Indexed In

- Open J Gate

- Genamics JournalSeek

- JournalTOCs

- China National Knowledge Infrastructure (CNKI)

- Electronic Journals Library

- RefSeek

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- SWB online catalog

- Virtual Library of Biology (vifabio)

- Publons

- MIAR

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Research Article - (2023) Volume 14, Issue 5

Experimental Investigation on Impact of Compression Ratio on Performance Characteristics and Emissions Characteristics of Mixture of Soybean and Sunflower Biodiesels

Shiva Kumar Reddy Devasani*Received: 02-May-2023, Manuscript No. JPEB-23-21190; Editor assigned: 05-May-2023, Pre QC No. JPEB-23-21190 (PQ); Reviewed: 19-May-2023, QC No. JPEB-23-21190; Revised: 03-Jul-2023, Manuscript No. JPEB-23-21190 (R); Published: 10-Jul-2023, DOI: 10.35248/2157-7463.23.14.537

Abstract

Extensive fossil fuel consumption led to extinction of fossil fuels. The rapid increment in demand for energy is a major concern added on with the emission issues. This lead to find a way for clean energy. The bio diesel's potentiality is being well analysed by the researchers. In the previous work, the performance of various ternary blends formed with soybean and sunflower biodiesels along with diesel were analysed. It is found that the blend of 70% diesel 15% sunflower biodiesel and 15% soybean biodiesel gives the optimum performance over the other blends. Hence, in this work the performance of this blend in a VCR CI engine is studied at different compression ratios. The performance of this blend is found to be superior at the compression ratio 18. The efficiencies are found to be superior at CR 18. In case of emission analysis, the smoke opacity, carbon monoxide and hydro carbon emissions are lowest at CR 18. Oxygen, carbon dioxide and nitrogen oxide emissions are high for CR 18. The overall analysis proves that the compression ratio of 18 is the optimum operating condition for this blend to get the superior performance from a CI engine without any modification.

Keywords

Soybean; Sunflower; Diesel; Biodiesel; CI engine; Variable compression; Ternary blend; Fossil fuel

Introduction

With the depletion of conventional fuels, researchers are working to find an alternate energy source. It was found that the biodiesel is a potential energy source which can replace the conventional fuel [1]. Biodiesel can solve the issues regarding the energy supply, sustainability and environmental concerns [2]. With the increasing fuel prices, it is required to reduce the fossil fuel dependency. When the conventional diesel is mixed with the biodiesels, it leads to increased availability of fuel and reduced emissions. Hence researchers are investigating the emissions as well as performance of the IC engine with different blends of biodiesel [3]. On contrary to this, NOx emissions is the concern for using bio diesel in IC engine. In the past few decades the researchers are adopting different methods such as EGR method, investigations on strategies related to fuel injection and analyzing the effect of ternary blends [4].

