Indexed In

- Academic Journals Database

- Genamics JournalSeek

- Academic Keys

- JournalTOCs

- China National Knowledge Infrastructure (CNKI)

- Scimago

- Access to Global Online Research in Agriculture (AGORA)

- Electronic Journals Library

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- SWB online catalog

- Virtual Library of Biology (vifabio)

- Publons

- MIAR

- University Grants Commission

- Geneva Foundation for Medical Education and Research

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Research Article - (2022) Volume 14, Issue 2

Kinetic Studies and Simulation of Microbial Fuel Cells Voltage from Clostridium Spp. and Proteus

Mbugua JK1*, Mbui DN1, Waswa AG2 and Mwaniki JM12Department of Physical Science, South Eastern Kenya University, Kitui, Kenya

Received: 07-Feb-2022, Manuscript No. JMBT-22-16072; Editor assigned: 09-Feb-2022, Pre QC No. JMBT-22-16072 (PQ); Reviewed: 23-Feb-2022, QC No. JMBT-22-16072; Revised: 28-Feb-2022, Manuscript No. JMBT-22-16072(R); Published: 07-Mar-2022, DOI: 10.35248/1948-5948.22.14.483

Abstract

Microbial Fuel Cells (MFC) can be employed in bio-remediation of organic pollutants. In In this study, MFC voltage generated from various fruit market wastes using Clostridium spp., Proteus spp. and rumen fluid microbes was fitted into linear, logistic and Gompertz growth models. The dual chamber MFC was constructed using 1.0 liters plastic containers. NaCl in 3% agarose based salt bridge was used to connect the two chambers while graphite rods and copper wires were used as electrodes. The study was done by inoculating microbes present in about 250 mL cow dung mixed with 250 mL water and 500 g of homogenized fruit wastes and market wastes respectively, then current/ voltage generated measured for 24 days. The control experiment had 250 mL cow dung spiked with water to 1000 mL. From this study, microscopic and biochemical studies of the cultures confirmed that Proteus and Clostridium spp. were found in the anodic compartment of MFC. The rumen fluid inoculate registered the highest current (0.074 mA) explained by a higher microbe’s population resulting in a higher substrate breakdown rate. Low voltage was recorded in a mixed culture of Clostridium spp. and Proteus ssp. compared to pure cultures. The Gompertz equation growth model was applicable, with regression values of 0.967 compared to 0.922 obtained in linear data fitting. The same was well reflected by the simulating growth model of Clostridium spp. In both cases, the voltage generated from the pure cultures could not be explained linearly due to low R2 of 0.911 and 0.962 for Clostridium spp and Proteus respectively compared to 0.96 and 0.98 for the Gompertz equation fitting.

Keywords

Bacterial inoculation; Deficit irrigation; Fatty acid; Flax; Oilseed; Protein

Introduction

Microbial bioremediation strategies can be either ex-situ or in-situ. Ex-situ techniques consist of transporting pollutants from polluted sites to another site for treatment, while in situ techniques treat polluted substances at the site itself. Ex-situ remediation technique owing to its limitations is not considered as a choice of cleanup by many researchers. It may or may not be lucrative at particular sites and may be possible that the microorganisms which assisted sites and may be possible that the microorganisms which assisted in clean-up of pollutants under in-vitro fail to remove them effectively under in-vitro conditions [1-3]. The mode of action and growth of microorganisms in polluted sites needs to be more studied for a better understanding [4]. Microbial fuel cells (MFC) can be employed in bio-remediation of organic pollutants like market wastes, pesticides etc. [5]. Microbial Fuel Cell is a device that uses bacteria as a biocatalyst to breakdown organic matter thereby generating current. These bacteria, called exoelectrogenic bacteria are oxidizing organic substrates to release electrons, which then harvested in an external circuit to produce bioelectricity [6].

