Indexed In

- Genamics JournalSeek

- JournalTOCs

- CiteFactor

- RefSeek

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Publons

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Research Article - (2023) Volume 12, Issue 2

Investigation of the Physical and Mechanical Properties of Scotch Pine and Oak Woods Modified with Natural Preservatives in the Aging Process

Mustafa Altunok* and Meryem UnverReceived: 25-Aug-2022, Manuscript No. JAME-22-17884; Editor assigned: 28-Aug-2022, Pre QC No. JAME-22-17884; Reviewed: 08-Sep-2022, QC No. JAME-22-17884; Revised: 04-Jan-2023, Manuscript No. JAME-22-17884; Published: 16-Jan-2023, DOI: 10.35248/2168-9873.23.12.465

Abstract

In this study, scotspine and oak wood, which are grown in large areas of our country, have high commercial value and are widely used at this rate, were modified with natural wood preservative solution. The protective feature of the modification material against temperature, humidity and sun rays in the external environment was investigated. Modification with a natural wood preservative solution was applied to B level samples of physical and mechanical property determination test samples prepared from scotch pine and oak woods. The natural preservative solution was obtained by extraction method from walnut bark and leaves. The preservative solution was impregnated with the samples by immersion for 8 hours. Impregnated (B level) and non-impregnated (A level) samples were kept in natural environment under seasonal effect for one year and natural aging was applied.

At the end of this process, the physical changes in the samples were examined by measurement and test method. As a result, it has been determined that wood preservative protects the physical and mechanical properties of both wood species, reduces the loss (change) in these properties, and reduces the shape deformation.

Keywords

Wood material; Scotch pine; Oak wood; Protection; Modification; Physical; Mechanical; Natural aging

Introduction

As long as the wood material used in external environments remains natural, it degrades in a short time. For this reason, wood material is modified with various protection methods and substances, increasing its resistance to external conditions. Some of those; these are treatments such as drying the wood, coating the upper surface with paint lacquer varnish, impregnation and heat treatment, and they protect the wood from outdoor conditions, decay, deformation and vermin attacks. However, it is known that methods and processes such as paint lacquer varnish and impregnation with various chemicals also spread their harmful effects on the environment while protecting the wood. From this point of view, environmentally friendly natural preservative solution obtained by extraction method from walnut tree bark, leaves and fruit wastes, which is widely grown in our country and encouraged to become more widespread by various government institutions due to the benefits of its fruit, is used as a modification agent. Walnut shell and leaves contain plenty of tannins. Pine, oak, chestnut and walnut woods, which naturally contain tannins, can withstand natural environmental conditions more than the woods of other tree species. Tannin is also traditionally used as a tanning agent in leather industry.

Wood material has an important place in human life. The need for wood material and its usage area are increasing day by day due to its many positive features and advantages such as being easy to process, insulating against sound and heat, being high resistance despite being light, being aesthetic compared to other materials [1]. In addition to the above mentioned positive features of wood, its flammability due to its being an organic material, its ability to be destroyed by insects, its decomposition by fungi, its change in dimensions due to the equilibrium humidity that changes depending on the temperature and relative humidity of the air, and its discoloration due to the effect of sunlight are considered to be its disadvantages [2]. It is important to protect the wood, which is exposed to external effects such as fungi, insects and ultraviolet rays of the sun, extend its life and increase its physical mechanical strength. One of the most common methods used to protect wood against these factors is impregnation [3].