Medhat Elkelawy, et al., investigated the performance along with emissions of sunflower and soybean bio diesel mixture on a diesel engine. It was reported that the biodiesel mixed in 30, 50 and 70% by volume given a decrement in emissions of HC, CO and CO2 by 1.8% to 4.2%, 2.5% to 10% and 6% to 14% respectively. It was stated that there was an increment in fuel consumption by 2.5% to 11.5% [5]. Lahane S, et al. worked about emissions along with performance of CI engine with various biodiesel-diesel mixtures. Authors reported a diminishment in smoke as well as other emissions with rise in content of biodiesel in the mixture [6]. Sharad, et al. analyzed the impact of biodiesel mixtures. The BSFC and mechanical efficiency were superior in respect to diesel with 3.5 and 4.5% [7]. Mubarak, et al. investigated the combustion as well as performance characteristics of Salvinia molesta oil biodiesel blends. It was reported that the maximum BTE and minimum BSFC was found with the blend of 20% biodiesel. Also stated that there was a great reduction of emissions [8]. In a study, Sukran Efe, et al. engine characteristics of biodiesels from five different biodiesels derived from canola, corn, soybean hazelnut and sunflower oils were analyzed. Biodiesels combined with fossil diesel fuel in various ratios and B100, B50 and B20 biodiesel mixtures were prepared. The SFC of mixtures was more than that of the diesel. It's rate of increment diminishes with engine speed inversely. Thermal efficiency of engine is commonly diminishing when fueled with biodiesel. But it is found that thermal efficiency increased, despite the increase in SFC with the use of B100. The increased efficiency was due to greater O2 content of 100% bio diesel. The imep of conventional diesel is found to be 1360000 Pascals. The emissions were decreased approximately to 6%. Maximum pressure when diesel used is 6228 kPa. And it is found to be decreased for all biodiesels [9]. Dilip, et al., conducted study on the diesel engine performance fueled with bio diesel produced from a multiple feedstock. Properties of the bio diesel obtained from multiple feed stock and also the individual biodiesels namely Polonga and Koroch biodiesels and Jatropha biodiesel found to be satisfying different biodiesel standards biodiesel of mixed feedstock is having better physical properties than that of individual biodiesels. Also with respect to transport and handling, biodiesel of mixed feedstock has an advantage over the other single biodiesels. Diesel engine fueled with mixed feedstock biodiesel gave better results than the single biodiesels. The BSFC for the mixed biodiesel is 3.6% less than Polonga biodiesel, 0.5% less than Koroch biodiesel and 3.6% less than Jatropha biodiesel at rated load. The engine thermal efficiencies fueled with mixed feed stock biodiesel are 0.61% higher than polonga biodiesel, 2.81% higher than Koroch biodiesel and 0.53% higher than Jatropha biodiesel at rated load. Also, it has given less exhaust emissions than that of individual bio diesels. When this biodiesel of mixed feedstock is blended with diesel and this B20 fueled engine shown much better performance and less emissions than that of Polonga, Koroch and Jatropha biodiesels. Existing diesel engine design and apparatus need not to be modified significantly for using this biodiesel of mixed feedstock as a fuel [10]. Sudalaiyandi K, et al. carried out a study on the emissions as well as performance characteristics of ternary blends of linseed and rubber seed oil. The paper states that the ternary biodiesel blends with rubber seed oils were prepared and engine was then fueled with them. The observations from this investigation show showed that both ternary blends of two different composition have equivalent characteristics like diesel. In equal conditions of load, the engine performance was found to be increased. The calorific value of first type of ternary blend is 42.2 MJ/kg and second type is 42 MJ/kg. The cetane number is also found to be equivalent to diesel, 51 for first type blend and 52 for second type. NO2 and Co missions were found to be less than that of diesel. These two blends can be selected as an alternative fuel for engine without modifying the engine [11]. The review papers published by Ramadhas, et al.; Shahabuddin, et al. gives an overview of biodiesel fuels' applicability [12].

In our previous work, the performance as well as emission characteristics of ternary blends of soybean and sunflower biodiesels along with diesel were analyzed. A total of ten different blends were prepared according to volume ratios and tested on a compression ignition engine. Among all the blends tested, the mixture 70% diesel 15% sunflower biodiesel and 15% soybean biodiesel gave an optimum performance with superior thermal efficiency. The tests were conducted at a compression ratio of 18.

As it was evident that the CR significantly impacts the performance, this work was focused on investigating the compression ratio impact on the performance of the blend. The performance of the ternary blend was analyzed at four variable compression ratios of 18,17,16 and 15.

Materials and Methods

Experimental setup

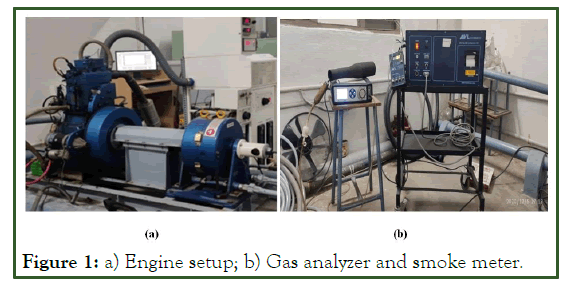

Experimental investigation was conducted on a 4 stroke 1 cylinder water cooled variable compression ratio multi fuel direct injection engine. Setup has a rated power of 3.5 kW@1500 rpm. The cylinder bore is 87.50 mm and stroke length is 110.00 mm. Length of connecting rod is 234.00 mm, and has orifice diameter 20.00 mm.

Figure 1: a) Engine setup; b) Gas analyzer and smoke meter.

The engine was connected with dynamometer for the application of variable loads. An emission analyzer was used to determine the emission levels and a smoke meter was used to determine the smoke levels. Different thermocouples were used to find the temperatures at different engine locations. Suitable measurement systems were provided for air and fuel flow rates measurement. The emissions and smoke values were recorded at different loads. The engine was made to run for sufficient time for accuracy. The excess fuel after experiment was drained and removed using drain valve. The measurement readings were directly fed into a computer system which were noted automatically in the system. Emissions and smoke readings were taken manually.