Despite all the potential, the bioelectricity production from MFC is still low and its relation with MFC conditions is uncertain as it is highly affected by any parameter that influences microbial activities [5]. Therefore, this study models the voltage generated from various market wastes in attempt to simulate the amount of voltage that can be obtained from various market wastes.

Methodology

As anode and cathode chambers, two 1.2 liter containers were packed as shown in Figure 1. The wire was inserted through two small holes drilled into the caps of the containers. A 5.7 cm long and 0.7 cm diameter graphite rod electrode was connected to one end of the copper wire. 2.5 litres of 1 M NaCl, 3 percent agarose solution, and lamp wicks were used to make a salt bridge. The wicks were boiled in a NaCl and 3% agarose solution for 10 minutes before being placed in the freezer at -4°C to solidify. The solidified salt bridge was passed through PVC pipes and secured to the chambers with Araldite adhesive, ensuring that they were leak-proof.

Figure 1: Set-up of H-shaped microbial fuel cells with a multi-meter.

Circuit assembly

The double chamber MFC was put together as depicted in Figure 1. The voltage and current was taken regularly via a multi-meter connected to copper wires joined to the carbon rods [7,8].

Isolation and culturing and identification of microbes form anodic chamber

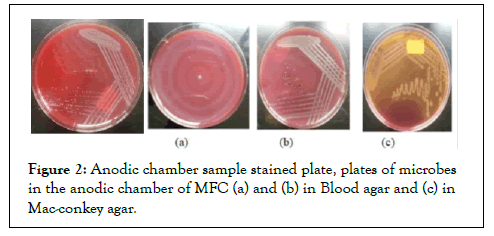

A sample containing microbes was taken from the anaerobic anodic chamber of a running MFC and microbial community cultured, isolated and identified, the following plates were obtained in Mac- Conkey and blood agar. In Figure 2, the anodic chamber sample was stained in a dish and two distinct cultures isolated. The isolates were then removed from the initial plate and cultured in blood and Mac-Conkey agar, as shown in Figure 2.

Figure 2: Anodic chamber sample stained plate, plates of microbes in the anodic chamber of MFC (a) and (b) in Blood agar and (c) in Mac-conkey agar.

Rumen fluid and cow dung were used as a microbe source in market waste microbial fuel cell. Further, the isolated microbes were also employed as bio-catalyst in voltage generation from the fruit wastes.

Investigation of the potential of fruit wastes and cow dung

Around 500 g each of watermelon, avocado, banana, tomato, and mango were cut into smaller sizes, minced with a meat mincer, and homogenized then put into the anodic chamber. About 500 ml distilled water was loaded in the cathodic chamber. A fruit mixture was also produced. To introduce the microbes, 250 ml cow dung in 250 ml water was added to each cell. The control experiment was 1000 ml cow dung in water. The current and voltage coming from the cells were measured every day for a period of 24 days.

Results and Discussion

Microscopic and biochemical studies of the cultures confirmed that Proteus and Clostridium spp. were found in the anodic compartment of MFC. The images obtained from an electron microscope are shown in Figure 3. These results compare with a previous study by Gagandeep et al., (2017) who identified Bacillus subtilis, Clostridium spp, Peptostreptococcus Species, Bacillus Cereus and Bacteroides Species in the anodic chamber of a running MFC which aided in electricity generation in the MFC [9]. The isolated microbes found in this study are also comparable to others [10-15].

Figure 3: Electron microscope images of (a) Proteus and (b) Clostridium sps . bacteria.

