Indexed In

- Open J Gate

- Genamics JournalSeek

- JournalTOCs

- China National Knowledge Infrastructure (CNKI)

- Electronic Journals Library

- RefSeek

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- SWB online catalog

- Virtual Library of Biology (vifabio)

- Publons

- MIAR

- Euro Pub

- Google Scholar

Useful Links

Share This Page

Journal Flyer

Open Access Journals

- Agri and Aquaculture

- Biochemistry

- Bioinformatics & Systems Biology

- Business & Management

- Chemistry

- Clinical Sciences

- Engineering

- Food & Nutrition

- General Science

- Genetics & Molecular Biology

- Immunology & Microbiology

- Medical Sciences

- Neuroscience & Psychology

- Nursing & Health Care

- Pharmaceutical Sciences

Review Article - (2023) Volume 14, Issue 2

A Brief Study and One Step Ahead of Plastic Sustainability vs. Genuine Plastic Recycling and Up Cycling Including Advantages and/or Benefits As Well As Future Opportunities across the Globe

Azizul Haque*Received: 14-Oct-2022, Manuscript No. JPEB-22-18376; Editor assigned: 17-Oct-2022, Pre QC No. JPEB-22-18376 (PQ); Reviewed: 31-Oct-2022, QC No. JPEB-22-18376; Revised: 27-Jan-2023, Manuscript No. JPEB-22-18376 (R); Published: 02-Feb-2023, DOI: 10.35248/2157-7463.22.14.507

Abstract

Plastic recycling is the reprocessing of plastic waste into new and useful products. When this job is performed correctly, can reduce dependence on landfill, conserve resources and protect the environment from plastic pollution and greenhouse gas emissions. Recycling is essential because almost all plastics are non-biodegradable and thus buildup in the environment, where it can cause harm. Presently, almost all recycling is performed by re-melting and reforming used plastic into new items; so-called mechanical recycling. In an alternative approach known as feedstock recycling, waste plastic is converted back into its starting chemicals, which can then be reprocessed back into fresh plastic. This whole work demonstrates the turning residual/old plastics into eco-friendly alternatives, synthetic oil, gas or fuel and nano-materials and chemical recycling as an environmental win-win situation and reinventing Recycling from rubbish to resources including live experiments/examples.

Keywords

Sustainability; Microplastics; Recycling; Recovery; Algae; Microalgae; Biodegradation; Byfusion; Landfill; Nanomaterials; Carbon footprint; Environmental; Fuel; Reusable; Chemical industry; Polymer; Monomer; Depolymerization; PETase; Real time; Waste; Pandemic.

Abbrevations

DPS: Deposit returns scheme; NEMO: New End Market Opportunity; PET: Polyethylene Terephthalate; LCA: Life Cycle Assessment; PRU: Pyrolysis Reactor Units; FMCG: Fast Moving Consumer Goods; SDG: Sustainable Development Goal

Introduction

In a nutshell, sustainability describes whether something (a product, an action or a resource etc.) can hold up over a long period. Solar energy, for example, is more sustainable than fossil fuel energy sources because the sun is not going anywhere anytime very soon. Fossil fuel sources, however, are quickly being exhausted. The plastics manufacturing industry sustains the best sustainability, maintaining a guideline/principle at all levels of operations, and conducts business in such a way that seeks to drive value creation for society, the environment, and the industry. It also strives for improvements to reduce impacts on natural resources, minimizing waste generation, and shifting toward renewable energy options all of which ultimately reduces greenhouse gas impacts. Meanwhile, manufacturers should be guided by scientific data that measures the impacts of many lifecycle stages of plastic products, consistent with the value of sustainable materials management, and strive to keep materials in circularity for remanufacturing when it yields the greatest environmental benefit. All these activities should be measured and reported with integrity. To achieve their sustainability goal, steps to be followed [1].

• Promoting: Sustainable manufacturing practices including the use of recycled plastics in new products.

• Educating: Companies about the aspects of sustainable manufacturing, for instance, how to reduce water and energy use and make their products easier for consumers to recycle.

• Demonstrating: Viable business models for collecting and recycling different types of plastic materials from different locations.

• Motivating: Companies to eliminate waste and increase recycling and measuring the amount of wasted recyclable plastic material.