The setup consists of sensors and instrumentation to sense and record parameters such as temperatures, pressures, fuel consumption, etc. The test is carried out with different compression ratios with variation in load at same speed on the engine.

Blend preparation

The ternary blend of sunflower biodiesel, soybean biodiesel and diesel with a ratio of 15:15:70 by volume was selected for this investigation with regard to the previous work. The blend was made by mixing the fuels in required ratio and mixed with the stirrer. The blend properties illustrated in Table 1.

| Property | Diesel (100%) | Sunflower biodiesel (100%) | Soybean biodiesel (100%) | D70X15Y15 |

|---|---|---|---|---|

| Density (gm/cm3) | 838 | 705 | 822 | 950 |

| Calorific value (kJ/kg) | 45000 | 40891 | 40565 | 41820 |

Table 1: Thermal properties of the fuels.

Results and Discussion

Performance analysis

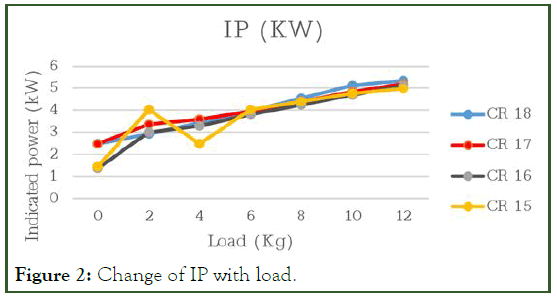

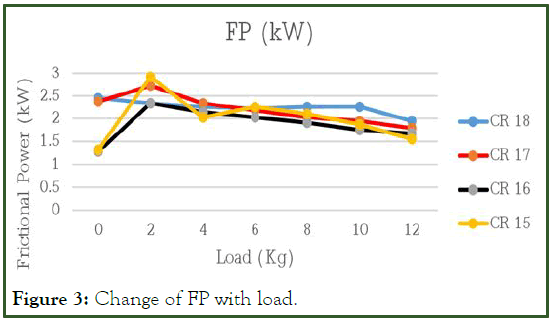

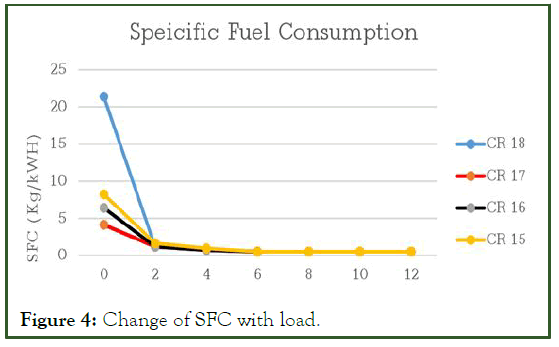

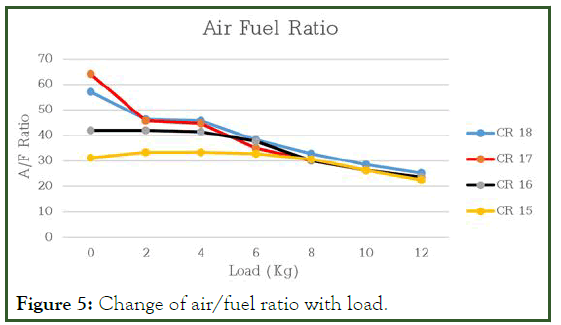

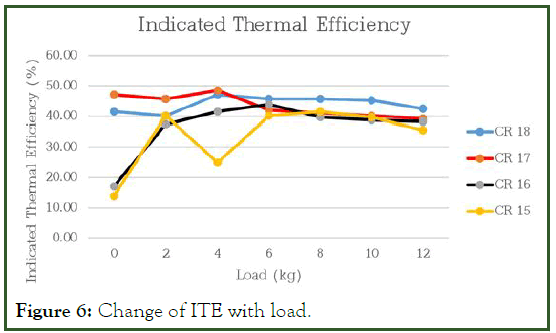

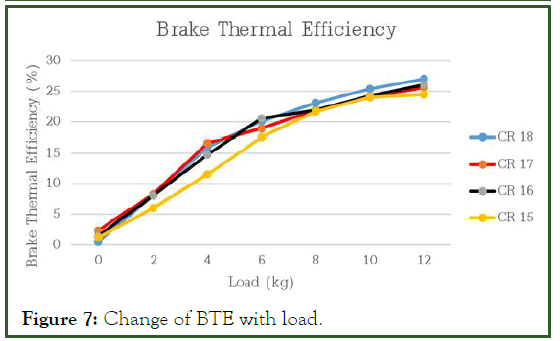

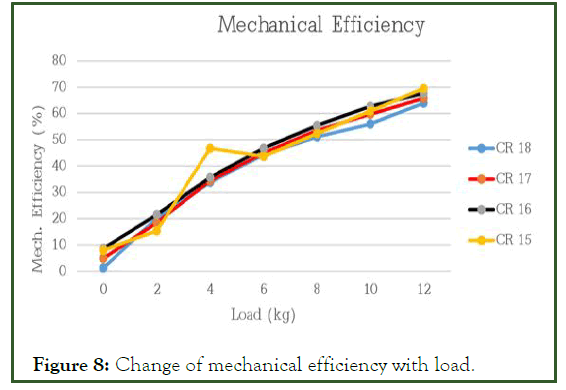

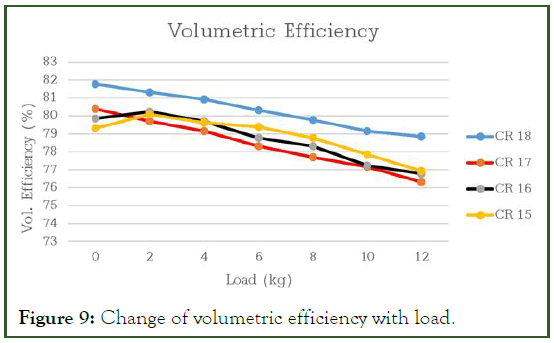

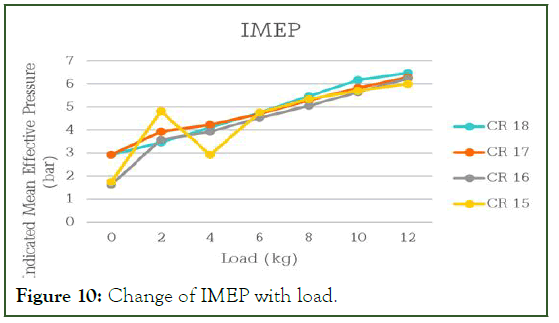

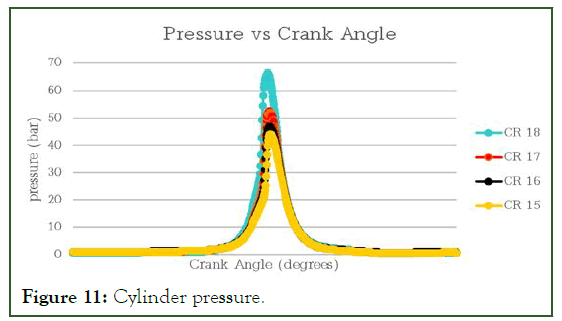

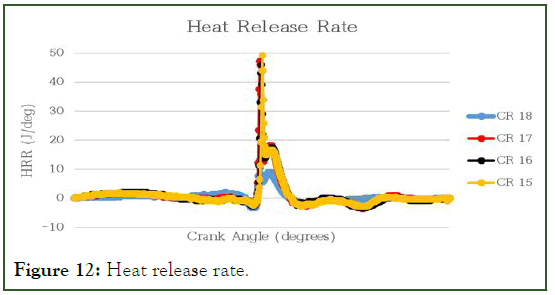

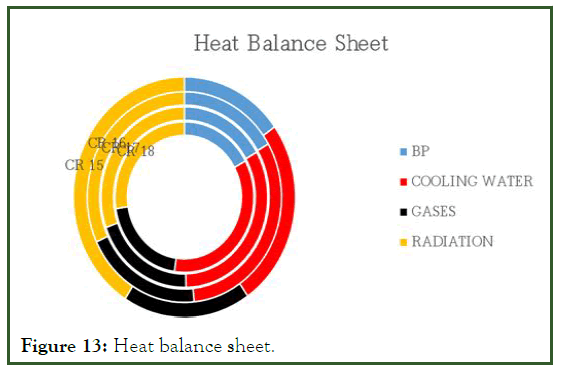

Figures 2 and 3 represents the variation in indicated power and frictional power in respect to load. The indicated power was found to be increased with respect to load and the frictional power decreased with load. It can be inferred from the figure that indicated power was superior at compression ratio of 