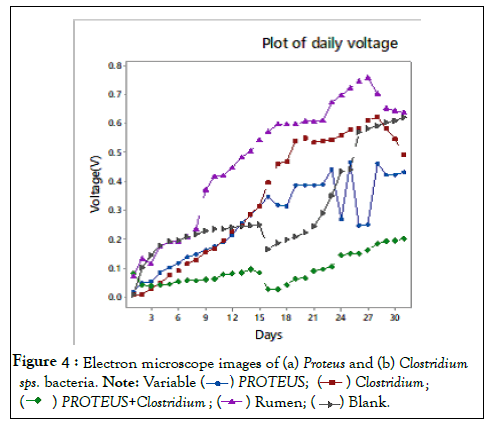

Proteus spp is a gram-negative proteo-bacterium found in decomposing animal matter, sewage and manure soil. It is also widely seen in the mammalian intestine.Proteus Vulgaris commonly grow in the Mac-Conkey agar culture plate. Clostridium is a rod shaped genus of gram-positive bacteria that are obligate anaerobes. This means that they are killed by exposure to atmospheric oxygen (20.9 5%) [16]. The voltage produced from decaying tomato wastes is shown by plots (Figure 4). In a study using five cultures, Paracoccus homiensis and Pseudomonas aeruginosa produced the maximum voltage of 320 mV and 300 mV, respectively. Bacillus thuringiensis had the least voltage of 150 mV. Likewise, Paracoccus sp and Pseudomonas ssp gave the maximum current of 10 mA and 20 mA, respectively [17].MFC performance differs for every bacterium. For example, 10.89 mA and 10.45 mA current were generated by Saccharomyces cerevisae and Clostridium acetobutylicum after 10 days of operation [17].

Figure 4:Electron microscope images of (a) Proteus and (b) Clostridium sps. bacteria.

Low voltage was recorded in a mixed culture of Clostridium sps. and Proteus sps. compared to pure cultures. This is explained by the fact that the two cultures require individual time to adapt to the anodic chamber environment in addition to collective time to adapt as a mixed culture [18]. This contradicts what was observed by Fatemi et al., 2012, who claimed that diverse culture produced more voltage than pure ones [19]. Rismani-Yazdi et al., (2007) used rumen microorganisms as inoculum to produce electricity from cellulose, in an H-type MFC; the voltage reached a steady- state level of 470 ± 2 mV after 14 days and an external load of 1000 Ω [20,21]. In another study, the voltage was generated using Clostridium cellulolyticum utilizing cellulose as a substrate while electron transfer Geobacter sulfurreducens was used [22,23]. The daily current generated is shown in Figure 4. Rumen fluid inoculated set up registered the highest current (0.074 mA) explained by a higher microbe’s population resulting in a higher substrate breakdown rate as per the total viable count data [8].

Voltage simulation and modeling

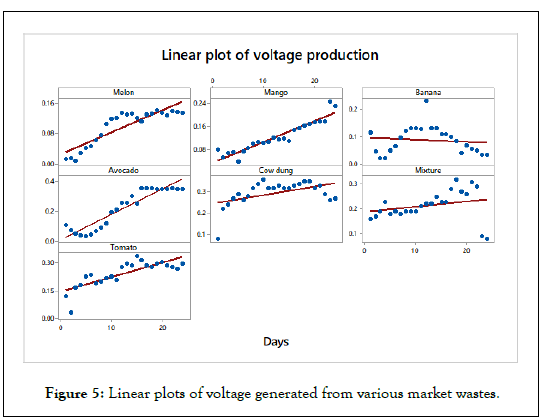

The main product of MFC is voltage generated from microbial breakdown of organic matter. The voltage generated was fitted into various kinetic models used to explain microbial activities. The models are linear, Gaussian and Gompertz models. In the linear model, it is assumed that voltage production rate will increase linearly with increase in time and after reaching a maximum point after sometime it would decrease linearly to zero with increase in time (Equation 1).

Where V is voltage generated, a and b are constant while t is the retention time. The fitted linear plots are shown in Figure 5. The linear fitness is indicated by R2 where in this case, mango fruit waste inoculated with rumen fluid was 0.9987 while for the other fruit wastes, the fitness ranged from 0.234 to 0.675 showing non –linear fitness.

Figure 5: Linear plots of voltage generated from various market wastes.

In addition, voltage production was simulated using Gompertz (Equation 2).

