Indexed In

- Open J Gate

- Genamics JournalSeek

- ResearchBible

- Electronic Journals Library

- RefSeek

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- SWB online catalog

- Virtual Library of Biology (vifabio)

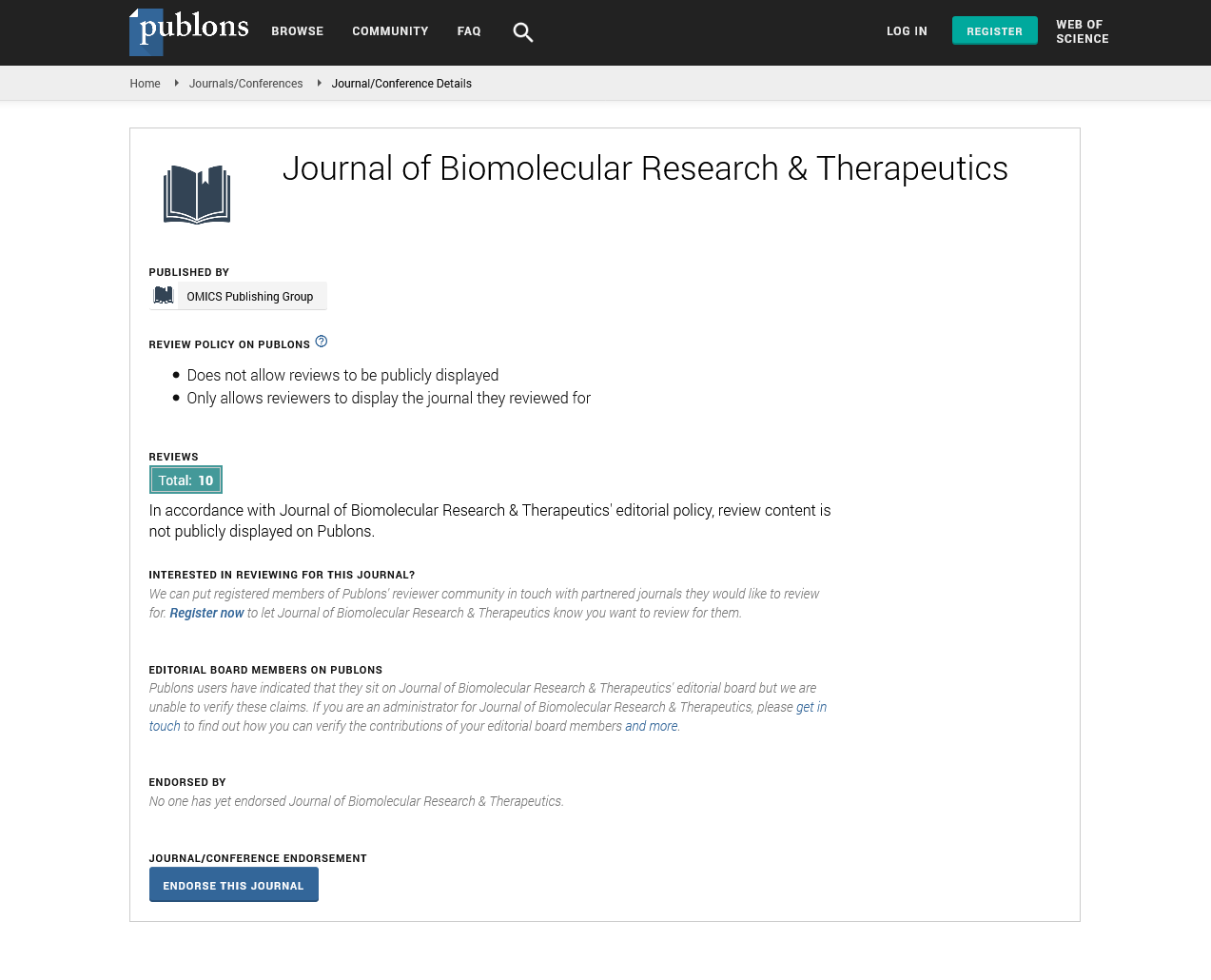

- Publons

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Editorial - (2021) Volume 10, Issue 7

