Indexed In

- Open J Gate

- Genamics JournalSeek

- JournalTOCs

- China National Knowledge Infrastructure (CNKI)

- Electronic Journals Library

- RefSeek

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- SWB online catalog

- Virtual Library of Biology (vifabio)

- Publons

- MIAR

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Research Article - (2021) Volume 12, Issue 6

Physicochemical evaluation of composts produced from coffee pulp and some locally available organic matterat Dale District, Ethiopia

Alemayehu Emana* and Giche Y HirphaReceived: 20-Apr-2021 Published: 11-May-2021, DOI: 10.35248/2157-7463.21.12.427

Abstract

Composting is proved to be environment friendly effective management option for the increasing volume of coffee wastes generated and causing significant environmental degradation in developing countries. In view of this, the quality of composts produced from coffee pulp with locally available organic matter following the windrow method was examined based on four treatments in randomized complete block design (4x3). The study involved determining some physicochemical parameters at 25, 55 and 80 days of composting. Mean values of bulk density, moisture content, pH, electric conductivity, organic matter, total organic carbon, total nitrogen, total phosphorous, total potassium and carbon to nitrogen ratio ranged from 483.6 kg/m –487.11 kg/m3, 50.74%–52.43%, 7.45-8.36, 3.08 mS/cm-3.42 mS/cm, 45.26%-46.99%, 26.19%-27.27%, 1.54%-1.61%, 0.41%-0.59%, 0.75%-1.15% and 17.5-18.44, respectively. Bulk density, total nitrogen, total phosphorous and total potassium increased with composting time in contrast to moisture content, organic matter, total organic carbon and C/N. pH and electrical conductivity initially increased but decreased at final stage. Mean physicochemical parameters of matured composts fell within the range of acceptable limits set by different countries guidelines. All parameters were not significantly different (p>0.05) except moisture content, pH and total potassium as compared to within treatments (p<0.05). The results revealed that a mixture of 50% coffee pulp,20% cow dung, 20% enset leaf and 10% top soil is more preferable to produce quality compost and consequently protect the environment.

Keywords

Composting; Environment; Enseteventricosum; Evaluation; Quality

Introduction

Coffee is one of the most important agricultural export commodities in the world economy, next to oil and it is the most important and strategic commodity on which Ethiopia's economy depends. From the time age-old, the coffee sector is one of the backbones of the economic and social development in Ethiopia. It provides livelihoods for more than 4.7 million households and about half a million hectares of land are covered by coffee plantations in 2015 that gave a yield of about 0.42 million metric tons of green coffee beans. Industrial coffee production process involves either a dry or a wet processing method for the removal of the shell and mucilaginous parts from the cherries, resulting in the production of coffee husk and pulp, respectively. This represents a serious environmental problem for the waste contains high level of tannins, phenolic compounds and chlorogenic acids that could inhibit plant root growth and lead in greenhouse gas emissions through anaerobic decomposition that necessitates the proper use and disposal of coffee waste [1].

The current practices of green coffee bean production are not promoting the health of the community as well as well-being of the land on which coffee cherries are being produced. Despite its contribution to the national as well as the regional economy, the coffee sector is among the most unsustainable as far as environmentally sound solid waste management is concerned. The residue from dry coffee processing is burnt while those from wet processing are dumped into rivers, both being disposed into landfills and surface water. The residue from the wet coffee processing factories particularly coffee processing effluents is causing considerable pollution to all components of environment. This waste is rich in organic matter that can be used for different purposes such as compost. In many developing nations, dealing with the environmental costs of solid waste is a current phenomenal challenge. The huge production of solid wastes together with poor management system result in a significant environmental degradation, thus the safe and environmentally harmonious management of solid wastes becomes a major issue for these nations. Today in all corners of the world managing different organic wastes at low capital and operational cost as well as in eco-friendly and energy saving basis has attracted much attention and composting is one of the techniques that have been applied in various parts of the world. This study attemptedto evaluatechanges in some physicochemical parametersduring composting of coffee pulp with locally available organic matter (cow dung and enset) and at maturity stage [2].