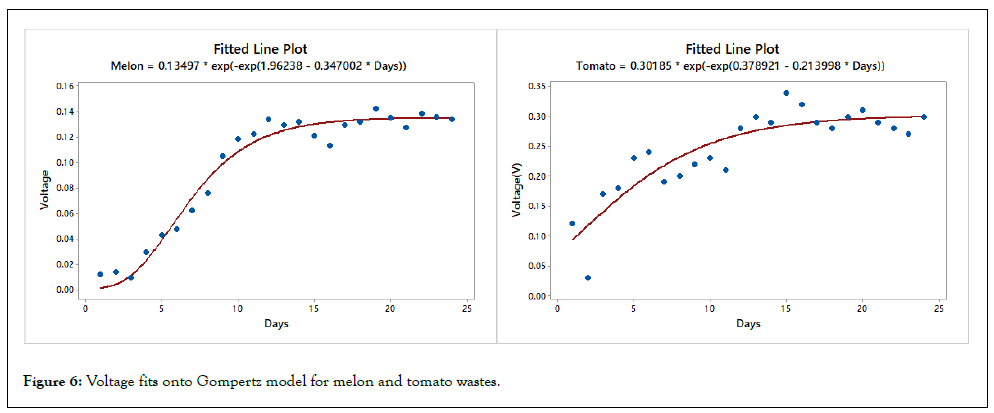

Where V is voltage, a, b and c are constants while t is the retention time in days. The experimental voltage generated by Proteus spp., clostridium spp, Proteus spp.+clostridium spp and rumen fluid microbes was fitted in linear and Gompertz growth models. The results obtained for melon and tomato are shown in Figure 6 where the fitness was observed to be 0.987 in melon compared to 0.786 in tomato wastes. The other fruits showed low regression values to Gompertz model in the range of 0.123 to 0.367 and therefore were unfit.

Figure 6: Voltage fits onto Gompertz model for melon and tomato wastes.

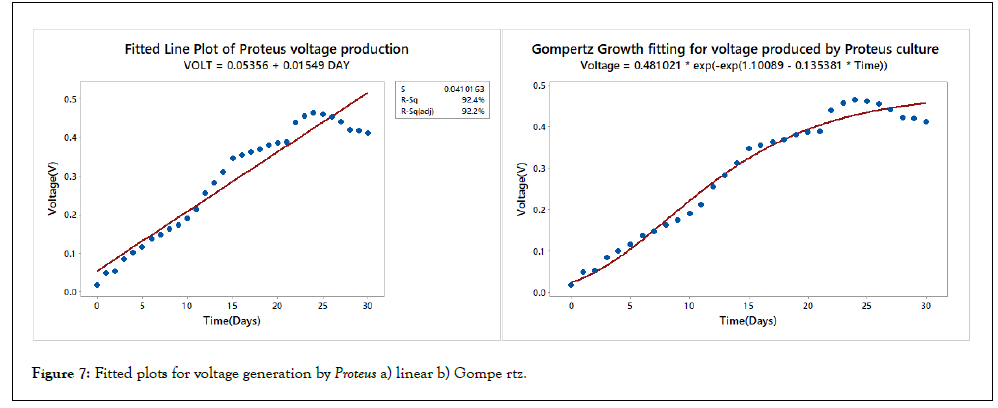

On modeling voltage from pure cultures, the daily voltage from Proteus spp. was fitted onto linear and Gompertz model as per equations 1 and 2 and the resultant plots are shown in Figure 7. The linear model showed a fitness value of 0.922 while Gompertz showed a fitness value of 0.976. This means that the voltage generated from the mixed market wastes inoculated with Proteus spp. can be explained by Gompertz model.

Figure 7: Fitted plots for voltage generation by Proteus a) linear b) Gompe rtz.