In a study by Alen, et al., they applied heat treatment to spruce (Picea abies L.) wood at 180°C-225°C for 2-8 hours. In the chemical investigations of heat treated samples, it was determined that carbohydrates were exposed to more destructive reactions than lignin during heating [4]. Aydemir, et al., stated in their research that the color of the wood becomes darker and the biological resistance and dimensional stability are improved with treatments at temperatures of 150°C and above [5]. Korkut, et al., applied heat treatment to Maple (Acer trautvetteri Medw.) wood at different temperatures (120°C, 150°C, 180°C) and for different durations (2 hours, 6 hours, 10 hours). At the end of the experiment, they stated that the technological properties of the wood material decreased as the temperature and duration of the heat treatment application increased [6]. Bekhta, et al., investigated the mechanical properties, dimensional stabilization and color change of beech (Fagus orientalis L.) wood treated at high temperatures. At the end of the experiment, it was determined that the mechanical properties decreased, the dimensional stabilization of the wood increased and the color of the wood darkened with the increase in temperature. It has been determined that the average decrease in the bending strength of wood material treated at high temperature is around 5%-40%, and these values in the Modulus of Elasticity (MOE) are between 4% and 9% [7]. Laminated wood materials from western beech and scotch pine wood, glued with PVAc-D4 glue, were kept in four different environments in accordance with the principles specified in BS EN 205, and then tensile strength test was applied in accordance with the principles of DIN 53255. According to the test results, PVAc-D4 from Western beech wood (I: 18.8 N/mm2, II: 12.0 N/mm2, III: 9.3 N/mm2, IV: 15.1 N) in places with different atmospheric conditions. It has been stated that laminated wood material combined with/ mm2) glue can be used [8].

It has been reported that the surface treatment applied after the impregnation of coniferous trees that are pre-impregnated with some chromium containing impregnation materials increases the life of the surface treatment materials more than 2 times in outdoor conditions [9]. In the research where beech and poplar wood, Protim-WR 230, Tanalith-C and Celcure AC 500 impregnations, Desmodur-VTKA, urea formaldehyde and polyvinyl acetate glues were used, it was determined that the Tanalith-C impregnation material had the least effect on the adhesion resistance. In experiments, D-VTKA glue was found to be the glue that is least affected by moisture [10]. Scotspine and red pine samples were impregnated using various impregnation materials and the changes in their adhesion, bending, hardness and weight were investigated. It has been reported that the impregnation process reduces the adhesion and bending resistance of wood material, increases its density, decreases the hardness in scots pine and increases the hardness in red pine [11]. Vineeth, et al., have reviewed the crosslinking of Nano Cellulose (NC) to enhance the performance of wood adhesives in a study [12].

In the literature given above, there are studies on wood protection and impregnation. However, it is seen that the natural preservative to be used in this research is not among them. For this reason, scotspine and oak woods, which are grown in large areas, have high commercial value and are widely used at this rate, were modified with a natural wood preservative solution, and the protective properties of the modification material against the damaging effects of temperature, humidity and sun rays on the wood material in the external environment were investigated.

Material and Methods

Wood

Scotspine (Pinus sylvestris) and Sapless oak woods were used in the experiments. Test draft woods can be obtained from ankara timber site by random method. It is not made of natural colors of wood designs, non-insect and fungus proof; knot free, ridge free, growth defects, smooth fibrous and living wood.

Glue

In this research, polyurethane based Desmodur-VTKA glue was used. D-VTKA glue is from the condensation polymers class. Therefore, it is a water and moisture resistant, solvent free, single component adhesive with active substance. It gives good results in bonding wood, metal, polyester, stone, ceramic, PVC and other plastic materials. Relaxation is achieved at 3000 psi-5000 psi (204-340 atm.) at room temperature. The cohesive force of the polyurethane glue is better than the adhesion force. The thickness of the glue layer in bonding is between 2 mil-6 mil=0.05 mm and 0.15 mm. Its resistance to shear resistance is 8000 psi, and its adhesion resistance decreases at low temperatures (-217°C) and high temperatures (121.11°C). It is difficult to machine and shows very good resistance to shock impacts. Since it is resistant to the humidity of water and air, it is used especially in the assembly and repair of the elements on the outer surfaces of marine vehicles and buildings (30).

Preparation of test samples

The number of test and measurement samples used at each level in the research process and the tests and measurements applied to these samples are given in Table 1.

| Process/level | Physical and mechanical properties | Number of samples (C+A+B) | Sample sizes (mm) | Standard no. |

|---|---|---|---|---|

| Control (not aged) A level (aged) B level (aged) |

Density | 10 × 3=30 | 20 × 20 × 30 | TS ISO 13061-2 |

| Distortion | 10 × 3=30 | 15 × 120 × 240 | TS EN 1910 | |

| Bending resistance | 10 × 3=30 | 20 × 20 × 350 | TS ISO 13061-3 | |

| Modulus of elasticity | 10 × 3=30 | 20 × 20 × 350 | ISO 13061-4: 2014 | |

| Adhesion resistance | 10 × 3=30 | 15 × 20 × 150 | TS EN 13354 | |

| Screw holding resistance | 10 × 3=30 | 20 × 50 × 50 | BS EN 320: 2011 | |

| Hardness | 10 × 3=30 | 20 × 50 × 50 | ISO 13061-12 | |

| The overall total | 210 × 3=630 | |||

Table 1: Physical and mechanical properties and tests.

