Indexed In

- Open J Gate

- Genamics JournalSeek

- Academic Keys

- ResearchBible

- Cosmos IF

- Access to Global Online Research in Agriculture (AGORA)

- Electronic Journals Library

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- SWB online catalog

- Virtual Library of Biology (vifabio)

- Publons

- Geneva Foundation for Medical Education and Research

- Euro Pub

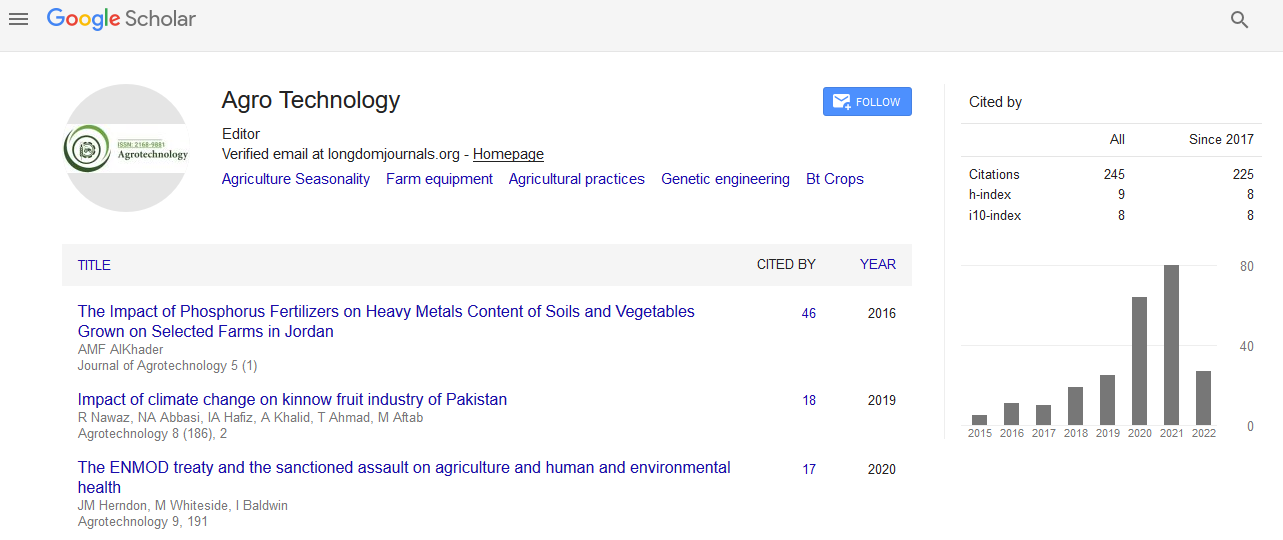

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Perspective - (2025) Volume 14, Issue 1

Adaptive Robotics Empowering Efficiency and Sustainability in Agriculture

Ava Hamilton*Received: 19-Feb-2025, Manuscript No. AGT-25-28742; Editor assigned: 21-Feb-2025, Pre QC No. AGT-25-28742 (PQ); Reviewed: 07-Mar-2025, QC No. AGT-25-28742; Revised: 14-Mar-2025, Manuscript No. AGT-25-28742 (R); Published: 21-Mar-2025, DOI: 10.35248/2168-9891.25.14.397

Description

Reconfigurable agricultural robotics represents a transformative approach in modern farming, providing systems that adapt their physical and functional configurations to meet a wide range of agricultural tasks. Unlike traditional machines designed for single-use operations, reconfigurable robots have the potential to enhance efficiency, reduce costs and offer flexibility across diverse farm environments. With global agriculture facing challenges such as labor shortages, climate variability and sustainability demands, such adaptable technologies are rapidly gaining traction.

Reconfigurable robotics lie in intelligent control strategies. These strategies enable machines to adapt in real time to the requirements of specific tasks such as seeding, weeding, pruning and harvesting. Advanced machine learning models and artificial intelligence systems allow robots to process sensory data, recognize environmental cues and adjust their configurations accordingly. For example, a single robotic unit might widen its stance for stability during heavy lifting or collapse into a compact form to navigate narrow crop rows. Control algorithms also ensure that transitions between configurations are smooth and safe, minimizing downtime and energy expenditure.

Modular hardware plays a significant role in enabling such reconfigurability. Robots built with swappable or extendable components can be physically altered to suit different functions. These modules, including manipulators, sensor arrays or locomotion units, are often connected via standardized interfaces, allowing for rapid reassembly or expansion. The coordination of these modules is governed by control systems that must handle the complexity of dynamic kinematics, balance and task execution. This fusion of hardware and intelligent control creates robots that are not only versatile but also scalable for large-scale operations.

Equally vital is the communication infrastructure that links these reconfigurable robots with each other, with farm management systems and with human operators. Wireless protocols such as 5G, Wi-Fi and low-power wide-area networks enable real-time data exchange. Through these networks, robots can operate in a coordinated swarm, avoiding collisions, sharing sensory data, or even reassigning tasks autonomously. For example, if one robot encounters an unexpected obstacle or mechanical failure, another can reconfigure itself to complete the abandoned task. These capabilities support collaborative, decentralized decision-making on the field, improving productivity and reducing risk.

The practical applications of reconfigurable agricultural robots are extensive. In crop monitoring, robots equipped with various sensors can adapt their height, angles or mobility to capture accurate data from different crops and terrains. Such real-time monitoring can inform precision irrigation or fertilization strategies, reducing input costs and environmental impact. During harvesting, the same robot might switch to a gripper module for gentle handling of delicate produce or a conveyor system for bulk collection. This adaptability makes them valuable assets in mixed farming systems, where crop diversity and changing seasonal requirements pose unique operational demands.

Reconfigurable robots are also showing promise in controlled environment agriculture, such as vertical farms or greenhouses. These settings demand machines that can operate within confined spaces while performing delicate, repetitive tasks. A robot capable of adjusting its shape or toolset to work within various structural constraints or plant growth stages significantly enhances efficiency. Moreover, the integration of such robots with digital twin systems allows for predictive maintenance, task simulation and process optimization before physical deployment.

Despite these advancements, several challenges must be addressed. High initial development and deployment costs can limit accessibility, especially for small-scale farmers. The complexity of design and control increases the risk of mechanical failure or software malfunction, requiring robust testing and fail-safe mechanisms. Additionally, the current lack of standardization in robotic interfaces and communication protocols can hinder interoperability among machines from different manufacturers. Addressing these issues through policy support, research incentives and industry collaboration is essential to ensure the broad adoption of reconfigurable robotic systems.

In conclusion, reconfigurable agricultural robotics presents a compelling solution to the evolving needs of global agriculture. By combining advanced control strategies, robust communication networks and modular design, these robots offer unprecedented adaptability across a wide array of farming operations. Their ability to perform multiple tasks, self-optimize based on environmental feedback and operate cooperatively positions them as a key enabler of sustainable, high-efficiency agriculture.

Citation: Hamilton A (2025) Adaptive Robotics Empowering Efficiency and Sustainability in Agriculture. Agrotechnology. 14:397.

Copyright: © 2025 Hamilton A. This is an open access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.