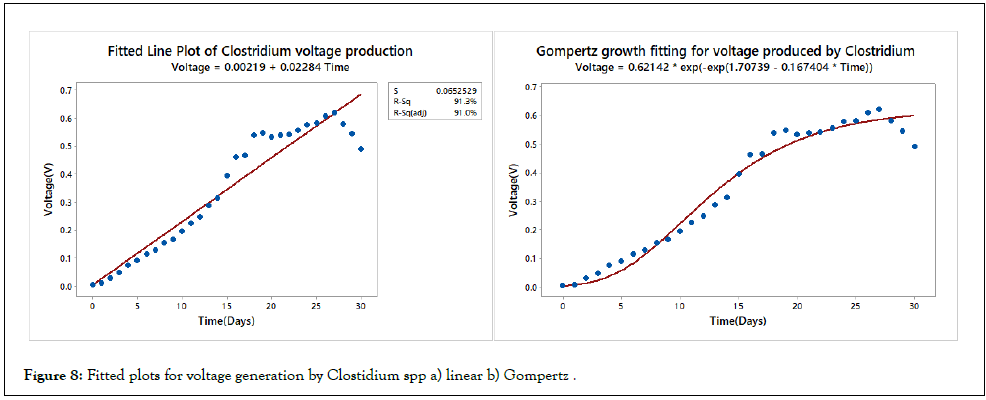

Similarly, the plots for the linear and Gompertz model for Clostridium spp is shown in Figure 8 where the fitness was 0.911 and 0.985 for linear and Gompertz model respectively.

Figure 8: Fitted plots for voltage generation by Clostidium spp a) linear b) Gompertz .

The results shown in Figure 7 shows that the growth of Proteus culture, which translates to voltage production is well explained by the Gompertz equation growth model with regression values of 0.967 compared to 0.922 obtained in linear data fitting. The same is well reflected by the simulating growth model of Clostridium spp. as shown in Figure 8. In both cases, the voltage generated from the pure cultures cannot be explained linearly due to low R2 of 0.911 and 0.962 for Clostridium spp and Proteus respectively compared to 0.96 and 0.98 for the Gompertz equation fitting.

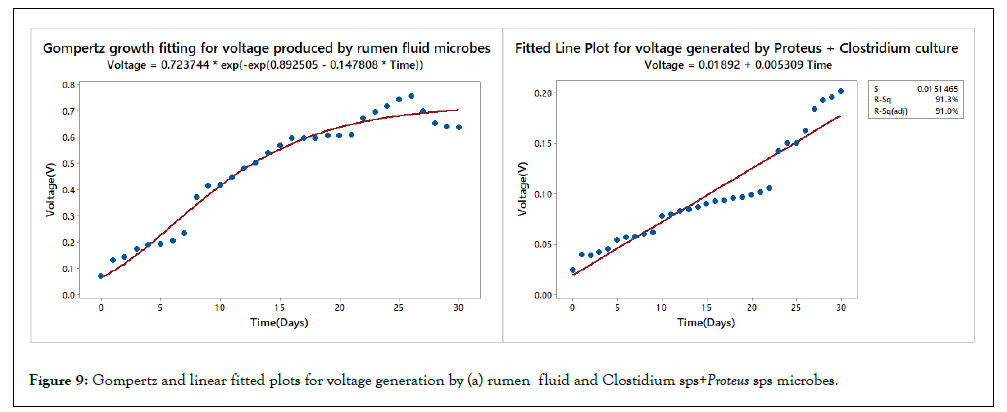

Figure 9 shows the best fits for the rumen fluid voltage and the Clostridium ssp.+ Proteus culture mix simulated models. The voltage produced from rotten tomato wastes by rumen fluid microbes is better explained by the Gompertz growth model while the mixed culture voltage fitted the linear model best. Only the best-fit curves are shown.

Figure 9: Gompertz and linear fitted plots for voltage generation by (a) rumen fluid and Clostidium sps+Proteus sps microbes.

The regression coefficient of the Clostridium spp.+Proteus spp. culture mix was 0.911 for linear plot compared to 0.87 for the Gompertz plot. This means that the Gompertz model should be employed in explaining electricity generation from MFC with a high concentration of microbes.