Preparation and impregnation of natural preventive care

Day and night with a protective design solution in liquid form with the green application method of the leaves and fruit of walnut trees that is based on immersion regulations. No control level and A level submissions were made. All samples were kept in the air conditioning device before and after they were placed outside, at 20°C temperatures and 65% relative humidity, until they reached equilibrium humidity (12%). The conditioning criterion places values after the control sample test has been applied. A level and B level specimens were placed on an inclined natural dating platform.

Natural aging application (12 months)

Samples modified (impregnated) by immersion (B level) and untreated A level samples were left to stand in open air conditions. For this purpose, the test samples were prepared for 1 year according to the principles specified in the ASTM G7 standard. In the garden of the faculty of technology, in the outdoor environment, the metal grid in an inclined position of 45° was placed on the platform properly and tied with a linen rope to prevent them from moving. The test samples placed on this platform were kept in the conditions of Ankara Meteorology station data for 1 year. Untreated and modified samples left to natural aging are given in Table 2.

| Control | A level | B level | |

|---|---|---|---|

| Not aged | X | ||

| Aged | X | X | |

| Note: Control: Untreated-not aged; A level: Unmodified-aged; B level: Modified-aged | |||

Table 2: Sample levels with and without aging and modification.

Experimental results

Within the scope of this research, physical and mechanical properties were determined by measuring and weighing method from control samples of each type of wood before aging and in samples of level A and level B of each type of wood after aging. In addition, the rates of change in these properties due to the interactions in the natural aging process are given below in tables and graphs.

Physical properties and rates of change

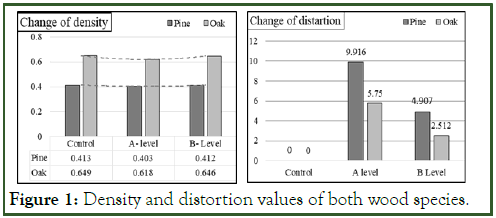

Density and distortion change: Density and distortion values obtained from control samples before aging and from A level and B level samples after aging are given in Table 3.

| Density | Control | A level | Changing (%) | B level | Changing (%) |

|---|---|---|---|---|---|

| Scotspine | 0.413 | 0.403 | -2.43 | 0.412 | -0.025 |

| Oak | 0.649 | 0.618 | -4.78 | 0.646 | -0.047 |

| Distortion | |||||

| Scotspine | - | 9.916 | 4.907 | ||

| Oak | - | 5.75 | 2.512 | ||

Table 3: Density and distortion values and rate of change in both wood types (%, mm).

Scotspine is known for its natural resin content and oak for its natural tannin content and wood species resistant to outdoor conditions. Therefore, they are preferred. However, the natural preservatives they contain are not sufficient to completely prevent the degrading effect of the external environment. In the natural aging process of A level scotspine samples, it is understood that high level deformation due to dehumidification and exposure to the sun's UV rays cause material loss on the outer surfaces of the sample. This situation negatively affected both the density and the distortion, the density decreased by 2.43%, and the maximum distortion, which is expressed as deviation from the plane, was 9.916 mm. Density and distortion were lower in oak than in scotspine. B level sample values in both wood species. It is seen that the natural tannin preservative solution protects the wood against outdoor conditions and reduces the density and distortion values. It can be said that this is due to the fact that the tannin molecules clinging to the fibrous walls of the wood by cross linking prevent excessive internal stress that will occur due to external environmental conditions. Density and distortion graphs of samples at different levels in both wood species are given in Figure 1.

Figure 1: Density and distortion values of both wood species.