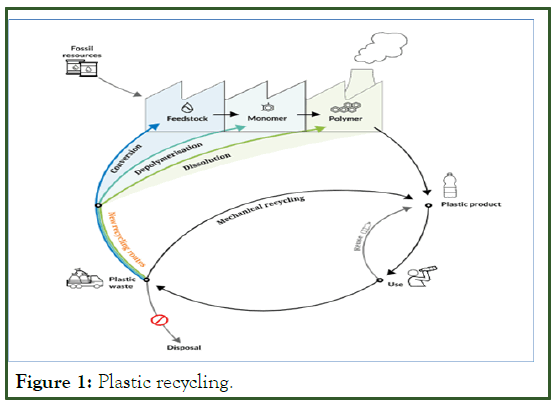

Plastics: It’s cheap! It’s light! It’s safe! It’s hygienic! Imagine the COVID-19 pandemic without plastic! More than 8 billion tons of plastic have been produced since it was invented in the 1950's. And that only 14% of plastics are recycled, with 79% of plastic waste ending up in the landfill, clogging up the oceans and being shipped from wealthy nations to poorer countries to dispose of microplastics have been found in both animal and human organs. It’s an environmental disaster and a global health crisis. Currently, waste plastic can only be exported if it is sorted into a single resin or polymer type, or processed with other materials into processed engineered fuel (Figure 1).

Figure 1: Plastic recycling.

Every year, more than 350 million tons of plastics have been produced worldwide. These plastics contain a large variety of chemicals that may be released during their lifecycle, including substances that pose a significant risk to people and the environment. There have been identified around 10,500 and out of 10,500, 2,480 substances (24%) are of potential concern. Reality is that almost quarters of all chemicals used in plastic are highly stable, accumulate in organisms, or are toxic and can cause cancer, or damage specific organs. Currently, it was finalized that waste plastic can only be exported if it is sorted into a single resin or polymer type, or processed with other materials into processed engineered fuel (Figure 2) [2].

Figure 2: Plastic waste.

Plastic waste is a problem! A big problem that the chemical industry can help to address. One of the most promising solutions provided by the chemical industry is chemical recycling. Using the chemical recycling technology kills two birds on one stone. First, we reduce the amount of plastic waste, and secondly, we improve our resource efficiency and reduce our dependence on non-renewable resources such as oil when making new chemicals. With chemical recycling technologies, the industry has developed complementary solutions to existing mechanical recycling to recycle mixed or contaminated plastic waste that otherwise would be incinerated or sent to landfill. These technologies can break down plastics and transform them into valuable secondary raw materials to produce new chemicals and plastics of similar quality to those made from fossil resources as well [3]

Background

Polyethylene usually has between 2,000 carbons and 10,000 carbons in a chain. This is one reason that it does not stick to metals, which are polar or charged. Importantly, the environmental impacts of many consumer products, including soft drinks, are tied to the products inside but not the packaging and consumers usually tend to focus on the impact of the packaging rather than the impact of the product itself. Common misperceptions are:

• The environmental impacts of plastics are greater than any other packaging material.

• Reusable products, having lower environmental impacts are always better than single use plastics.

• Recycling and composting, environmental benefits should be the highest priority.

Therefore, to place the plastic waste problem in a proper context, it’s critical to verify the environmental impacts that occur at every stage of a product’s lifetime. Life-Cycle Assessment (LCA) is a tool that used to quantify lifetime environmental impacts in multiple categories, including climate change and energy use, water and resource exhaustion, biodiversity loss, solid waste generation, and human and ecological toxicity etc.

Initiation of the work/coincidence

To cut down on plastic waste, packaging is taking on different forms that can be more easily recycled or that do away with plastic altogether. For instance, soda and beer companies are ditching plastic six-pack rings. The changes are taking different forms from cardboard to six-pack rings made with leftover barley straw. While the transition can be a step toward sustainability, simply switching to different packaging materials could be the wrong solution or not enough and that more plastic needs to be recycled and remade. For example, the Lafarge cement factory gets 80% of its fuel from waste [4].

