Indexed In

- Open J Gate

- Genamics JournalSeek

- ResearchBible

- Electronic Journals Library

- RefSeek

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- SWB online catalog

- Virtual Library of Biology (vifabio)

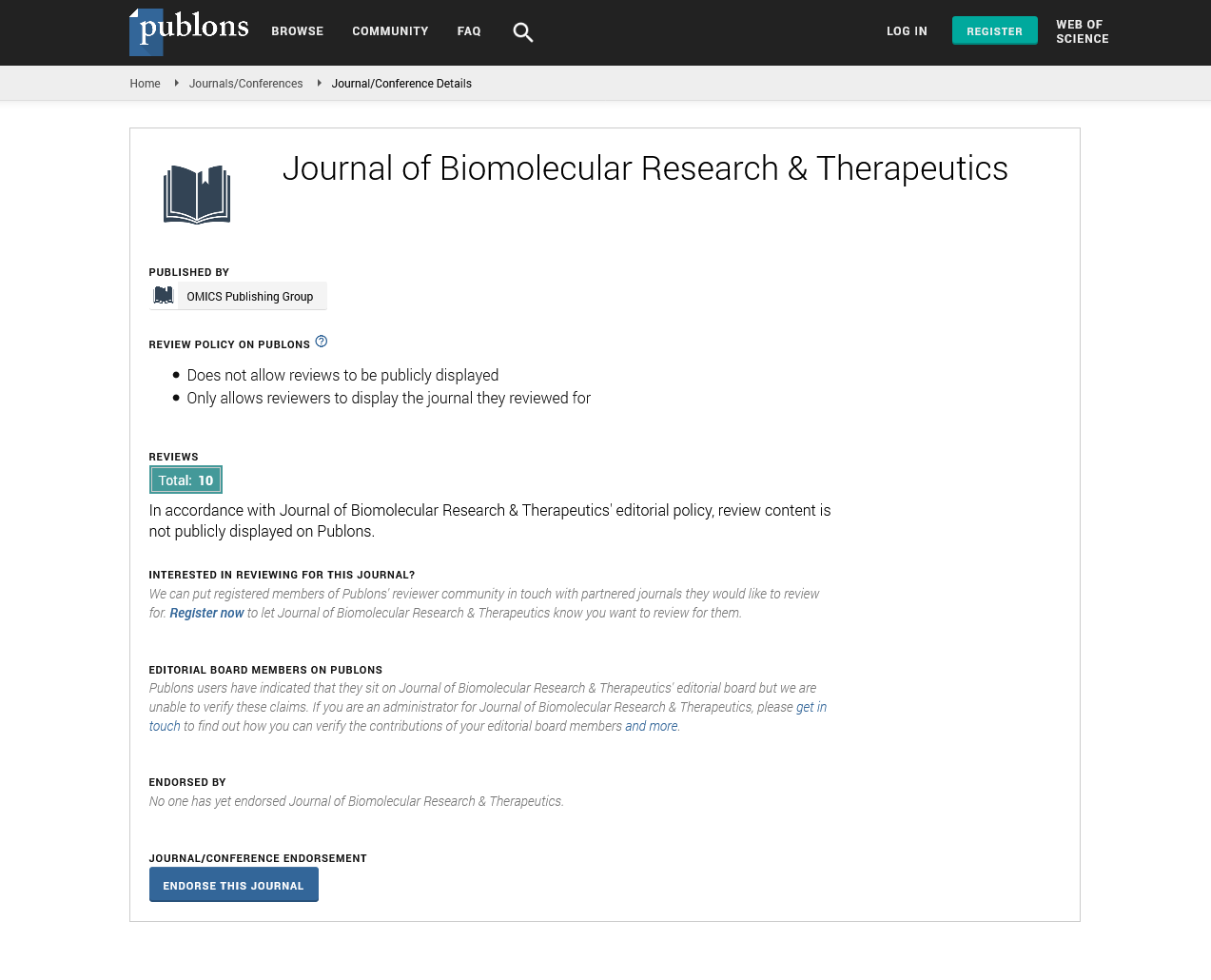

- Publons

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Perspective - (2023) Volume 12, Issue 1