17 upto half of the load and with further increase in load, the indicated power at CR 18 was superior. The average indicated power at CR 18 and 17 was found to be about 3.93 kW and 3.91 kW. It indicates that the blend produces high amount of energy when fuelled to engine at CR 17 and 18. The average IP for the CR 16 and 15 was about 3.6 and 3.68 kW respectively. The friction power was highest at CR 18 which is 2.22 kW average and lowest at CR 16 which was 1.85 kW. The average brake power was found highest at CR 16. Figures 4 and 5 represents the variation in fuel consumption and the air/fuel ratio for the blend in respect of load at different CRs. It can be analysed that the fuel consumption along with air fuel ratio decrease with respect to load. It was found that the fuel consumption and air/ fuel ratio were inversely proportional to the brake power. It was due to that sfc depends on bp and air/fuel ratio was the function of load. It was observed that the sfc was high at compression ratio 15 which was 0.63 kg/kWh average and low for compression ratio 18 that was 0.511 kg/kWh average. The air fuel ratio was found to be lower at compression ratio of 15 by about 29.95 averages and higher at compression ratio 16 by about 40.19 averages. Figures 6 and 7 represents both thermal efficiencies of the blend at different compression ratios. The brake thermal efficiency was reported to be increased with load as it was the function of bp. It was found that thermal efficiencies for the blend at CR 17 are superior upto half of the rated load. With further increase in load they were found to be reduced for CR 17 and found to be superior for CR 18. On an average the high thermal efficiencies