Materials and Methods

Description of the study area

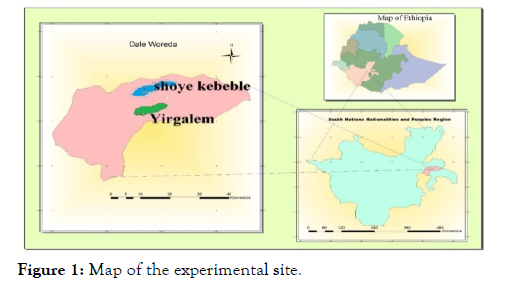

The study was conducted at Dale district Shoyekebele 10 km North of Yirgalem town 320 km south of Addis Ababa along the main road to Moyale. It is located at 06028'15.5"-07004'50.3"N and 38020'7.8"-38032'36.5"E and an altitude of 1750 m.a.s.l. The area receives an annual minimum and maximum rainfall of 858.1 mm and 1676.3 mm, respectively. The annual average minimum and maximum air temperatures are 11.00 C and 28.40 C, respectively. The major soil types of the center are eutric-nitosoland chromoticcambisolsthat are highly suitable for coffee production [3].

Composting materials

The basic raw materials used for composting included Coffee Pulp (CP), Cow Dung (CD), and enset leaf. CP was directly collected from shoyekebele cooperative union wet and dry coffee processing firms dumping sites. CD and EL was collected from farmsteads and the common bulking agent top soil was taken from the unions’ land area (Figure 1) [4].

Figure 1: Map of the experimental site.

Treatment design and layout

Triplicates of four different treatments named T1, T2, T3 and T4 were prepared in Randomized complete block design. The treatments involved composting CP with top soil; CP with CD and top soil; CP with EL and top soil; and CP with CD, EL and top soil, respectively. Treatments were assigned at random to the blocks and each treatment appeared once in each block. The composting area was of 1m3 volume and lined with plastic sheet membrane in order to protect mixing of base soil and the composts under preparation. Each treatment was covered by grass for protection of water loss. The compost piles were turned and watered twice per week uniformly for all the treatments for the first two months and once per week later on to enhance the composting process by blending and breaking up the composting materials (Table 1) [5].

| Heap Type | Treatment | |||

|---|---|---|---|---|

| T1 | T2 | T3 | T4 | |

| CP | 90% | 65% | 65% | 50% |

| CD | _ | 25% | _ | 20% |

| EL | _ | _ | 25% | 20% |

| Top soil | 10% | 10% | 10% | 10% |

Table 1: Percentage proportion of the composting materials.

Where, T1=Treatment1 (CP), T2=Treatment2 (CP and CD), T3=Treatment3 (CP and EL), and T4=Treatment4 (CP, CD and CD). Top soil was added to each layer to aid the composting process.

Sampling and analyses of parameters

Some physiochemical parameters of the raw materials were analyzed before starting the composting process. Three samples were taken 25 days, 55 days and 80 days after the composting started from each treatment and replications from all corner and center of the heap and mixed together to get a representative sample of each treatment. The compost samples were then ground using a grinder and mortar to pass through <2 mm sieve. The physicochemical parameters of the samples such as Moisture Content (MC), Bulk Density (BD), pH, Total Nitrogen (TN), Total Phosphorous (TP), Total Potassium (TK), Organic Matter (OM), Total Organic Carbon (TOC), Carbon to Nitrogen ratio (C:N), and electrical conductivity were analyzed at Ambo University Chemistry Department Laboratory [6].

Determination of physical parameters

Moisture content: Five gram of representative fresh sample was weighed for the determination of moisture content in a clean, dry, pre-weighed and recorded moisture free tin and loaded in an oven at 1050 C up to a constant weight (24 hours). Oven dried sample was cooled in desiccator for 30 minutes and reweighed.

pH: A sub-sample (5g) of air dried ground compost (<2 mm) was transferred into a flask and 25 ml of distilled water for 1:5 compost/water suspension. Samples were transferred into an automatic stirrer and stirred for 30 minutes. The flasks were covered and shaken mechanically for 15 min and allowed to stand for 30 minute. The pH of the suspension was measured using an electronic pH meter.

OM and TOC: Air-dried compost sample (2 g) was transferred to a 500 ml Erlenmeyer flask and 10 ml 1N K2 Cr2O7 solution was added to both samples and blank with pipette. Next, 20 ml conc. H2SO4 was carefully added with measuring cylinder in the fume cupboard and the flask was swirled and allowed standing asbestos or corking pad for 30 minutes. Then, 200 ml distilled water was added and it was allowed to cool. Subsequently, 10ml conc. Orthophosphoric acid was added just before titration, and then 0.5 ml of barium diphenylamine sulphonate indicator was added. Both samples and blanks were titrated with 0.5 N ferrous sulfate solution until the color changed to purple or blue; ferrous sulfate solution was added drop by drop until the color flashes to green and then to a light green end point [7].