Literature Review

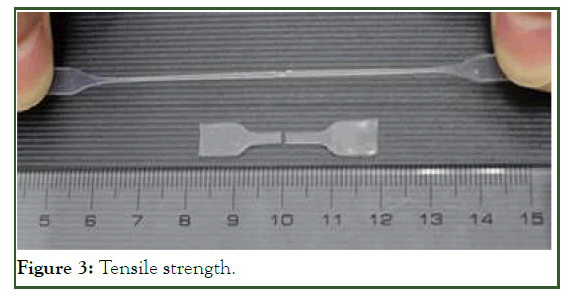

Experiment shows that we can even recycle the material into monomers several times, without loss of quality. Although 87% of the monomers can already be recovered, the scientists want to get as close to a hundred percent as possible. Hard and soft elastic polymers can be fully depolymerized but still remains challenging and their elastomeric polymer could be stretched to almost 14 times of its original length before breaking. And when cut in two, the polymer restored itself within five minutes to recover 99% of its toughness and 97% of its tensile strength (Figure 3).

Figure 3: Tensile strength

Some examples of experiments of plastic recovery by different diversities across the globe

Critical advances and future opportunities in cycling commodity polymers: The vast majority of commodity plastics do not degrade and therefore they permanently pollute the environment. At present, less than 20% of postconsumer plastic waste in developed countries is recycled predominately for energy recovery or repurposing as lower-valued materials by mechanical recycling. Chemical recycling offers an opportunity to revert plastics back to monomers without altering the properties of the material or the economic value of the polymer. For plastic waste that is either cost prohibitive or infeasible to mechanically or chemically recycle, the growing field of chemical cycling promises to use chemical or engineering approaches to place plastic waste at the beginning of a new value chain. Here state of the art methods are highlighted for cycling plastic waste into value-added performance materials, fine chemicals, and specialty polymers, realizing a sustainable plastic economy [5].

Reuse plastic bottle to make a solar bottle lamp: Solar bottle lamp is a solar-powered light that is constructed from waste plastic bottles. The design idea is to reuse waste plastic bottles by attaching a 3D printed solar lamp in place of their old plastic cap. It can be fitted into almost all soft drink bottles. Solar bottle lamps can be used to provide lighting in rural areas as well. These lights are surprisingly bright, illuminating campsite, backyard, pathways, or even at home in the case of a power outage. Some benefits are:

• Reusing plastic bottles can significantly reduce pollution, greenhouse gas emissions, and energy usage.

• The use of the solar lamp will decrease the amount of local air pollution and save energy.

• It can provide access to solar lamps at an affordable price to a wide range of people living in remote areas.

• Also as an alternative business model with the potential to strengthen the overall rural economy by generating technology based livelihood opportunities.

Turning off the plastic tap: The figures for plastic waste are shocking. Seventy years ago, production was relatively low, within 2 million tons by 1950. Today production is pushing towards 350 million tons and much of it is going into packaging, textiles and consumer goods. Yet, despite recycling rates increasing to a little over 20%, the majority of plastics (55%) are discarded with the remainder incinerated. There are clear opportunities for conventional recycling technologies to reform graded plastics into new items. However, this leads to a lower quality product than with virgin petrochemicals [6].

Tiny pieces of plastic: Micro plastics are tiny plastic particles formed when larger pieces of plastic degrade over time and they are ubiquitous, found everywhere from Mount Everest to the Mariana Trench. They can act as magnets for environmental pollution, transforming them into potentially toxic particles.

We know that we ingest about 2000 tiny pieces of plastic every week. These minute specks of plastic are everywhere. The microplastics included Polyethylene Terephthalate (PET) commonly used in clothing and drink bottles and polymers of styrene, often used in vehicle parts, carpets, and food containers. On average, 1.6 micrograms of plastic material were measured for every milliliter of blood, with the highest concentration being just over 7 micrograms. However, more research will be needed on larger, more diverse groups to map just how and where micro plastics spread and accumulate in humans, and how our body eventually discards them [7].

Plastic-eating bacteria: Plastic eating bacteria could help to one day tackle some of the 14 million tons of plastic that is offloaded into our oceans every year. Plastic pollution leads to a severe impacts on marine ecosystems and can affect human health. After analyzing the bacteria, it has been found that it produced two digestive enzymes called hydrolyzed PET or PETase. When these enzymes interact with PET plastic, it breaks down the long molecular chains into shorter chains (monomers) called terephthalic acid and ethylene glycol. These monomers are then broken down further to release energy for the growth of the bacteria. PETase only decomposes PET plastic.