were found to be 43.69% and 19.8% at CR 18. The thermal efficiencies were observed to be lower for CR 15 at all loads. Figures 8 and 9 represents the mechanical and volumetric efficiencies at different compression ratios. It was evident that the mechanical efficiency was high for the blend at compression ratio 16 with average of 48.11% and at compression ratio 18, the volumetric efficiency was superior relative to all other compression ratios with an average value of 80.26%. Figures 10 and 11 illustrates the indicated mean effective pressure and cylinder pressure for different compression ratios. The imep graph shows similar trend as the indicated power. The IMEP was seen to be superior with average of 4.74 bar. From the pressure vs. crank angle graph it can be inferred that maximum cylinder pressure decreases with decrease in compression ratio. Figures 12 and 13 represents heat release rate and the heat balance sheet at various compression ratios. It can be seen that the net heat release rate was superior at CR of 15 with average value of 49 joules per degree of crank angle. From heat balance sheet, we can analyse the at CR of 18 the heat equivalent brake power was found to be superior at an average of 19.8%.

Figure 2: Change of IP with load.

Figure 3: Change of FP with load.

Figure 4: Change of SFC with load.

Figure 5: Change of air/fuel ratio with load.

Figure 6: Change of ITE with load.

Figure 7: Change of BTE with load.

Figure 8: Change of mechanical efficiency with load.

Figure 9: Change of volumetric efficiency with load.

Figure 10: Change of IMEP with load.

Figure 11: Cylinder pressure.

Figure 12: Heat release rate.

Figure 13: Heat balance sheet.