Total Nitrogen: Nitrogen in the sample was estimated following the micro kjeldhal method. Dried sample (0.5 g) was digested using 10 ml of conc. H2S04 in presence of 0.3 g of catalytic mixture containing potassium sulfite, copper sulphate and selenium powder in the ratio 50:10:1 in the micro Kjeldhal digestion unit. The digested samples were diluted with distilled water and distilled after the addition of sufficient quantities of 40% NaOH to make the sample alkaline in the micro Kjeldhal distillation unit [8].

Results and Discussions

Physicochemical characterization of feedstock

Some physiochemical characteristics of the raw materials used for composting determined are presented. Correction of some physiochemical parameters of the feedstock material used for composting that have a huge impact on the composting process was the first task undertaken.

Physicochemical parameters of composts

Bulk density: Bulk density increased with composting time might be because of the increased decomposition rate of organic matter since organic matter and bulk density are inversely related. Bulk density was not significantly different (p>0.05) among the treatments which might be due to similar buildup of raw material particles (Figure 2, Table 2) [9].

Figure 2: Average bulk density and moisture content of composts at different stages.

| Parameters | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Raw material | MC (%) | pH | EC (ms/ cm) | OC (%) | OM (%) | TN (%) | AP | EK | C/N |

| CP | 58.0 | 4.64 | 7.74 | 40.3 | 69.5 | 1.05 | 1.11 | 2.49 | 38.3 |

| 2 | 1 | 9 | |||||||

| CD | 50.7 | 8.73 | 5.95 | 33.3 | 57.42 | 1.25 | 1.43 | 1.99 | 26.6 |

| 6 | 1 | 5 | |||||||

| EL | 61.34 | 6.3 | 4.69 | 46.9 | 80.9 | 1.5 | 1.36 | 3.66 | 31.29 |

| 3 | |||||||||

Table 2: Some physiochemical characteristics of the raw materials.

Moisture content: Moisture content decreased with increasing composting time might be mainly because of water loss during the composting process. According to the reduction in moisture at the end of composting process is attributed to microbial heat generation causing improved aridness. This result is also in agreement who reported a decrease in MC of compost from 61.1% to 54% within composting time. Mean MC was significantly different (P<0.05) betweenT1 and T4, T2 and T4, and T3 and T4.This might be attributed to the combination of three different composting feedstock in T4 that can hold the water content than the other. The result of this study is in agreement who reported compost MC in the range from 40% to 60%which is suggested as acceptable ranges by the EFEPA [10].

pH: The mean pH of the composts increased from D25 to D55 and then decreased at D80. The increase of pH during composting from D25 to D55 might indicate evolution of ammonification processes as a result of microbial activities. The differences in pH between T1and T3, T1 and T4, T2and T3, T2 and T4, T3 and T4 were significantly different (p<0.05).The difference in pH among the composted types might be due to the differences in chemical composition of the starting materials, the mixing ratio and the inter action within the composted materials during composting. The combined effects of ammonification and accumulation of organic acids also regulate the pH dynamics during the composting process.

Electrical conductivity: Mean EC of the compost increased from D25 to D55 and then decreased at D80. The initial increase of EC might be attributed to the organic matter degradation and release of different mineral salts such as phosphate, ammonium, and potassium whereas the decrease at later stage could be due to consumption of produced organic acids at the process and their conversion to ammonia. This finding is in agreement [11].

The mean EC was not significantly different among the treatments (p>0.05). This might be explained by similar release and conversion of soluble salt into ammonia. This might also be due to the similarity in the interaction within the composted materials during composting time. The result is also supported with who reported the EC of compost produced from green waste in the range between 0.46 mS/cm and 3 mS/cm. This finding is also in compliance with the quality of compost recommended by countries such as Dutch, Belgium, and Italy that is <5 mS/cm.

Total organic carbon: Total organic carbon content decreased with increasing composting time which might be explained by a decrease in the rate of carbon degradation gradually as composting progressed because of the reduction in available carbon sources as stated. The OC of the composts ranged between 26.19% and 27.27% and mean values were not statistically significantly different among the treatments (p>0.05). This might be explained by the presence of comparable amount of organic matter contents in the treatments [12].

Total Nitrogen: Nitrogen content increased with composting time which might be attributed to the concentration effect caused by carbon loss associated with mineralization of the organic matter. The mean TN content was not significantly different among the treatments (p>0.05). The comparable TN content in the composts might be due to the similarity in mineralization/immobilization of nitrogen and the interaction within the composted materials. The non-significant difference among composts might be due to the similarity of nitrogen content in the raw materials.