Protein Engineering and its Synthesis in Biofuel Production

Grace Joyce*Received: 02-Jan-2023, Manuscript No. BOM-23-19829; Editor assigned: 05-Jan-2023, Pre QC No. BOM-23-19829 (PQ); Reviewed: 20-Jan-2023, QC No. BOM-23-19829; Revised: 26-Jan-2023, Manuscript No. BOM-23-19829 (R); Published: 03-Feb-2023, DOI: 10.35248/2167-7956.23.12.254

Description

Lignocellulose hydrocarbons are the only predicted sustainable, renewable alternative energy source to transportation fossil fuels. However, the refractory nature of lignocellulose presents technical challenges to the development of a commercially successful bio refinery. Low enzymatic hydrolysis efficiency as well as low biofuel productivity, yield are among the major cost factors. Protein engineering has been utilized to increase the efficacy of enzymes that degrade lignocellulose as well as proteins involved in biofuel manufacturing pathways. Protein engineering, in contrast to its enormous success in other industrial applications has achieved only modest improvements in enhancing lignocellulose to biofuels efficiency. Modern society is primarily reliant on fossil fuels which provided 88% of world energy supply in 2007. Oil, natural gas and coal based on current reserves to production ratios, could only endure for about 40, 60 and 130 years respectively.

Renewable energy sources have sparked strong political and intellectual interest in order to society's reliance on fossil fuels and minimize greenhouse gas emissions. Other renewable energy sources such as solar, wind, geothermal and hydropower are more suited for stationary power applications. Biomass-derived liquid fuels are the only risks alternative to petroleum-based transportation fuels. Although maize or sugar cane ethanol presently dominates the biofuels industry, it has limited agricultural development potential and inherent physical limitations as a principal fuel for transportation such as high corrosively, hygroscopicity and low energy content. As a result, producing alternative biofuels from a more sustainable resource, such as lignocellulose, which is obtained from useless portions of plant biomass in the form of agricultural, industrial, residential and forest leftovers is extremely desirable. However, the resistant crystalline structure of lignocellulose biomass, which confers resistance to biodegradation on the plant cell wall, impedes its biological conversion to biofuels. Hydrolysis of cellulose is one of the two most expensive processing processes in cellulosic biofuels production (the other being pre-treatment, which is discussed elsewhere, owing to low enzyme catalytic efficiency. To get the same hydrolysis outcome, cellulose requires 40-100 times more enzyme than starch, despite the fact that the cost of enzyme synthesis is not much different. As a result, improving catalytic efficiency in enzymes is extremely desirable for commercializing lignocellulose biofuels. Furthermore, improved enzymes may necessitate less severe pre-treatment conditions reducing the generation of chemicals that hinder further lignocellulose hydrolysis and bioconversion resulting in a further reduction in production costs. Bacterial conversion of simple sugars to target biodiesel molecules is another crucial processing step required for the commercial success of lignocellulose biofuels.

This is owing to the poor activity of the pathway enzymes, as well as the modified microorganisms' limited fuel tolerance and imbalanced redox state as well as proteins involved in biofuel synthesis pathways, with an emphasis on how some of the new tools developed in the field may be able to address technical challenges. The most difficult obstacle in the development of lignocellulose-to-biofuels technology is the refractory nature of the plant cell wall. Its main structural component, cellulose is shielded by a matrix composed primarily of hemicellulose and lignin, restricting hydrolytic enzyme access. While cellulose engineering has primarily focused on optimizing cellulosomal components, protein engineering has been utilized to increase the performance of single non-completed celluloses. Despite ongoing efforts to increase non-complexed cellulose efficiency, protein engineering approaches have only yielded incremental gains, owing to the complexity of the insoluble substrates and the lack of a high throughput screening or selection mechanism.

Citation: Joyce G (2023) Protein Engineering and its Synthesis in Biofuel Production. J Biol Res Ther. 12:254.

Copyright: © 2023 Joyce G. This is an open access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.