Emission analysis

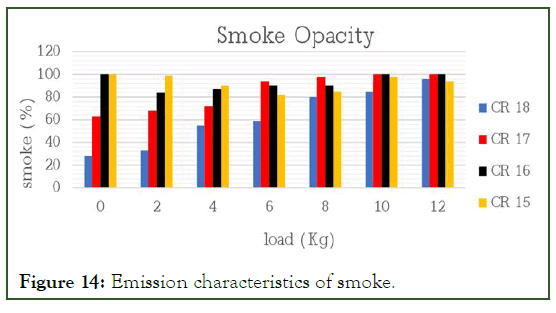

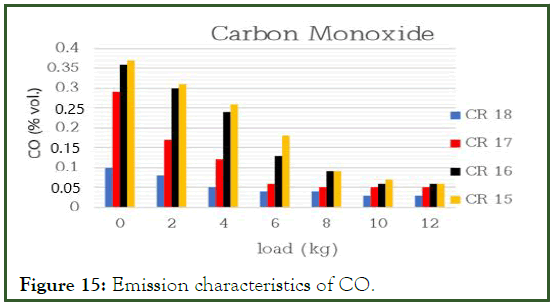

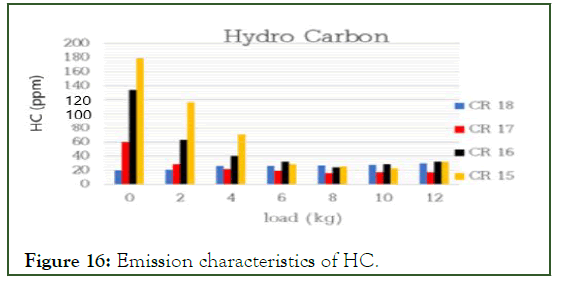

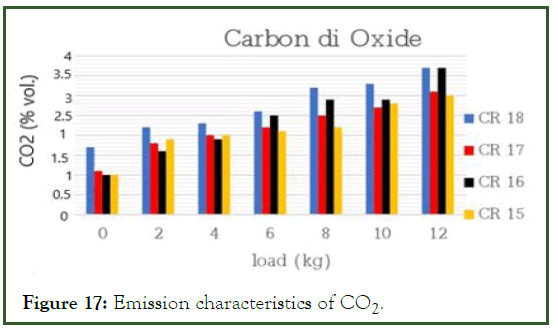

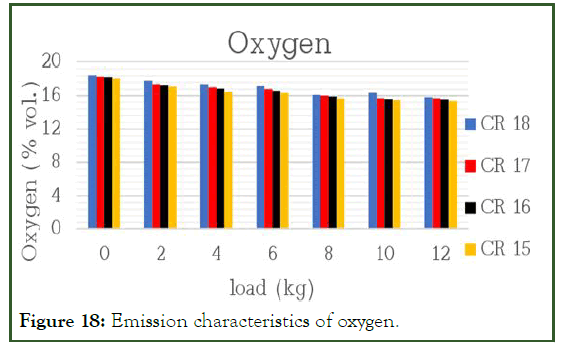

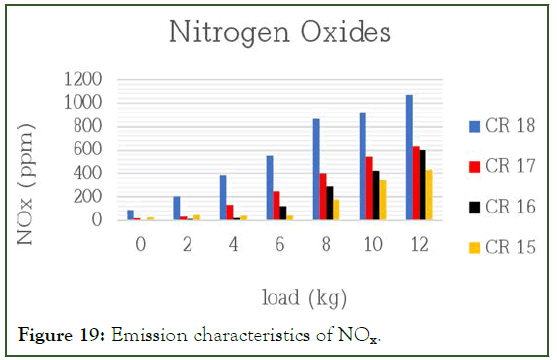

Figures 14 and 15 indicates the smoke opacity and CO emissions in respect of load for various compression ratios. It was seen that with the load increment, the smoke opacity also incremented. On other hand, the carbon monoxide emissions decreased with the increase in load. Also the smoke opacity and CO emissions are found to be inversely proportional to the compression ratio. When compression ratio decreased, the smoke opacity and CO emission increased. Both smoke opacity and CO emissions were found to be less at compression ratio of 18. Figures 16 and 17 illustrates the change in hydrocarbon and carbon di oxide emissions with load for different CRs. The hydrocarbon emissions have decreased with respect to load for all compression ratios. And it was seen that at compression ratio of 17, the hydrocarbon emissions were lowest relative to other compression ratios. The CO2 emissions were seen to be increasing with load. From the graph it can be inferred that the CO2 emissions were less for low compression ratio and high for higher compression ratio. Figures 18 and 19 show the variation of oxygen content and nitrogen oxides. It can be seen that the oxygen decreased with increment in load and NOx emissions raised with load. This was because of the reason that the high oxygen content of biodiesel was being utilized to form the nitrogen oxide emissions. It was found that at compression ratio of 18 both oxygen and nitrogen oxide emission were found to be high and at compression ratio of 15, both were lowest. Hence it can be concluded that the oxygen and nitrogen oxides in emissions were directly proportional to the compression ratio.

Figure 14: Emission characteristics of smoke.

Figure 15: Emission characteristics of CO.

Figure 16: Emission characteristics of HC.

Figure 17: Emission characteristics of CO2.

Figure 18: Emission characteristics of oxygen.

Figure 19: Emission characteristics of NOx.