Total Phosphorous: Total Phosphorus of the composts increased with an increase in composting time. This might be attributed to solubilization of the inorganic phosphate existing in the compost by microorganism which agrees. The TP recorded in the study was not significantly different among the treatments (p>0.05) might be because of the similarity in the available microorganisms and the interaction within the composted materials. The value recorded in this study ranged between 0.41%-0.59% and supported [13].

Total Potassium: Total potassium correspondingly increased with composting time. This might be explained by increased decomposition rate and the concentration effect caused by carbon loss associated with mineralization of the organic matter. The highest exchangeable potassium content was recorded might be because of the high decomposition rate of the composting material. The relatively higher potassium content determined in the composts might be due to the higher concentration of potassium in the combination of CP, CD and EL raw materials [14].

Conclusion and Recommendations

The physicochemical qualities of the composts evaluated lie in the range of quality compost guidelines and standards set by Ethiopia, Dutch, Belgium and Italy. The compost produced from coffee pulp composted with cow dung and Enseteventricosumin the proportion (50% of CP, 20% of CD, 20% of EL and 10% of top soil) is more preferable due to the statistically high TK content and suitability to use without any treatment for pH. Thus, coffee pulp composting with cow dung and Enseteventricosum at this proportion can be considered as a viable option for environmental management in the area of coffee processing stations.

REFERENCES

- Beyene A, Kassahun Y, Addis T, Assefa F, Amsalu A, Legesse W, et al. The impact of traditional coffee processing on river water quality in Ethiopia and the urgency of adopting sound environmental practices. J Environ Monit Assess. 2012;184(21):7053–7063.

- Haddis A, Devi R. Effect of effluent generated from coffee processing plant on the water bodies and human health in its vicinity. J Hazrd Mater. 2008;152(1):259–262.

- Bernal MP, Alburquerque JA, Moral R. Composting of animal manures and chemical criteria for compost maturity assessment: A review. J Biore Techn. 2009;100(22):5444-5453.

- Dzung NA, Dzung TT, Khanh VTP. Evaluation of Coffee Husk Compost for Improving Soil Fertility and Sustainable Coffee Production in Rural Central Highland of Vietnam. J Res Environ. 2013;3(4):77-82.

- Shemekit F, Brandon MG, Whittle IHF, Praehauser B, Insam H, Assefa F, et al. Coffee Husk Composting an Investigation of the Process Using Molecular and Non-Molecular Tools. J Waste Mana. 2014;34(3):642-652.

- Getahun T, Nigusie A, Entele T, Gerven TV, Bruggen BVD. Effect of turning frequencies on composting biodegradable municipal solid waste quality. J Reso, Conser Recy. 2012;65(2):79-84.

- Huang GF, Wong JWC, Wu QT, Nagar BB. Effect of C/N on composting of pig manure with sawdust. J Waste Manag. 2004;24(15): 805-813.

- Murthy PS, Naidu MM. Sustainable management coffee industry by products and value addition-A review. Resou Conser Recy. 2012;66:45-58.

- Pandey A, Soccol CR, Nigan P, Brand D, Mohan R, Rovossos S, et al. Biotechnological potential of coffee pulp and husk for bio-process. J Biochem Engin. 2000;6(3):153-162.

- Reyes MT, Oviedo ERO, Dominguez I, Komilis D, Sanchez A. A systematic review on the composting of green waste : Feedstock quality and optimization strategies. J Waste Manag. 2018;77(6):486-499.

- Tiquia SM, Tam NF. Characterization and composting of poultry litter in forced aeration piles. J Proc Biochem. 2002;37(22):869-880.

- Wang H, Nie Y. Municipal solid waste characteristics and management in China. J Air Waste Manag Assoc. 2001;51(2):250-263.

- Wang P, Changa CM, Watson ME, Dick WA, Chen Y, Hoitink HA. Maturity indices for composted dairy and pig manures. J Soil Bio Biochem.2004;36(7):767- 776.

- Jiang-Ming Z. Effect of turning frequency on co-composting pig manure and fungus residue. J Air Waste Manag Assoc. 2017;67(3): 313-321.

Citation: Emana A, Hirpha GY. (2021) Physicochemical Evaluation of Composts Produced from Coffee Pulp and Some Locally Available Organic Matter at Dale District Ethiopia. J Petrol Env Biotech. 12.6:427.

Copyright: © 2021 Emana A, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.