Turning residual plastic into fuel and nanomaterials: No matter how many times we try and recycle the plastic, one day, it will reach ends of life. As a waste stream it is problematic landfills don’t want it, while environmentalists believe burning it when it is in its residual state, no matter how ‘clean’ the technology is unacceptable. Those who champion zero waste work on ways of making it more biodegradable or give it properties that greatly reduce its end of life impact on the environment. However, turning such a useful product and it is useful in many ways into something that is more environmentally friendly is not as easy as it sounds. There is a great potential that problematic plastics, if processed through this approach, can have much reduced environmental impact, indeed. Ultimately, we have to look at what we can do the best to damage the environment the least.”

Synthetic gas and oil from old plastics: The term “chemical recycling” should only be used for plastic wastes and reconverted into new plastics. If those plastics are transformed into fuels or petrochemical products, the process should be called “recovery” instead. Shakespeare wrote that changing what a rose is called does not change what it is in essence. The same logic goes for the term ‘chemical recycling’ the conversion of used plastics, mainly to produce synthetic gas (syngas) and oils where plastics need to go through highly polluting processes. Some might try to call this ‘recycling’ but it’s not. It’s ‘recovery’ [8].

Only 30% of all generated plastic waste is collected for recycling and chemical recovery of plastics to produce new materials could be a welcome complement to mechanical recycling and a useful way to reduce waste.

Instead of proper recycling, industry in Europe is promoting technologies that process plastic waste through highly polluting processes such as pyrolysis and gasification to mainly produce outputs like syngas and oils. In some cases, these outputs are used as fuels, releasing the carbon previously locked inside the plastic into the atmosphere.

SDGs: The global community is at a critical moment in its pursuit of the Sustainable Development Goals (SDGs). More than a year into the global pandemic, millions of lives have been lost, the human and economic toll has been unprecedented and recovery efforts so far have been uneven, inequitable, and insufficiently geared towards achieving sustainable development. The current crisis is threatening decades of development gains, further delaying the urgent transition to greener, more inclusive economies and throwing progress on the SDGs even further off track, which outlines some significant impacts in many areas that are already apparent. The global extreme poverty rate rose for the first time in over 20 years and 119 million to 124 million people were pushed back into extreme poverty in 2020 while an additional 101 million children have fallen below the minimum reading proficiency level. Women have faced increased domestic violence; child marriage is projected to rise after a decline in recent years and unpaid and underpaid repair work is increasing excessively, impacting educational and income opportunities and health.

A recommitment by governments, cities, businesses and industries to be developed to ensure that recovery reduces carbon emissions, conserves natural resources, creates better jobs, advances gender equality and tackles growing poverty and inequalities.

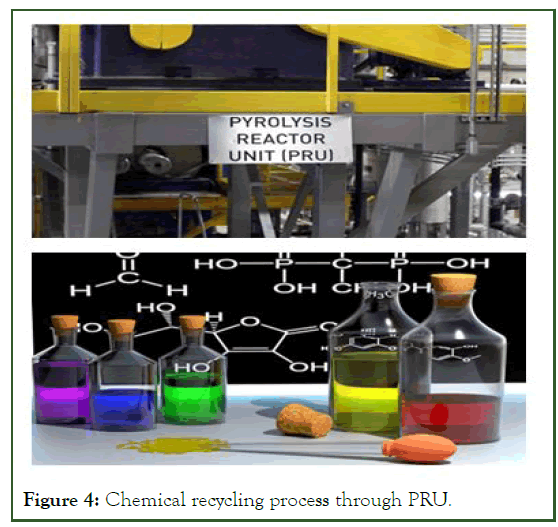

Chemical recycling of plastics-an environmental wing: On a life cycle basis, is the overall environmental impact positive or negative in regard to using advanced recycling technologies (also called chemical recycling through PRU-Pyrolysis Reactor Units) to convert plastic waste that would otherwise end up in a landfill? The answer in the net impact is positive (Figure 4).

Figure 4: Chemical recycling process through PRU.

Chemical recycling usually refers to technologies that break down plastic with some combination of heat, pressure, depleted oxygen, catalysts, and/or solvents into either fuel or building blocks for new plastic. The oil and gas outputs of most of these technologies can either be burned as a dirty fuel or further processed to be made into new plastic. Although some companies do aim to produce polymers, the outputs are usually burned on site as turning them into plastic requires extensive decontamination and enrichment. Turning plastic into fuel (“plastic-to-fuel”) does not displace virgin plastic, and therefore cannot be considered a recycling solution; it does not contribute to a circular economy. If combusted, the products result in similar environmental impacts to other fossil fuels.