Conclusion

An investigation was conducted on the performance along with emission characteristics evaluation for the ternary mixture of diesel, sunflower biodiesel and soybean biodiesel on a CI engine at a CR of 18 in the previous work. From that work, it was concluded that the blend having sunflower and soybean biodiesels with 15% ratio by volume each and rest diesel, has superior performance characteristics. Hence the present work was to evaluate the performance and emission characteristics pertaining to this blend at different compression ratios to find out the optimum compression ratio and following conclusions were drawn.

• The indicated power was found to be directly proportional to

the compression ratio and superior indicated power was found

to be average of 3.93 kW at CR 18. Highest brake power and

lowest frictional power are found at CR 16 with average of

1.75 and 1.85 kW.

• The thermal and mechanical efficiencies were found to be

superior at CR 18 and the thermal efficiencies decrease with

decrease in load.

• Specific fuel consumption was lowest at CR 18 and highest at

CR 15.

• The smoke and CO emissions were lowest at CR 18 and

increased with load and CR.

• The HC and CO emissions were found to be lowest and

highest at CR 18 respectively.

• The oxygen and nitrogen oxides were found to be highest for

CR 18 and decreased with decrease in CR and load.

Hence it is evident that the ternary blend of 15% sunflower biodiesel, 15% soybean biodiesel and 70% diesel composition produces desired and promising results at the compression ratio of 18 in a CI engine without any modifications.

References

- Devasani SK, Vodnala S, Singarapu D, Nair JN. A comprehensive review on performance, combustion and emissions of ternary and quaternary biodiesel/diesel blends. Environ Sci Pollut Res Int. 2022;29(34):51083-51094.

[Crossref] [Google Scholar] [PubMed]

- Pramanik K. Properties and use of Jatropha curcas oil and diesel fuel blends in compression ignition engine. Renew Energ. 2003;28(2):239-248.

- El Shenawy EA, Elkelawy M, Bastawissi HA, Panchal H, Shams MM. Comparative study of the combustion, performance, and emission characteristics of a direct injection diesel engine with a partially premixed lean charge compression ignition diesel engines. Fuel. 2019;249:277-285.

- Gad MS, El-Shafay AS, Hashish HA. Assessment of diesel engine performance, emissions and combustion characteristics burning biodiesel blends from jatropha seeds. Process Saf Environ Prot. 2021;147:518-526.

- Elkelawy M, Bastawissi HA, Esmaeil KK, Radwan AM, Panchal H, Sadasivuni KK, et al. Experimental studies on the biodiesel production parameters optimization of sunflower and soybean oil mixture and DI engine combustion, performance, and emission analysis fueled with diesel/biodiesel blends. Fuel. 2019;255:115791.

- Lahane S, Subramanian KA. Effect of different percentages of biodiesel–diesel blends on injection, spray, combustion, performance, and emission characteristics of a diesel engine. Fuel. 2015;139:537-545.

- Mubarak M, Shaija A, Suchithra TV. Experimental evaluation of Salvinia molesta oil biodiesel/diesel blends fuel on combustion, performance and emission analysis of diesel engine. Fuel. 2021;287:119526.

- Efe S, Ceviz MA, Temur H. Comparative engine characteristics of biodiesels from hazelnut, corn, soybean, canola and sunflower oils on DI diesel engine. Renew Energ. 2018;119:142-151.

- Bora DK, Baruah DC, Das LM, Babu MK. Performance of diesel engine using biodiesel obtained from mixed feedstocks. Renew Sustain Energy Rev. 2012;16(8):5479-5484.

- Sudalaiyandi K, Alagar K, VJ MP, Madhu P. Performance and emission characteristics of diesel engine fueled with ternary blends of linseed and rubber seed oil biodiesel. Fuel. 2021;285:119255.

- Shahabuddin M, Liaquat AM, Masjuki HH, Kalam MA, Mofijur M. Ignition delay, combustion and emission characteristics of diesel engine fueled with biodiesel. Renew Sustain Energy Rev. 2013;21:623-632.

- Ramadhas AS, Jayaraj S, Muraleedharan CJ. Use of vegetable oils as IC engine fuels-a review. Renew Energ. 2004;29(5):727-742.

Citation: Devasani SKR (2023) Experimental Investigation on Impact of Compression Ratio on Performance Characteristics and Emissions Characteristics of Mixture of Soybean and Sunflower Biodiesels. J Pet Environ Biotechnol. 14:537.

Copyright: © 2023 Devasani SKR. This is an open access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.