Results and Discussion

Mechanical properties and rates of change

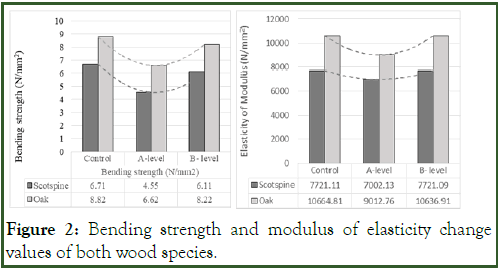

Bending strength and MOE change: Based on the bending strength values of the control samples that were not aged in both wood species, it was determined that there was a significant decrease in the bending strength of the aged A level samples. The most degraded by the aging process was 32.19% in scotspine and 24.9% in oak.

Flexural strength and modulus of elasticity are mechanical properties that act in parallel in a wooden element. The elastic modulus of the A level samples was adversely affected by the degrading external environment during the aging process, and decreased by 9.31% in scotspine and 15.49% in oak. The loss of bending strength and modulus of elasticity in B level samples from both wood species modified with natural wood preservative tannin solution decreased significantly and gave results close to the values obtained in the control samples. The bending strength loss is highest in B level scotspine; it was realized with a rate of 6.8% in oak with a rate of 8.9% modulus of elasticity; it remained the same in scotspine and oak, and the loss was at A level of one or two per thousand. It can be said that this is due to the fact that the natural tannin solution molecules cross-link with the cellulose molecules, and the UV rays of the sun weaken the cellulose molecule chains and prevent them from decomposing, and the flexibility that lignin provides to cellulose remains unchanged (Figure 2).

Figure 2: Bending strength and modulus of elasticity change values of both wood species.

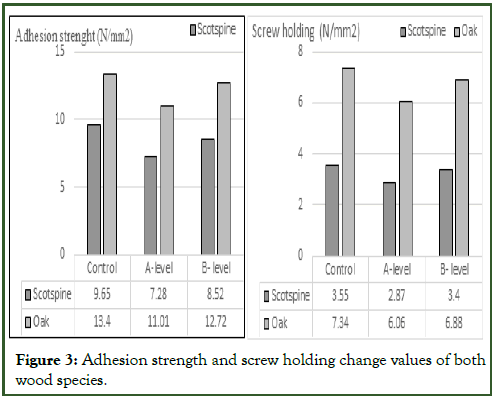

Adhesion strength and screw holding change: In the case of aging in a one year outdoor environment, loss of adhesion strength in A level samples without protective treatment; 24.55% in scotspine and 17.83% in oak. It has been determined that the loss of screw holding strength is in scotspine 19.15% and oak 17.43%. It can be said that this is due to the operation during dehumidification (inner cracks formation in the glue joint) in both wood species during the aging process and the UV rays of the sun to degrade the glue grout and wood texture (Figure 3).

Figure 3: Adhesion strength and screw holding change values of both wood species.

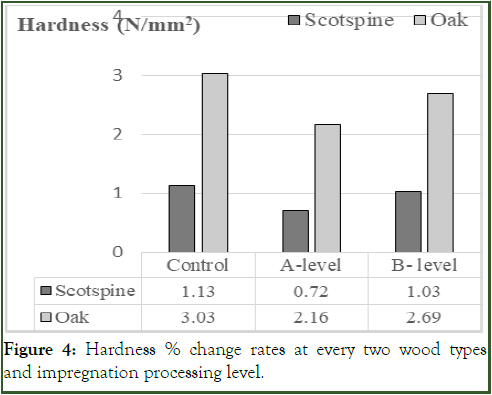

Hardness: In the case of ages of one year on the outside, the hardness values of the control samples are taken into consideration. Hardness loss of scotspine 33.6% and oak 28.7% occurs in the untreated A level samples.

Hardness loss decreases to 9% in scotspine B level and 11% in oak B level. The best hardness was determined to be the protective B level impregnation solution. Pine hardness change is less than oak (Figure 4 and Table 4).