While typical chemical recycling doesn’t work for polymer wastes with low fixed carbon content, generate CO2 sorbents including polypropylene and high and low-density polyethylene, the main constituents in municipal waste especially well for capturing CO2 when treated with potassium acetate. Waste plastic is now turned into powder, mixed with potassium acetate and heated at 600°C (1,112 F) for 45 minutes to optimize the pores, most of which are about 0.7 nanometers wide. Higher temperatures led to wider pores. The process also produces a wax byproduct that can be recycled into detergents or lubricants. Another option to pull CO2 out of the air is the interchange between permeability and selectivity. In general, the more selective the membrane, the more slow gases can flow through it. Then joined with an intermittent layer of polyamine, which selectively attracts carbon dioxide.

Discussion

Therefore, we need to consider all options to safely and sustainably manage the enormous amount of waste that we generate, nearly four pounds per person per day. The decisions we make about which options to use should be backed by reliable scientific data. Ultimately, the common objective must be to divert as much waste as possible from landfills, recover as much material and energy as possible from the waste stream, and recirculate it through the economy.

Reinventing recycling: Taking plastics from rubbish on resources: The contamination of our oceans and rivers is one direct consequence of the lack of alternatives for managing plastic waste. Perhaps the most studied case of chemical recycling is that of polyethylene phthalate, or PET, a type of plastic used in soda bottles and medical blister packs. This type of polyester can be reacted with other small molecules in the presence of adequate catalysts during a process called “depolymerization”. Recently, a chemistry team at the university of Oxford, led by Professor Charlotte Williams, has discovered a different depolymerization method for plastics derived from Carbon Dioxide (CO2), limonene oxide and decalactone, a series of bio-sourced and renewable monomers. These new polyester-polycarbonate thermoplastic materials are very elastic and show superior mechanical properties than some commercial polymers derived from other renewable sources. The researchers demonstrated that the polycarbonate units could be partially depolymerized back to CO2 and limonene oxide, the original building block molecules. Closed-loop recycling could create a revolution in the perception of discarded plastics. What is now, rubbish would become a resource.

On the global recycling day, we can all make a difference. The power is in all of us consumers, producers, and policy makers, to contribute to a more sustainable and less wasteful future, for us and for the planet.

Some live examples of experiments/projects of plastic sustainability, initiated by different organizations across the globe

P and G India becomes “plastic waste neutral” company: The company, which has a portfolio of powder brands including Ariel, Tide, Whisper, Gillette, Oral B, Head and Shoulders and Vicks, joined the club of a few FMCG companies in India that have achieved plastic waste neutrality in FY 2021-2022, after having recycled 100 percent of post-consumer plastic packaging waste. The company is also taking a deliberate approach towards reducing the impact of its operations and setting up in-house solar plants. They are fully committed to making a positive impact in the world and creating a sustainable future for generations to come. Several FMCG makers such as Dabur and Nestle, India, have already achieved the tag of being plastic waste neutral companies.

Making shampoo more sustainable by eliminating the most useless ingredient, water in it: 80 percent of our regular shampoo is made of water. This water, however, does not enhance the formula. On the contrary, it dilutes the product only. As a result, consumers need a larger quantity for a single wash. Also, when we do shampoo, we still need to wet our hair to lather the product. Therefore why do we need to add water to the shampoo formula! Therefore, to reduce single-use plastic and the carbon footprint of transporting products, simply remove water from the formula. However, don’t confuse these for dry shampoo and consumers need to be applied directly to wet hair for the full lathering shampoo experience.

HSBC: The Hong Kong and Shanghai Banking Corporation (HSBC) has set a goal to provide between $750 billion and $1 trillion investment globally in the next decade to support its clients to lower carbon emissions and achieve sustainable growth to encourage them to turn their production facilities green and guide them towards net zero emissions. This is the first-ever sustainability-linked loan, which is connected to environmental, social, and governance performance targets.

Boxed water, an eco-friendly alternative to plastic bottles: Recently, a North West family has introduced an eco-friendly and 100% recyclable carton boxes called boxy water. Boxy Water is made of cartons sleeves which are thick boxes with a thin layer of plastic that are strong enough to package liquids. These plastic bottles have a very hardy plastic, meaning they are not biodegradable and are incapable of being decomposed, which then increases the chances of pollution. Once the sleeves were delivered, the real work began with boxy water. Once the water is pumped, it gets filtered and purified. Even with filtration and purification processes, the family chose a more environmentally friendly way instead of using industrial chemicals; they use ozone treatment, which is similar to chlorine, to purify the water.