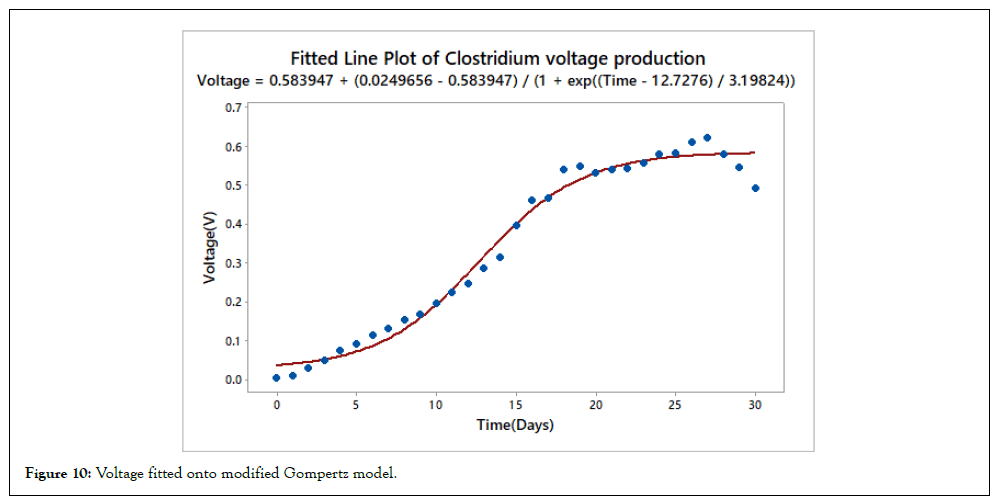

Finally, the voltage generated from mixed fruit market wastes was fitted onto modified Gompertz model depicted by equation 3 and Figure 5: Linear plots of voltage generated from various market wastes. the resulting plot is shown in Figure 10.

Figure 10: Voltage fitted onto modified Gompertz model

Conclusion

The MFC for rumen fluid inoculate registered the highest current (0.074 mA) explained by a higher microbe’s population resulting in a higher substrate breakdown rate. Low voltage was recorded in a mixed culture of Clostridium spp. and Proteus spp. compared to pure cultures. The Gompertz equation growth model was applicable, with regression values of 0.967 compared to 0.922 obtained in linear data fitting. The same was well reflected by the simulating growth model of Clostridium spp. Hence, the modified Gompertz model can be used to simulate voltage generation from different market wastes in MFC.

REFERENCES

- Head IM, Singleton I, Milner MG. Bioremediation; A critical review. 2003.

- Singh RP, Prasad V, Vaish B. Advances in Waste-to-energy Technologies. CRC Press. 2019.

- Barupal T, Meena M, Sharma K. Inhibitory effects of leaf extract of Lawsonia inermis on Curvularia lunata and characterization of novel inhibitory compounds by GC–MS analysis. Biotechnol Rep. 2019;23:e00335.

[Google Scholar], [Crossref], [Pubmed].

- Lovley DR. Analysis of the genetic potential and gene expression of microbial communities involved in the in situ bioremediation of uranium and harvesting electrical energy from organic matter. Omics. 2002;6(4):331-339.

[Google Scholar], [Crossref], [Pubmed].

- Mbugua JK. Fabrication and optimization of an effective anaerobic digester for biogas production using vegetable wastes from Wakulima and Kangemi Markets in Nairobi County, Kenya (thesis). 2021.

- Shahirah RS, Nur KBA, Umi AA, Aidee KK, Anwar J, Nadzreeq NM, et al. Enhancement of Bioelectricity Production from Soil Microbial Fuel Cell (SMFC) by Additional Glucose, Nutrient Broth and Escherichia coli bacteria. Jurnal Kejuruteraan SI. 2019;2(1):137-142.