Editorial Note on Synthetic Fibres

Robert Kale*Received: 04-Jul-2021 Published: 14-Aug-2021, DOI: 10.35248/2167-7956.21.10.166

Editorial

Manufactured filaments are man-made strands, the vast majority of them are ready from crude material petrol called petrochemicals. All textures are gotten from filaments, while strands are acquired from fake or man-made sources. They comprise of a little unit or a polymer which is produced using many rehashing units known as monomers. They incorporate nylon, acrylics, polyurethane, and polypropylene. A huge number of huge loads of these strands are delivered all around the world every year.

The cutting edge material industry is incomprehensible today without manufactured strands. Man-made filaments like silk have consistently been enormously esteemed for its gleam and fineness. Man-made strands are smooth. They can be recognized by taking a gander at a cross-area.

Some manufactured strands are recorded beneath.

• Rayon

• Nylon

• Polyester

This fiber discovers its applications in family articles like ropes, can, furniture, and so forth.

Manufactured filaments are produced using little particles combined polymers. The substances used to deliver such strands are separated from crude materials, for example, synthetic compounds dependent on oil or petrochemicals. Such materials are polymerized into a substance that integrates two adjoining iotas of carbon.

Fiber-built up polymer composites are significant in different fields from family articles to autos. Regular and manufactured filaments have minimal expense, light weight, and have high explicit and mechanical strength. Normal filaments have constraints in various applications because of dampness ingestion and low warm soundness. The dampness content makes an obstacle for fiber/tar great holding in composites. Fiber treatment assists with lessening dampness content and upgrade interfacial holding among strands and network.

Half breed composites are a combination of two unique kinds of fiber that are built up in one polymer or the other way around. It shows extraordinary properties that are hard to accomplish from one kind of fiber-supported polymer composite. Determination of polymer with filaments ought to consistently be considered in light of the fact that polymers assume a vital part of similarity with strands and in the strength of half breed composites. Various sorts of polymers need various types of assembling measures for creation of half and half composites. Thermoset assembling strategies of composites comprise of a hand lay-up strategy, pressure shaping procedure, and a pultrusion cycle. Hand lay-up and pressure forming procedures are generally acknowledged in creating cross breed composites.

These methods are normal in both thermosets and thermoplastics polymers. Fiber-built up half breed composites have been arising broadly as likely materials for creation of composites for various applications. Utilizing such all-around portrayed handling procedures and change strategies help to accomplish beneficial characteristics in items.

Engineered strands are made utilizing plant materials and minerals thick comes from pine trees or petrochemicals, while acrylic, nylon and polyester come from oil and coal. Thick fiber is gotten from the cellulose flexibility permits mimicking materials like cotton or silk.

Engineered filaments are produced using combined polymers of little atoms. The mixtures that are utilized to make these filaments come from crude materials, for example, oil based synthetic compounds or petrochemicals. These materials are polymerized into a compound that bonds two adjoining carbon molecules. Varying substance compounds are utilized to deliver various sorts of engineered filaments.

Manufactured strands represent about portion of all fiber utilization, with applications in each field of fiber and material innovation. Albeit numerous classes of strands dependent on manufactured polymers have been assessed as conceivably important business items, four of them nylon, polyester, acrylic and polyolefin - rule the market. These four record for roughly 98% by volume of manufactured fiber creation, with polyester alone representing around 60% or around 98% by volume of engineered fiber creation, with polyester alone representing around 60%.

Citation: Kale R (2021) Editorial Note on Synthetic Fibres. J Biomol Res Ther. 10: 166.

Copyright: © 2021 Kale R. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.