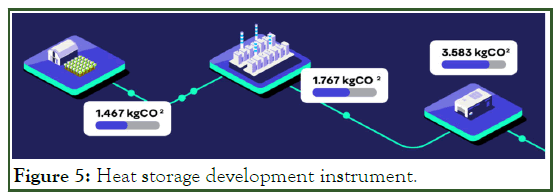

Avery dennison: Avery Dennison recently launched atma.io, a groundbreaking sustainability feature to minimize carbon footprint and eliminate waste across the supply chain. The new ‘Real-time Waste Elimination Tool’ uses artificial intelligence and machine learning to analyze and alert on anomalies and inefficiencies across the supply chain. It flags up products that are close to expiry or potentially compromised, allowing minimizing spoilage, reduce losses, cut waste and greenhouse gas emissions. This new feature provides brands with data-driven insights regarding the carbon footprint of products, including scope 3 emissions and beyond. This is a powerful new tool that captures data from every stage of a product’s journey from raw material to consumer and can help to comply with the forthcoming EU ‘Digital Product Passports regulations as well as the existing US Food Safety Modernization Act (FSMA) (Figure 5).

Figure 5: Heat storage development instrument.

Heat storage development of new material that is stable, efficient, and eco-friendly: A new heat storage material could help to significantly improve the energy efficiency of buildings. It can be used to store surplus heat and release it back into the environment, if required. Unlike existing materials, the new one can absorb significantly more heat, is more stable and is made of harmless substances. This is a so-called shape-stabilized phase change material. It can absorb large amounts of heat by changing its physical state from solid to liquid. The stored heat is then rereleased when the material hardens. However, it could be used by the construction industry as large panels that could be integrated into walls. These would then absorb heat during the sunny hours of the day and release it again later when the temperature goes down. This could save a lot of energy. It has been calculated that when the new material heats up, it can store under the right conditions up to 24 times per 10°C more heat than conventional concrete or wallboard.

Unlike hand warmers, the panels made of this material mixture do not melt when they absorb heat. The heat storage material is enclosed in a framework of solid silicate and cannot escape due to high capillary forces; the substances used in its production are environmentally friendly, harmless fatty acids like those found in soaps and creams. Even the additives that lend the material its strength and increased thermal conductivity can be obtained from rice shells. Therefore, in the future, this will help to make buildings significantly more energy efficient.

Majority responsibility of ecological damage caused by excess use of raw materials: Not all nations are equally responsible for this trend; some nations use substantially more resources per capita than others through material extraction, production, consumption, and waste. The study shows that high-income countries (with 16% of the world's population) are responsible for 74% of the global excess resources over the years 1970-2017 period, driven mainly by the United States (27%) and highincome countries in the European Union (25%), Spain ranks 11th in the list of 15 countries, exceeding the planetary sustainable limit of raw material usage. Spain is responsible for 2% of the excess, behind countries such as Japan, Germany, France, the United Kingdom, Canada and Italy, among others.

By fusion: By fusion has found a new way to reuse plastic that would never get recycled. Therefore a broad range of clients, from waste management companies to municipalities, can utilize them to fit their needs and then produce the blocks themselves instead of transporting worthless plastics and dealing with associated compliance issues, cities and companies (and even universities) could create these blocks. By Fusion will buy back any surplus and sell to the market on their behalf.

Conclusions

Algae can be our next secret weapon to combat plastic pollution. Plastic pollution has become an alarming problem worldwide. It has been projected that by 2025, around 100 million metric tons 250 million metric tons of plastic waste could enter our oceans every year. However, even if all drastic measures were put in place to stop plastic production tomorrow, we would still have around 5 billion tons of plastic waste in landfills and the environment. Research has shown that plastics can disintegrate into micro-plastics. Microalgae, for instance, are the most promising nature-based candidate capable of destroying micro plastics. It is a unicellular species that exists individually or in chains or groups, depending on the species, their size can range from a few millimeters to hundreds of micrometers. Cultivating microalgae is simple because it does not require fertile land, large quantities of freshwater and pesticides compared to other aquaculture crops. Microalgae are also capable of growing rapidly. Open pond cultivation has been one of the oldest and simplest ways to cultivate microalgae on a large scale. Some people also use photo-bioreactors in an enclosed system to increase microalgae cultivation.

