a passive fit and which allows an exit pathway for the outflow of the excess cement. Wong [20] has shown increased seating forces results in increased pulp-ward pressure transmission.

Analysis of the results of this study suggested that the metal copings fabricated using die spacer involving the cervical third shows clinically acceptable marginal fit and increased force requirement for dislodgement of the metal coping from the prepared tooth, though there is no statistical difference in retention values when compared to metal copings fabricated using die spacer design involving the occlusal surface of the occlusal third.

Limitations of the Study

1. Additional studies could be conducted with increased sample size and more number of evaluation sites per sample along with measurement of absolute marginal discrepancy as that could reflect a more accurate average measurement.

2. The copings were not cemented on the prepared tooth in this study for marginal discrepancy, and which may produce different results if cemented

Conclusion

An in vitro study was carried out to evaluate, compare and correlate the marginal fit and retention of metal copings fabricated using two different die spacer designs. Within the limitations of the study, the following conclusions were drawn:

1. The marginal fit of the copings fabricated using die spacer on occlusal surface of the occlusal third region (Group Ia) was within the clinically acceptable range. The marginal fit of the midmesial and midlingual surfaces was better than the midbuccal and middistal surfaces with midlingual showing lowest marginal discrepancy and middistal showing highest marginal discrepancy

2. The marginal fit of the copings fabricated using die spacer on cervical third surface (Group IIa) was within the clinically acceptable range. The marginal fit of the midlingual and middistal surfaces was better than the midbuccal and midmesial surfaces with middistal showing lowest marginal discrepancy and midbuccal showing the highest marginal discrepancy

3. The marginal fit of the metal copings fabricated using die spacer on occlusal surface of occlusal third region (Group Ia) was better than that of die spacer on the cervical third surface (Group IIa) though both the groups produced metal copings with clinically acceptable marginal fit. There was no statistically significant difference between the overall means of the copings of group Ia and group IIa

4. The retention of the metal copings fabricated using die spacer on occlusal surface of the occlusal third region (Group Ib) shows no statistically significant difference was observed of the metal copings within the group

5. The retention of the metal copings fabricated using die spacer on cervical third (Group IIb) shows no statistically significant difference was observed of the copings within the group

6. The retention of the metal copings fabricated using die spacer on the cervical third surface (Group IIb) was better than die spacer on occlusal surface of occlusal third region (Group Ib). There was no statistically significant difference between the overall means of the copings of group Ib and group IIb

7. The marginal fit of metal copings fabricated using die spacer on the occlusal surface of the occlusal third region (Group Ia) was better. The retention of the copings (Group Ib) was less. It has been observed that the correlation between group Ia and Ib is statistically non- significant. The retention of the metal copings fabricated using the die spacer on the cervical third region (Group IIb) was better. The marginal fit of the copings (Group IIa) was less than that of (Group Ia). It has been observed that the correlation between the group IIa and IIb is statistically non-significant

Conflict of Interest

None

REFERENCES

- Steven MC, Peter RW. The effect of die-spacing on crown retention. Int J Prosthet Dent. 1996;9:21-29.

- Holmes JR, Bayne SC, Holland GA, Sulik WD. Considerations in measurement of marginal fit. J Prosthet Dent. 1989;62:405-408.

- Ng J, Ruse D, Wyatt C. A comparison of the marginal fit of crowns fabricated with digital and conventional methods. J Prosthet Dent. 2014;112:555-560.

- Lorey RE, Myers GE. The retentive qualities of bridge retainers. J Am Dent. 1968;76:568-572.

- Anna BO, Tetsuo S. The effect of die-spacing on retention and fitting of complete cast crowns. J Prostho. 2006;15:243-249.

- White SN, Ingles S, Kipnis V. Influence of marginal opening on microleakage of cemented artificial crowns. J Prosthet Dent. 1994;71:257-264.

- Schwartz NL, Whitsett LD, Berry TG, Stewart JL. Unserviceable crowns and fixed partial dentures: life-span and causes for loss of serviceability. J Am Dent Assoc. 1970;81:1395-1401.

- Pradíes G, Zarauz C, Valverde A, Ferreiroa A, Martínez RF. Clinical evaluation comparing the fit of all-ceramic crowns obtained from silicone and digital intraoral impressions based on wave-front sampling technology. J Dent. 2015;43:201-208.

- Örtorp A, Jönsson D, Mouhsen A, von Steyern PV. The fit of cobalt chromium three-unit fixed dental prostheses fabricated with four different techniques: A comparative in vitro study. Dent Mater. 2011;27:356-363.

- Santamaria MP, Suaid FF, Carvalho MD, Nociti FH, Casati MZ, Sallum AW, et al. Healing patterns after subgingival placement of a resin-modified glass-ionomer restoration: a histometric study in dogs. Int J Periodontics Restorative Dent. 2013;33:679-687.

- Passon C, Lambert RH, Lambert RL, Newman S. The effect of multiple layer of die spacer on crown retention. J Prosthet Dent. 1992;17:42-49.

- Christensen GJ. Marginal fit of gold inlay castings. J Prosthet Dent. 1966;16:297-305.

- Abduo J, Lyons K, Swain M. Fit of zirconia fixed partial denture: a systematic review. J Oral Rehab. 2010;37:866-876.

- Ural Ç, Burgaz Y, Saraç D. In vitro evaluation of marginal adaptation in five ceramic restoration fabricating techniques. Quintessence Int. 2010;41:585-590.

- Ting SS, Jian S. Intraoral digital impression technique: a review. J Prosthodont. 2015;24:313-321.

- Jorgensen KD, Esbensen AL. The relationship between the film thickness of zinc phosphate cement and the retention of veneer crowns. Acta Odontol Scand. 1968;26:169-175.

- Gegauff AG, Rosentiel SF. Reassesment of die spacer with dynamic loading during cementation. J Prosthet Dent. 1989;61:655-675.

- Wilson PR, Goodkind RJ, Delong R, Sakaguchi R. Deformation of crowns during cementation. J Prosthet Dent. 1990;64:601-609.

- Wilson PR. The effect of die spacing on crown deformation and seating time. Int J Pros. 1993;6:397-401.

- Wong RH, Wilson PR. The effect of seating force and die spacing on pulp-ward cementation pressure transmission: a laboratory study. Int Dent J. 1997;47:45-52.

Citation: Dave KC, Rathod AM, Mistry G, Shetty O (2020) Comparative Evaluation and Correlation of Marginal Fit and Retention of Metal Copings Fabricated Using Two Different Designs of Die Spacer–An In Vitro Study. Dentistry 10: 566. doi: 10.35248/2161-1122.20.10.566

Copyright: © 2020 Dave KC, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Sources of funding : Nil