Figure 4: Hardness % change rates at every two wood types and impregnation processing level.

| Properties | A-level | B-level | ||

|---|---|---|---|---|

| Scots pine | Oak | Scots pine | Oak | |

| Density | -2.43 | -4.78 | +0.025 | +0.047 |

| Distortion | 9.91 mm | 5.75 mm | 4.9 mm | 2.51 mm |

| Bending | -24.55 | -17.83 | -8.9 | -6.8 |

| MOE | -9.3 | -34.2 | -0.1 | -0.2 |

| Adhesion | -24.5 | -17.8 | -11.7 | -5.1 |

| Screw holding | -19.15 | -17.43 | -4.2 | -6.2 |

| Hardness | -36.28 | -28.71 | -8.84 | -11.22 |

Table 4: Properties change % ratios by wood type and modification level.

Conclusion

The values of some physical and mechanical properties were compared in A level samples that were kept in the aging process for one year and A and B samples that were preserved.

• In this comparison, the physical and mechanical properties values of the non-preserved A level specimens have been found to decrease in significant quenching and increase in deformation (distortion and cracking) in these specimens.

• The loss of physical and mechanical property values of the preserved B level samples is significantly reduced (B is best level) and close to the control level values.

• In the aging process of the B level protective solution, it can be suggested that the B level natural tannin solution can be used primarily that does not damage the environment.

Acknowledgement

This research is supported by Gazi university scientific research center.

Conflict of Interest

No conflict of interest was declared by the authors.

References

- Ozalp M. Investigation of physical, mechanical and chemical characteristics change of water repellent and preservative treated pine specimens and their use water cooling towers. Doctoral dissertation, Ph. D. Thesis, Zonguldak Karaelmas University, Institute of Science and Technology, Zonguldak, Turkey. 2003;10-12. [Google Scholar]

- Alen R, Kotilainen R, Zaman A. Thermochemical behavior of Norway spruce (Picea abies) at 180°C–225°C. Wood Sci Technol. 2002;36(2):163-71. [Crossref] [Google Scholar]

- AydeiIr D, Gunduz G. The effect of heat treatment on physical, chemical, mechanical and biological properties of wood. BAROFD. 2009;11(15):71-81. [Google Scholar]

- Korkut S, Kok MS, Korkut DS, Gürleyen T. The effects of heat treatment on technological properties in Red-bud maple (Acer trautvetteri Medw.) wood. Bioresour Technol. 2008;99(6):1538-1543. [Crossref] [Google Scholar] [PubMed]

- Bekhta P, Niemz P. Effect of high temperature on the change in color, dimensional stability and mechanical properties of spruce wood. Holzforschung. 2003;57(5):539-546. [Crossref] [Google Scholar]

- Atar M, Ozcifci A. On the bonding strength of laminated wood materials produced from European beech (Fagus Sylvatica) and scots pine (Pinus Sylvestris Lipsky) glued with Polyvinyl Acetate (PVAc)-D4 Adhesive. Zonguldak Karaelmas University: Tech Educ Fac Technol J. 2005;8(4):305-331. [Google Scholar]

- Feist WC. Protection of wood surfaces with chromium trioxide. Research Paper FP, Forest Products Laboratory, Forest Service, US Department of Agriculture. 1979:19-20. [Google Scholar]

- Vineeth SK, Gadhave RV, Gadekar PT. Chemical modification of nanocellulose in wood adhesive. Open J Polym Chem. 2019;9(4):86-99. [Google Scholar]

- Tomak ED, Ustaomer D, Yildiz S, Pesman E. Changes in surface and mechanical properties of heat treated wood during natural weathering. Measurement. 2014;53:30-39. [Crossref] [Google Scholar]

- Tesarova D, Capikova A, Jerabkova E, Cech P, Ekielski A, Mishra PK. Effect of ethylene oxide sterilization and accelerated ageing on the physical and mechanical properties of beech, oak, and elm wood: Part 1. BioResources. 2018;13(4):8251-8262. [Google Scholar]

- Piernik M, Wozniak M, Pinkowski G, Szentner K, Ratajczak I, Krauss A. Color as an indicator of properties in thermally modified scots pine sapwood. Materials. 2022;15(16):5776. [Crossref] [Google Scholar] [PubMed]

- Dong Y, Liu X, Liu J, Yan Y, Liu X, Wang K, et al. Evaluation of anti-mold, termite resistance and physical-mechanical properties of bamboo cross-linking modified by polycarboxylic acids. Construct Build Mater. 2021;272:121953. [Crossref] [Google Scholar]