Microalgae can significantly change the properties of plastic, including its biodegradation, the alteration of plastic density, and sinking behavior. Moreover, microalgae may take control, gather, and stick to micro-plastics on their surface, regardless of their size. There are four stages of plastic biodegradation.

• First is the attachment of microalgae to plastic surfaces. This starts the biodegradation process and alters the surface properties.

• The second is bio-deterioration; microalgae will excrete specific enzymes, which are pivotal for plastic biodegradation.

• The third is the bio-fragmentation process. In this stage, the plastic material loses its mechanical stability and becomes fragile.

• The last stage is the assimilation process, where microbial filaments and water start to penetrate plastics, which results in the decomposition and utilization of plastic by microorganisms.

• To prevent plastic disasters, we also need improvements in plastic recycling and reusing strategies as well as waste management, reduction or substitution of plastic usage, redesign of plastic products and packaging, doubling plastic waste collection rates, and expansion of waste disposal facilities etc. The goal is to boost plastic packaging recycling from 16 percent to 70 per cent by 2025. It comes after 176 countries endorsing a United Nations resolution to establish a legally binding treaty by 2024 to end plastic pollution.

Survey: People are being encouraged to count how much plastic packaging they throw away in a week. The data will contribute to a national picture of how much plastic packaging is being thrown away and how much is recycled. Hope, the results of the big plastic count will push the government to bring in stricter policies to reduce plastic waste, including setting a target to reduce single-use plastic. They are also calling for a ban on all plastic waste exports and the implementation of a deposit return scheme (DPS) for recycling and reusing all drink containers. Moreover, a collaborative project like NEMO, new end market opportunity can be formed based on objectives:

• Focuses on improving reuse through recycling of a plastic product.

• Works across the supply chain, partnering trade associations and their members, academics and other contributing experts.

• Addresses technical or logistical challenges data generation/ collection as well as proof-of-concept demonstration projects.

• Results of publication of reports, case studies, best practices, etc. for use by the industry.

Acknowledgements

First and foremost, I would like to express my thanks to all of my colleagues who support me to write this wonderful article/ Abstract: “A brief study and one step ahead of Plastic sustainability across the globe” which will clearly help in my future research work. Besides, I would like to convey my special thanks to my organization for giving an opportunity in writing this article. Moreover, I would like to thank and immense gratitude to all of my friends and family members for unconditional, unequivocal, and loving support without which I couldn’t be able to complete this article. Last but not least, I would like to thank everyone who helped and motivated me in writing this article.

References

- Gu F, Guo J, Zhang W, Summers PA, Hall P. From waste plastics to industrial raw materials: A life cycle assessment of mechanical plastic recycling practice based on a real-world case study. Sci Total Environ. 2017;601:1192-207.

[Crossref] [Google Scholar] [PubMed]

- Borman MR, Gabriel DS, Nurcahyo R. Impact of plastic packaging design on the sustainability of plastic recyclers. Int J Appl Sci Eng. 2019;16(1) :25-33.

- Nkwachukwu OI, Chima CH, Ikenna AO, Albert L. Focus on potential environmental issues on plastic world towards a sustainable plastic recycling in developing countries. Int J Ind Chem. 2013;4(1):1-3.

- Miller L, Soulliere K, Sawyer-Beaulieu S, Tseng S, Tam E. Challenges and alternatives to plastics recycling in the automotive sector. Materials. 2014;7(8):5883-5902.

[Crossref] [Google Scholar] [PubMed]

- Subramanian PM. Plastics recycling and waste management in the US. Resources, Conservation and Recycling. 2000;28(3-4):253-263.

- Sardon H, Dove AP. Plastics recycling with a difference. Science. 2018;360(6387):380-381.

- Arena U, Mastellone ML, Perugini F. Life cycle assessment of a plastic packaging recycling system. Int J Life Cycle Assess. 2003;8(2):92-98.

- Vinodh S, Prasanna M, Prakash NH. Integrated Fuzzy AHP–TOPSIS for selecting the best plastic recycling method: A case study. Appl Math Model. 2014;38(19-20):4662-72.

Citation: Haque A (2023) A Brief Study and One Step Ahead of Plastic Sustainability vs. Genuine Plastic Recycling and Up Cycling Including Advantages and/or Benefits As Well As Future Opportunities Across the Globe. J Pet Environ Biotechnol. 14:507.

Copyright: © 2023 Haque A. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.