- Kamau JM, Mbui DN, Mwaniki JM, Mwaura FB. Utilization of rumen fluid in production of bio–energy from market waste using microbial fuel cells technology. J Appl Biotechnol Bioeng. 2018;5(4):227-231.

- Kamau JM, Mbui DN, Mwaniki JM, Mwaura FB. Characterization of voltage from food market waste: microbial fuel cells. Int J Biotech Bioeng. 2018;4:3.

- Gagandeep K, Yadwinder SB, Kothari DP. Isolation and identification of bacteria’s from cattle dung used in microbial fuel cells to generate bioelectricity. Inter Refe J Rev Res. 2017;5(6): 2001-2348.

- Adegunloye DV, Adetuyi FC, Akinyosoye FA, Doyeni MO. Microbial analysis of compost using cow dung as booster. Pak J Nutri. 2007;6(5):506-510.

[Google Scholar], [Crossref].

- Gopinath LR, Christy PM, Mahesh K, Bhuvaneswari R, Divya D. Identification and evaluation of effective bacterial consortia for efficient biogas production. IOSR J Environ Sci Toxicol Food Tech. 2014;8(3):80-86.

[Google Scholar], [Crossref]

- Shiv K, Harash DK, Ghireesh BK. A study on electrical generation from cow dung using microbial fuel cells. J Biochem Tech. 2012;3(4):442-447.

- Nene. Utilizing traditional knowledge in agriculture, traditional knowledge of India and Sri Lanka. 1999:32-38.

- Sawant AA, Hegde NV, Straley BA, Donaldson SC, Love BC, Knabel SJ, et al. Antimicrobial-resistant enteric bacteria from dairy cattle. App Environ Microbio. 2007;73(1):156-163.

[Google Scholar], [Crossref], [Pubmed].

- Gupta KK, Aneja KR, Rana D. Current status of cow dung as a bioresource for sustainable development. Biores Biopro. 2016;3(1):1-1.

[Google Scholar], [Crossref].

- Sizar O, Unakal CG. Gram Positive Bacteria. In StatPearls. Stat Pearls Pub. 2021.

- Mathuriya AS, Sharma VN. Bioelectricity production from various wastewaters through microbial fuel cell technology. J Biochem Tech. 2010;2(1):133-137.

- Das A, Mondal C. Comparative kinetic study of anaerobic treatment of thermally pretreated source-sorted organic market refuse. J Engineer. 2015:1-15.

[Google Scholar], [Crossref].

- Fatemi S, Ghoreyshi AA, Najafpour G, Rahimnejad M. Bioelectricity generation in mediator-less microbial fuel cell: application of pure and mixed cultures. Iranica J. Energy Environ. 2012;3(2).

- Rismani-Yazdi H, Christy AD, Carver SM, Yu Z, Dehority BA, Tuovinen OH. Effect of external resistance on bacterial diversity and metabolism in cellulose-fed microbial fuel cells. Bioresour Technol. 2011;102(1):278-83.

[Google Scholar], [Crossref], [Pubmed].

- Rismani-Yazdi H, Carver SM, Christy AD, Tuovinen OH. Cathodic limitations in microbial fuel cells: an overview. J Power Sourc. 2008;180(2):683-694.

[Google Scholar], [Crossref].

- Ren Z, Steinberg LM, Regan JM. Electricity production and microbial biofilm characterization in cellulose-fed microbial fuel cells. Water Sci Technol. 2008;58(3):617-622.

[Google Scholar], [Crossref], [Pubmed].

- Chaturvedi V, Verma P. Microbial fuel cell: a green approach for the utilization of waste for the generation of bioelectricity. Biores Biopro. 2016;3(1):1-4.

[Google Scholar], [Crossref].

Citation: Mbugua JK, Mbui DN, Waswa AG, Mwaniki JM (2022) Kinetic Studies and Simulation of Microbial Fuel Cells Voltage from Clostridium Spp. and Proteus. J Microb Biochem Technol. 14:483.

Copyright: © 2022 Mbugua JK, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited